Polymerized toner having high resolution

A toner and pigment technology, applied in the field of polymerized toner, can solve the problems of insignificant charge quantity and poor compatibility of toner.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

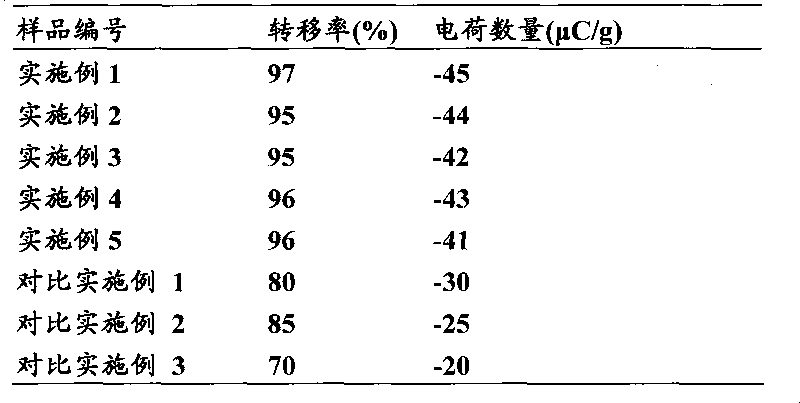

Examples

Embodiment 1

[0043] 10 g of colloidal silica as a dispersant and 0.5 g of polyoxyethylene alkylphenyl ether ammonium sulfate (HS-20, Daiichi Kogyo Seiyaku) as a reactive anionic surfactant with reactive functional groups were dissolved in a 500 ml reactor 400g of distilled water. The mixture was heated to a reaction temperature of 70° C. to prepare an aqueous dispersion.

[0044] 160g styrene as a monomer, 36g butyl acrylate and 4g acrylic acid, 4g allyl methacrylate as a polar grafting agent, 0.02g n-dodecyl mercaptan as a molecular weight modifier, and 10g cyanide For cyan pigment, stir in a bead mill at 2,000 rpm for 2 hours. The beads are removed from the monomer / pigment mixture. After heating 105 g of the monomer / pigment mixture to 70° C. in a water bath, 5 g of paraffin wax were added thereto. Stir for 20 minutes to fully dissolve the monomer mixture. 2 g of azobisisobutyronitrile was added to the solution as a polymerization initiator, and stirring was continued for 5 minutes. ...

Embodiment 2

[0047] The toner was prepared in the same manner as in Example 1, except that 0.5 g of potassium alkyl succinate sulfate (ASK, KAO) was used as the reactive anionic surfactant.

Embodiment 3

[0049] The toner was prepared in the same manner as in Example 1 except that 0.5 g of ELEMINOL RS3000 (Sanyo Kasei) was used as a reactive anionic surfactant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com