Fiber base multilayer structure friction nanometer power generator and preparation method thereof

A nanogenerator and multi-layer structure technology, applied in the direction of triboelectric generators, can solve the problems of difficulty in large-scale use, large damage to material structure, complex process, etc., and achieve shortened decay time, low cost, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

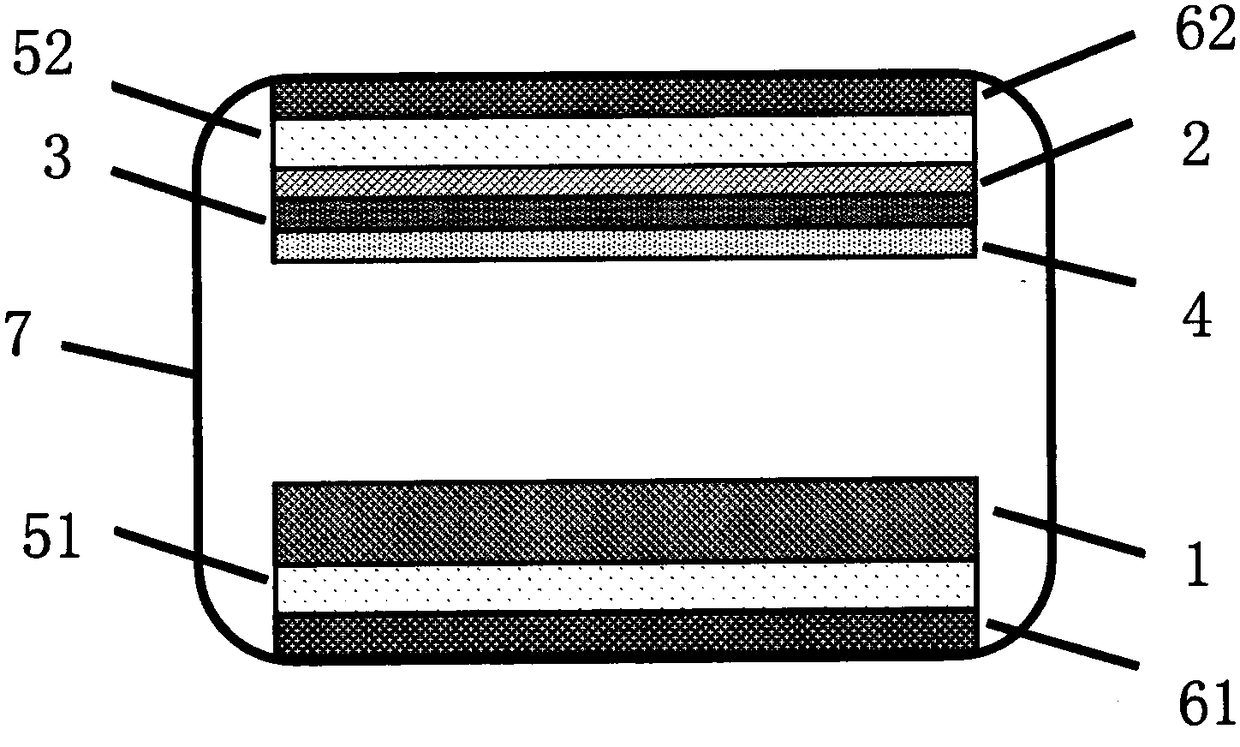

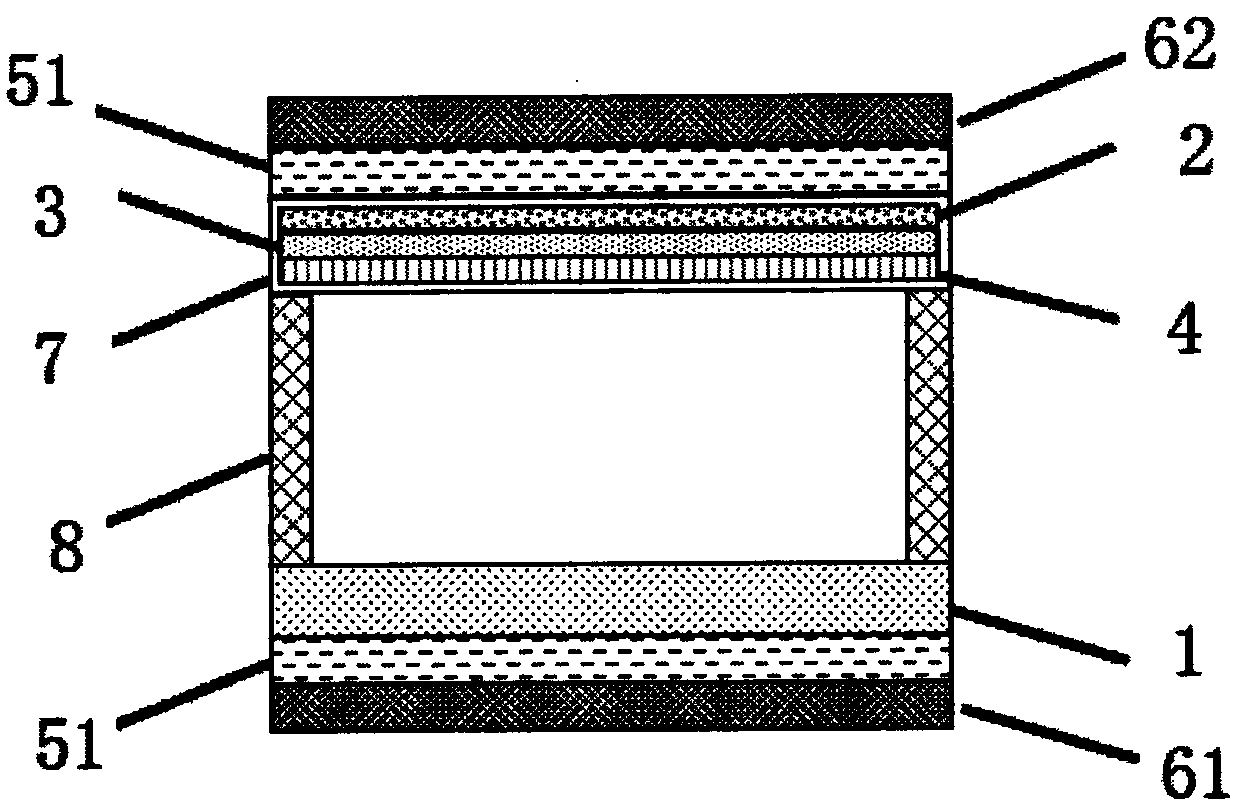

[0040]A fiber-based multilayer structure triboelectric nanogenerator, comprising a stacked upper base layer, an upper electrode layer, an electronegative friction layer, and a stacked electropositive friction layer, a lower electrode layer, and a lower base layer; Both the electropositive friction layer and the electronegative friction layer are electrospun nanofiber membranes; the working mode of the fiber-based multilayer friction nanogenerator is a vertical separation contact type.

[0041] The electronegative friction layer includes a power storage layer, a conductive layer and a friction contact layer from top to bottom, and the friction contact layer is used as an electronegative friction material to contact and separate from the electropositive friction layer to generate charges. The conductive layer is used to transmit the charge; the storage layer is used to store and utilize the charge; the upper electrode layer and the lower electrode layer are respectively attached ...

Embodiment 2

[0051] A fiber-based multilayer structure triboelectric nanogenerator, comprising a stacked upper base layer, an upper electrode layer, an electronegative friction layer, and a stacked electropositive friction layer, a lower electrode layer, and a lower base layer; Both the electropositive friction layer and the electronegative friction layer are electrospun nanofiber membranes; the working mode of the fiber-based multilayer friction nanogenerator is a vertical separation contact type.

[0052] The electronegative friction layer includes a power storage layer, a conductive layer and a friction contact layer from top to bottom, and the friction contact layer is used as an electronegative friction material to contact and separate from the electropositive friction layer to generate charges. The conductive layer is used to transmit the charge; the storage layer is used to store and utilize the charge; the upper electrode layer and the lower electrode layer are respectively attached...

Embodiment 3

[0061] A fiber-based multilayer structure triboelectric nanogenerator, comprising a stacked upper base layer, an upper electrode layer, an electronegative friction layer, and a stacked electropositive friction layer, a lower electrode layer, and a lower base layer; Both the electropositive friction layer and the electronegative friction layer are electrospun nanofiber membranes; the working mode of the fiber-based multilayer friction nanogenerator is a vertical separation contact type.

[0062] The electronegative friction layer includes a power storage layer, a conductive layer and a friction contact layer from top to bottom, and the friction contact layer is used as an electronegative friction material to contact and separate from the electropositive friction layer to generate charges. The conductive layer is used to transmit the charge; the storage layer is used to store and utilize the charge; the upper electrode layer and the lower electrode layer are respectively attached...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com