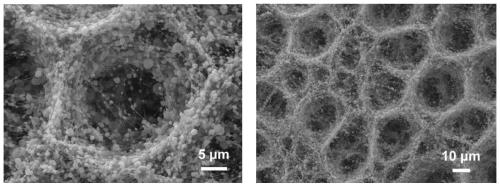

High-specific-surface-area honeycomb-like structure nano fiber material and preparing method thereof

A technology with high specific surface area and honeycomb structure, which is applied in fiber processing, textiles and papermaking, non-woven fabrics, etc., can solve the problem that it is difficult to obtain small-sized through-hole structures, and it is impossible to endow materials with unidirectional moisture-wicking and moisture-absorbing and quick-drying properties. The problem of low specific surface area of porous structure fiber materials can achieve the effect of improving capillary effect, excellent unidirectional moisture conduction and moisture absorption and quick drying performance, and enhancing moisture absorption and moisture conduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

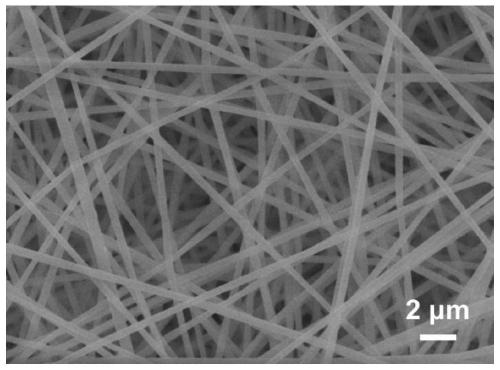

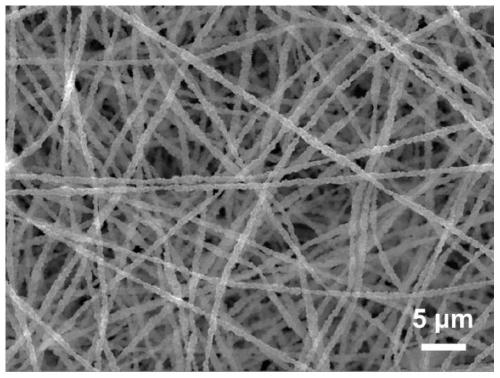

Image

Examples

Embodiment 1

[0046] A method for preparing a honeycomb structure nanofiber material with a high specific surface area, the specific steps are as follows:

[0047] (1) First, add MIL-101(Cr) into N,N-dimethylformamide, ultrasonically disperse for 3 hours, then add polyacrylonitrile to the above dispersion, and stir continuously at room temperature for 12 hours with a magnetic stirring device to obtain A uniform and stable mixed solution, wherein polyacrylonitrile accounts for 5% by mass of the mixed solution, MIL-101 (Cr) accounts for 20% by mass of the mixed solution, the viscosity of the mixed solution is 30mPa·s, and the electrical conductivity is 146.4 μS / cm;

[0048] (2) Dry the non-woven fabric in deionized water for 3 minutes. The deionized water can be used as a conductor to eliminate static electricity, remove the residual charge on the surface of the non-woven fabric, and use the non-woven fabric after deionized treatment as the receiving substrate;

[0049] (3) Electrospinning w...

Embodiment 2

[0086] A method for preparing a honeycomb structure nanofiber material with a high specific surface area, the specific steps are as follows:

[0087] (1) First MIL-101(Cr)-NH 2 Add N,N-dimethylformamide, ultrasonically disperse for 4 hours, then add polyacrylonitrile to the above dispersion, and stir continuously for 14 hours with a magnetic stirring device at room temperature to obtain a uniform and stable mixed solution. Among them, polyacrylonitrile The mass percentage of the mixture is 8%, MIL-101(Cr)-NH 2 The mass percentage of the mixed solution is 24%, the viscosity of the mixed solution is 53mPa·s, and the conductivity is 256.4μS / cm;

[0088] (2) Dry the non-woven fabric in isopropanol for 1 minute. Isopropanol can be used as a conductor to eliminate static electricity, remove residual charges on the surface of non-woven fabrics, and use the non-woven fabric after charge-eliminating treatment as a receiving substrate;

[0089] (3) Electrospinning was carried out with...

Embodiment 3

[0092] A method for preparing a honeycomb structure nanofiber material with a high specific surface area, the specific steps are as follows:

[0093] (1) First MIL-101(Cr)-NH 2 Add in deionized water, ultrasonically disperse for 3 hours, then add polyvinyl alcohol into the above-mentioned dispersion, and stir continuously for 12 hours with a magnetic stirring device at room temperature to obtain a uniform and stable mixed solution, wherein the mass percentage of polyvinyl alcohol in the mixed solution is 6%, MIL-101(Cr)-NH 2 The mass percentage of the mixed solution is 24%, the viscosity of the mixed solution is 43mPa·s, and the conductivity is 5079μS / cm;

[0094] (2) Place the electrospun fiber membrane in deionized water for 2 minutes and then dry it. Deionized water can be used as a conductor to eliminate static electricity and remove residual charges on the surface of the electrospun fiber membrane, and use the electrospun fiber membrane after deionization treatment as th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com