High-strength wear-resistance ceramic-plastic gear and preparation method thereof

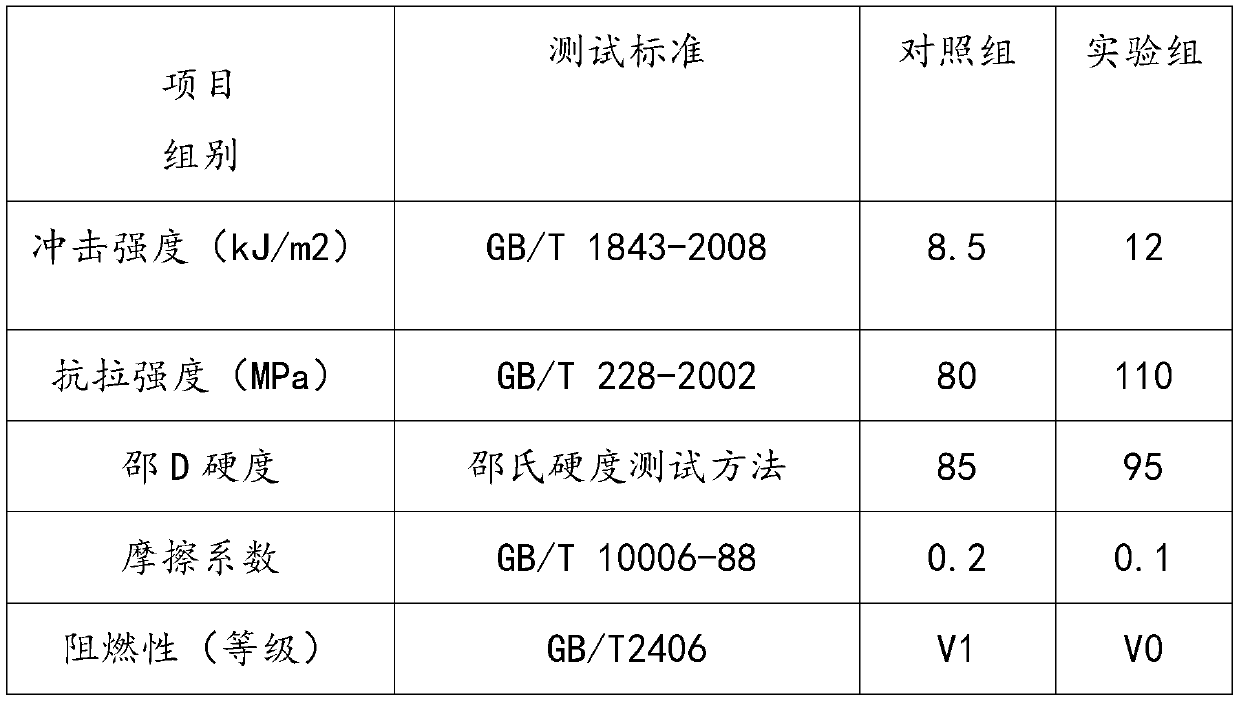

A wear-resistant ceramic and plastic gear technology, which is applied in the field of high-strength wear-resistant ceramic plastic gear and its preparation, can solve the problems of easy wear and insufficient strength, and achieve increased heat resistance, prevention of molten droplet dripping, excellent heat insulation and smoke suppression Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] A high-strength wear-resistant ceramic plastic gear, made of the following materials in proportion by weight: 70 parts of modified polyether ether ketone, 20 parts of ceramic fiber, 18 parts of polyoxymethylene, 18 parts of polyamide, dodecyloxyboric acid 16 parts of lanthanum, 16 parts of ethylene glycol, 10 parts of heat dissipation liquid crystal polyester, 8 parts of polyethylene terephthalate, 8 parts of nano-alumina, 2,6-tertiary butyl-4-methanol 5 parts of phenylphenol, 5 parts of trioctyl ester, 5 parts of diisononyl phthalate, 4 parts of polysiloxane, 4 parts of ammonium polyphosphate and 3 parts of acetyl acetyl p-methoxyaniline.

[0013] A preparation method of a high-strength wear-resistant ceramic plastic gear, comprising the following steps:

[0014] 1) Take 70 parts of modified polyether ether ketone, 20 parts of ceramic fiber, 18 parts of polyoxymethylene, 18 parts of polyamide and 16 parts of lanthanum dodecyloxyborate, put them into a mixer and mix the...

Embodiment 2

[0022] A high-strength wear-resistant ceramic plastic gear, made of the following materials in proportion by weight: 60 parts of modified polyether ether ketone, 30 parts of ceramic fiber, 26 parts of polyoxymethylene, 26 parts of polyamide, dodecyloxyboric acid 24 parts of lanthanum, 20 parts of ethylene glycol, 18 parts of heat dissipation liquid crystal polyester, 12 parts of polyethylene terephthalate, 12 parts of nano-alumina, 2,6-tertiary butyl-4-methyl 7 parts of phenylphenol, 7 parts of trioctyl ester, 7 parts of diisononyl phthalate, 6 parts of polysiloxane, 6 parts of ammonium polyphosphate and 5 parts of acetyl acetyl p-methoxyaniline.

[0023] A preparation method of a high-strength wear-resistant ceramic plastic gear, comprising the following steps:

[0024] 1) Take 60 parts of modified polyether ether ketone, 30 parts of ceramic fiber, 26 parts of polyoxymethylene, 26 parts of polyamide and 24 parts of lanthanum dodecyloxyborate, put them into a mixer and mix the...

Embodiment 3

[0032] A high-strength wear-resistant ceramic plastic gear, made of the following materials in proportion by weight: 65 parts of modified polyether ether ketone, 25 parts of ceramic fiber, 22 parts of polyoxymethylene, 22 parts of polyamide, dodecyloxyboric acid 20 parts of lanthanum, 18 parts of ethylene glycol, 14 parts of heat-dissipating liquid crystal polyester, 10 parts of polyethylene terephthalate, 10 parts of nano-alumina, 2,6-tertiary butyl-4-methyl 6 parts of phenylphenol, 6 parts of trioctyl ester, 6 parts of diisononyl phthalate, 5 parts of polysiloxane, 5 parts of ammonium polyphosphate and 4 parts of acetyl acetyl p-methoxyaniline.

[0033]A preparation method of a high-strength wear-resistant ceramic plastic gear, comprising the following steps:

[0034] 1) Take 65 parts of modified polyether ether ketone, 25 parts of ceramic fiber, 22 parts of polyoxymethylene, 22 parts of polyamide and 20 parts of lanthanum dodecyloxyborate, put them into a mixer and mix them...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com