Patents

Literature

47results about How to "Improve electrical output performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

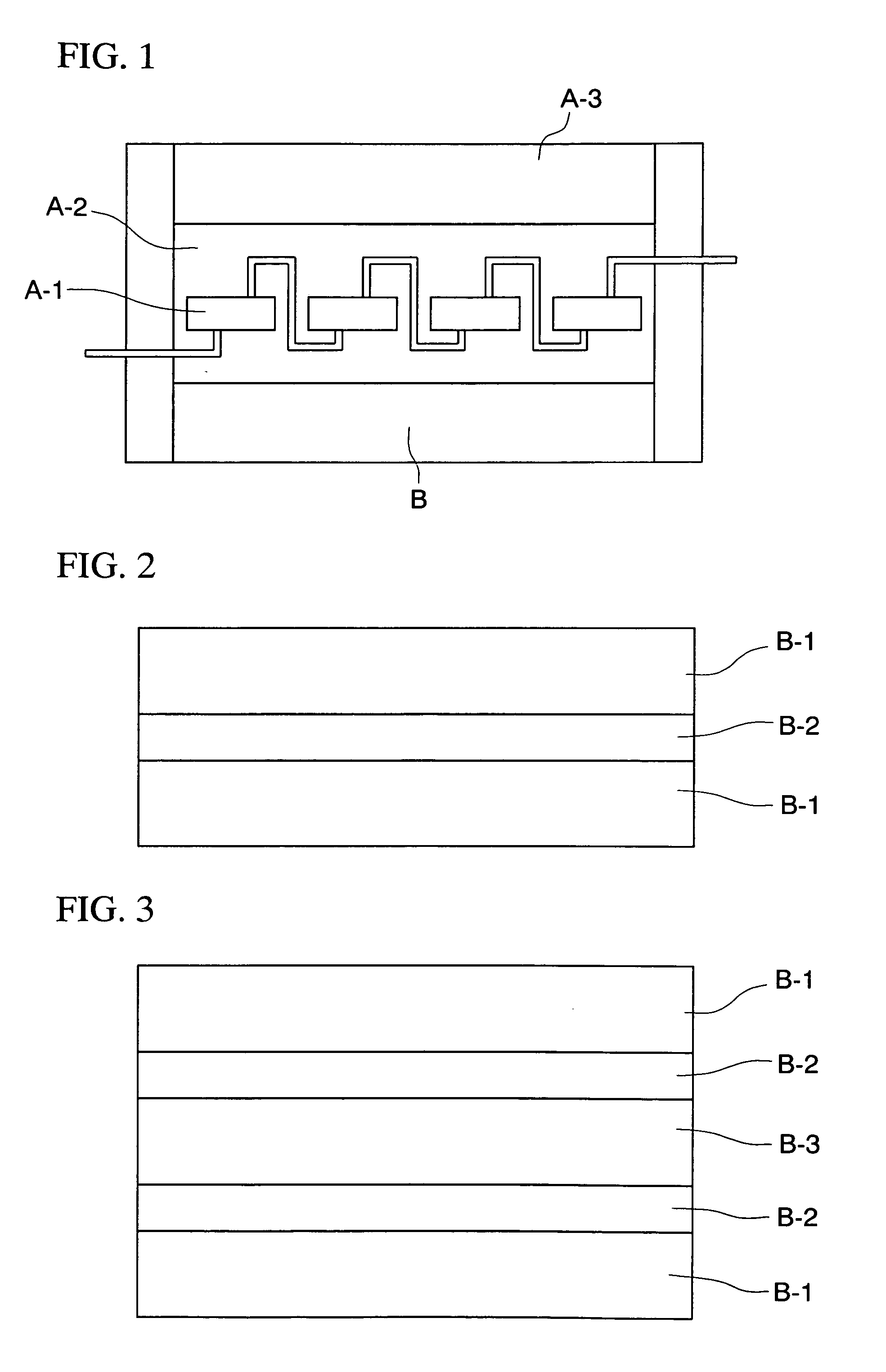

Sheet for sealing rear surface of solar cell

InactiveUS20100229945A1Improve hydrolysis resistancePrevent degradationPolyureas/polyurethane adhesivesSynthetic resin layered productsAdhesiveEngineering

The present invention provides a sheet for sealing a rear surface of a solar cell in which degradation due to hydrolysis of the material constituting the solar cell is prevented, and the weather resistance is excellent such that electric output properties of the solar cell can be maintained not only under conditions of actual usage of the solar cell module but also conditions for evaluation under high temperatures and high moistures, and provides a sheet for sealing a rear surface of a solar cell comprising a laminate in which at least two substrates are laminated by an polyurethane-based adhesive, wherein the polyurethane-based adhesive comprises an adhesive having hydrolysis resistance which satisfies the following conditions: condition 1: the lamination strength of the adhesive is 1 N / 15 mm or more after keeping the laminate in a chamber which acts as a highly accelerated stress test system under pressurized steam conditions of 105° C. and 1.05 atm for 168 hours; and condition 2: the adhesive does not bring on a delamination and a blister between the substrates after keeping the laminate in a chamber which acts as a highly accelerated stress test system under pressurized steam conditions of 105° C. and 1.05 atm for 168 hours.

