Improved friction nano-generator

A nano-generator and an improved technology, applied in the direction of triboelectric generators, can solve the problems of low output power and low triboelectric charge density of the motor, and achieve the effect of increasing output power, high power density and increasing triboelectric charge density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

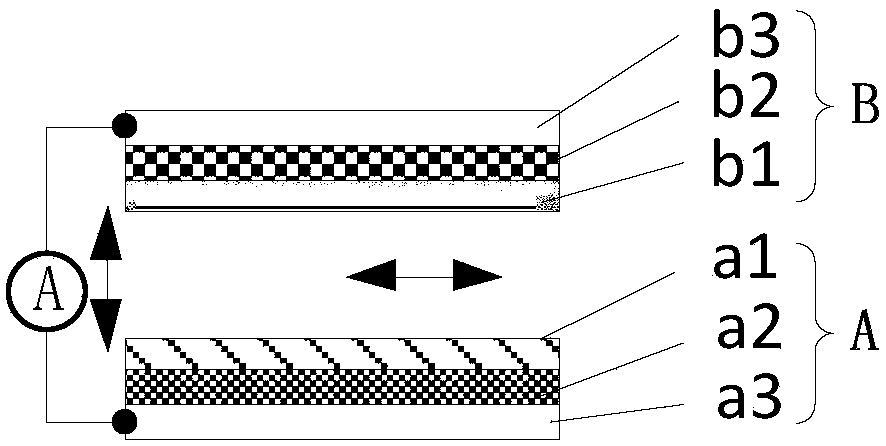

[0049] A typical structure of the triboelectric nanogenerator provided by this embodiment can be found in figure 1 , comprising a first power generation component A and a second power generation component B, wherein the first power generation component A comprises a first friction layer a1, a first ferroelectric layer a2 and a first electrode layer a3, wherein the first friction layer a1 is placed The upper surface of the first ferroelectric layer a2, the first electrode a3 is placed on the lower surface of the first ferroelectric layer; the second power generation component B includes a second friction layer b1, a second ferroelectric layer b2 and a second electrode layer b3, wherein , the second friction layer b1 is placed on the lower surface of the second ferroelectric layer b2, and the second electrode b3 is placed on the upper surface of the second ferroelectric layer b2. The second electrode b3 is used for outputting electric energy when the second power generation comp...

Embodiment 2

[0066] In Embodiment 1, the second electrode b3 of the second power generation component is electrically connected to the first electrode a3 of the first power generation component. In such a structure, the two electrodes move with each other due to external force, which is not conducive to the use of the device.

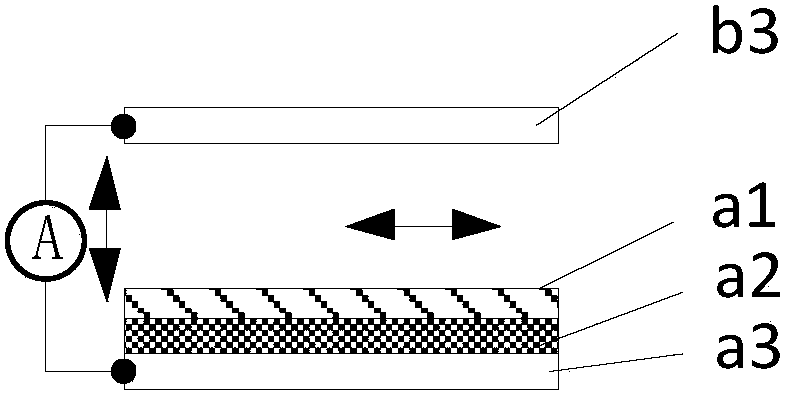

[0067] In this embodiment, the typical structure of the generator can be found in Figure 5 , comprising a first power generation component A and a second power generation component, wherein the first power generation component A comprises a first friction layer a1 and a first ferroelectric layer a2, wherein the first friction layer a1 is placed on the side of the first ferroelectric layer a2 Upper surface; the second power generation component includes a second electrode layer b3. The second electrode b3 is used for outputting electric energy when the second electrode rubs against the first friction layer a1 of the first power generation component A.

[0068] In t...

Embodiment 3

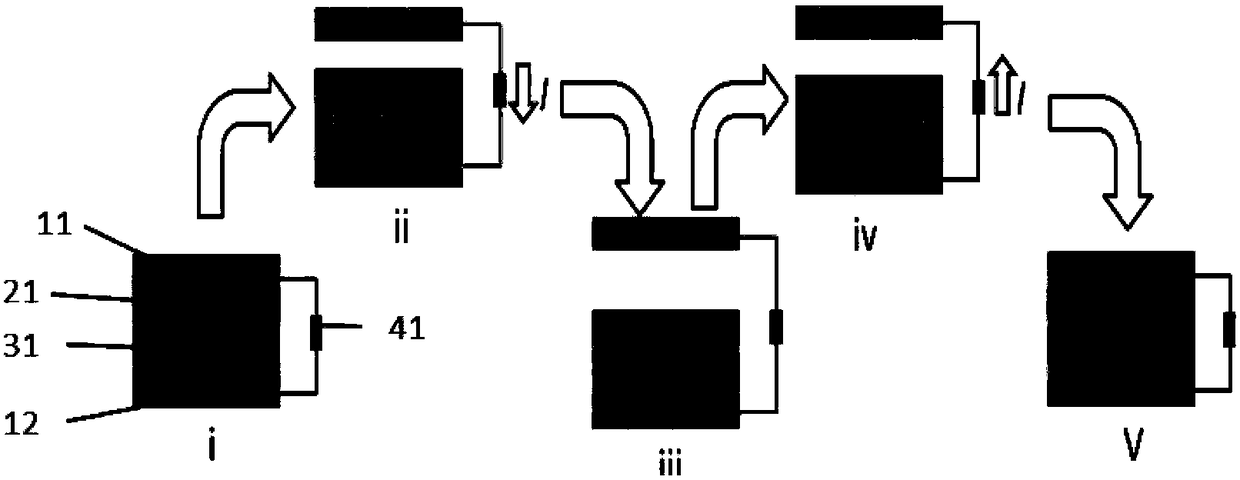

[0073] In this example, the typical structure of the triboelectric nanogenerator can be found in Figure 7 , including a first power generation component and a second power generation component, wherein the first power generation component includes a first friction layer a1 and a first ferroelectric layer a2, wherein the first friction layer a1 is placed on the surface of the first ferroelectric layer a2; The second power generation part includes a second electrode layer b3 and a third electrode b4. The second electrode b3 is electrically connected to the third electrode, and the friction between the second power generation component and the first friction layer is that the first friction layer a1 rubs against the second electrode b3 and the third electrode b4 in turn, and the first power generation component and the third electrode b4 rub against each other. During the rubbing process of the second power generating components, due to electrostatic induction, charges flow betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com