Friction nano-generator friction layer material as well as preparation method and application thereof

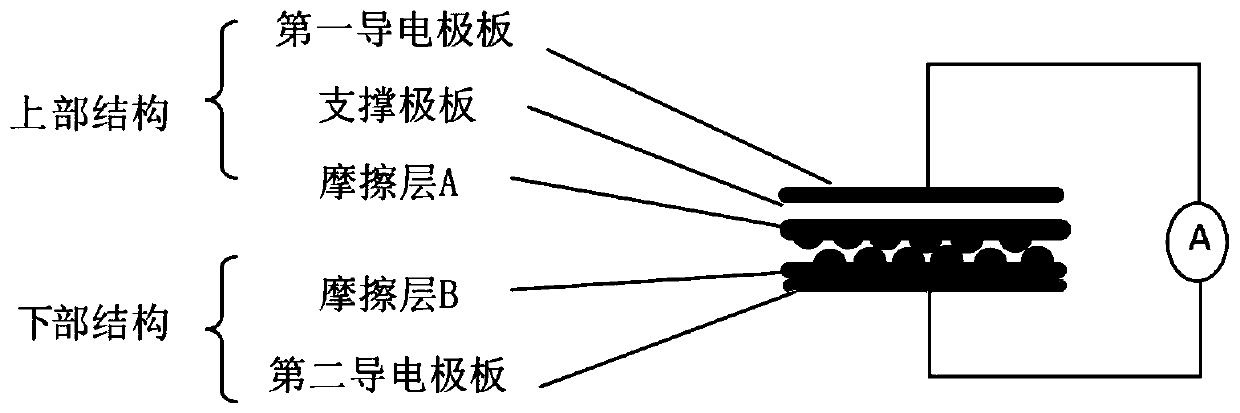

A nanogenerator and friction layer technology, applied in the direction of triboelectric generators, can solve the problems of high cost, complicated operation, and decreased electrical output performance, and achieve the effects of low cost, simple operation and expansion of application fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A method for preparing a friction layer material of a friction nanogenerator, comprising the following steps:

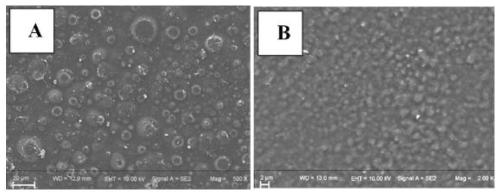

[0059] 1) The friction layer A and the friction layer B are laser etched, so that the roughness of the bottom surface of the friction layer A reaches 75%, and the roughness of the top surface of the friction layer B reaches 90%. The etched pattern is triangular and circular, the angle of the second laser etching is adjusted to 90°, the laser etching power is 5W, the laser etching speed is 500mm / s, and the line width spacing is 0.02mm. The photomicrographs of friction layer B before and after laser etching are shown in figure 2 ,in, figure 2 A is the photomicrograph before etching, figure 2 B is the photo after laser etching, and the pattern structure formed when the bubbles burst on the surface can be observed. This is the first time to increase the surface roughness of the friction layer B, and the roughness can reach about 40%. After two times of laser ...

Embodiment 2

[0065] A method for preparing a friction layer material of a friction nanogenerator, comprising the following steps:

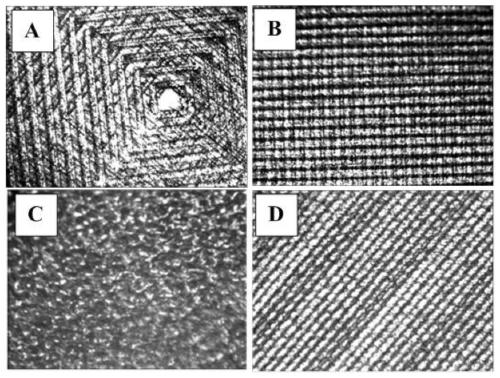

[0066] 1) Laser etching the friction layer A and the friction layer B, so that the roughness of the bottom surface of the friction layer A reaches 70%, and the roughness of the top surface of the friction layer B reaches 70%. The etched pattern is back-shaped, and the second laser etching is performed after the laser scanning angle is rotated by 45°. The laser etching power is 10W, the laser etching speed is 500mm / s, and the line width spacing is 0.05mm. Friction layer B etching micro-pattern structure see image 3 a.

[0067] 2) Put the bottom surface of the friction layer A and the top surface of the friction layer B into the plasma generator respectively for plasma treatment, the time of plasma treatment is 20min, the voltage of plasma treatment is 10KV, and the current of plasma treatment is 0.6A;

[0068] in:

[0069] Friction layer A has a thickness o...

Embodiment 3

[0072] A method for preparing a friction layer material of a friction nanogenerator, comprising the following steps:

[0073] 1) Laser etching the friction layer A and the friction layer B, so that the roughness of the bottom surface of the friction layer A reaches 90%, and the roughness of the top surface of the friction layer B reaches 85%. The pattern to be etched is linear, rotated 90° during the second laser etching, the laser etching power is 15W, the laser etching speed is 1000mm / s, and the line width spacing is 0.01mm. Friction layer B etching micro-pattern structure see image 3 b.

[0074] 2) Put the bottom surface of friction layer A and the top surface of friction layer B into the plasma generator respectively for plasma treatment, the time of plasma treatment is 15min, the voltage of plasma treatment is 10KV, and the current of plasma treatment is 0.5A;

[0075] in:

[0076] The friction layer A has a thickness of 35 μm and a size of 4×4 cm 2 , the method of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com