Owner:TOPPAN PRINTING CO LTD +1

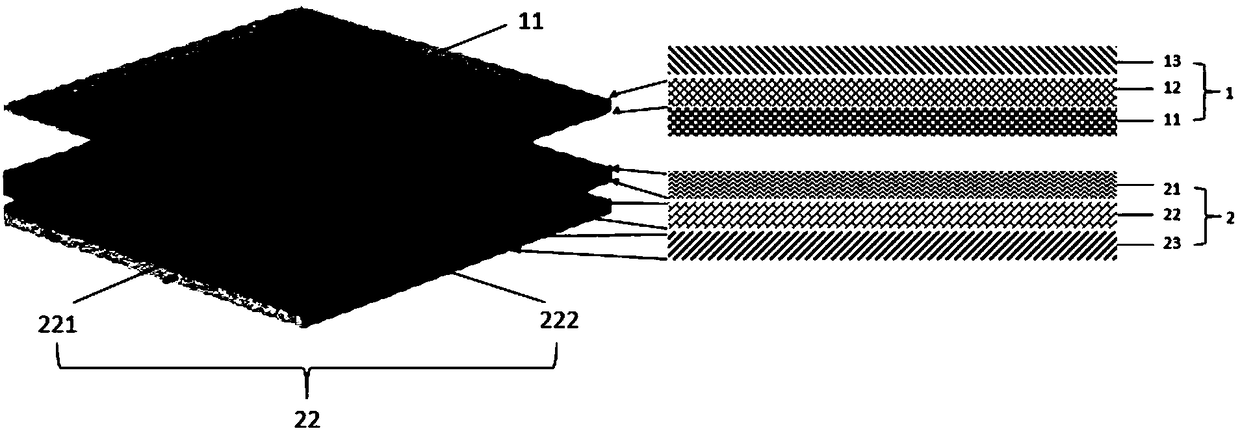

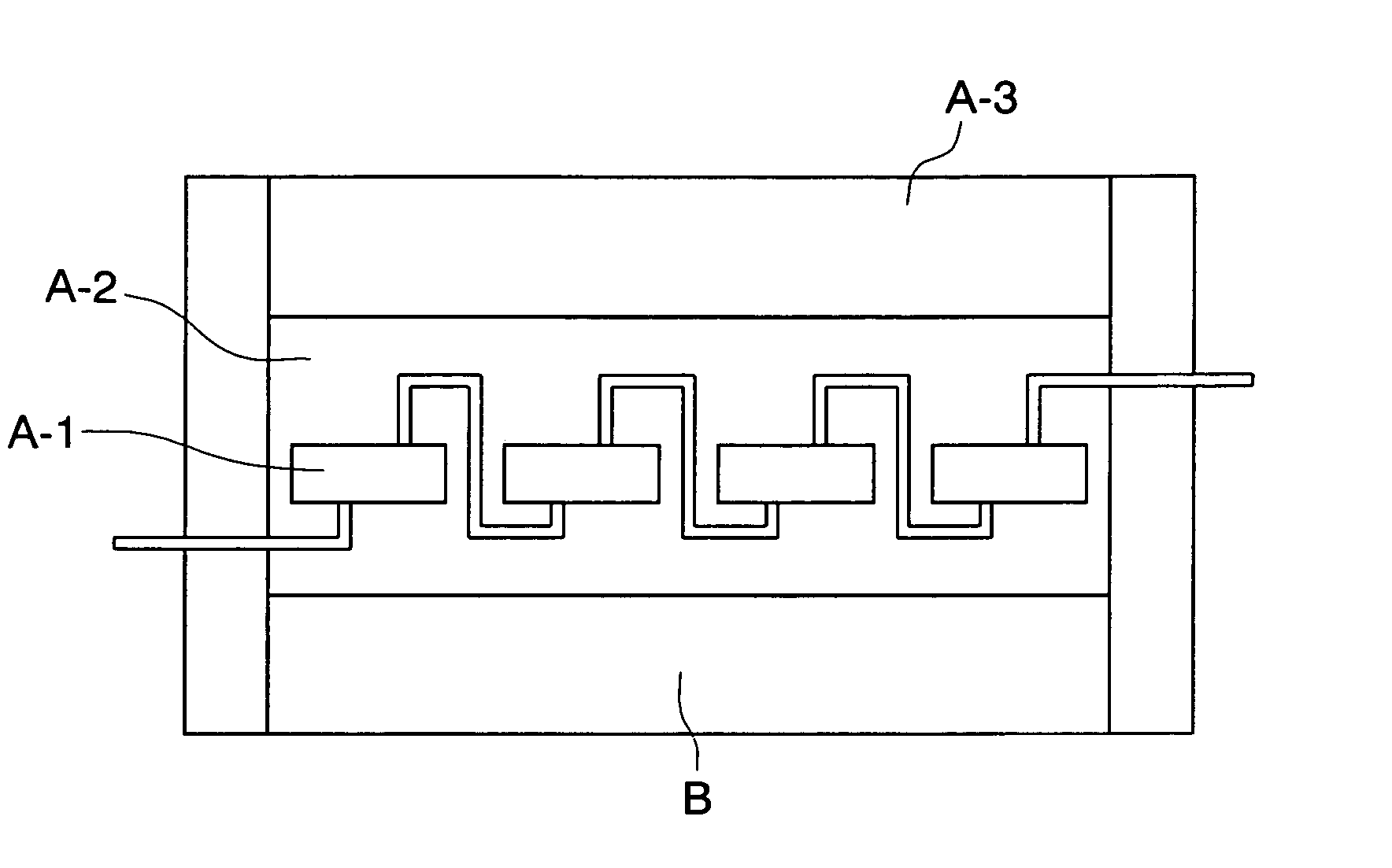

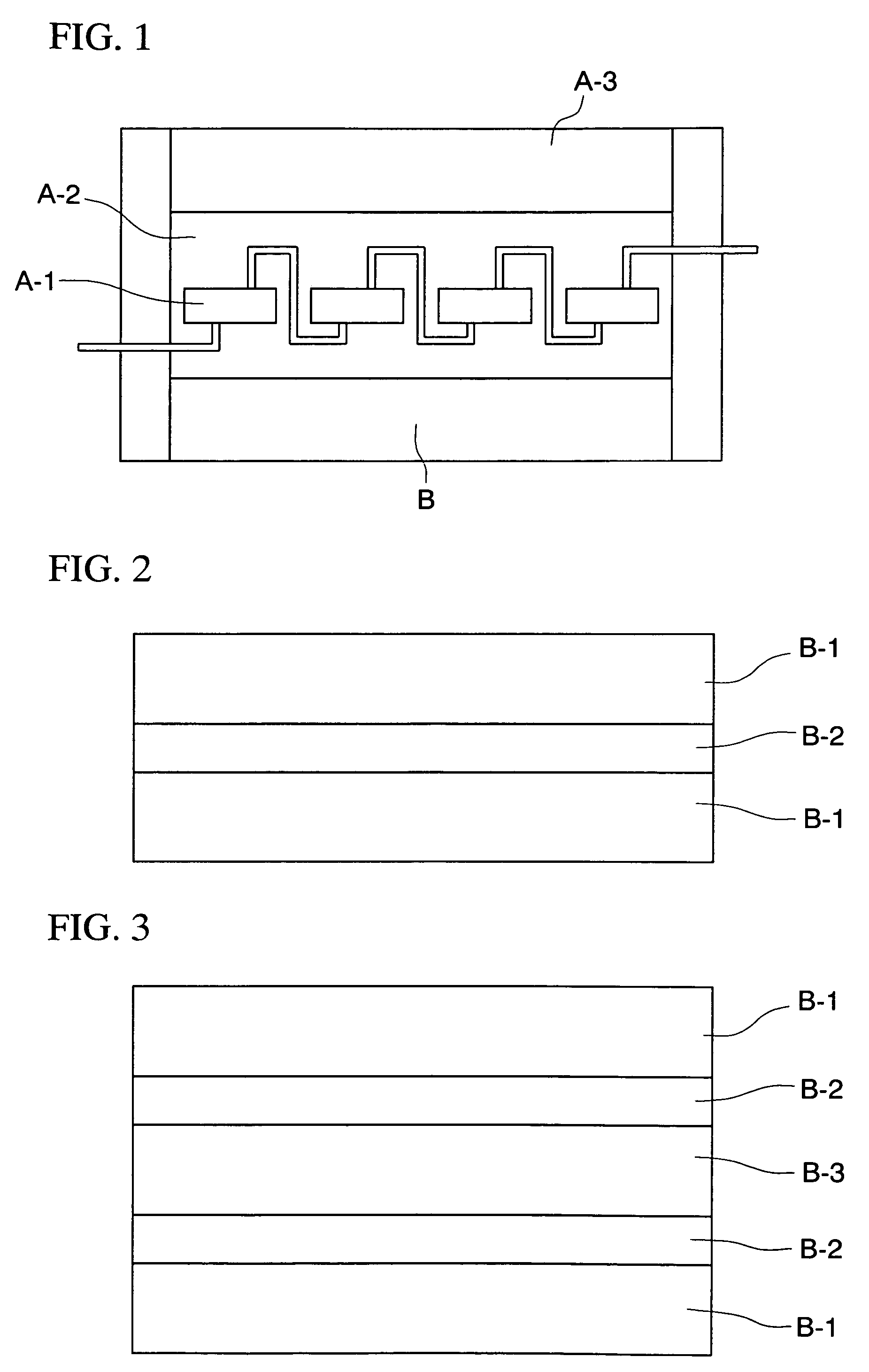

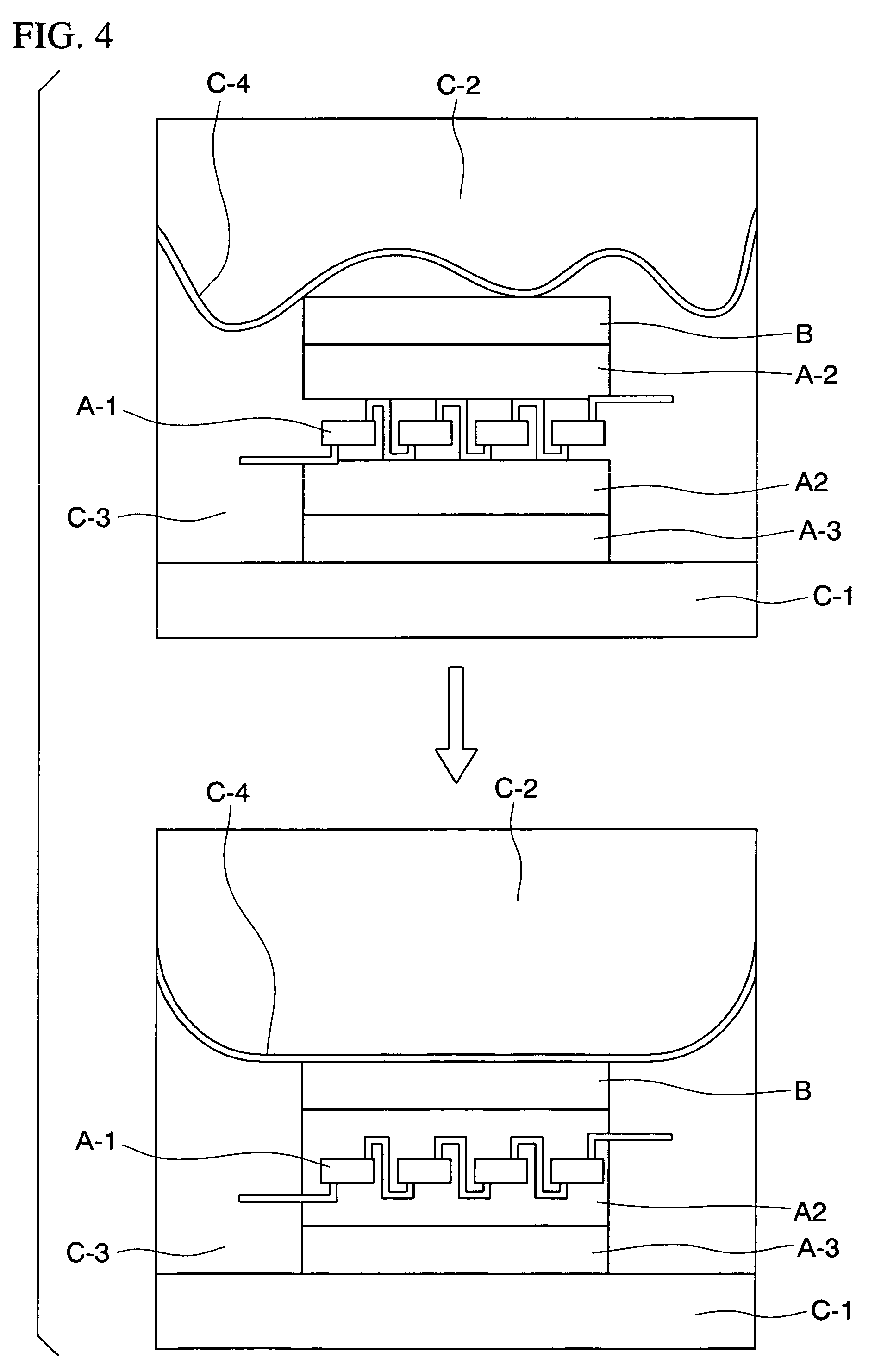

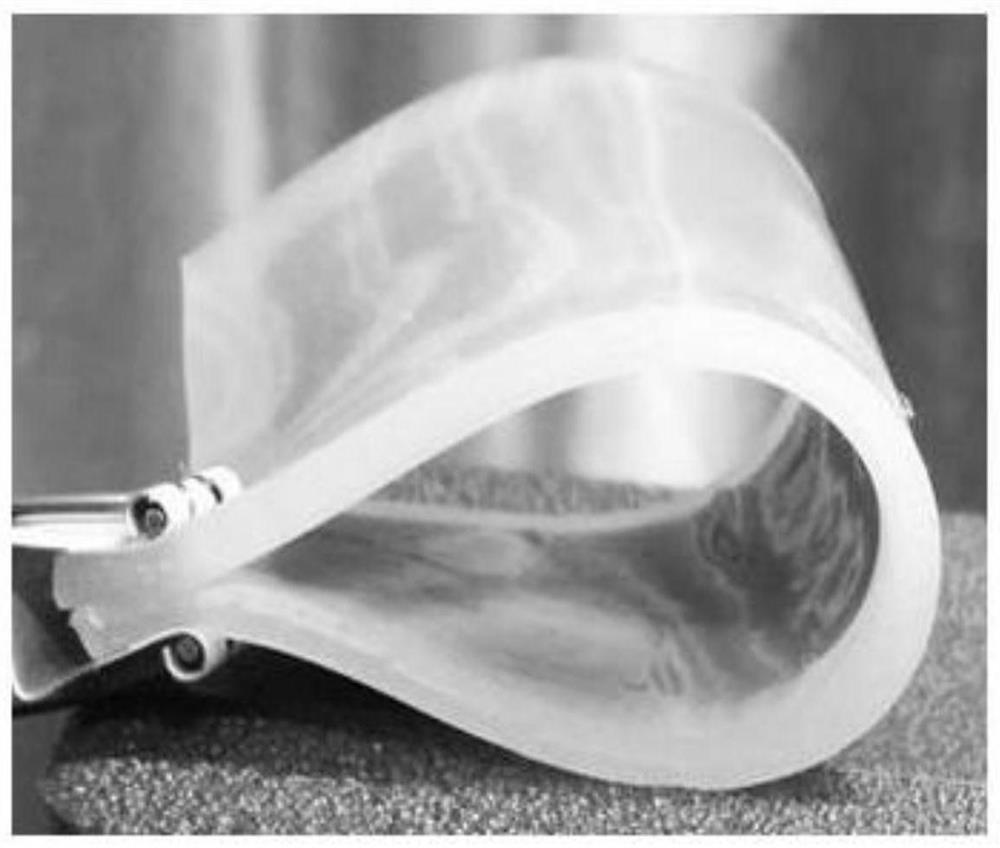

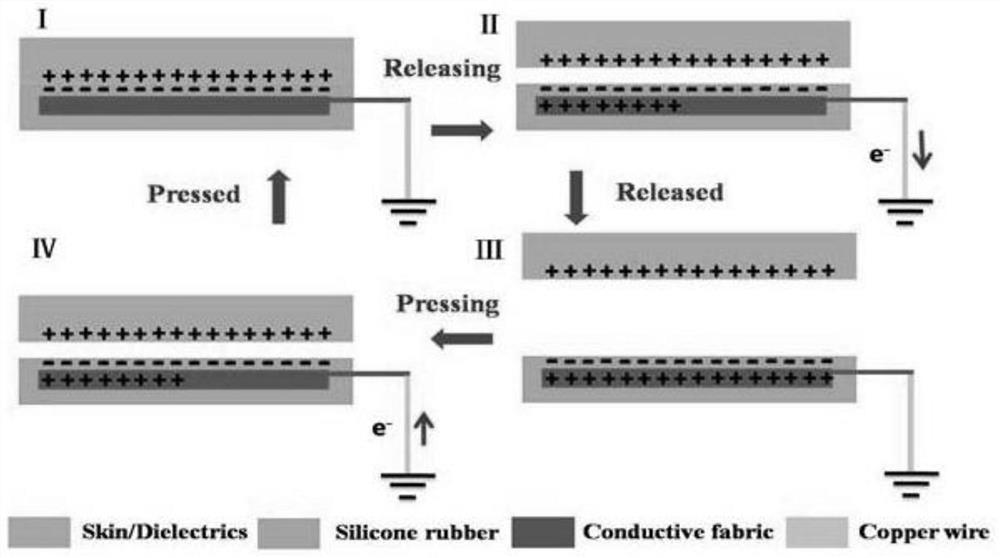

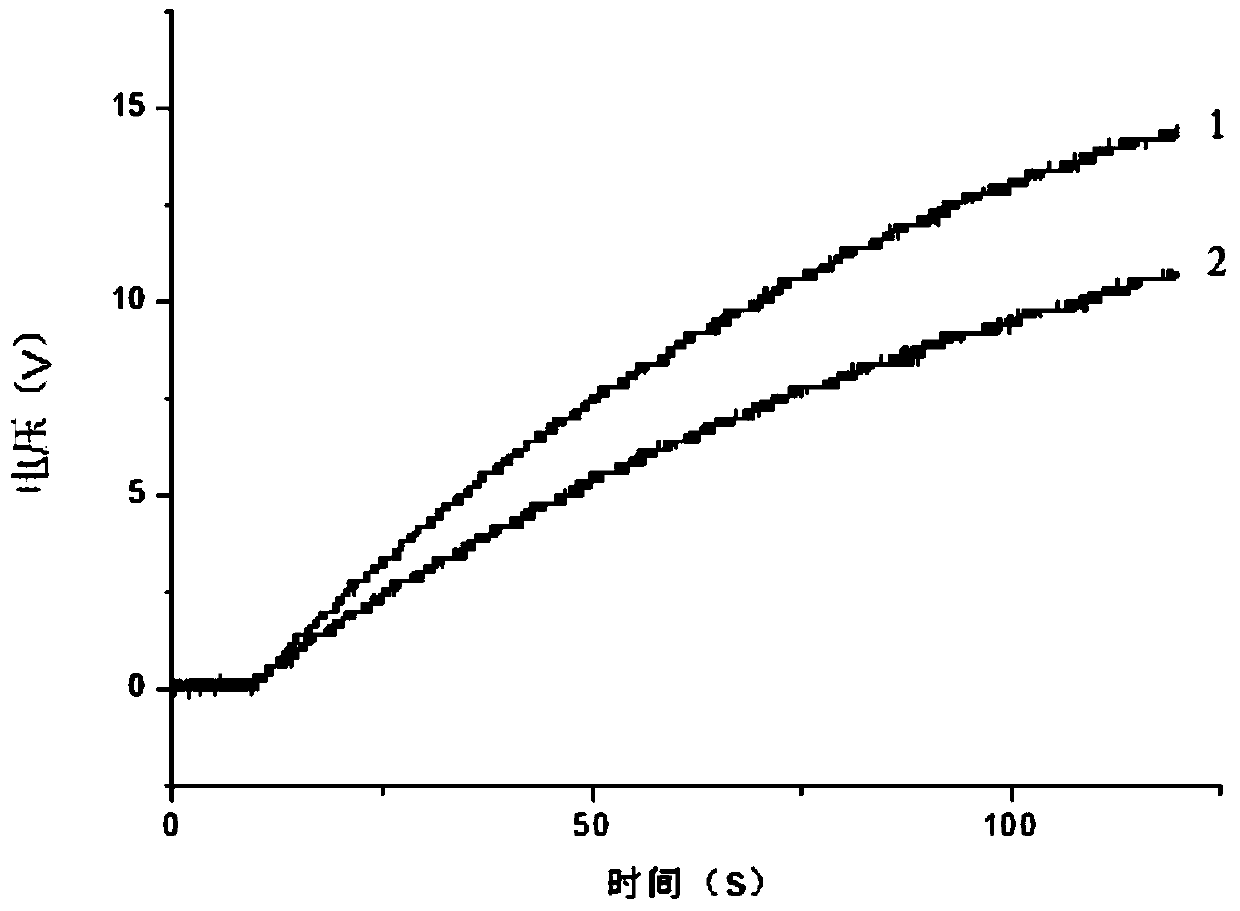

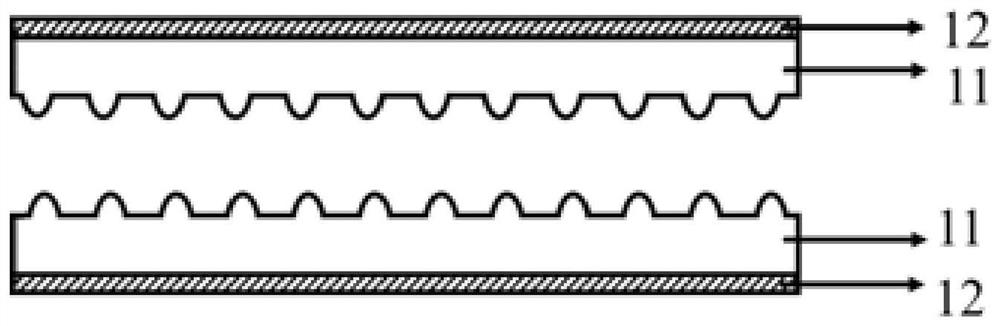

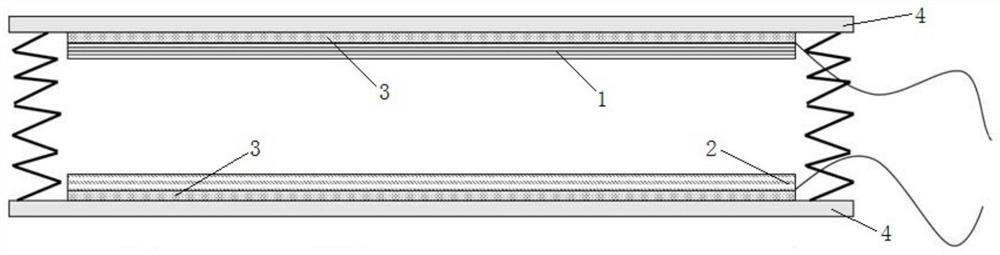

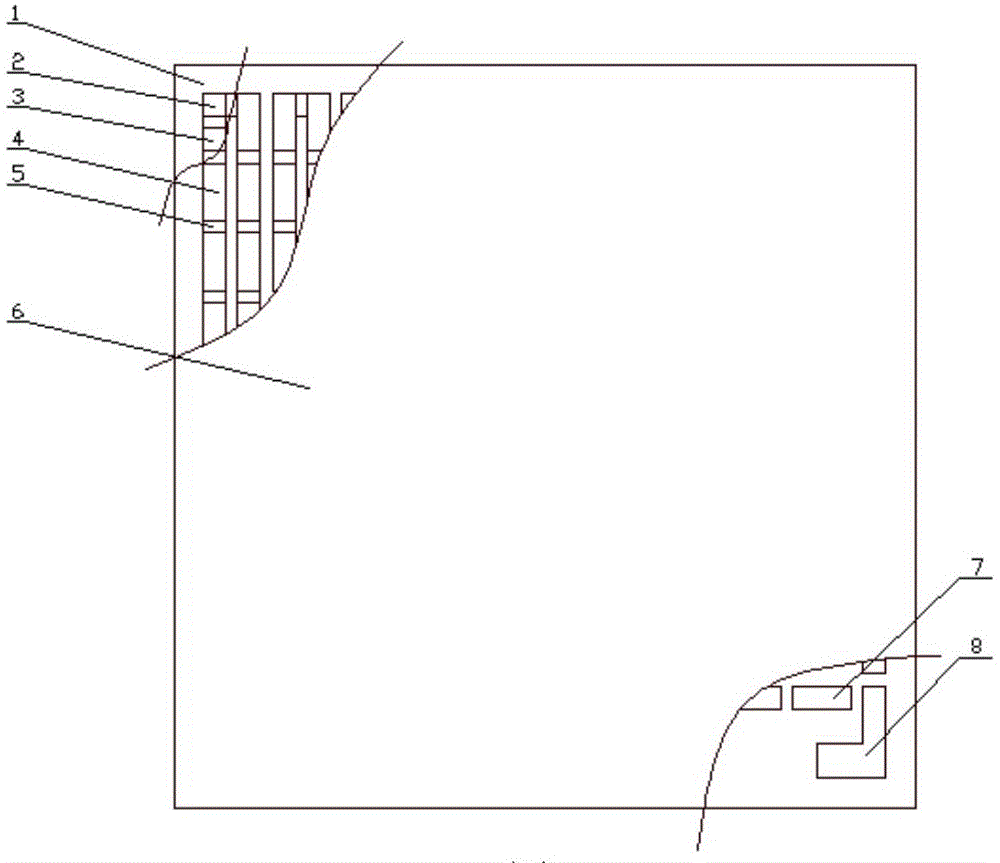

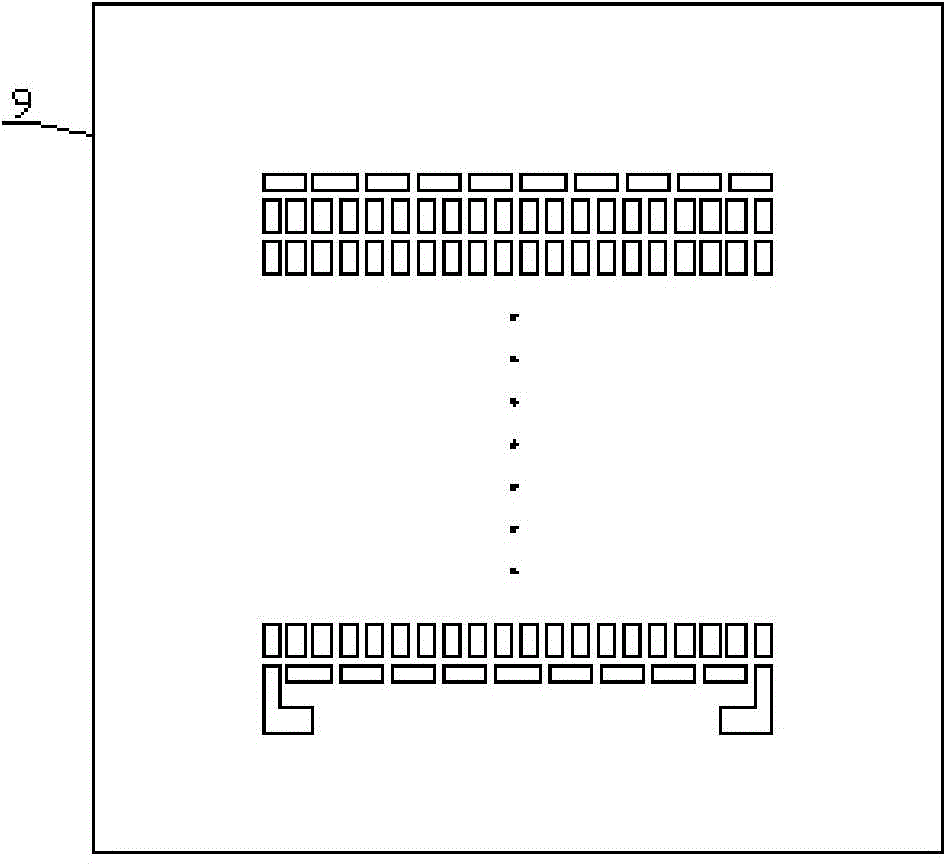

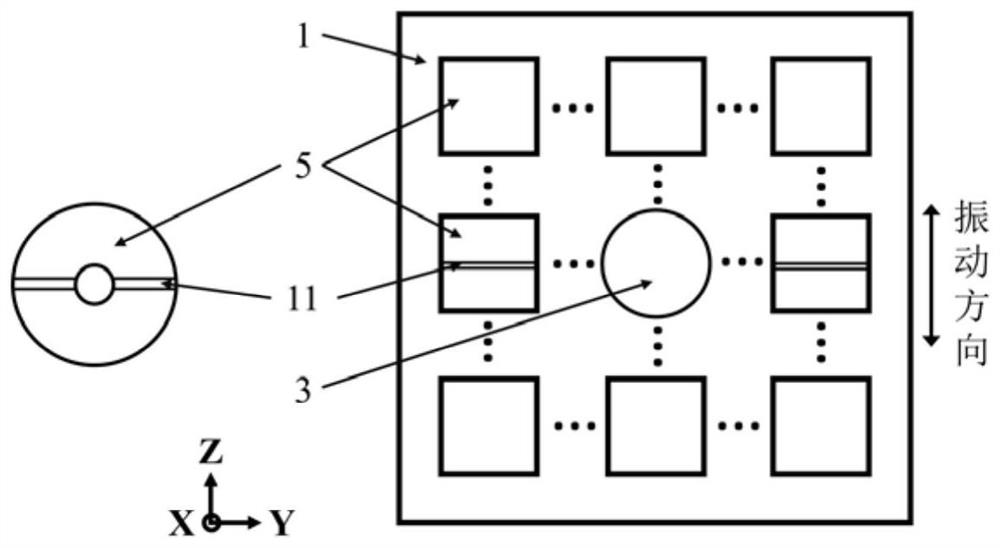

Flexible wearable friction nanometer power generator with comprehensive multi-mode mechanical energy collecting functions

PendingCN108233762AEfficient collectionImprove electrical output performanceFriction generatorsElectricityNanogenerator

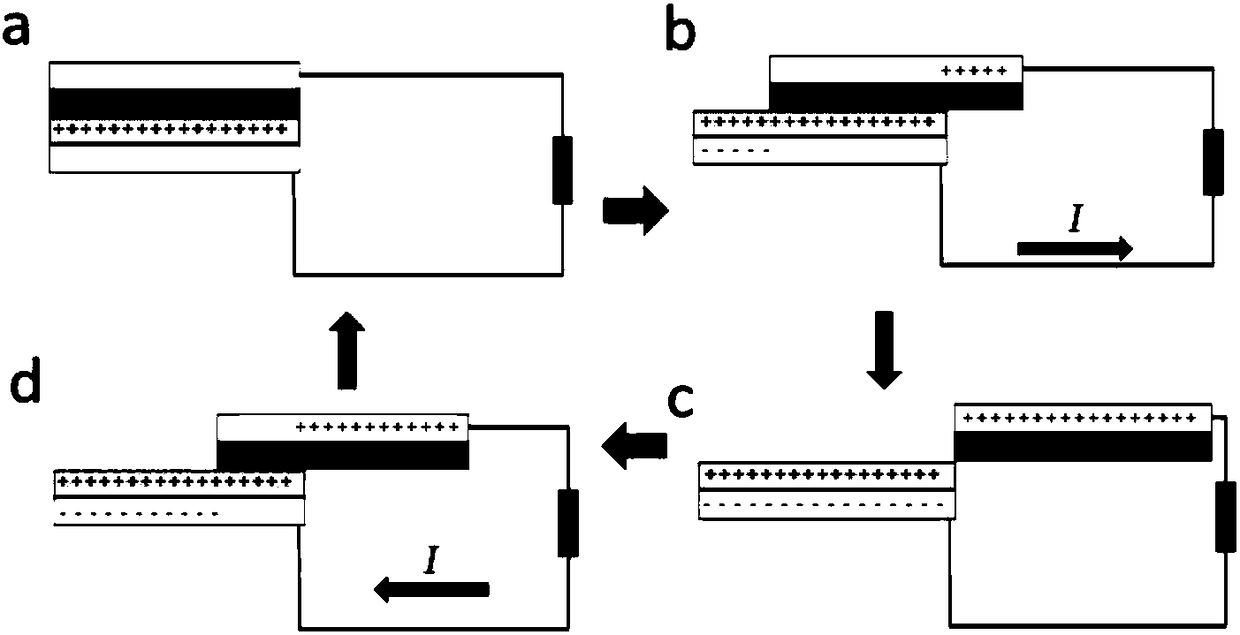

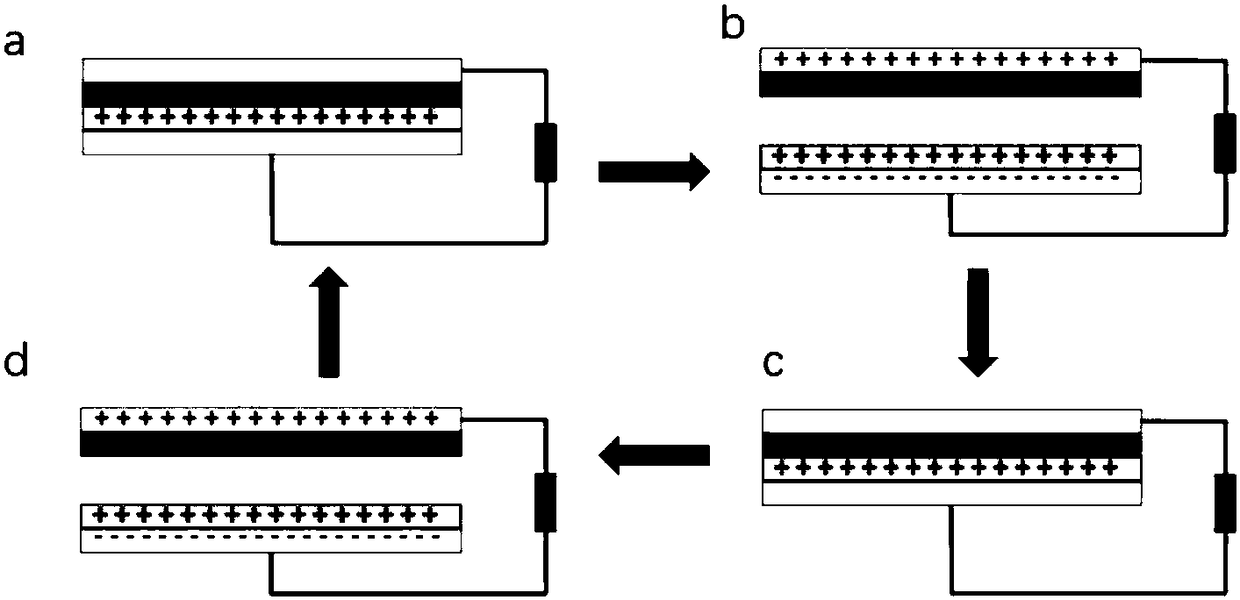

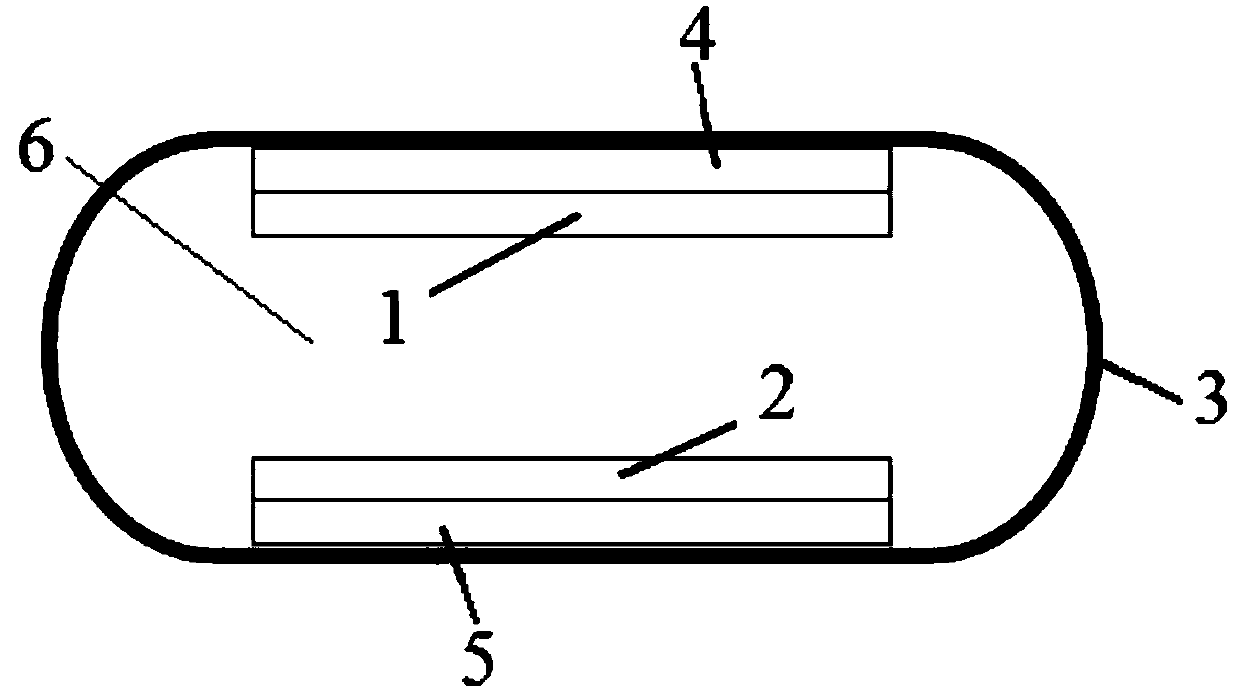

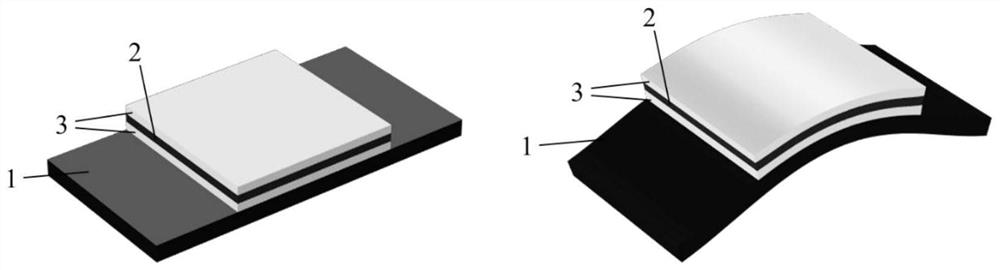

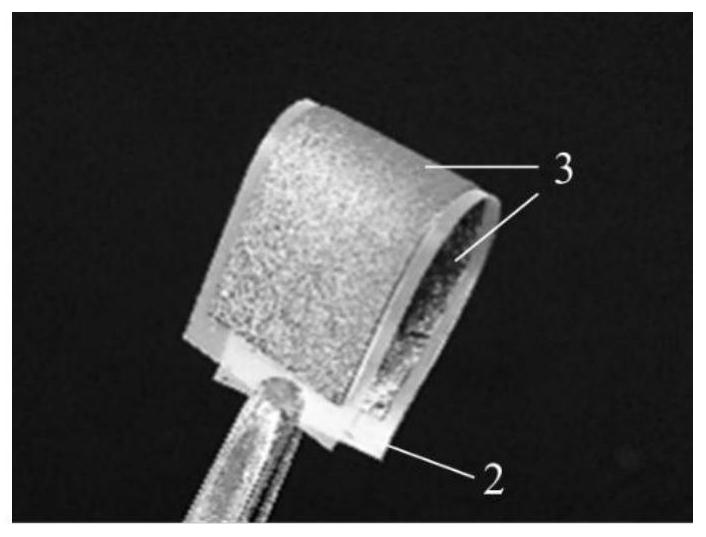

The invention belongs to the technical field of flexible devices, and discloses a flexible wearable friction nanometer power generator with comprehensive multi-mode mechanical energy collecting functions. The flexible wearable friction nanometer power generator comprises a first friction component and a second friction component. Each friction component comprises an insulating isolation layer, a conductive element and a friction layer. A first friction surface and a second friction surface are in contact-separation cycle under the effect of normal external force when the flexible wearable friction nanometer power generator is in contact and separation modes under the effect of external force, the normal relative distances between friction units on the two friction surfaces change, and electric signals can be outputted to outer circuits by the first conductive element and the second conductive element; the first friction surface and the second friction surface relatively slide under theeffect of tangential external force when the flexible wearable friction nanometer power generator is in independent friction modes, the tangential relative locations of the first friction units and the second conductive element change, and electric signals can be outputted to the outer circuits by two secondary second conductive elements of the second conductive element. The flexible wearable friction nanometer power generator has the advantages that the multi-dimensional mechanical energy collecting performance of the flexible wearable friction nanometer power generator can be enhanced, andthe electric output performance of the flexible wearable friction nanometer power generator can be improved.

Owner:DALIAN UNIV OF TECH

Friction nanometer power generator for converting mechanical energy to electric energy and fabrication method of friction nanometer power generator

ActiveCN109412456ASolve the problem of not being able to make nanofibersSolve the problem that most fluorine-containing materials, except polyvinylidene fluoride, cannot be directly prepared into nanofibers by electrospinningFriction generatorsFiberElectricity

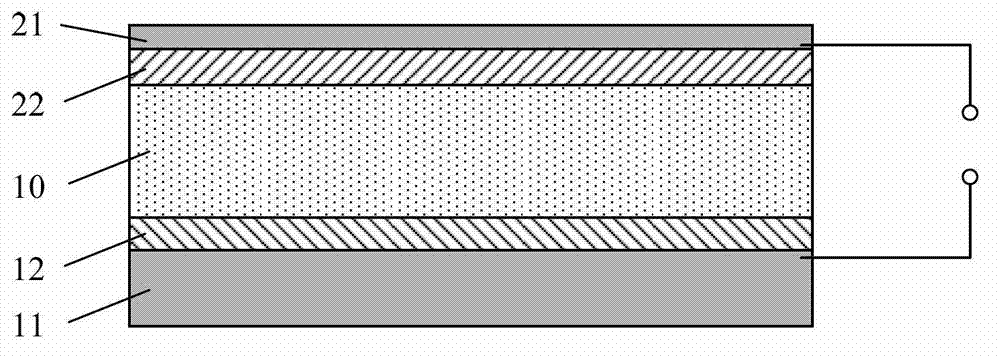

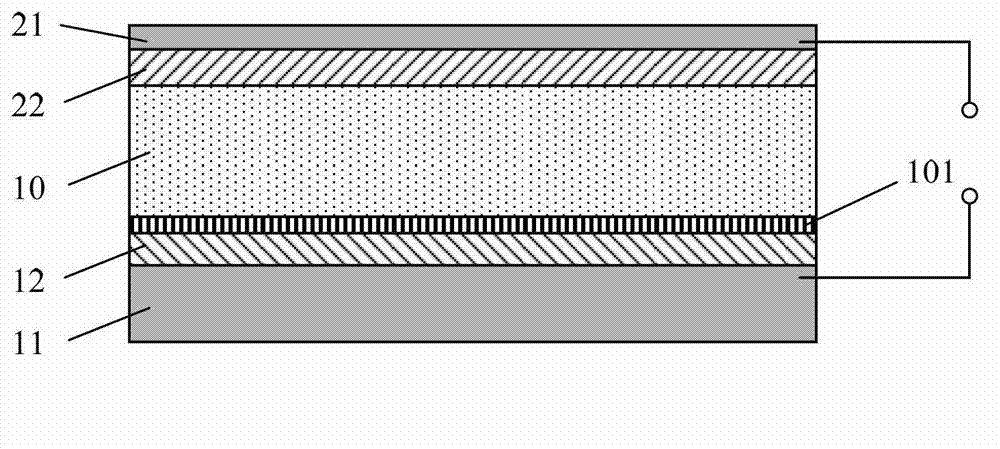

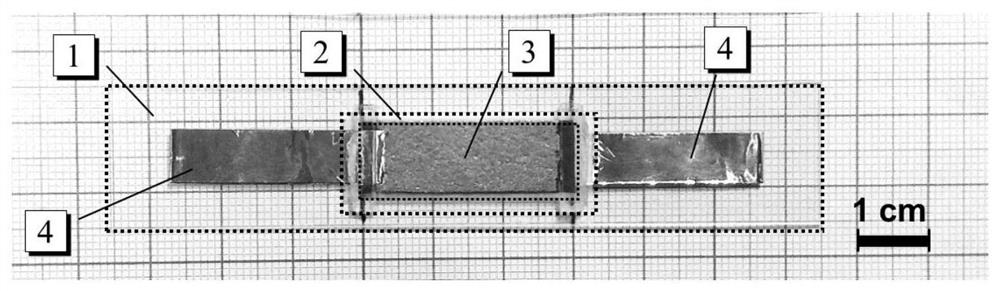

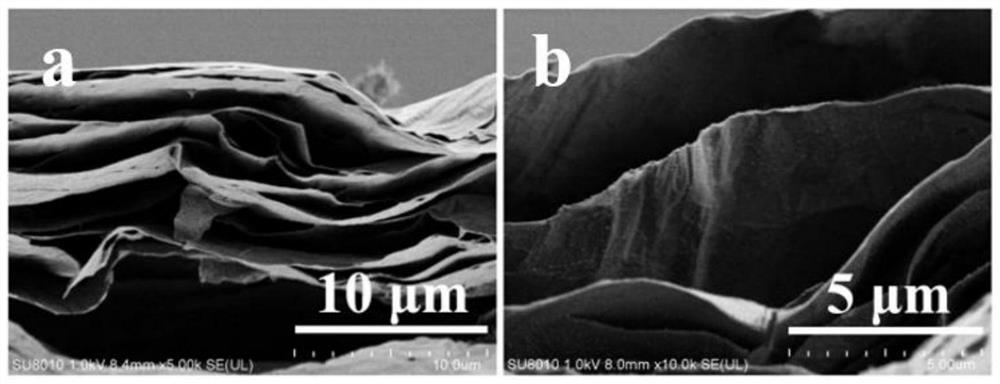

The invention relates to a friction nanometer power generator for converting mechanical energy to electric energy and a fabrication method of the friction nanometer power generator. The fabrication method comprises the steps of packaging a flexible substrate layer I, an electrode material layer I, an electrical negative friction layer, an electrical positive friction layer, an electrode material layer II and a flexible substrate layer II according to a sequence, and then connecting the two flexible substrate layer at the outmost layer so that the electrical negative friction layer and the electrical positive friction layer are arranged at intervals to fabricate the friction nanometer power generator, wherein the electrical negative friction layer is fabricated by automatically assembly a friction electrical negative substance on a surface of aerogel. The fabricated friction nanometer power generator for converting the mechanical energy to the electric energy comprises the electrical negative friction layer and the electrical positive friction layer, and the electrical negative frication layer mainly comprises nanometer fiber of the self-assembled friction electrical negative substance. The fabrication method is simple, the fabricated product is low in cost, the sensitivity on mechanical energy of tiny biology is high, the electrical output performance is excellent, and the frication nanometer power generator has favorable application prospect in the field of self power supply sensing and wearability.

