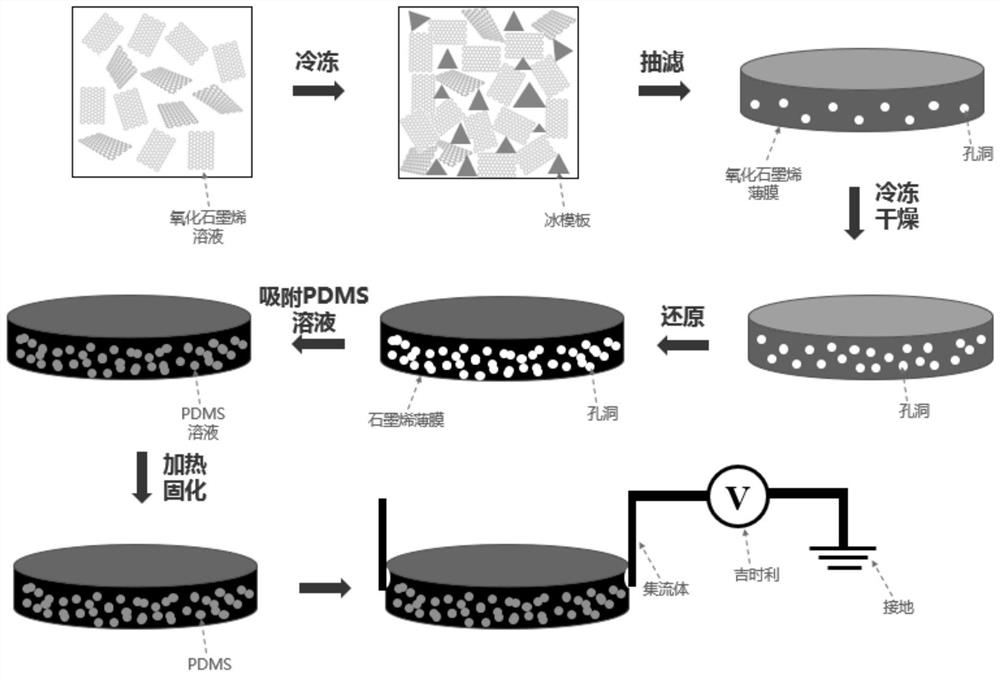

Preparation method of a flexible three-dimensional porous graphene/polydimethylsiloxane composite triboelectric nanogenerator

A technology of dimethylsiloxane and nano-generators, applied in the direction of triboelectric generators, graphene, nano-carbon, etc., which can solve the problem that the three-dimensional porous graphene film flexible tribo-nanometer generators have not been realized, and it is difficult to fully utilize graphene characteristics, complex structure, etc., to achieve excellent electrical performance and work efficiency, good electrical output performance, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) At room temperature, disperse 80 mg of graphite oxide in 40 mL of deionized water to form a dispersion with a concentration of 2 mg / mL, stir mechanically for 3 h, and ultrasonically in a water bath for 6 h to obtain a uniformly dispersed graphene oxide solution.

[0037] (2) Seal the bottom of the sand core funnel with plastic wrap, place the sand core funnel in a foam mold, then pour the graphene oxide solution in step (1) into the sand core funnel, and freeze with liquid nitrogen for 3 minutes to obtain graphite oxide ene "ice cubes"; remove the preservative film at the bottom of the sand core funnel, vacuum filter 24h, put the graphene oxide film together with the filter membrane into a freeze-dryer for freeze-drying 20h, then use 55% hydroiodic acid ( The mass ratio of graphene oxide to hydriodic acid is 1:10) and reduced for 1 h, washed with deionized water and alcohol alternately for 3 times, then put into a freeze dryer and freeze-dried for 12 h to obtain a fl...

Embodiment 2

[0047] (1) At room temperature, disperse 400mg of graphite oxide in 40mL of deionized water to form a dispersion with a concentration of 10mg / mL, mechanically stir for 5h, and ultrasonicate in a water bath for 10h to obtain a uniformly dispersed graphene oxide solution.

[0048] (2) Seal the bottom of the sand core funnel with plastic wrap, place the sand core funnel in a foam mold, then pour the graphene oxide solution in step (1) into the sand core funnel, and freeze with liquid nitrogen for 5 minutes to obtain graphite oxide ene "ice cubes"; remove the preservative film at the bottom of the sand core funnel, vacuum filter for 48h, put the graphene oxide film together with the filter membrane into a freeze-dryer for freeze-drying for 24h, then use 55% hydroiodic acid ( The mass ratio of graphene oxide to hydriodic acid is 1:50) and reduced for 1 h, washed with deionized water and alcohol alternately for 3 times, then put into a freeze dryer and freeze-dried for 12 h to obtain...

Embodiment 3

[0052] (1) At room temperature, disperse 20 mg of graphite oxide in 40 mL of deionized water to form a dispersion with a concentration of 0.5 mg / mL, stir mechanically for 1 h, and ultrasonicate in a water bath for 2 h to obtain a uniformly dispersed graphene oxide solution.

[0053] (2) Seal the bottom of the sand core funnel with plastic wrap, place the sand core funnel in a foam mold, then pour the graphene oxide solution in step (1) into the sand core funnel, and freeze with liquid nitrogen for 1 min to obtain graphite oxide ene "ice cubes"; remove the plastic wrap at the bottom of the sand core funnel, vacuum filter for 3h, put the graphene oxide film together with the filter membrane into a freeze-dryer for freeze-drying for 12h, then use 55% hydroiodic acid ( The mass ratio of graphene oxide to hydriodic acid was 1:100) and reduced for 10 minutes, washed alternately with deionized water and alcohol for 3 times, and then put into a freeze dryer for 12 hours to freeze-dry t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com