Owner:DONGHUA UNIV

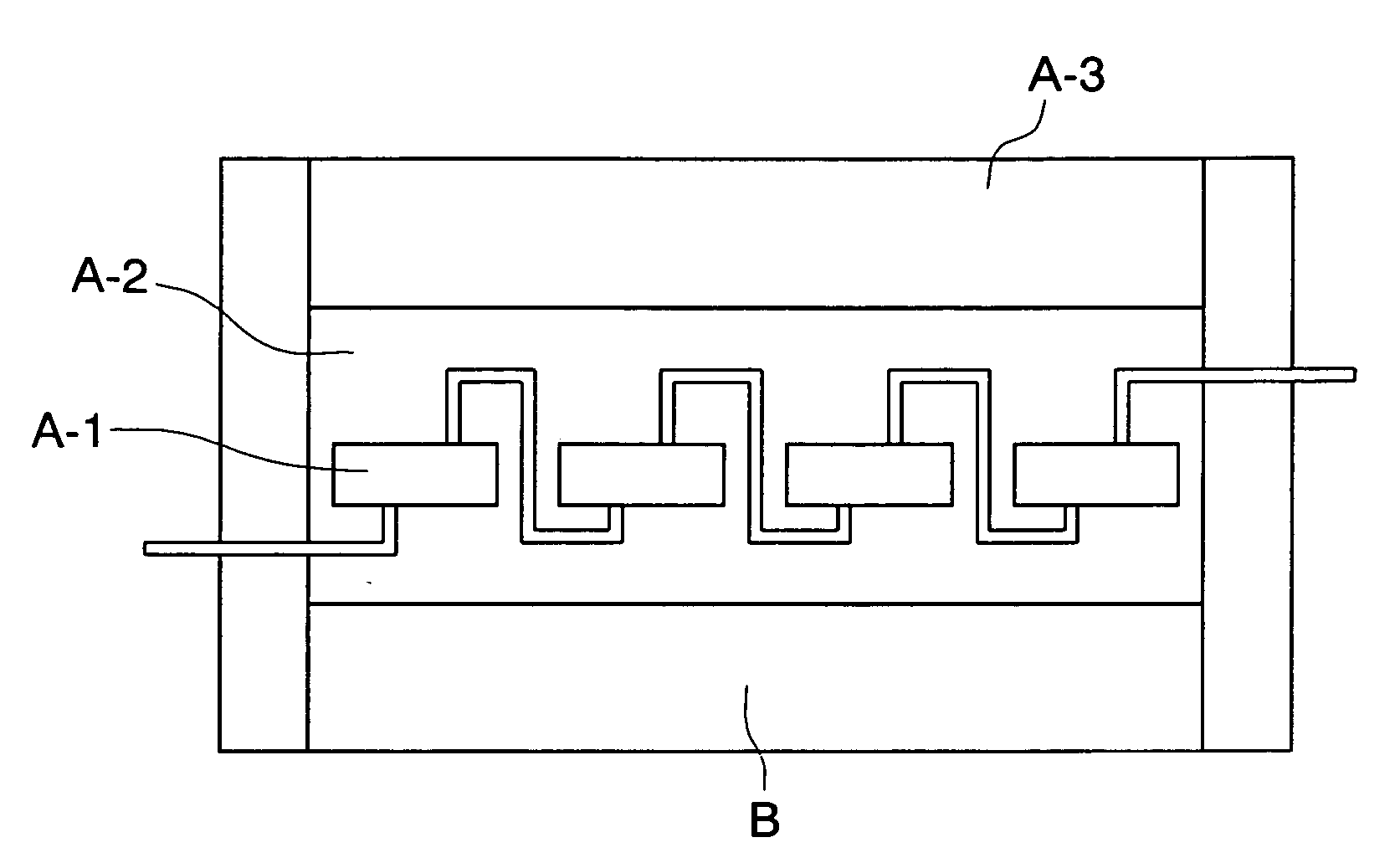

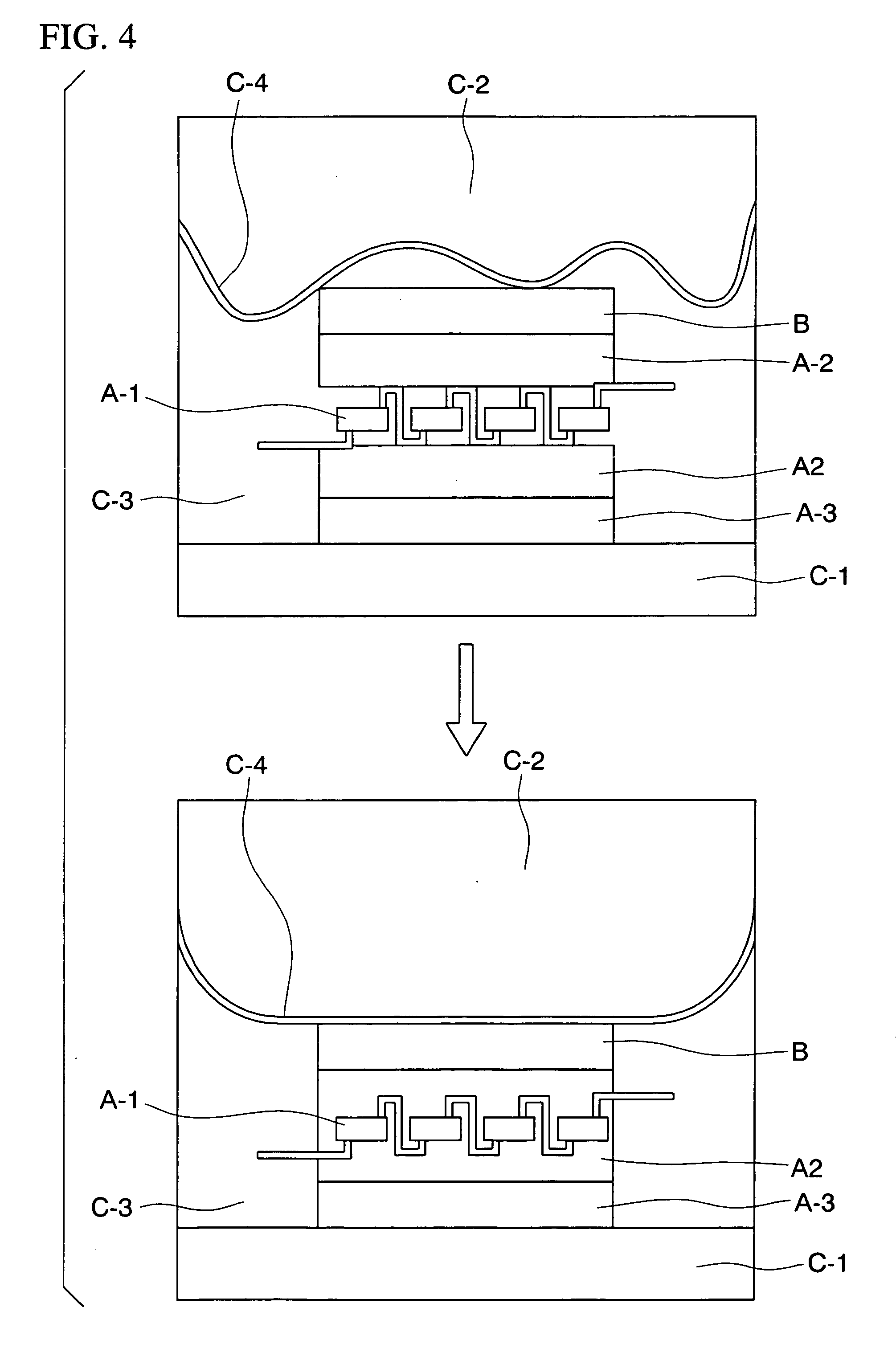

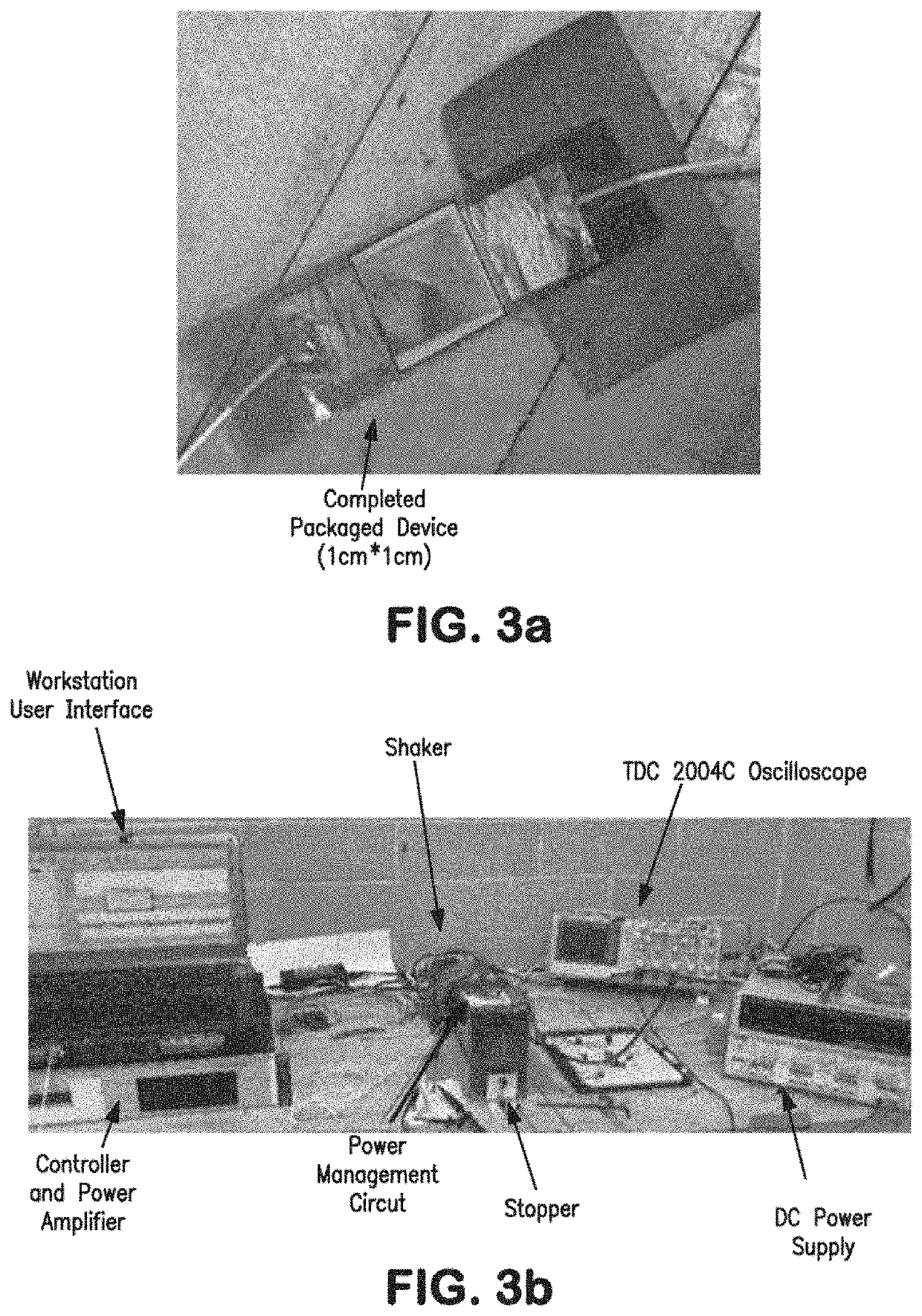

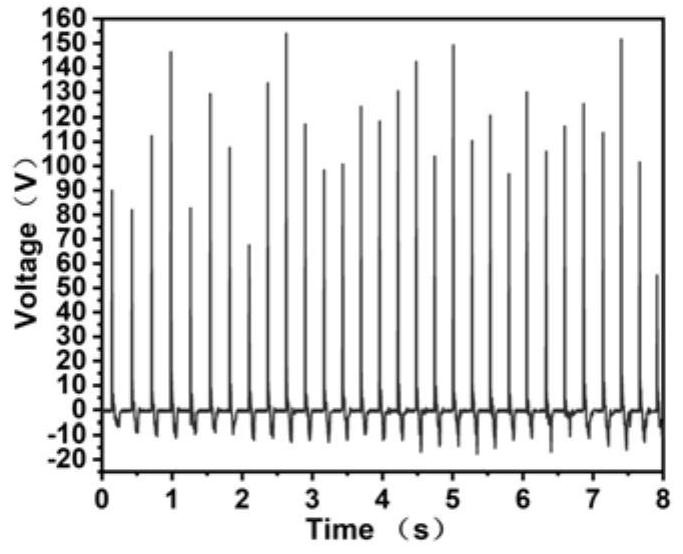

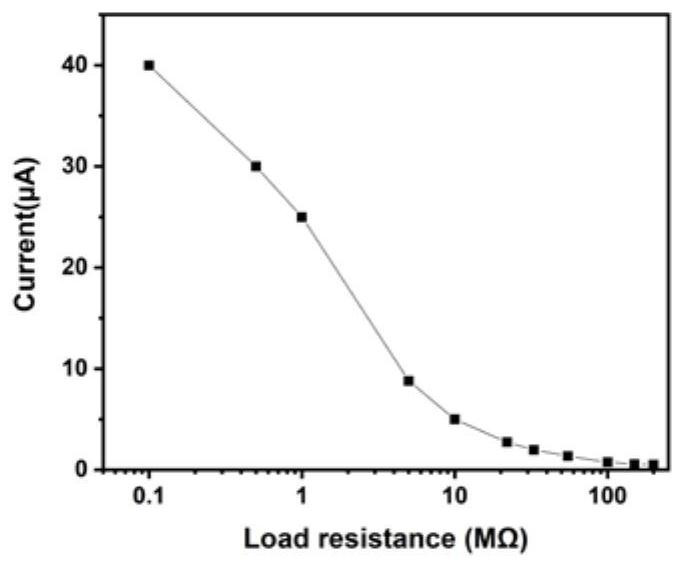

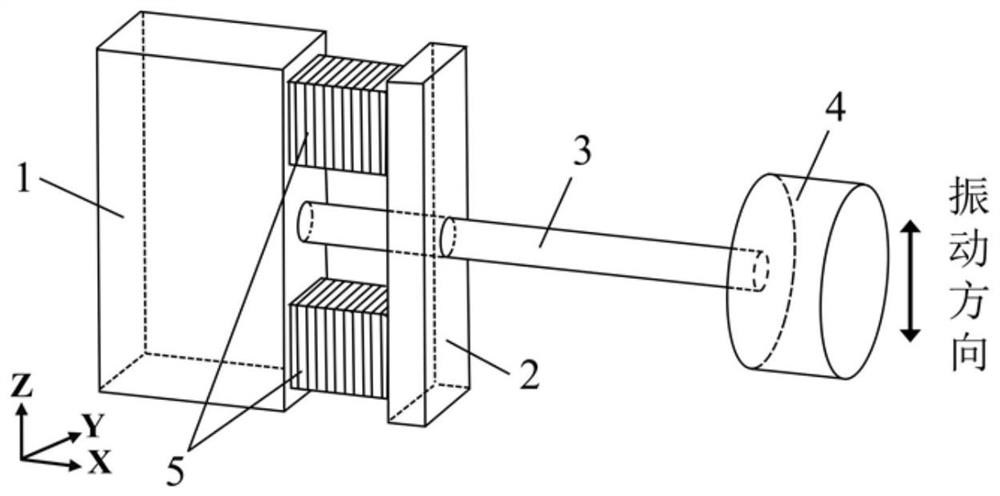

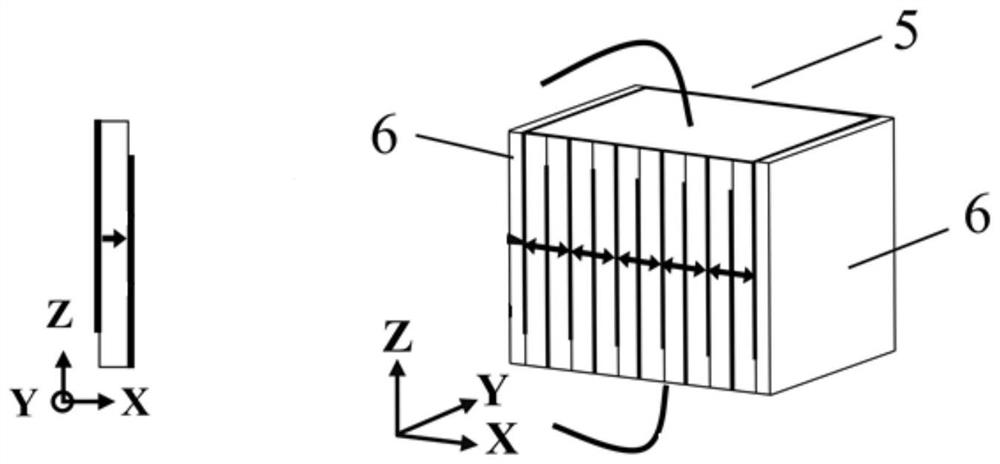

Frictional nano-generator for collecting vibration energy and vibration sensor

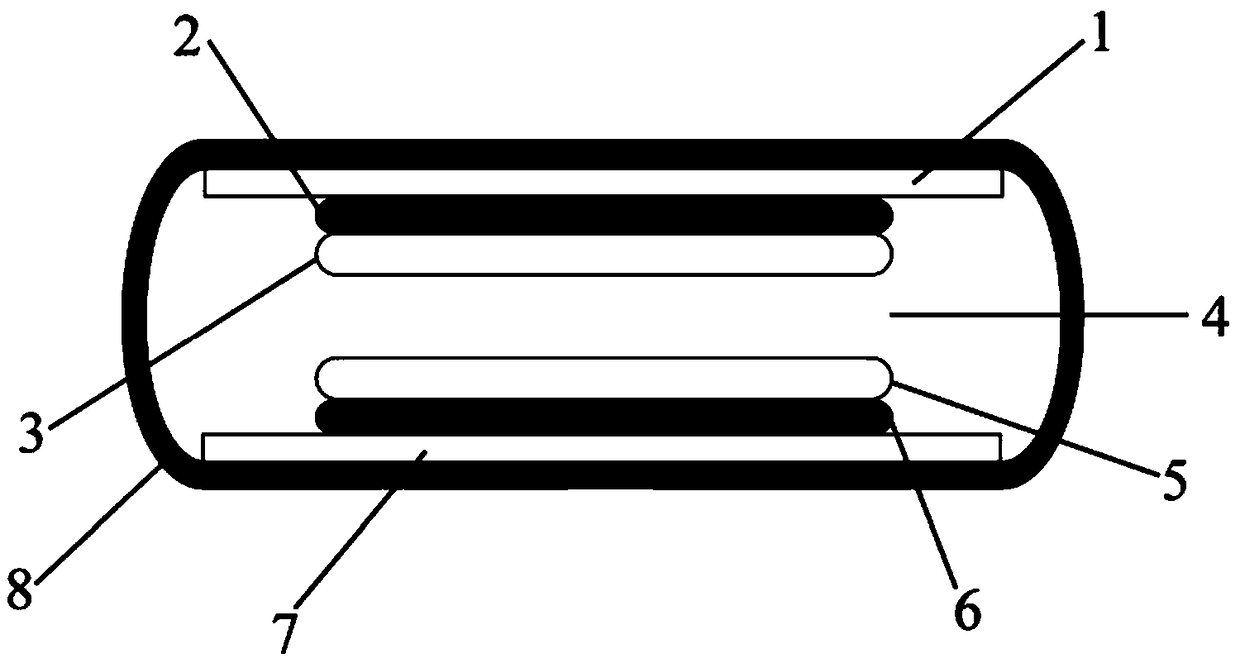

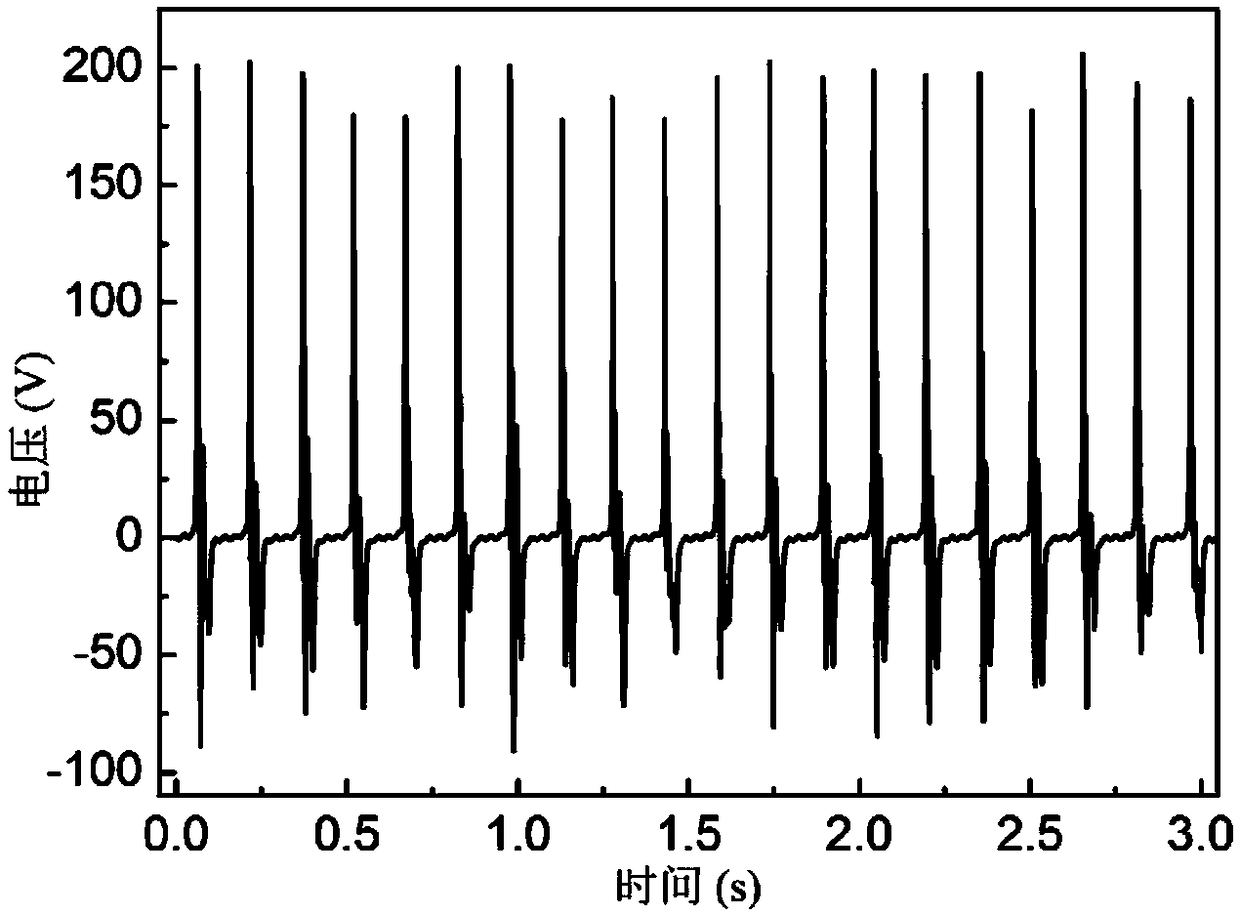

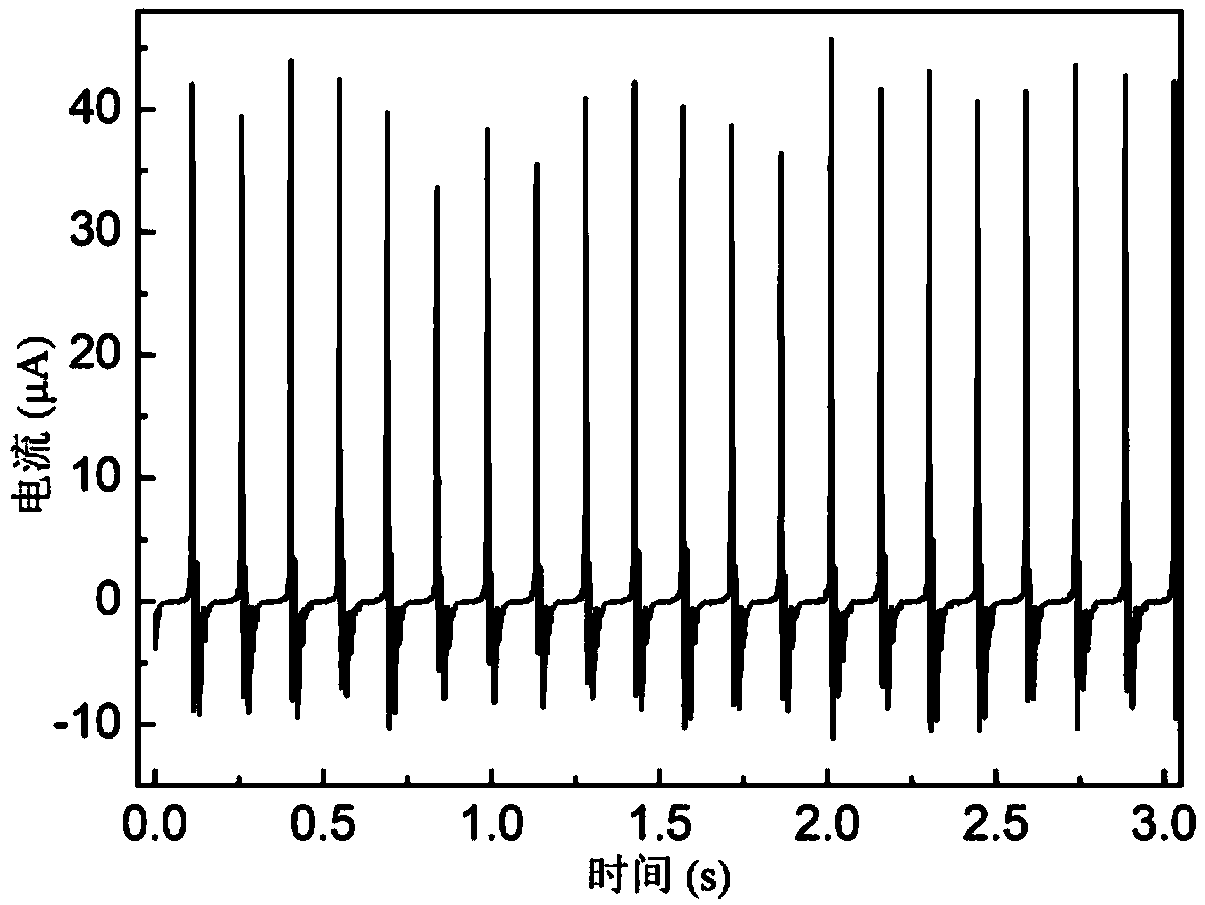

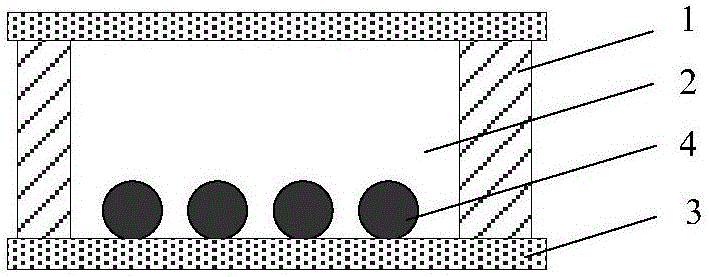

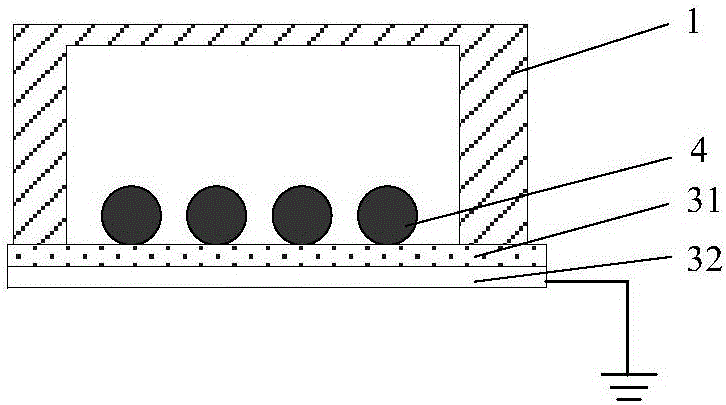

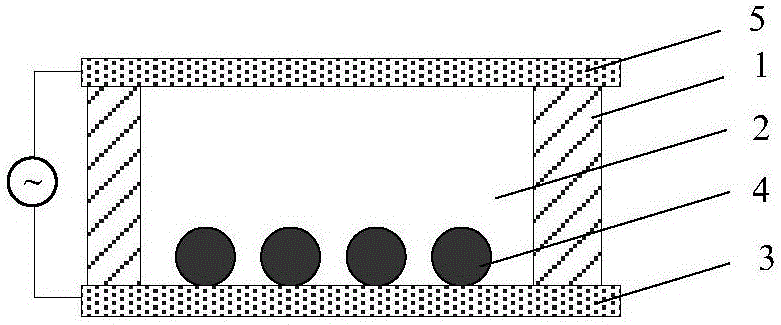

InactiveCN106602924AExcellent output electrical performanceImprove electrical output performanceSubsonic/sonic/ultrasonic wave measurementUsing electrical meansElectric generatorElectricity

The invention discloses a frictional nano-generator for collecting vibration energy, and the nano-generator comprises a plurality of power generation units, a vibration power generation membrane, and a supporting part, wherein the supporting part is provided with a cavity. The vibration power generation membrane is disposed at the opening of the cavity, and comprises an electrode layer. The electrode layer is electrically connected with a conductive object or an isoelectric level. The plurality of power generation units are disposed in the cavity. The vibration power generation membrane vibrates under the vibration effect, and the power generation units collide with the vibration power generation membrane, and form induction in the electrode layer to generate charges. The nanp-generator of the above structure can collect the vibration energy at high and low frequency, presents excellent output electric performances, and can continuously drive various types of wearable electronic equipment without a big-size energy management circuit.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

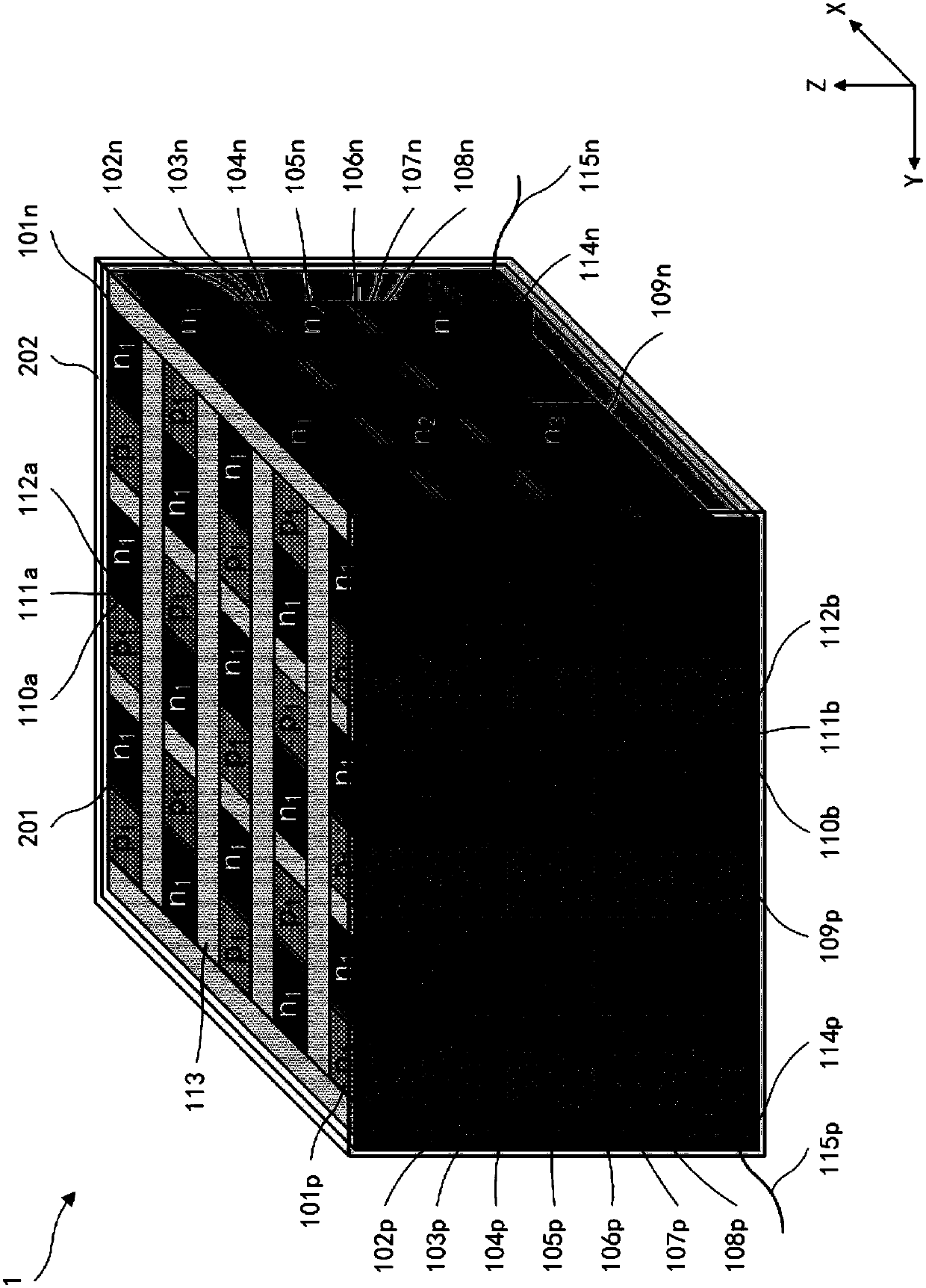

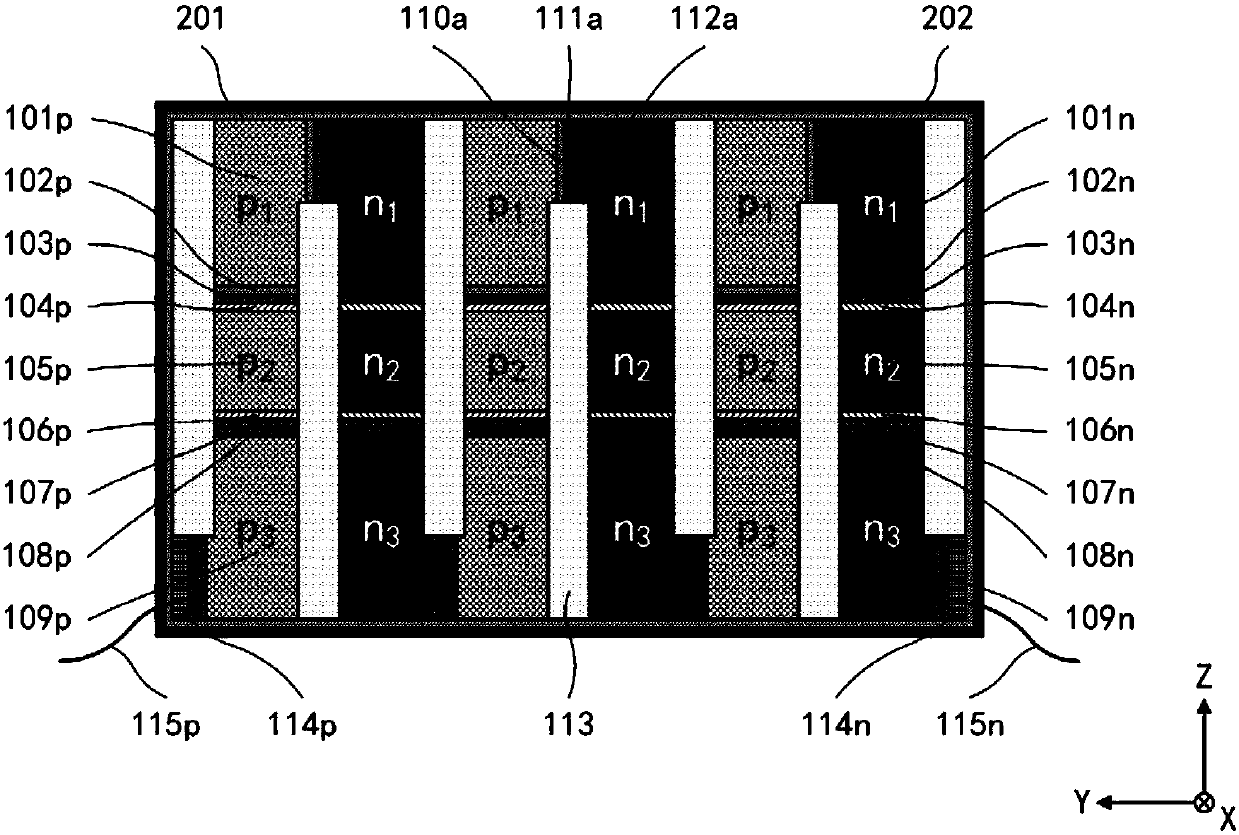

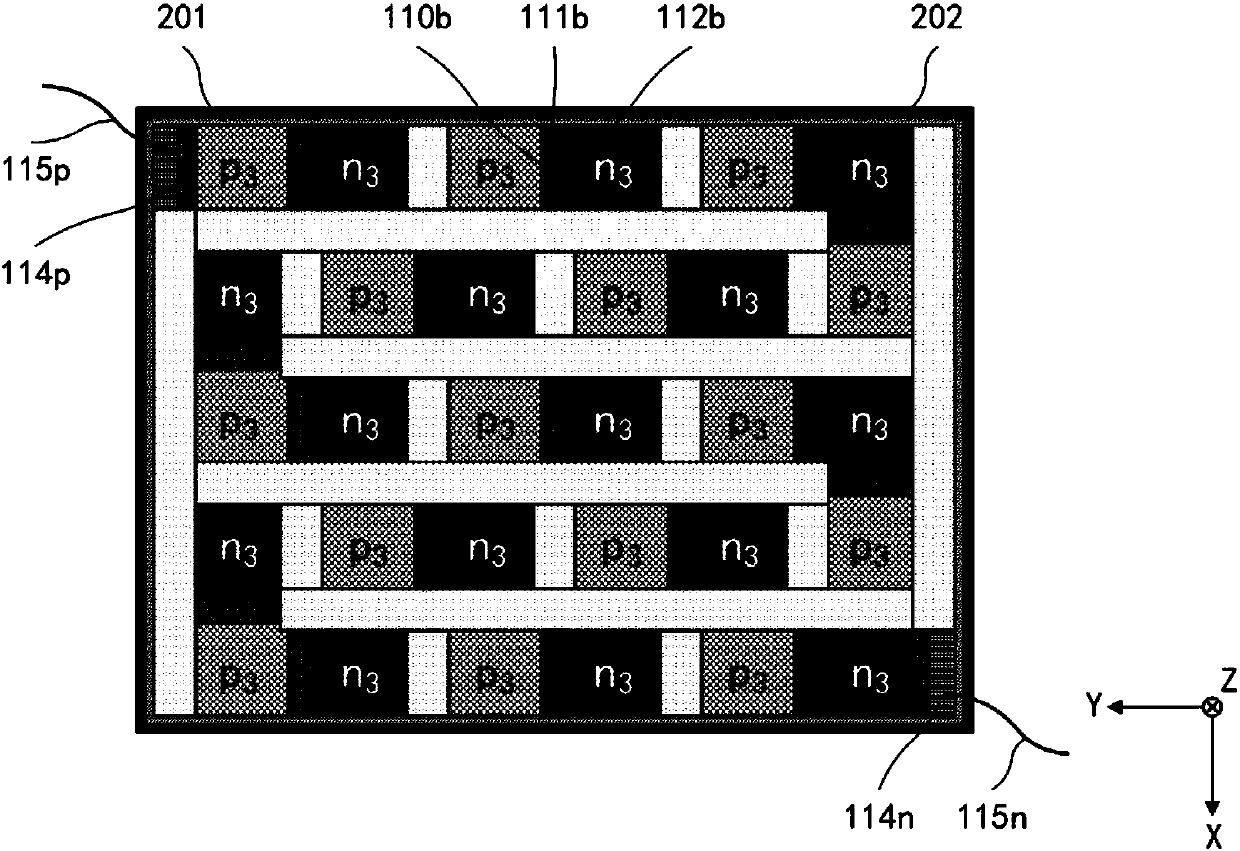

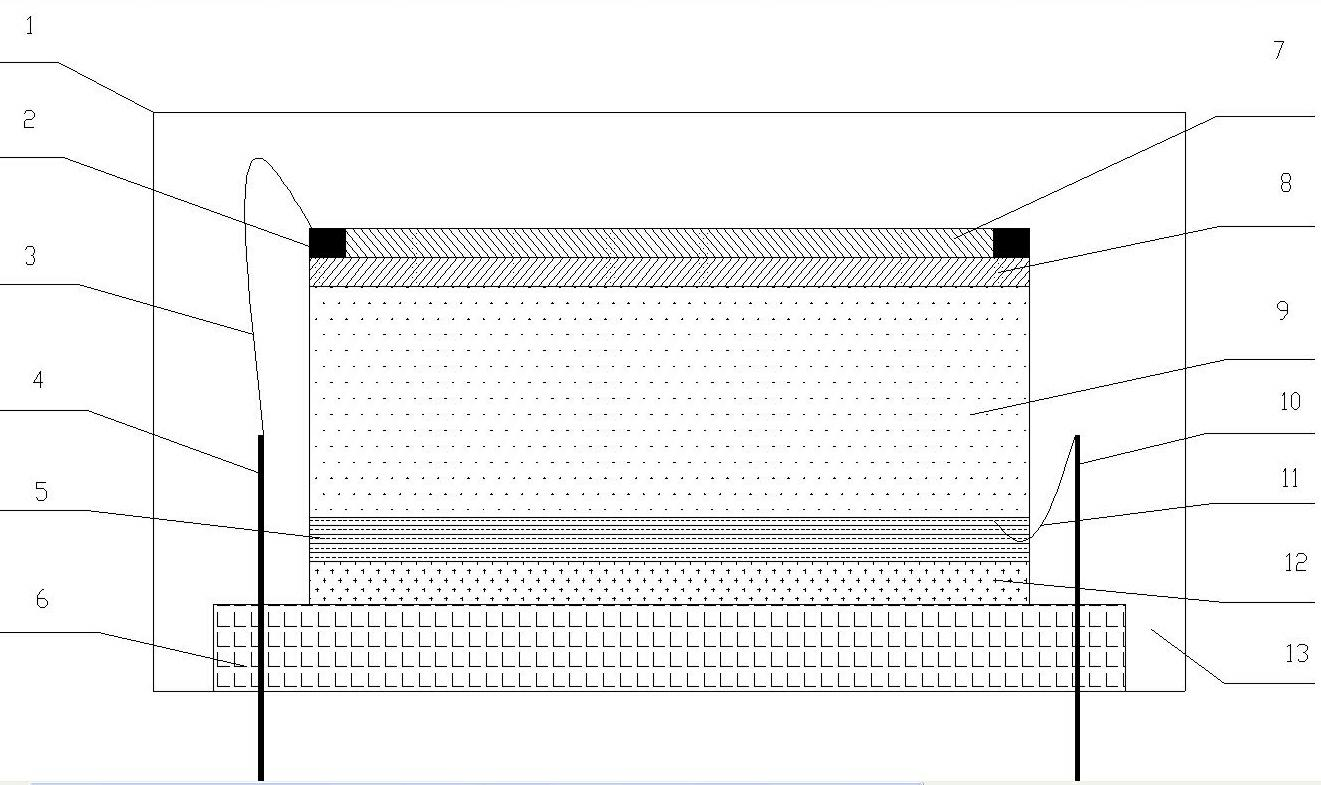

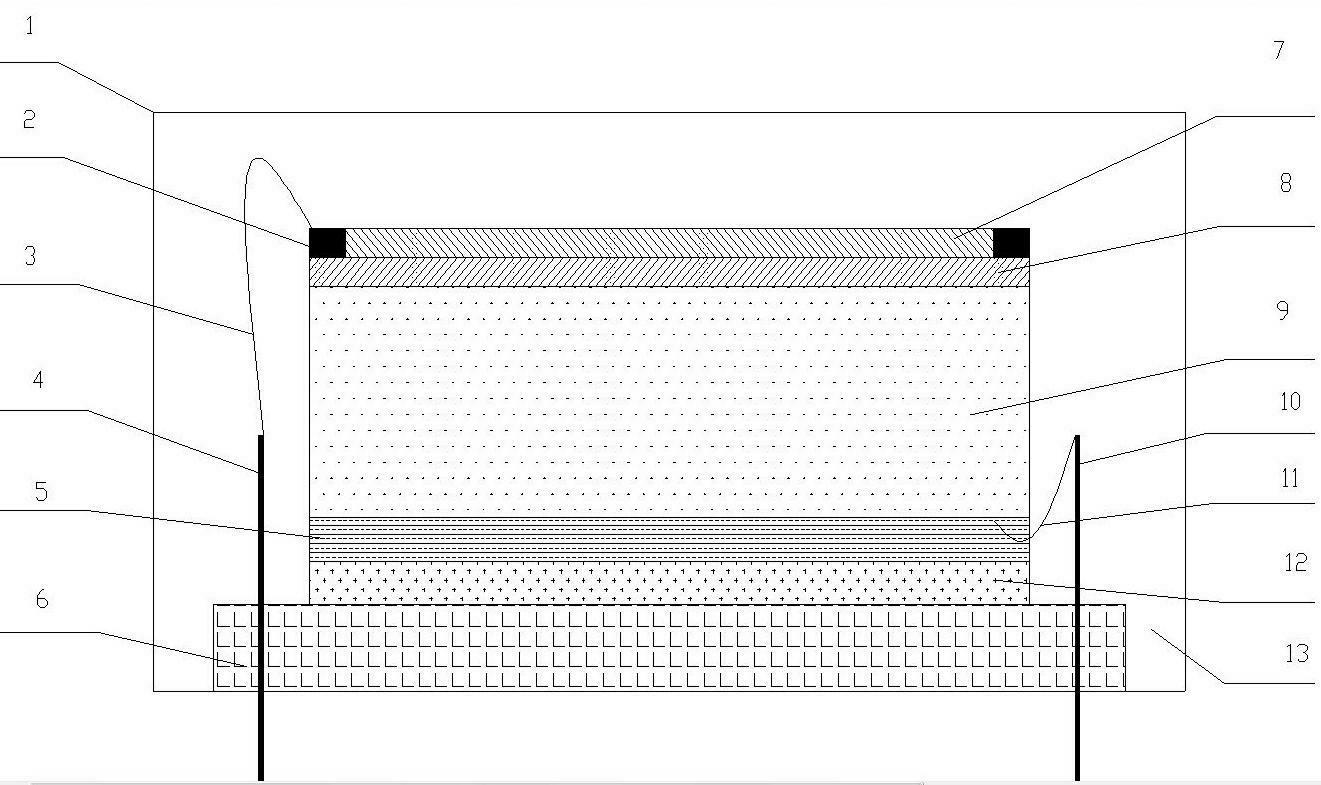

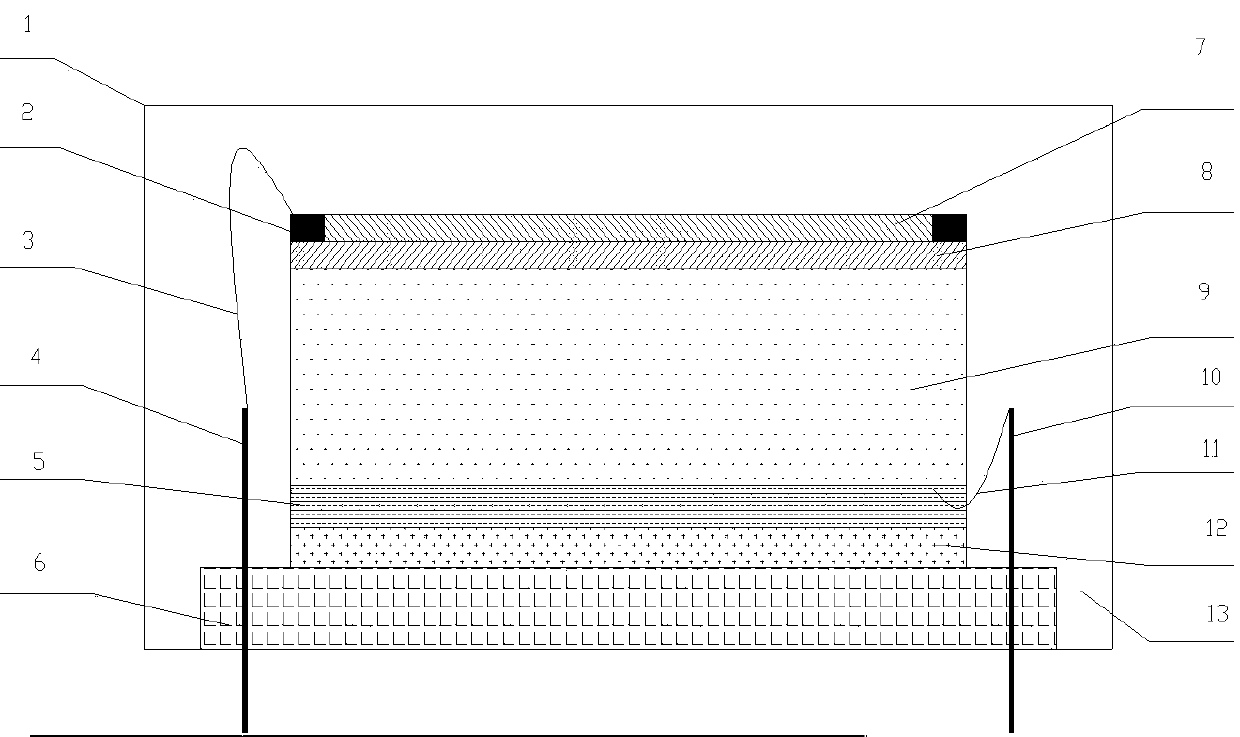

High-performance thermoelectric device and ultrafast fabrication method thereof

ActiveCN107946452AImprove electrical output performanceImprove job stabilityThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermoelectric materialsEnergy conversion efficiency

The invention discloses a high-performance thermoelectric device and an ultrafast fabrication method thereof. In the high-performance thermoelectric device, a segmented structure is employed to perform optimal matching of a thermoelectric material and a temperature difference environment, a blocking layer and a buffer stress layer are employed to reduce interface element migration and longitudinalcontact thermal expansion stress and improve bonding strength, a phonon scattering layer and a negative thermal expansion buffer layer are embedded to fix a thermoelectric leg so as to improve internal thermal resistance and horizontal thermal matching performance of the high-performance thermoelectric device, internal package and external package are employed to prevent the thermoelectric material from being oxidized and sublimed and improve external collision-resistant capability, the technical bottlenecks of low energy conversion efficiency, small specific power, poor thermal stability, poor collision performance, complicated fabrication process and the like of a traditional thermoelectric device are effectively broken through, meanwhile, the thermal stability and the mechanical structural performance of the high-performance thermoelectric device are improved to a great extent, long-term and excellent electrical output performance is guaranteed, and the working environment is expanded.

Owner:深圳热电新能源科技有限公司

Piezoelectric nanometer generator, eyeball moving monitor sensor and monitor method

ActiveCN103780143AResponsiveRealize monitoringPiezoelectric/electrostriction/magnetostriction machinesSensorsEyelidElectricity

This invention relates to a piezoelectric nanometer generator, an eyeball moving monitor sensor and a monitor method. The piezoelectric nanometer generator comprises a lower electrode layer, a first insulation layer positioned on the upper surface of the lower electrode layer, a piezoelectric layer positioned on the upper surface of the first insulation layer, and an upper electrode layer positioned above the piezoelectric layer. The thickness of the generator is less than 20 Mum. The flexible piezoelectric nanometer generator is constructed by utilizing the piezoelectric properties possessed by piezoelectric thin film materials and the eyeball moving monitor sensor is manufactured based on the piezoelectric nanometer generator. The ultrathin flexible piezoelectric generator is attached on the surface of the eyelid. When the eyeball is moving, the pressure applied by the eyeball on the eyelid changes constantly along the moving, which causes the stress on the eyelid to change, and the change acts on the piezoelectric generator so as to output electric signals to the outside. The eyeball moving monitor sensor disclosed by the invention can perform long time monitor on human eyes, and is low in cost, easy for carrying and simple in structure.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

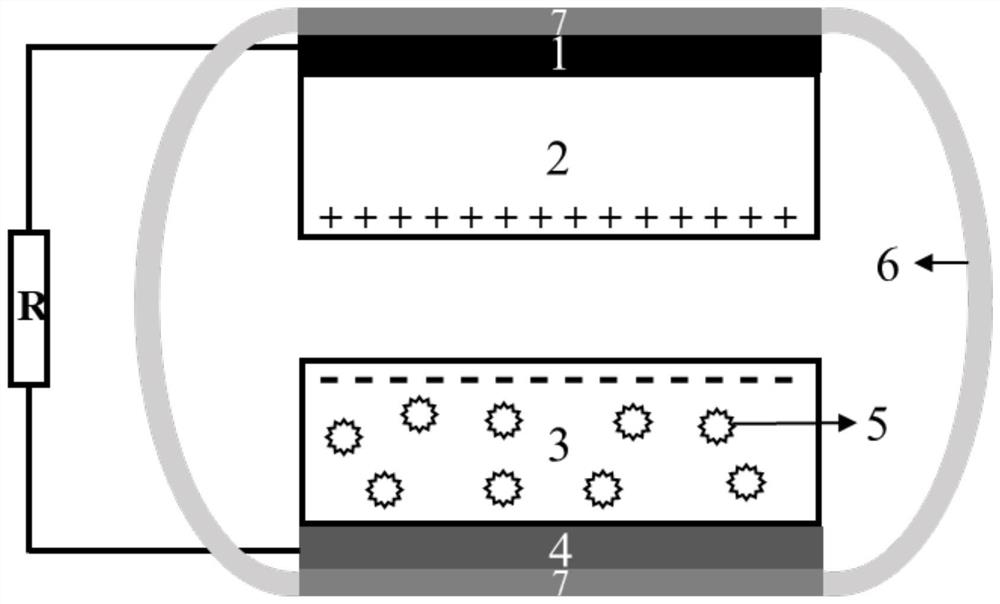

Air interval type friction nanometer generator

The invention relates to an air interval type friction nanometer generator. The air interval type friction nanometer generator comprises a first friction layer, a second friction layer and a sealing structure prepared from an elastic material; an upper electrode material is fixed on the upper part of the inner surface of the sealing structure while a lower electrode material is fixed on the lowerpart; the back surface of the first friction layer is adhered to the upper electrode material; the back surface of the second friction layer is adhered to the lower electrode material; air is reservedbetween the first friction layer and the second friction layer; when external force is applied to the sealing structure, the first friction layer and the second friction layer are in mutual contact;and when the external force is released, the first friction layer and the second friction layer are separated. The service life and stability of the air interval type friction nanometer generator canbe prolonged and improved.

Owner:DONGHUA UNIV

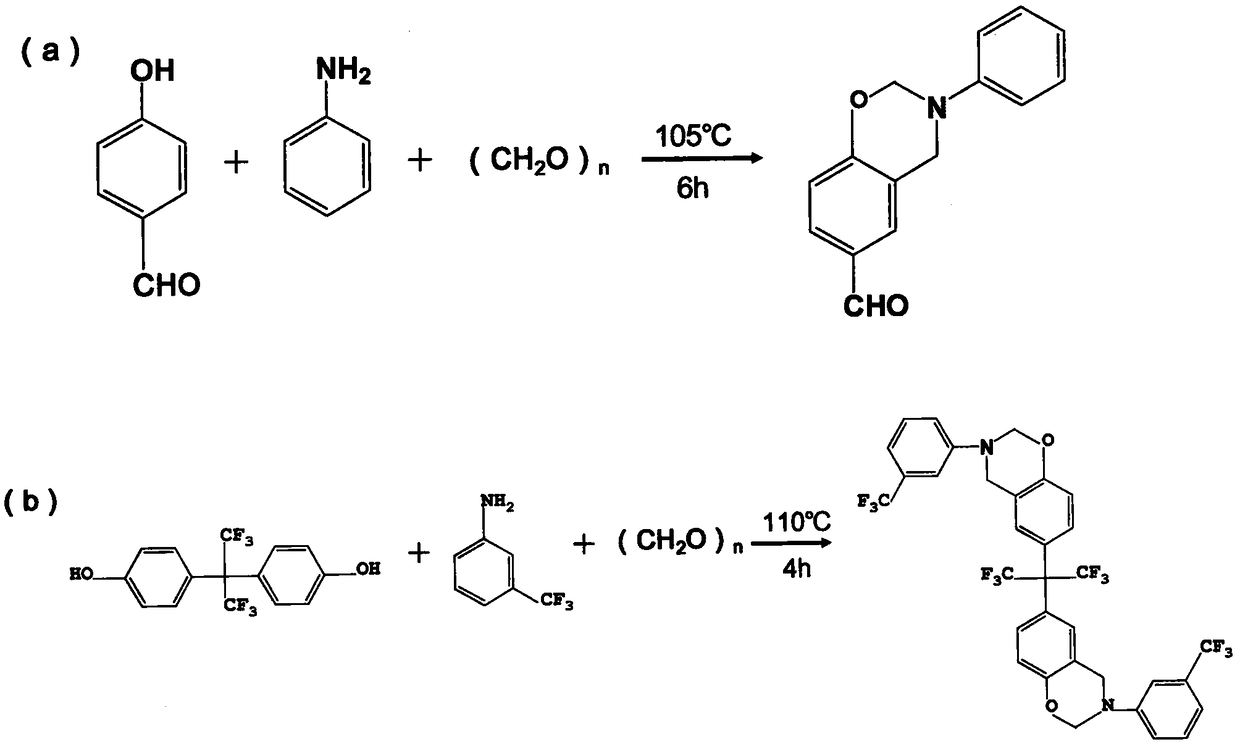

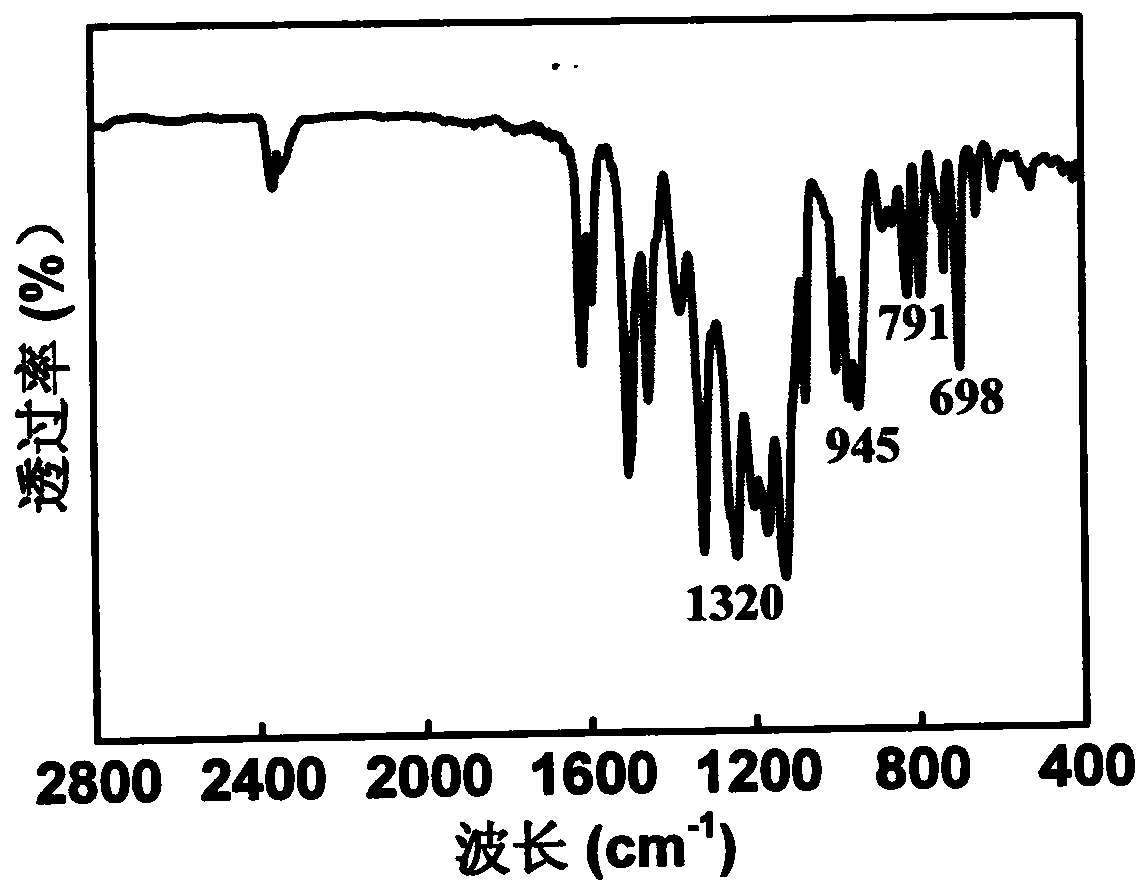

In-situ polymerized surface modified fiber-based friction nano-generator and preparation thereof

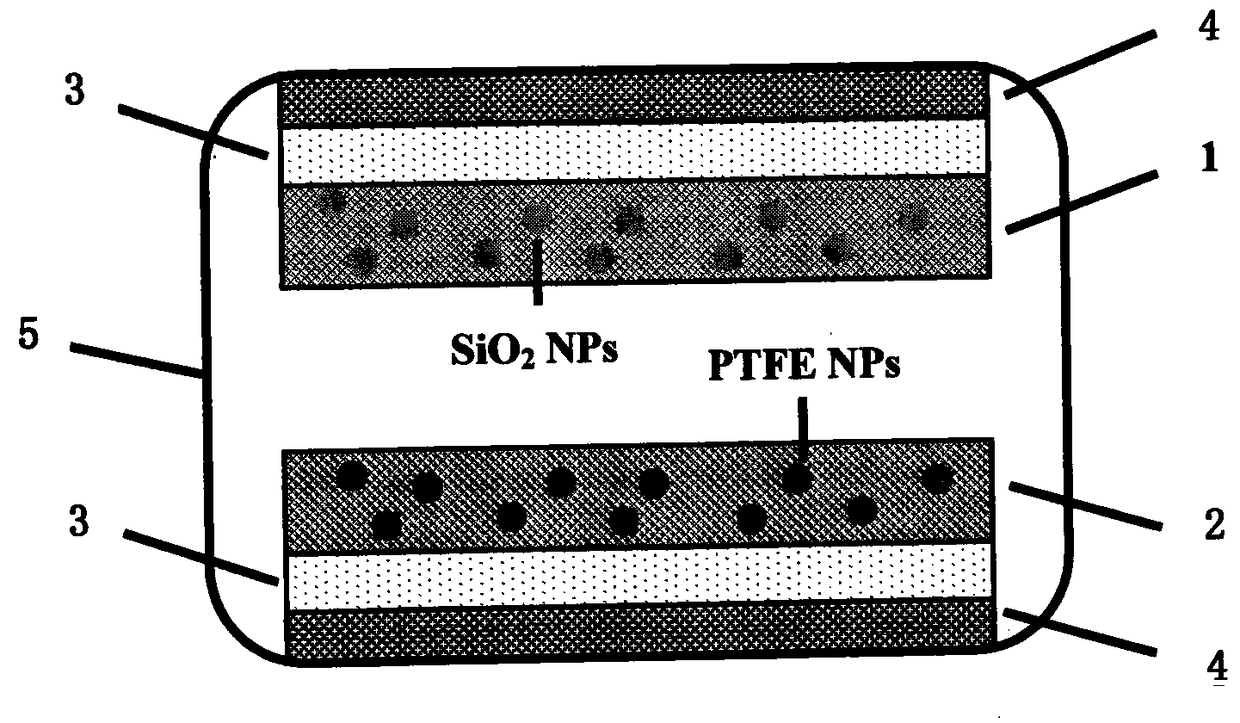

The invention provides an in-situ polymerized surface modified fiber-based friction nano-generator and a preparation method thereof. The in-situ polymerized surface modified fiber-based friction nano-generator is characterized by comprising a friction electropositive nanofiber membrane having in-situ constructed silica nanoparticles (SiO2 NPs) on a surface, and friction electronegative nanofiber membrane having in-situ constructed polytetrafluoroethylenen nanoparticles(PTFE NPs). The surface charge of the friction nano-generator after in-situ polymerized surface modification is expected to increase by 10 to 300%, the short-circuit current is expected to increase by 20 to 300%, and the open circuit voltage is expected to increase by 50 to 300%. The friction nano-generator of the invention has high electric output performance, small volume, simple structure and short preparation process. With the further improvement of its performance, the friction nano-generator will have a broader prospect in the field of wearable electronics.

Owner:DONGHUA UNIV

Preparation method of fabric-based portable flexible pressure sensor

ActiveCN111174947AIncrease the effective contact areaHigh sensitivityForce measurementCatheterEngineeringMedical diagnosis

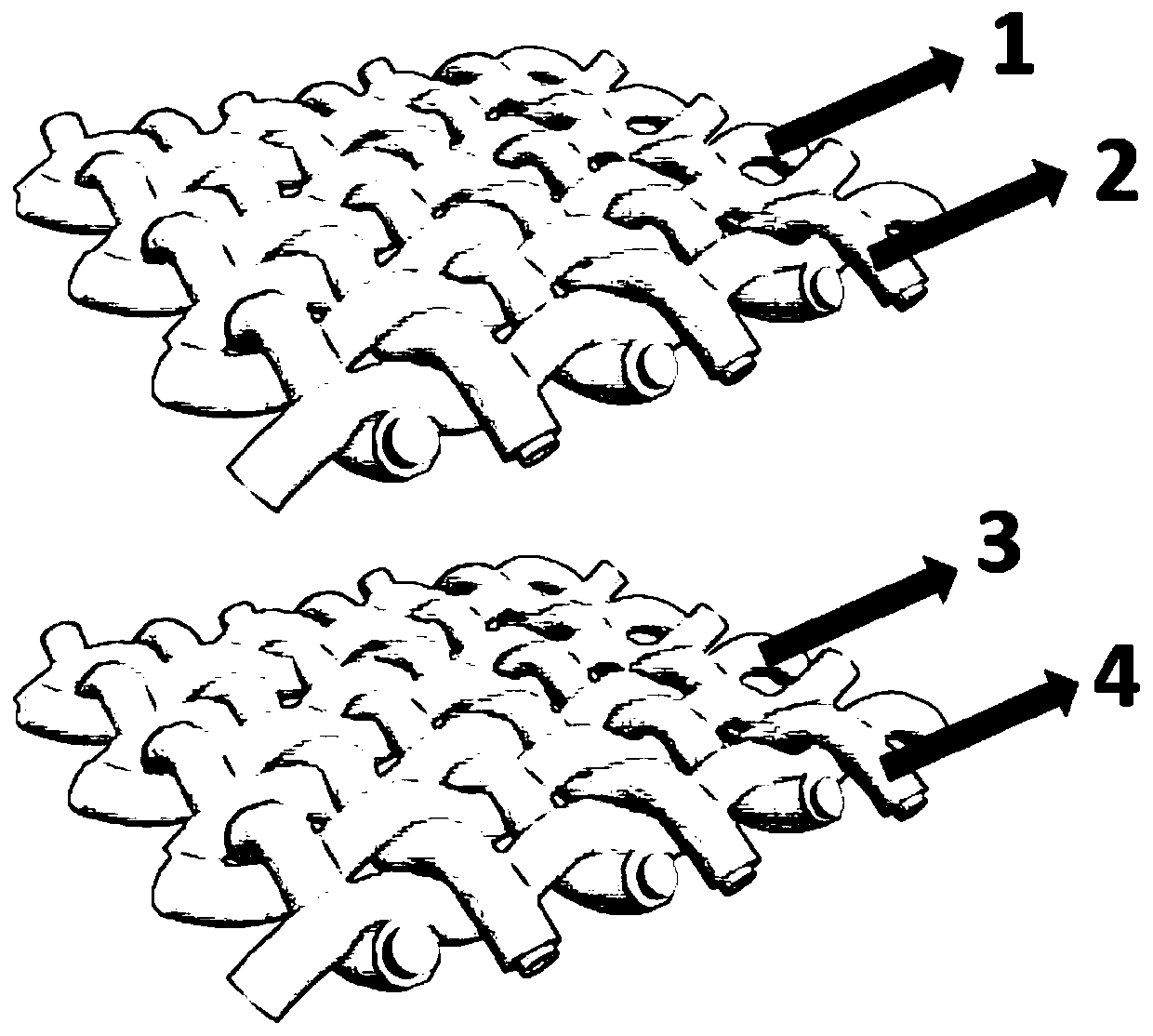

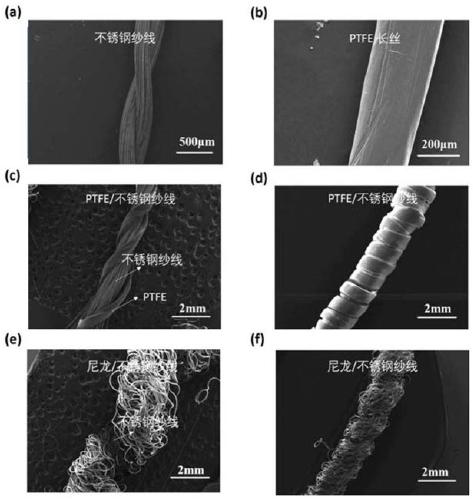

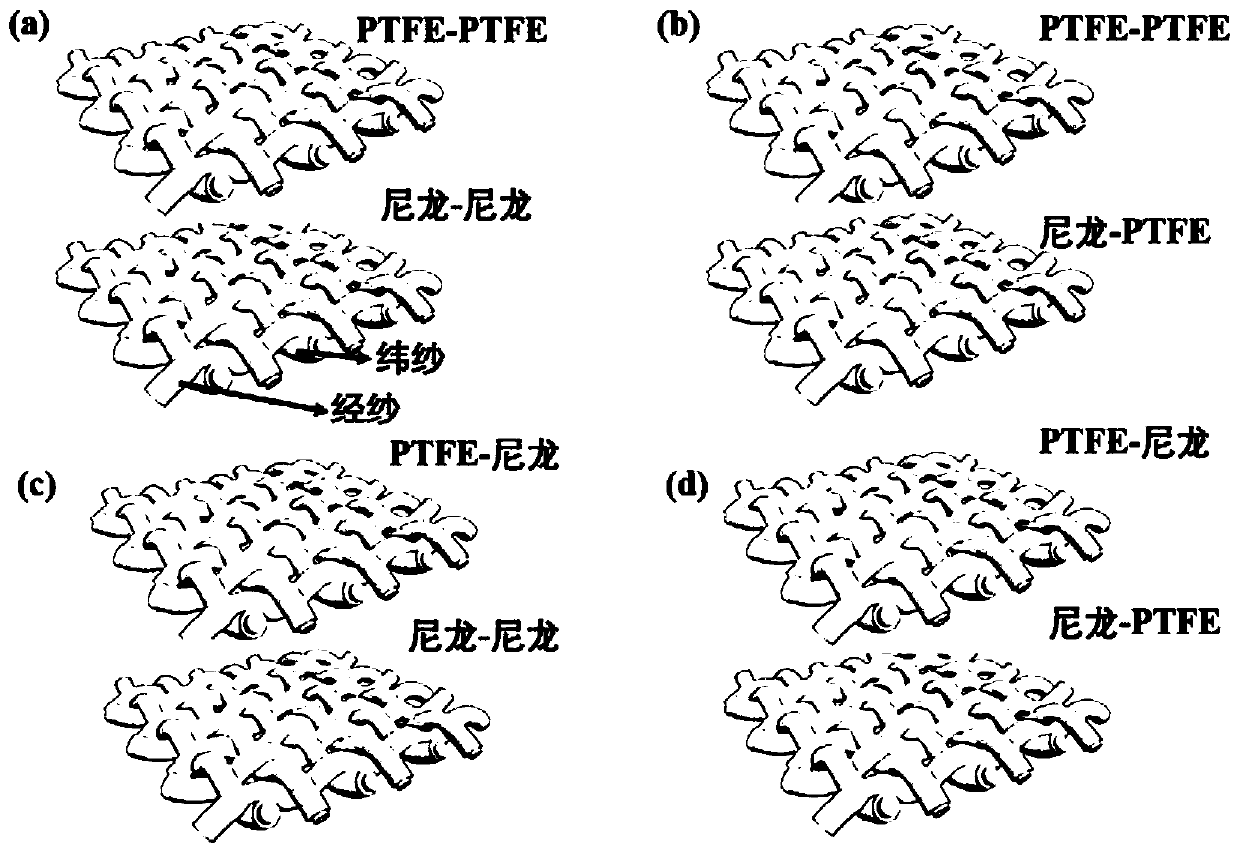

The invention discloses a preparation method of a fabric-based portable flexible pressure sensor. The method is characterized by comprising the following steps: preparing triboelectric positive fasciated yarns and triboelectric negative fasciated yarns, and weaving the obtained triboelectric positive / negative fasciated yarns as weft yarns and nylon yarns or PTFE filaments as warp yarns to form a corresponding triboelectric positive fabric; and combining the triboelectric positive fabric with a triboelectric negative fabric to form the fabric-based portable flexible pressure sensor. By improving the effective contact area between an electropositive friction material and an electronegative friction material in unit area, the electric output performance of a friction nano-generator is improved, and the sensing performance of the flexible pressure sensor based on the friction nano-generator is improved; the sensor is used for monitoring carry-on motion signals at human joint parts and monitoring human pulse signals at carotid arteries to obtain corresponding signal results with reference values such that effective reference bases are provided for medical diagnosis and health assessment.

Owner:DONGHUA UNIV

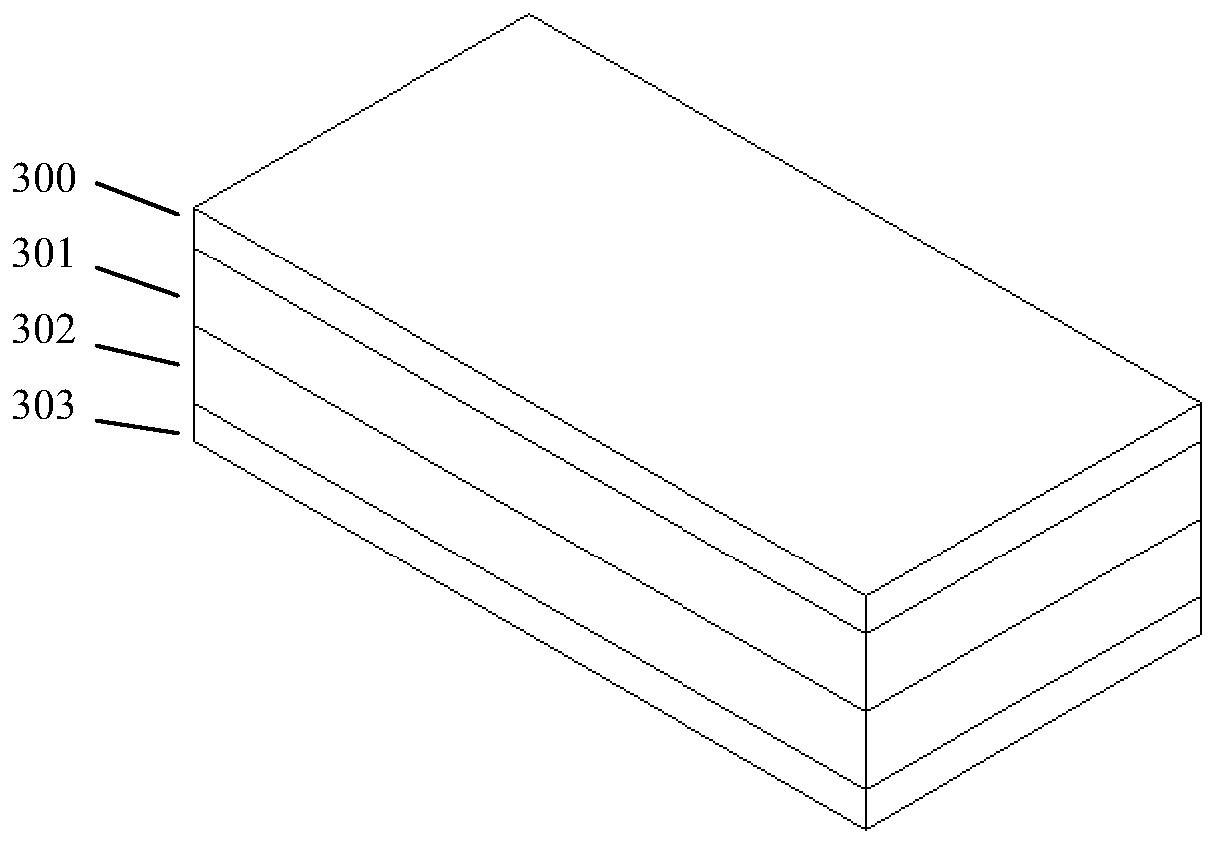

Flexible piezoelectric energy collector based on negative poisson ratio macroscopic graphene film

PendingCN111682796AImprove electrical output performancePiezoelectric/electrostriction/magnetostriction machinesGrapheneGraphitePiezoelectric membrane

The invention relates to a flexible piezoelectric energy collector based on a negative poisson ratio macroscopic graphene film. The collector comprises a flexible substrate, and a laminated structurepiezoelectric power generation unit fixed on the surface of the flexible substrate. A wire is arranged on the surface of the laminated structure piezoelectric power generation unit. The wire is used for leading out charges / voltages generated after tensile deformation of the flexible piezoelectric energy collector, and the laminated structure piezoelectric power generation unit comprises a negativepoisson ratio macroscopic graphene film and a flexible piezoelectric film. According to the invention, flexibility and high conductivity are utilized, the energy collector has a macroscopic graphenefilm with negative Poisson's ratio effect, a negative Poisson's ratio effect is introduced into the flexible piezoelectric energy collector. By means of the strain coupling between the piezoelectric film and the negative poisson ratio macroscopic graphene film in the laminated structure piezoelectric power generation unit, the tensile deformation of the piezoelectric film is changed from the original one-way stretching into stretching in two vertical directions in the plane when the device works, so that the electric output performance of the device is improved.

Owner:武汉汉烯科技有限公司

Sheet for sealing rear surface of solar cell

InactiveUS8507791B2Improve hydrolysis resistancePrevent degradationPolyureas/polyurethane adhesivesSynthetic resin layered productsAdhesiveEngineering

Owner:TOPPAN PRINTING CO LTD +1

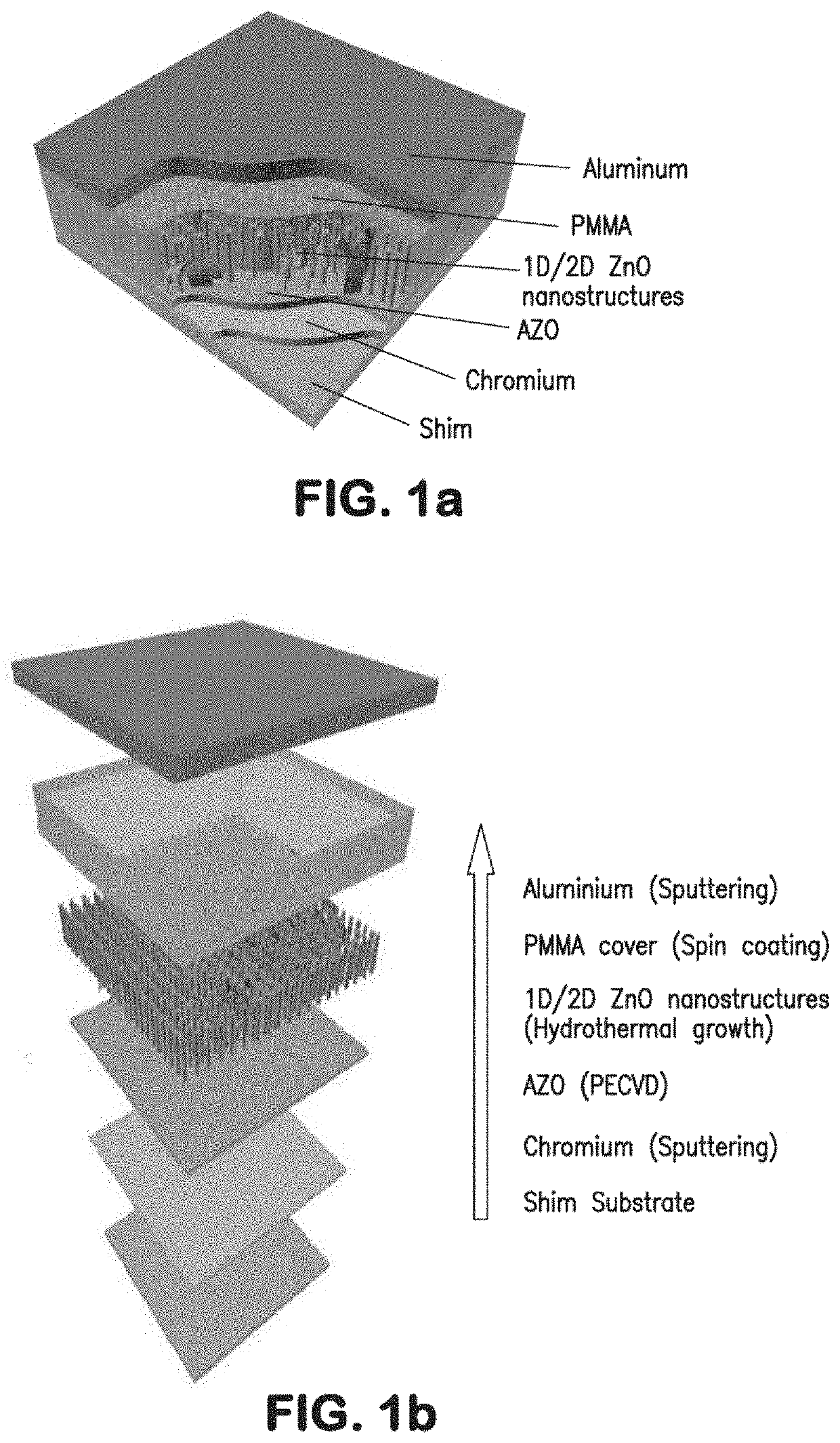

1d/2d hybrid piezoelectric nanogenerator and method for making same

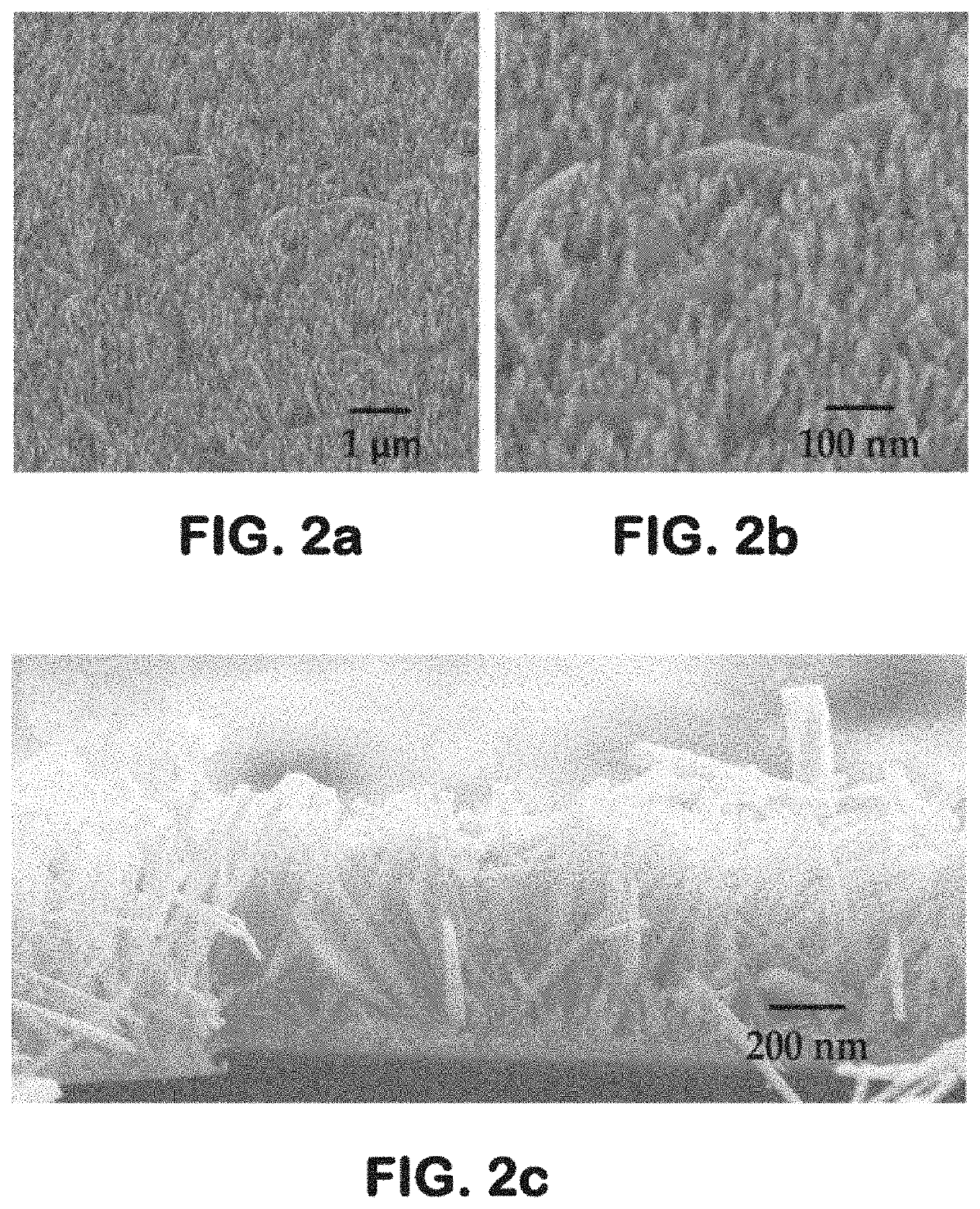

PendingUS20200204089A1Improve electrical output performanceImprove mechanical performanceMaterial nanotechnologyPiezoelectric/electrostrictive device manufacture/assemblyNanogeneratorNano structuring

The present invention relates to a piezoelectric nanogenerator (PENG) that is capable of harvesting mechanical energy into electricity. The PENG comprises one dimensional (1D) and two dimensional (2D) nanostructures integrated together to form a composite nanostructure. A major advantage of the present invention is that the composite nanostructure provides enhanced electrical output and enhanced mechanical stability as compared to previously reported 1D or 2D nanostructures alone. Also described is a hybrid nanogenerator that combines the PENG with a triboelectric nanogenerator (TENG). A method of synthesizing the composite nanostructure PENG, in which the 1D and 2D nanostructures are grown together on the same substrate using a low temperature hydrothermal method is also described. The provided method is simple and cost-effective.

Owner:SHIMCO NORTH AMERICA INC

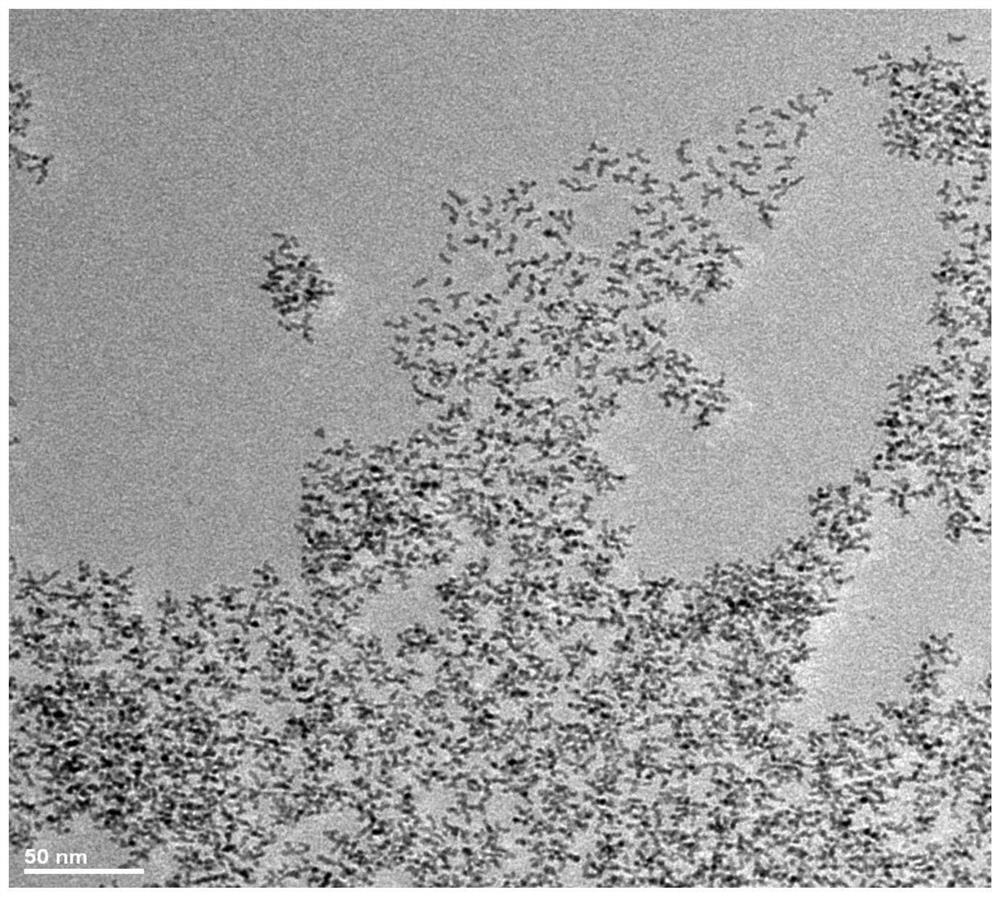

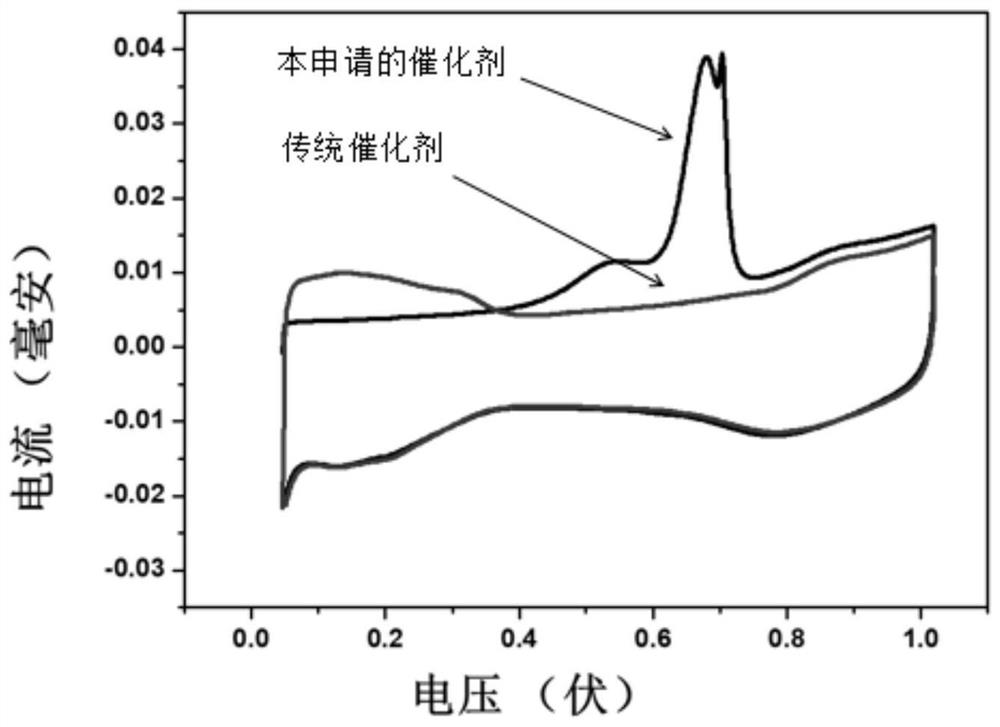

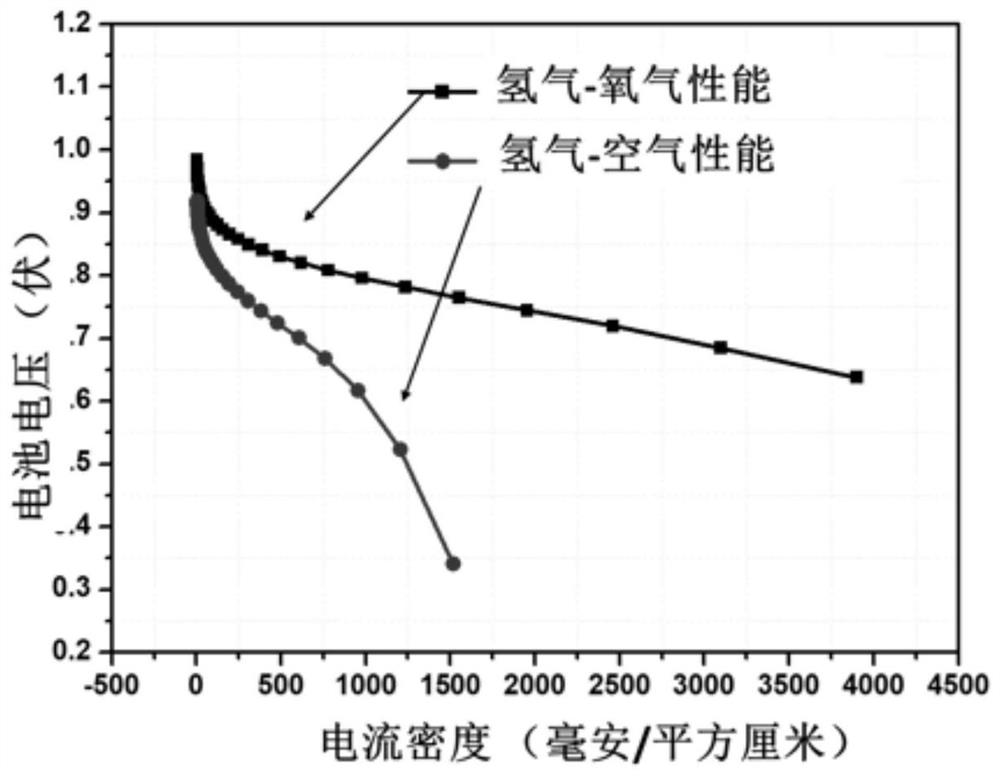

Alloy nano-catalyst, preparation method thereof and fuel cell

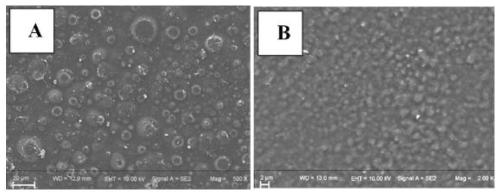

InactiveCN111816888AGood chemical stabilityImprove conductivityCell electrodesNano catalystPtru catalyst

The invention relates to the technical field of catalysts, and provides an alloy nano-catalyst which comprises a carbon-based supporter and alloy nano-particles adsorbed on the surface of the carbon-based supporter, and the alloy nano-particles are wormlike. According to the alloy nano-catalyst provided by the invention, the alloy nano-catalyst takes a carbon base as a supporter, and the carbon base supporter is smooth in surface, few in gaps and relatively high in chemical stability; wormlike alloy nanoparticles are adsorbed on the surface of the carbon base supporter, the wormlike alloy nanoparticles have higher specific activity, and the structure exposes more alloy nanoparticle sites, so that the alloy nano-catalyst has good conductivity, higher chemical stability and high electrochemical stability; wormlike alloy nano-particles can be anchored on the surface of the carbon base supporter more stably, the stability is higher, and the alloy nano-catalyst can be applied more widely.

Owner:SHENZHEN ACAD OF AEROSPACE TECH

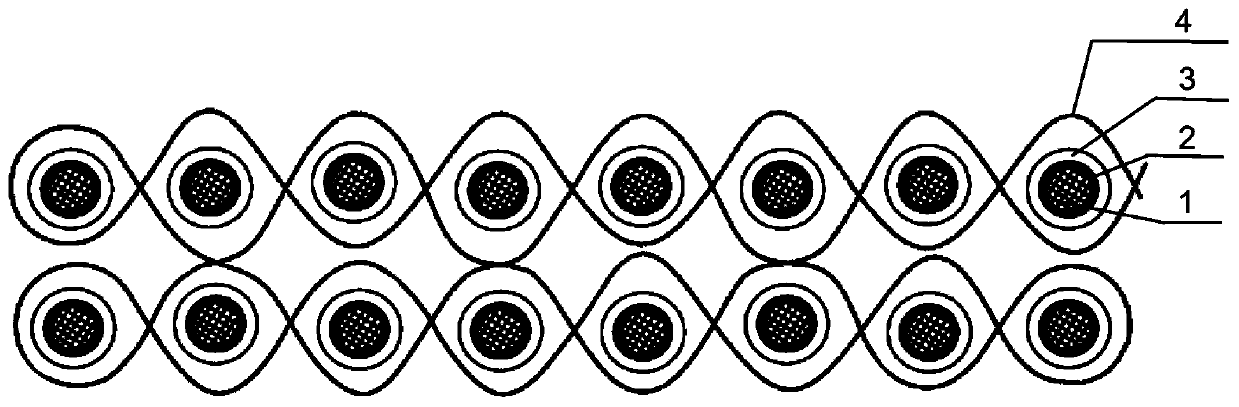

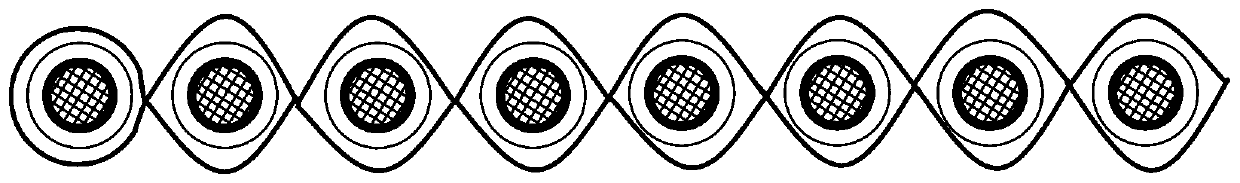

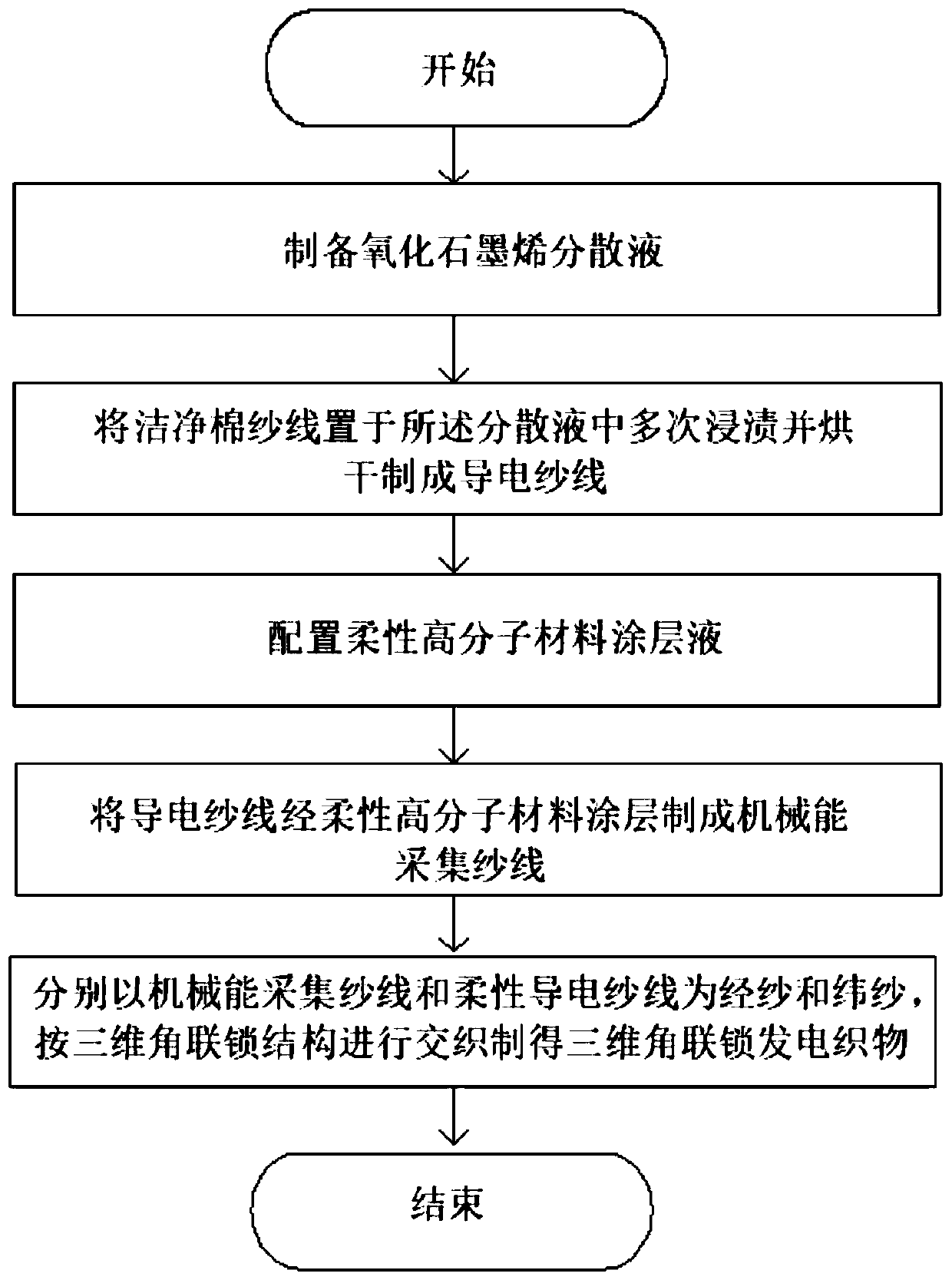

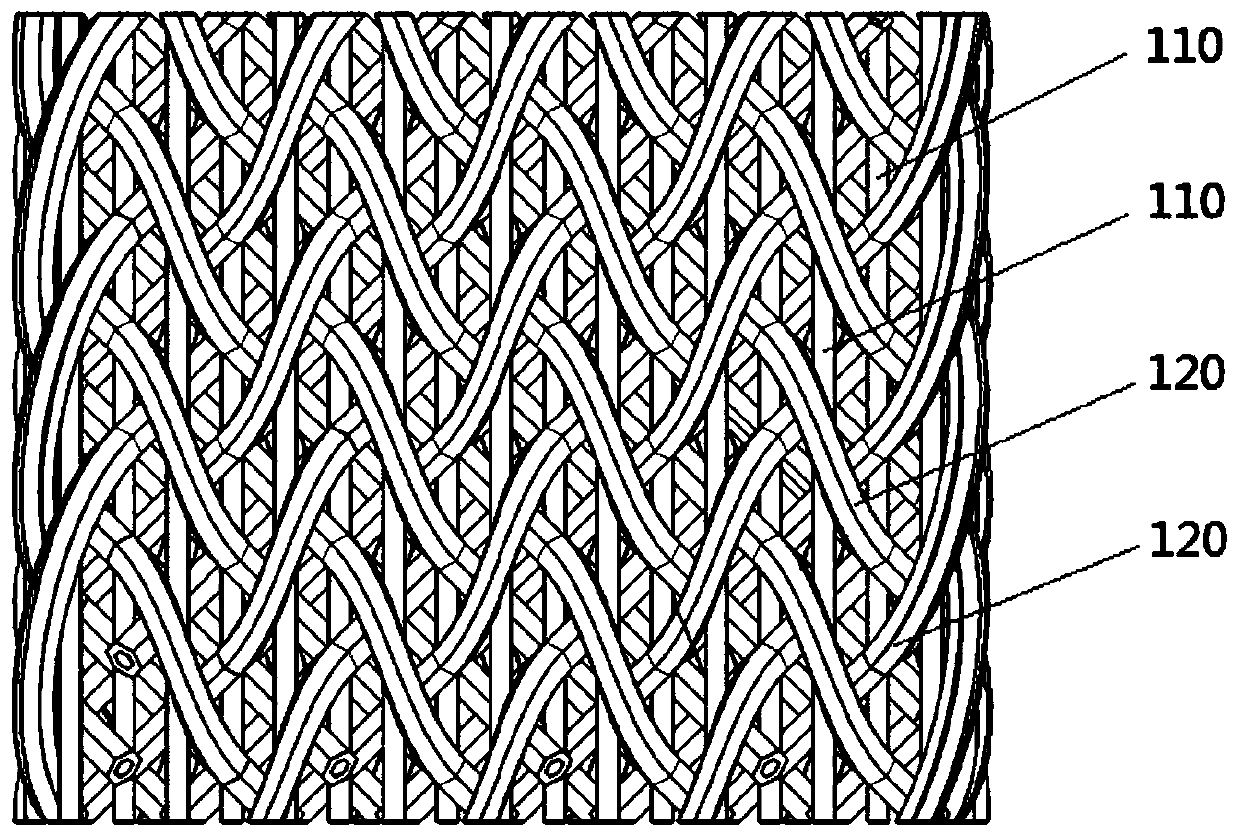

Three-dimensional angle interlocking power generation fabric and preparation method thereof

The invention relates to three-dimensional angle interlocking power generation fabric and a preparation method thereof. The three-dimensional angle interlocking power generation fabric is three-dimensional angle interlocking fabric formed by two yarn systems which are a warp system and a weft system, and composition yarn of the warp system and the weft system is different and is mechanical energyacquisition yarn or flexible conductive yarn; the largest power density of the three-dimensional angle interlocking power generation fabric is 48.45 mW / m<2>, the number of layers of the three-dimensional angle interlocking fabric is 2-10, the warp density is 14-18 count / 5 cm, the weft density is 12-20 count / 5 cm, and the gram weight us 0.6-1 g / cm<2>. The preparation method of the three-dimensionalangle interlocking fabric comprises steps as follows: the mechanical energy acquisition yarn and the flexible conductive yarn are taken as warp and weft and interwoven in a form of a three-dimensional angle interlocking structure, and the three-dimensional angle interlocking power generation fabric is prepared. The three-dimensional angle interlocking power generation fabric has a multi-layer structure, is easy to deform and has good power output performance, and the contact area between the warp and the weft is larger.

Owner:DONGHUA UNIV

Preparation method of sisal fiber paper-based friction nano-generator

ActiveCN112593436ALow costThe preparation method is simple and easyWashing/displacing pulp-treating liquorsPulp bleachingCellulosePolymer science

The invention discloses a preparation method of a sisal fiber paper-based friction nano-generator. The preparation method comprises the following steps: cleaning, drying and shearing sisal fiber raw materials, putting the sisal fiber raw materials into a high-temperature reaction kettle, and adding a NaOH solution for hydrothermal treatment; and carrying out suction filtration and cleaning on thesolid substance obtained by hydrothermal treatment for many times by using deionized water, and bleaching, drying and crushing the solid substance to obtain the dried sisal cellulose; dispersing 1-3gof sisal cellulose into 200-300mL of deionized water, carrying out suction filtration to form a film, carrying out rolling treatment on the sisal cellulose film by using a hydraulic machine, and drying to obtain the sisal cellulose paper; then using the sisal hemp cellulose paper and the polytetrafluoroethylene film as polar plates to assemble the sisal hemp cellulose paper-based friction nano-generator. The method is simple and easy to operate and low in material preparation cost; the sisal fiber is enabled to become friction material of friction nano-generator, electrical performance tests show that the sisal fibers have relatively good output performance and stability, and a new way is provided for resource utilization of the sisal hemp.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

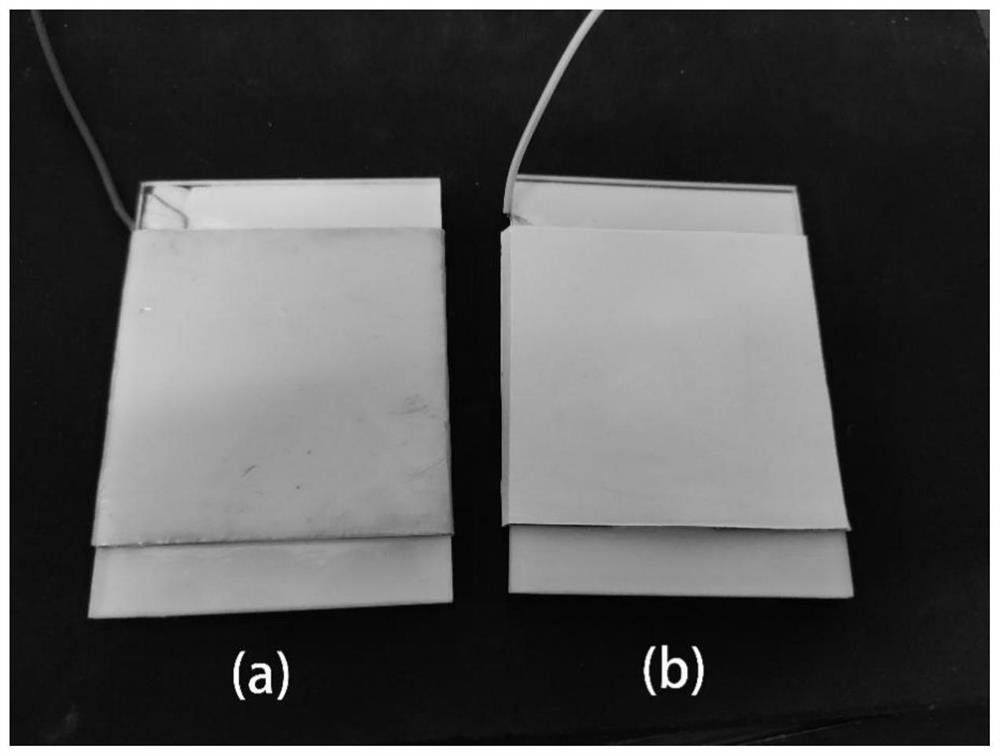

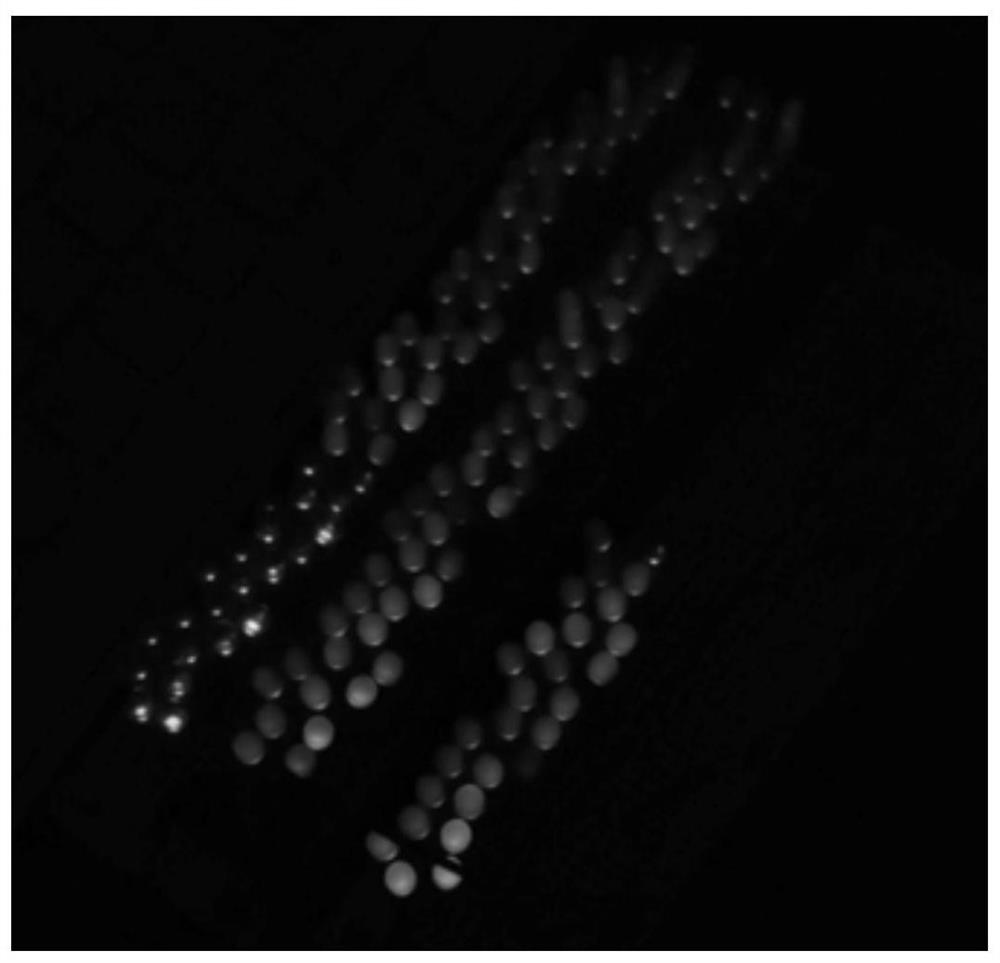

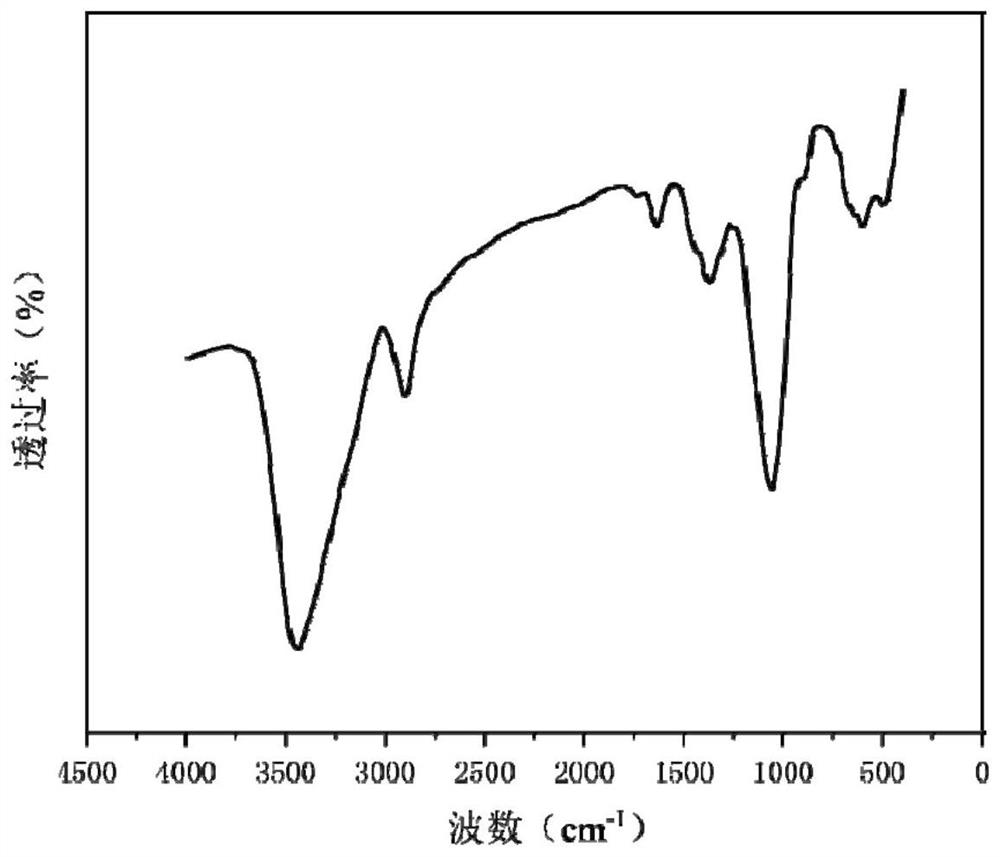

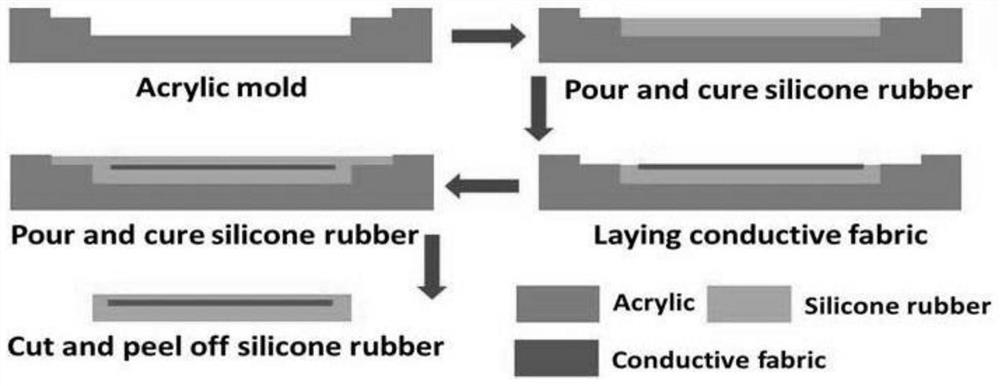

Flexible single-electrode friction nano generator

The invention relates to a flexible single-electrode friction nano generator which comprises a three-layer structure, wherein the upper layer is a thin silica gel sheet used as a friction layer, the lower layer is a thick silica gel sheet used as a supporting layer, and flexible conductive cloth is arranged between the friction layer and the supporting layer. The flexible single-electrode friction nano generator S-TENG which is simple and easy to popularize is prepared by taking liquid silica gel, flexible conductive cloth, copper foils and copper wires as raw materials, and the prepared S-TENG has good flexibility, stability and a low-frequency mechanical energy collection function. Collected low-frequency mechanical energy can be effectively converted into electric energy, 240 LED lamp beads can be lightened, and an electronic watch and a small calculator can be driven. The nano generator has the advantages of being simple, low in cost, high in electrical output performance, good in stability and easy to produce on a large scale, and the prepared S-TENG sample has important potential application value in the fields of novel electronic devices and biomedicine.

Owner:LUOYANG INST OF SCI & TECH

Holocellulose-based friction nano-generator

ActiveCN111355400AEasy to chargeIncrease short circuit currentAerogel preparationVegetal fibresCelluloseChemical physics

The invention discloses a holocellulose-based friction nano-generator. According to the holocellulose-based friction nano-generator, a cellulose nano-fibril-based aerogel film modified by positive ions is used as a friction electronegative material, and the cellulose nano-fibril-based aerogel film is used as a friction electropositive material; cellulose conductive composite electrode materials are arranged on the back faces of the cellulose nano-fibril-based aerogel films modified by the cations and the back faces of the cellulose nano-fibril-based aerogel films, and a gap is formed between the two aerogel films. The surface charge quantity of the holocellulose-based friction nano-generator is increased by 10-500%, the short-circuit current is increased by 20-500%, and the open-circuit voltage is increased by 50-500%. The holocellulose-based friction nano-generator is short in technological process, simple in equipment and low in cost, the electric output performance is remarkably improved, and the holocellulose-based friction nano-generator has wide application prospects in the field of flexible wearable sensing devices.

Owner:GUANGXI UNIV

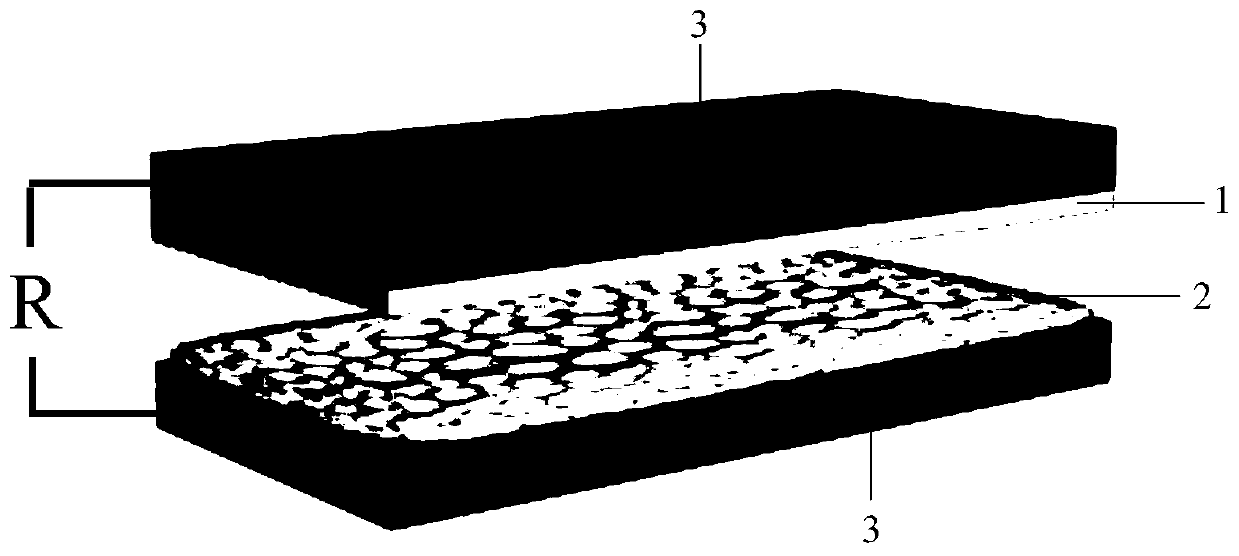

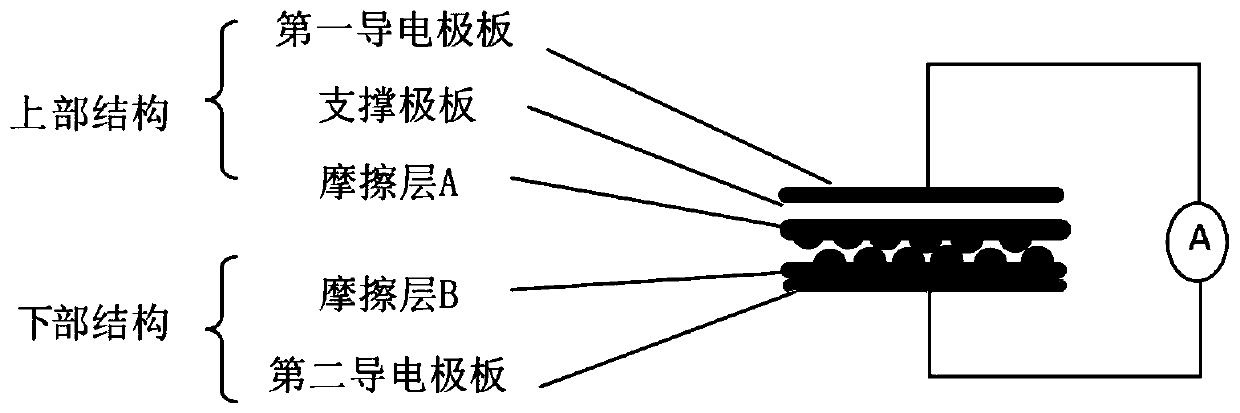

Friction nano-generator friction layer material as well as preparation method and application thereof

ActiveCN111327223AHigh gain/loss electron performanceImprove electrical output performanceFriction generatorsPlasma treatmentPlasma processing

The invention discloses a friction nano-generator friction layer material as well as a preparation method and application thereof. The preparation method comprises the steps of carrying out laser etching on a friction layer A and a friction layer B so as to enable the roughness of the bottom surface of the friction layer A to reach 30-90% and enable the roughness of the top surface of the frictionlayer B to reach 30-90%; and carrying out plasma treatment respectively on the bottom surface of the friction layer A and the top surface of the friction layer B, wherein the plasma treatment time is1-120min, the plasma treatment voltage is 5-15KV, and the plasma treatment current is 0.5-0.6A. The invention provides a preparation method of the friction nano-generator friction layer material. Thepreparation method is low in cost and simple to operate. According to the preparation method, the selection range of an easily-obtained electronic polymer material and a volatile electronic polymer material is wide, the electron obtaining / losing performance of the obtained friction nano-generator friction layer material is high, then the electric output performance of the friction nano-generatoris improved by 50%-500%, and the application field is expanded.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

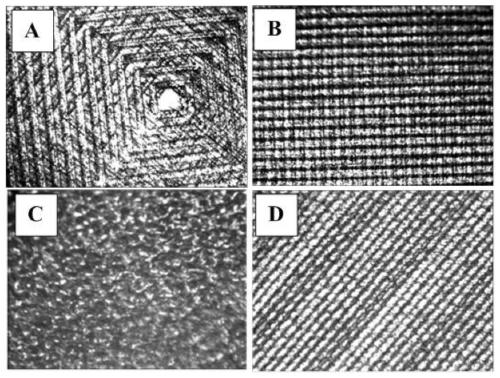

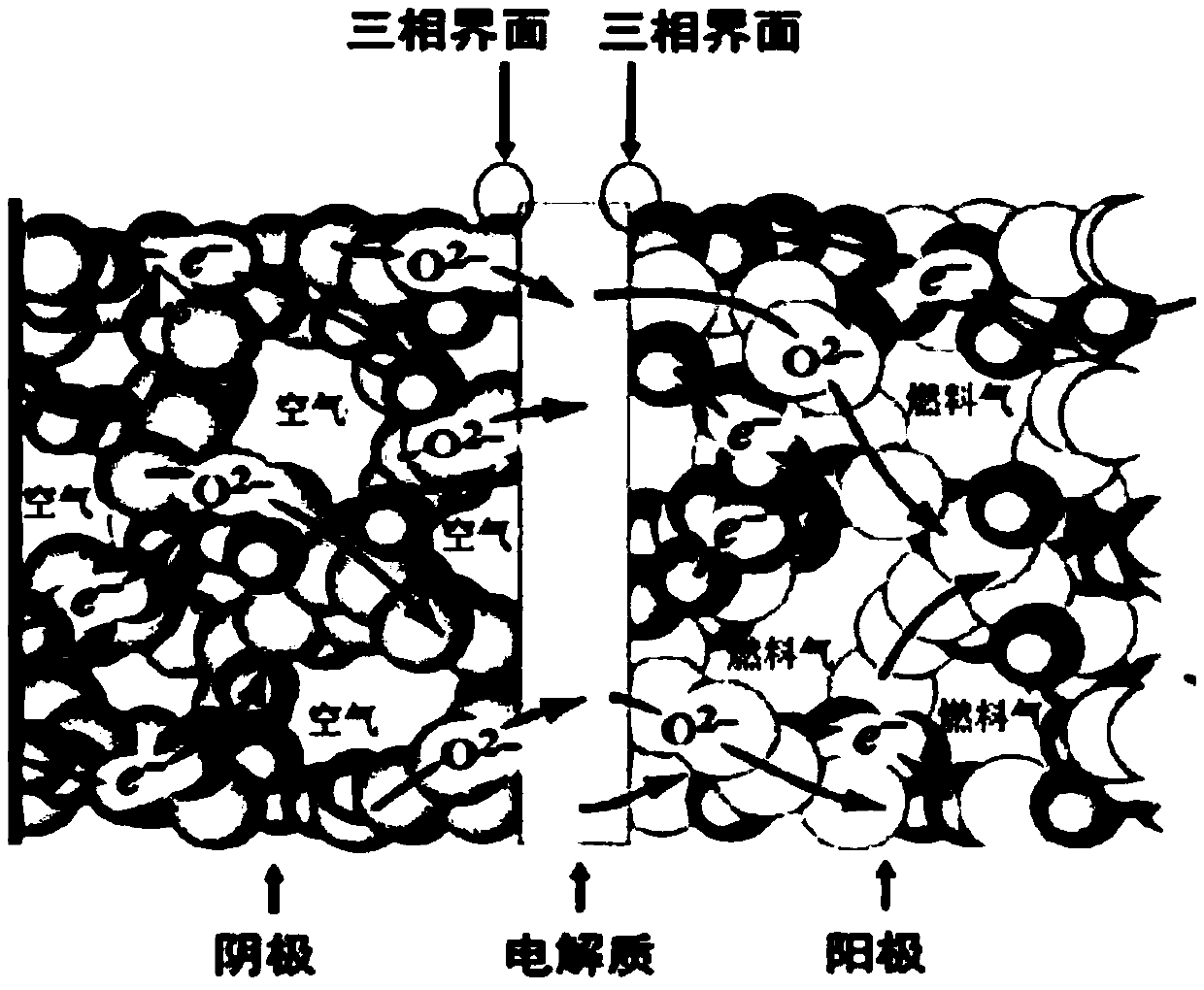

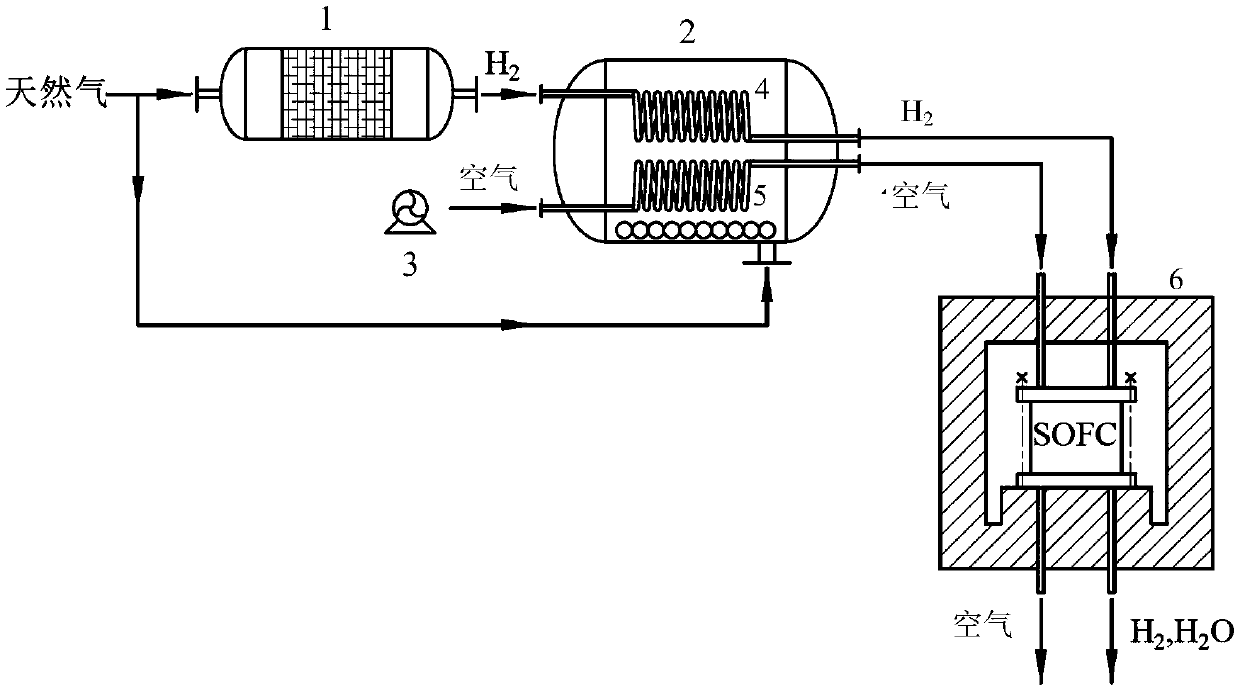

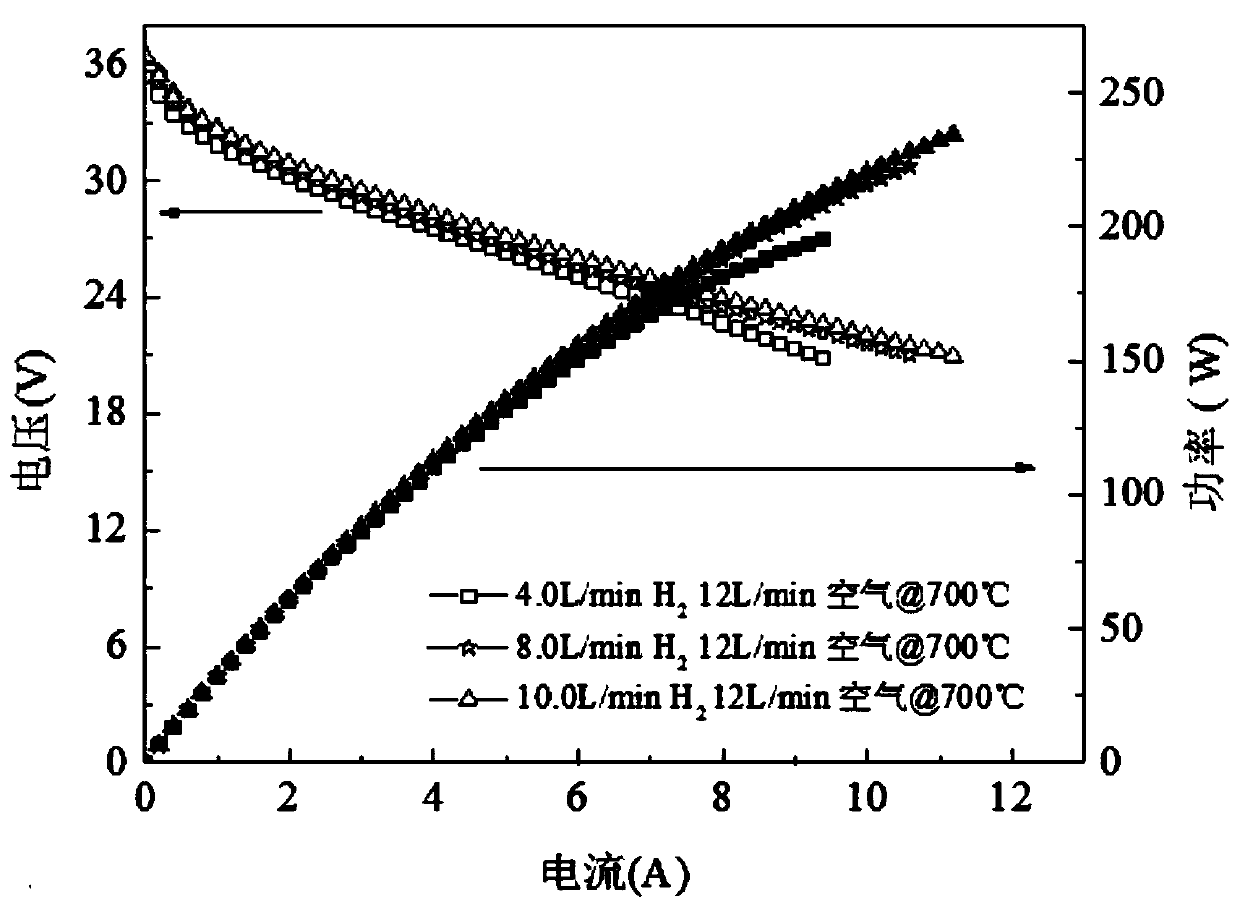

Heating starting method and heating device of solid oxide fuel cell stack

InactiveCN110911708ASolve the problem of uneven heatingIncrease temperatureFuel cell heat exchangeFuel cellsEngineering

The invention provides a heating starting method and a heating device of a solid oxide fuel cell stack. According to the method, fuel gas and air are preheated and then introduced into the galvanic pile to achieve the purpose of heating the galvanic pile; the problem that the inside and the outside of the electric pile are heated unevenly when the electric pile is heated by an electric heating furnace is solved, and preheated fuel gas and air are directly introduced into a three-phase boundary reaction area in the electric pile, so that the heating efficiency is high, the heating is balanced,and the electric pile has good, stable and adjustable electric output performance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

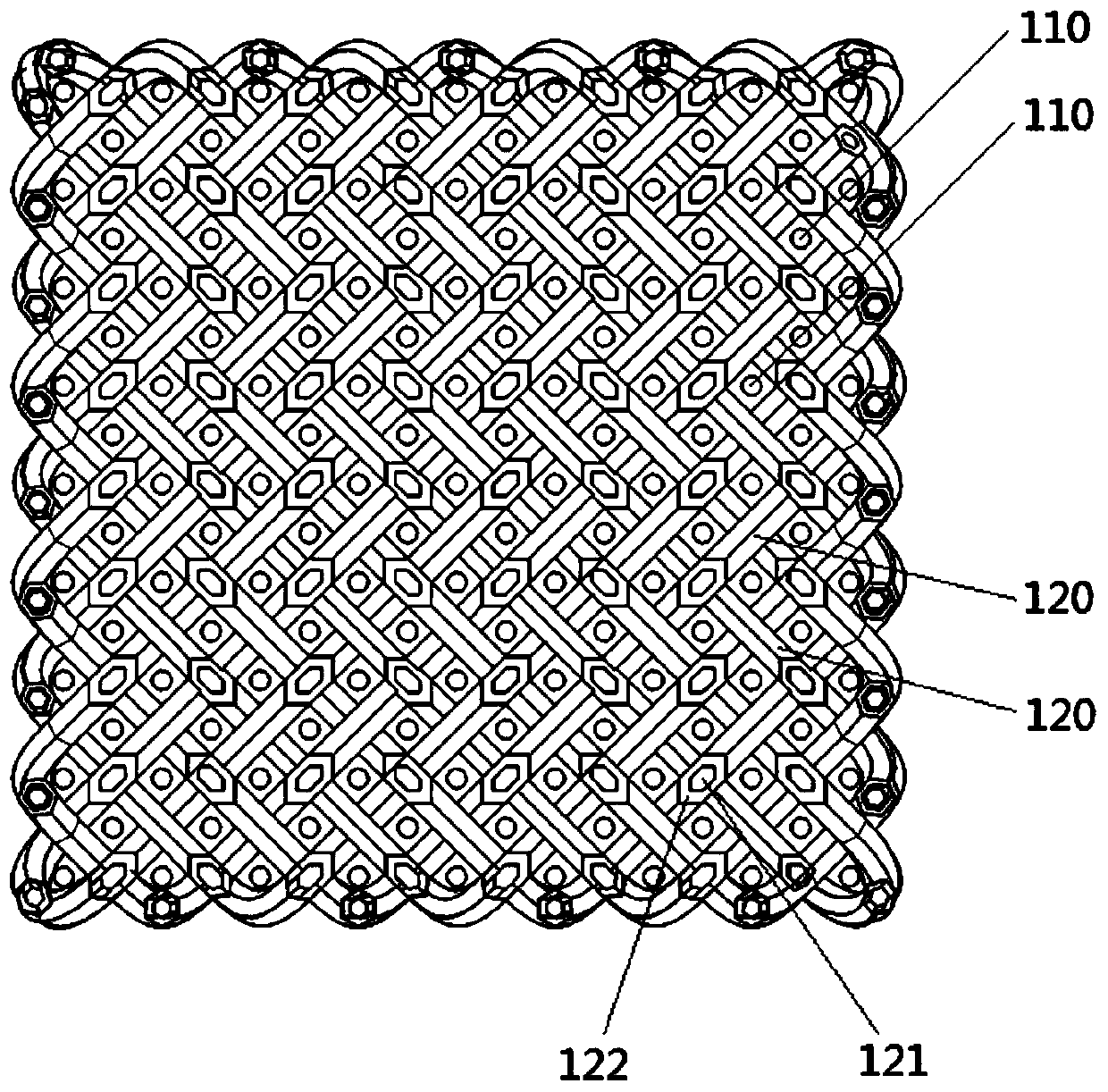

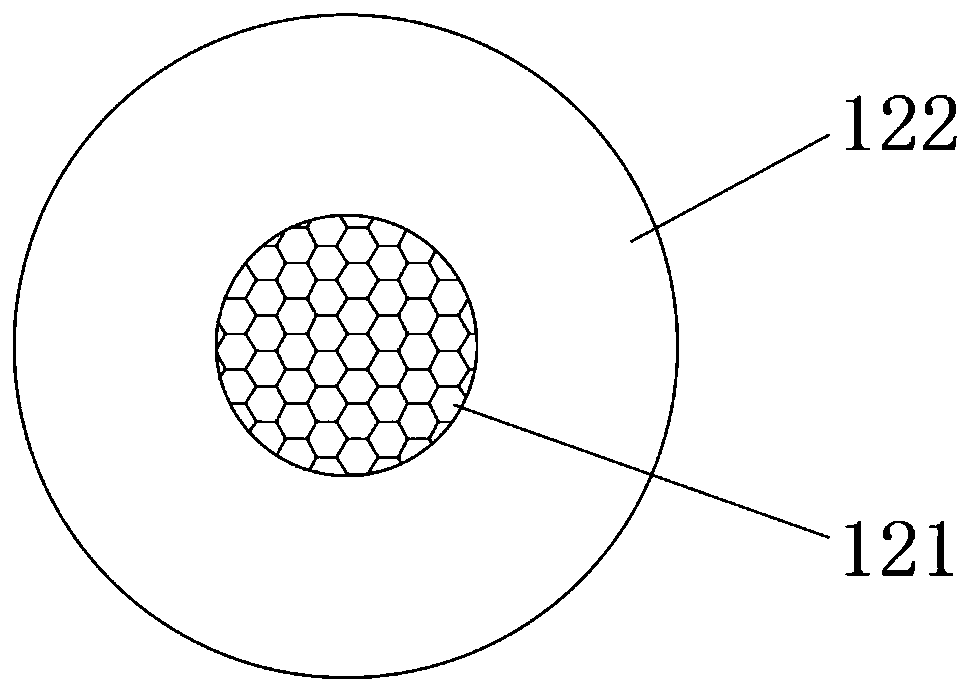

Power generation knitted piece, intelligent sole and intelligent carpet

ActiveCN110965200AImprove energy conversion efficiencyImprove electrical output performanceSolesCarpetsYarnEngineering

The invention discloses a power generation knitted piece, an intelligent sole and an intelligent carpet. The power generation knitted piece comprises a plurality of conductive shaft yarns arranged ina first direction, and a plurality of knitted yarns interspersed between the plurality of conductive shaft yarns and extending in the axial direction of the conductive shaft yarns, wherein the plurality of knitted yarns and the plurality of conductive shaft yarns form a planar or three-dimensional structure together, wherein the knitted yarns comprise a conductive beam and a dielectric layer covering the conductive beam; the conductive shaft yarns and the knitted yarns deform under an external force, the conductive shaft yarns make contact with the dielectric layers of the plurality of knittedyarns around the conductive shaft yarns, and during the contact and separation processes, an electrical output is generated between the conductive shaft yarns and the conductive beams of the plurality of knitted yarns. According to the power generation knitted piece, the energy conversion efficiency and the electrical output performance of the power generation knitted piece are improved, and meanwhile, the pressure sensing sensitivity is improved, and the application range of friction nanometer power generation fabric is expanded.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

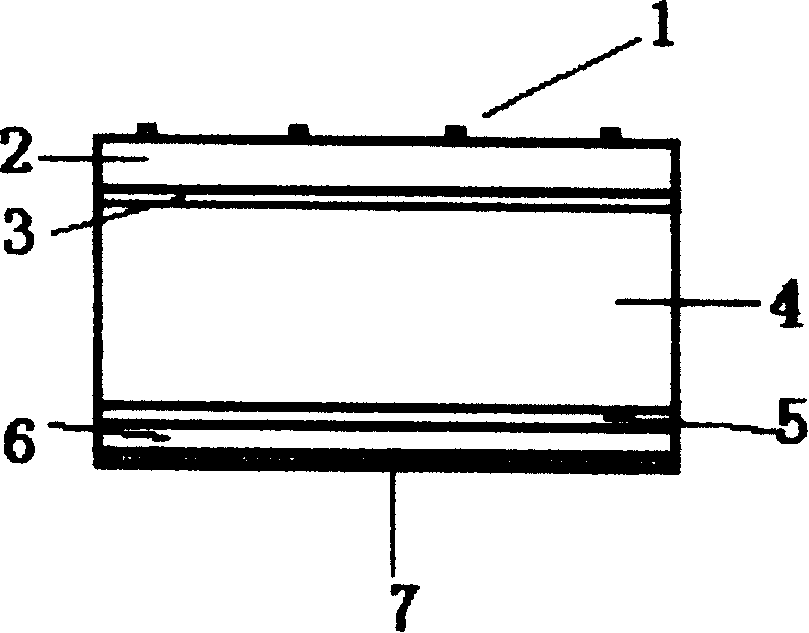

Samarium isotope minisize cell and manufacturing method thereof

The invention discloses a samarium isotope minisize cell and a manufacturing method thereof. The cell is formed by a transduction unit and an appurtenance. The transduction unit comprises: samarium-151 radioactive source sheet, a Si3N4 layer and a silicon-based PN junction. The appurtenance comprises: an outer encapsulation layer, a ring electrode, a positive lead, a positive electrode, a gold layer, a pedestal, a negative electrode, a negative lead, a ceramic chip and an inner encapsulation layer. The Si3N4 layer is located on an upper surface of the silicon-based PN junction. The ring electrode is on an epitaxy of the Si3N4 layer. The samarium-151 radioactive source sheet is fixed on the upper surface of the Si3N4 layer by using the inner encapsulation layer. A lower surface of the silicon-based PN junction is the gold layer. One end of the negative lead is connected with the gold layer and the other end is connected with the negative electrode. One end of the positive lead is connected with the ring electrode and the other end is connected with the positive electrode. The ceramic chip is located below the gold layer. The ceramic chip is located on the very center of the pedestal. The outer encapsulation layer covers the outside of the pedestal. The samarium isotope minisize cell of the invention has a small size and can work without energy provided from the outside. The cell can continuously output a 100nA-muA current and 0.1muA-1muA for more than 45 years. The manufacturing method of the invention is safe and reliable.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Samarium isotope minisize cell and manufacturing method thereof

InactiveCN102496399BOutput uninterruptedImprove electrical output performanceRadiation electrical energyGold layerIsotope

The invention discloses a samarium isotope minisize cell and a manufacturing method thereof. The cell is formed by a transduction unit and an appurtenance. The transduction unit comprises: samarium-151 radioactive source sheet, a Si3N4 layer and a silicon-based PN junction. The appurtenance comprises: an outer encapsulation layer, a ring electrode, a positive lead, a positive electrode, a gold layer, a pedestal, a negative electrode, a negative lead, a ceramic chip and an inner encapsulation layer. The Si3N4 layer is located on an upper surface of the silicon-based PN junction. The ring electrode is on an epitaxy of the Si3N4 layer. The samarium-151 radioactive source sheet is fixed on the upper surface of the Si3N4 layer by using the inner encapsulation layer. A lower surface of the silicon-based PN junction is the gold layer. One end of the negative lead is connected with the gold layer and the other end is connected with the negative electrode. One end of the positive lead is connected with the ring electrode and the other end is connected with the positive electrode. The ceramic chip is located below the gold layer. The ceramic chip is located on the very center of the pedestal. The outer encapsulation layer covers the outside of the pedestal. The samarium isotope minisize cell of the invention has a small size and can work without energy provided from the outside. The cell can continuously output a 100nA-muA current and 0.1muA-1muA for more than 45 years. The manufacturing method of the invention is safe and reliable.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

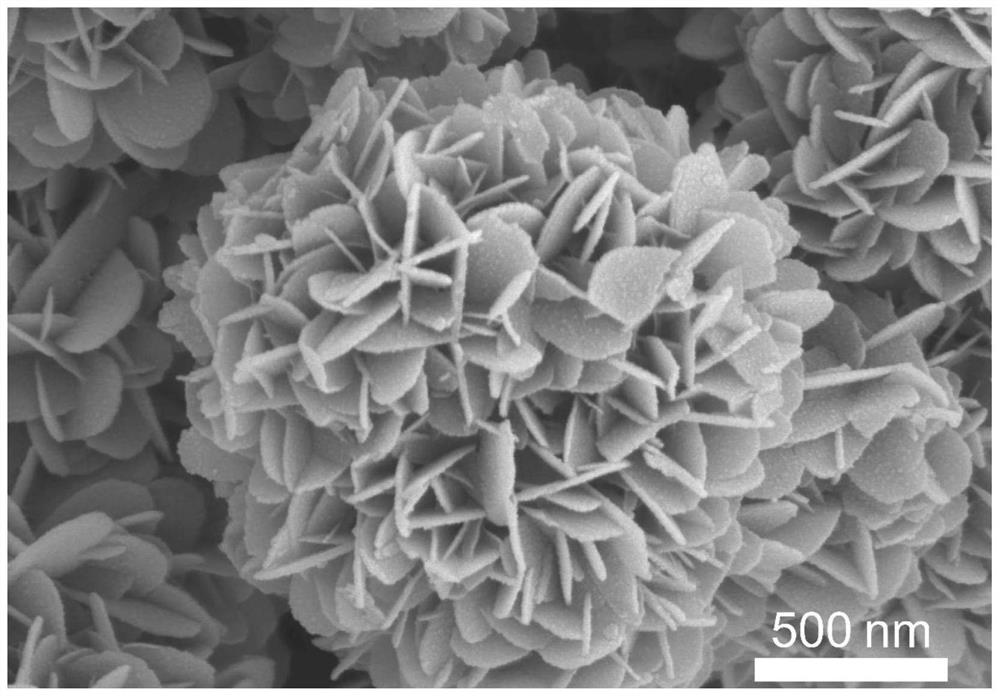

Preparation method and application of titanium dioxide/carbon nanoflower composite PDMS film

ActiveCN113258819ASimple preparation processHigh repeatabilityCoatingsFriction generatorsThin membraneCapacitance

The invention relates to an energy conversion material and device technology, and aims to provide a preparation method and application of a titanium dioxide / carbon nanoflower composite PDMS film. The preparation method comprises the following steps of: mixing cyclohexane and polydimethylsiloxane, and stirring until the mixture is clear; dispersing a titanium dioxide / carbon nanoflower filling material in the solution to obtain a uniform suspension; and adding a curing agent and stirring, coating an acrylic plate with an aluminum electrode with the suspension in a spin coating manner, and drying and forming to obtain a film-shaped composite material. The method is simple in preparation process, high in repeatability and suitable for mass production. The interface polarization effect can be remarkably improved, and a large amount of local micro-capacitance is constructed in the composite material by an in-situ introduced conductive carbon simple substance, so that the dielectric property is synergistically improved, the surface charge density is improved, and the output performance of a friction nano-generator is further improved. The output performance of the friction nano- generator device can be regulated and controlled by adjusting the content of the titanium dioxide / carbon nanoflowers; and low-frequency mechanical energy can be converted into electric energy.

Owner:ZHEJIANG UNIV

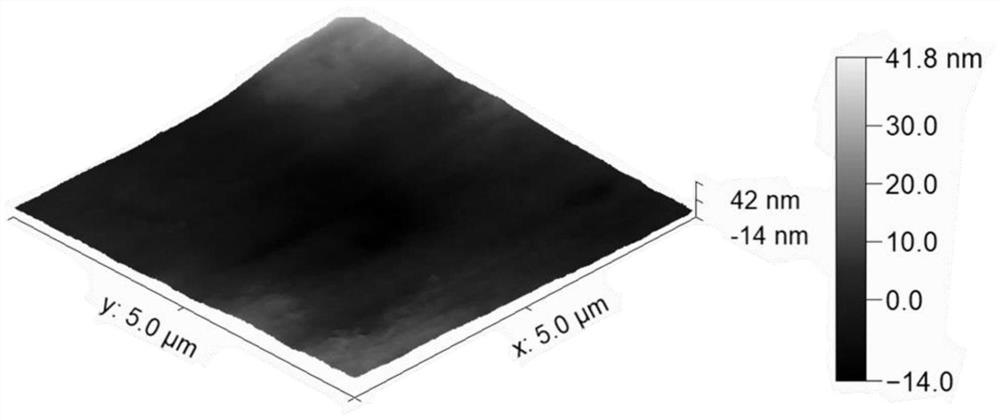

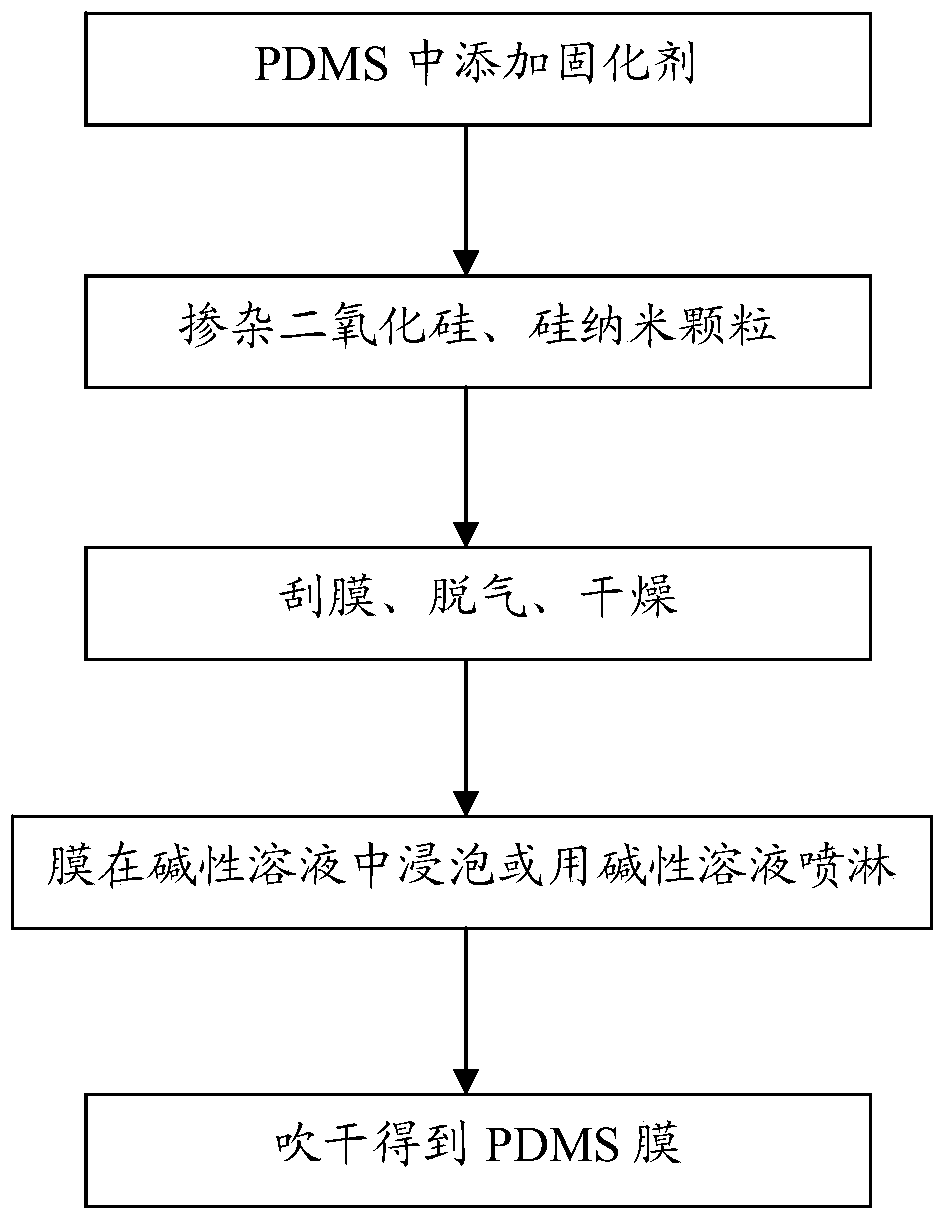

Preparation method of polydimethylsiloxane film, polydimethylsiloxane film prepared by the method and application thereof

ActiveCN106903831BAchieve modificationIncreased structure concentrationFlat articlesCoatingsMicro nanoElectronegativity

The invention provides a method for preparing a polydimethylsiloxane film, comprising: adding a curing agent to the polydimethylsiloxane, stirring evenly to obtain a mixture; doping the mixture with negatively charged micro-nano particles on the surface Polydimethylsiloxane slurry is obtained; the polydimethylsiloxane slurry is coated on the template, and the film is degassed, and then the film is dried; the film is immersed in an alkaline solution or an alkaline The solution is sprayed on it, followed by washing and drying to obtain a polydimethylsiloxane film. The invention also provides the polydimethylsiloxane film prepared by the method and a triboelectric generator using the film. The method of the invention realizes the modification of the polydimethylsiloxane, improves the negative charge of the film, and thus improves the electrical output performance of the triboelectric generator using the polydimethylsiloxane film.

Owner:NAZHIYUAN TECH TANGSHAN LLC

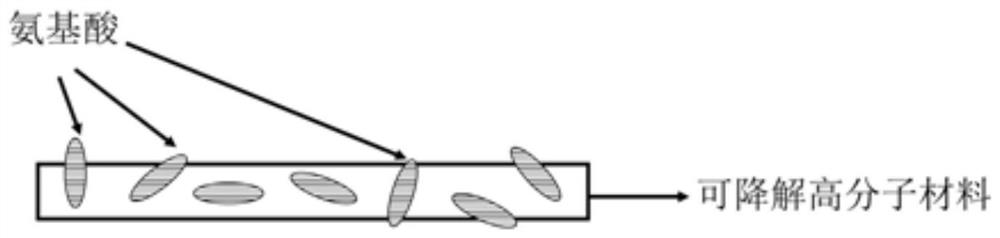

Full-degradable friction nano-generator and preparation method and application thereof

PendingCN114257118AImprove electrical output performanceFriction generatorsPhysicsAmino acid composition

The invention relates to an all-degradable friction nano-generator and a preparation method and application thereof. The all-degradable friction nano-generator comprises a first friction layer and a second friction layer, the first friction layer comprises a first amino acid composite material layer and a first metal current collector layer which are sequentially overlapped; and the second friction layer comprises a second amino acid composite material layer and a second metal current collector layer which are sequentially overlapped. Amino acid crystal compounds with different functional group structures are introduced to the surface of the friction layer material in a manner of adding amino acids with wide sources into the friction layer material to form a composite material, so that the electron gain and loss capacities between the friction layers are greatly differentiated; the purpose of effectively improving the electric output performance of the friction nanometer generator is achieved, and the electric output performance is adjustable.

Owner:SHENZHEN INST OF ADVANCED TECH

Bionic degradable friction nano-generator and preparation method thereof

PendingCN114531055ALow raw material costPromote environmental protectionWind energy generationFriction generatorsCotton clothPolymer chemistry

The invention discloses a bionic degradable friction nano-generator and a preparation method thereof, the friction nano-generator uses woven bamboo fiber cloth as a positive friction material and cotton cloth as a negative friction material, the two friction materials are contacted and separated, and the friction electricity generation effect and electrostatic induction are utilized to generate alternating current to realize power generation. Bamboo fibers are degradable and low in cost, have good flexibility and friction performance, can still keep good performance under the action of certain bending and torsion, and are beneficial for improving the power transmission performance of products. The friction nanometer generator disclosed by the invention is simple in preparation process, and the preparation efficiency is obviously improved.

Owner:JIANGSU UNIV OF SCI & TECH

Manufacturing method of high integration-level flexible film thermoelectric cell

ActiveCN105322088AGood flexibilityHighly integratedThermoelectric device manufacture/treatmentElectricityLithographic artist

The invention relates to a manufacturing method of a high integration-level flexible film thermoelectric cell. The method comprises the following steps of making micro-area lithography mask plates of a cold end conducting layer, an N / P type thermoelectricity monomer, a cold and hot end conducting interlayer insulating layer and a hot end conducting layer whose figures correspond to each other; using the lithography mask plate to make the cold end conducting layer and a cold end conducting layer output port on a micron-order polyimide film; making the N / P type thermoelectricity monomer; making the cold and hot end conducting interlayer insulating layer; making the hot end conducting layer; packaging. In the invention, the micron-order polyimide film is selected to be taken as an insulation matrix of the cell; based on a condition that the cell possesses good flexibility, the micro-area lithography mask plate is used to integrate multilayer materials into one body through a method of combining physical magnetron sputtering and microelectronic lithography. Hundreds to tens of thousands of P-N monomer pairs are integrated on a 0.1cm<2>-10cm<2>, an integration level of the cell is effectively increased and cell power output performance is greatly improved.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

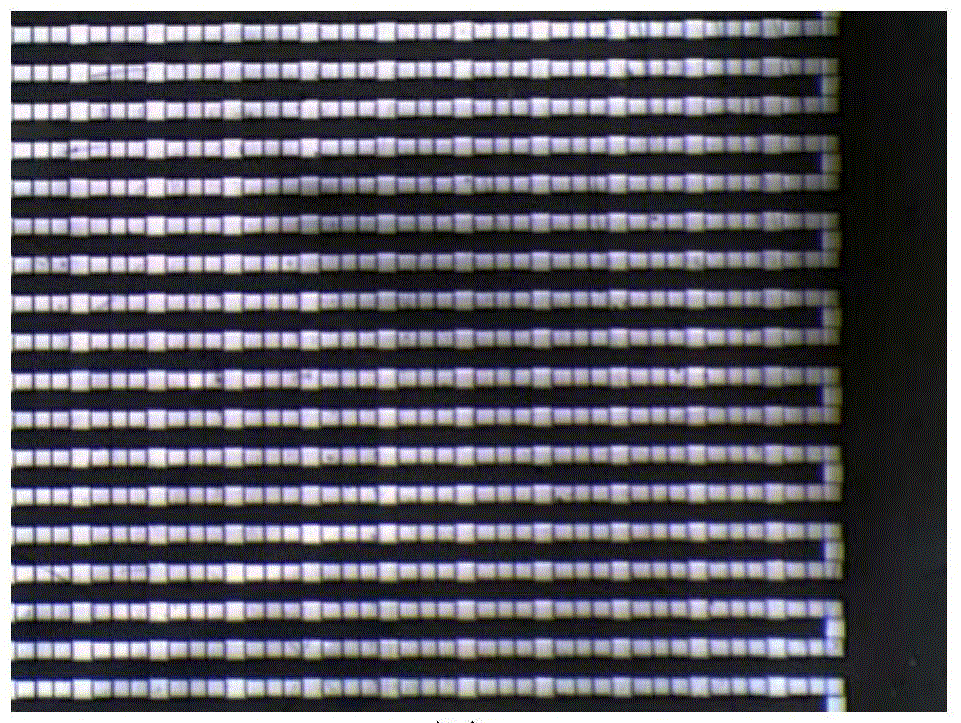

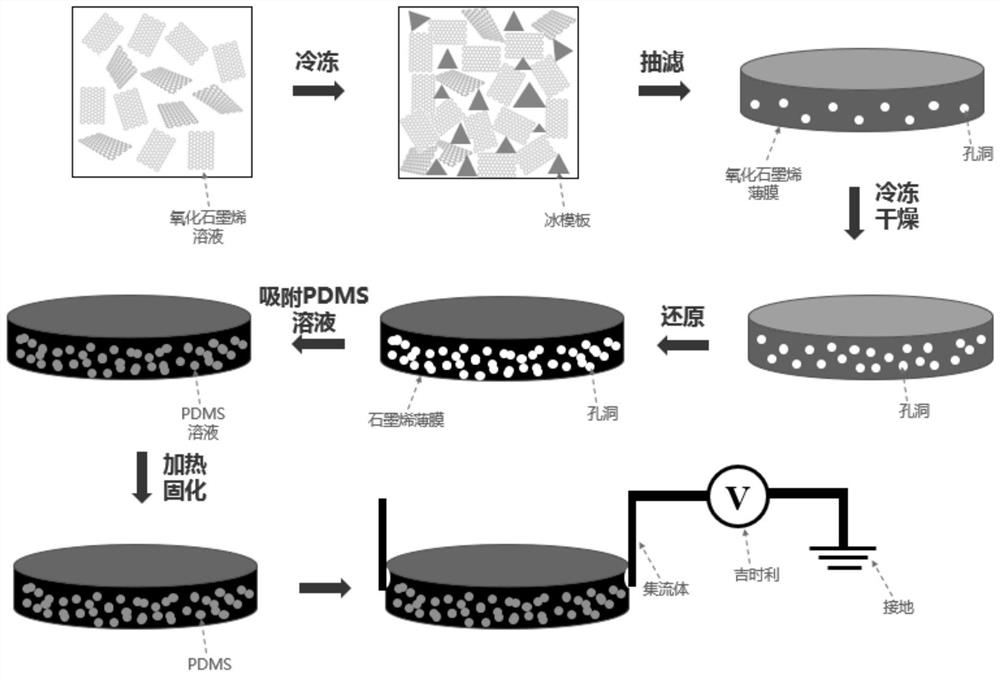

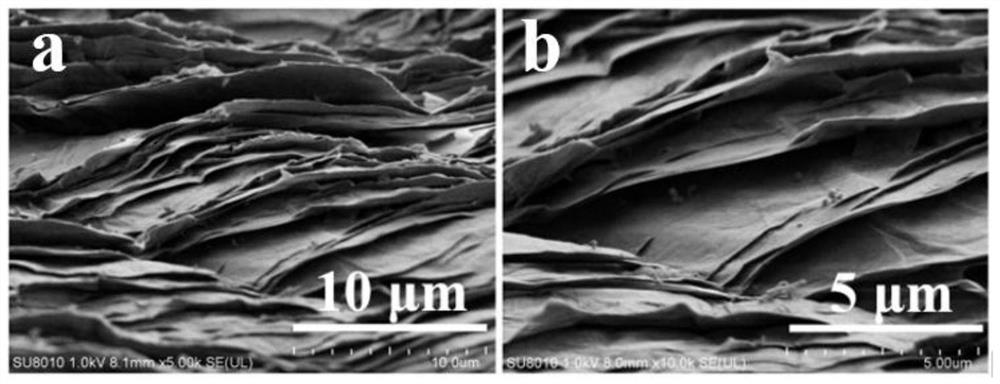

Preparation method of a flexible three-dimensional porous graphene/polydimethylsiloxane composite triboelectric nanogenerator

ActiveCN108455574BImprove electrical output performanceWith roughnessGrapheneFriction generatorsPorous graphenePolymer science

The invention relates to a method for preparing a flexible three-dimensional porous graphene / polydimethylsiloxane composite friction nanogenerator, comprising: preparing a flexible three-dimensional porous graphene film by using an ice template method to assist gravity self-assembly, and using Joule heat The three-dimensional porous graphene / PDMS composite film is prepared by the method of assisted adsorption, and the three-dimensional porous graphene / PDMS composite film is connected with the current collector to prepare the triboelectric nanogenerator. The invention has a simple manufacturing process, uses graphene synthesized by chemical methods on the market, and has low cost; the prepared three-dimensional porous graphene / polydimethylsiloxane composite friction nanogenerator has a simple structure, is soft and light, and can be used in complex and multi-functional It is used in a variable environment, and has excellent mechanical properties and good cycle stability. Due to the good electrical conductivity of the graphene film and the large roughness of the PDMS surface, the generator has excellent electrical properties and working efficiency.

Owner:DONGHUA UNIV

A Dumbbell-shaped Piezoelectric Force-Electric Transducer

ActiveCN112803830BAvoid crackingImprove stabilityPiezoelectric/electrostriction/magnetostriction machinesCantilevered beamEngineering

A dumbbell-shaped piezoelectric force-electric transducer provided by the present invention includes a frame, a piezoelectric material, a screw and a mass block, wherein the piezoelectric material is provided with a plurality of piezoelectric materials along the circumference The directions are evenly distributed in the frame; one end of the screw is connected to the frame, and the other end is connected to the mass block; compared with the traditional cantilever beam force-electric transducer, since the piezoelectric material is in a clamped state, it works in 33 modes , only bears normal stress, so the piezoelectric material is not easy to crack, so the stability of the transducer with this structure is higher. Compared with the traditional 31-mode cantilever beam transducer, its service life will be significantly improved.

Owner:XI AN JIAOTONG UNIV

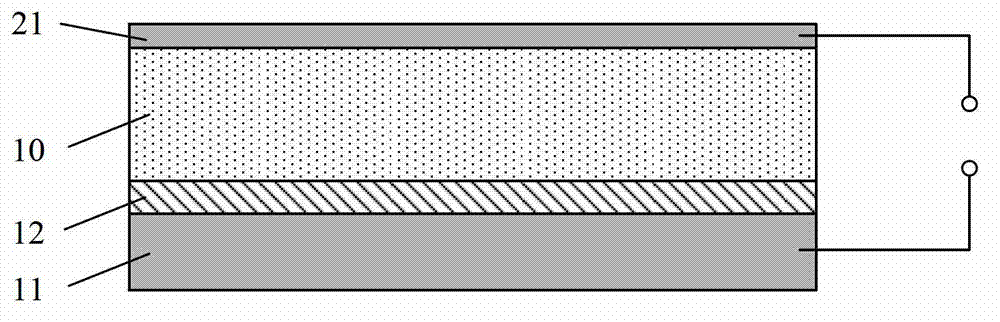

Tin dioxide thin film and silicon heterojunction solar battery

InactiveCN100399584CReduced series resistanceImprove electrical output performancePhotovoltaic energy generationSemiconductor devicesTin dioxideGrating

This invention is tin dioxide membrane and silicon heterojuncion solar battery in the field of semiconductor technology. It concludes: battery counter-light side grating electrode, fluorine-doped tin dioxide layer, silicon dioxide layer, n type silicon base, intrinsic non-crystalline silicon membrane, phosphor- doped non-crystalline silicon membrane and aluminium back electrode. The battery counter-light side grating electrode is on the top of the tin dioxide layer which is mixed into fluorine. A layer of silicon dioxide is interlaid between the tin dioxide layer which is mixed into fluorine and n type silicon base. At the back of n type silicon base deposit the intrinsic non-crystalline silicon membrane, phosphor mixing with non-crystalline silicon membrane and aluminium back electrode in turn. This invention reduces membrane series-wound resistance. The intrinsic non-crystalline silicon membrane, phosphor mixing with non-crystalline silicon membrane and silicon slice form high-low junction and improve battery electricity exporting ability. The efficiency of solar battery can reach 13% under 100mW / cm standard light intensity.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com