Full-degradable friction nano-generator and preparation method and application thereof

A nanogenerator and friction layer technology, which is applied in the field of medical devices, can solve the problems of low transfer charge, single composition, low output performance of triboelectric nanogenerators, etc., and achieve the effect of improving electrical output performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

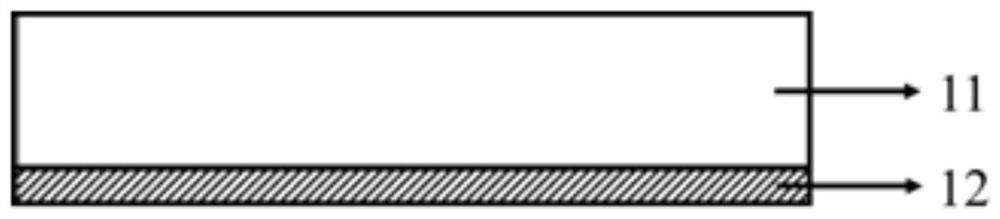

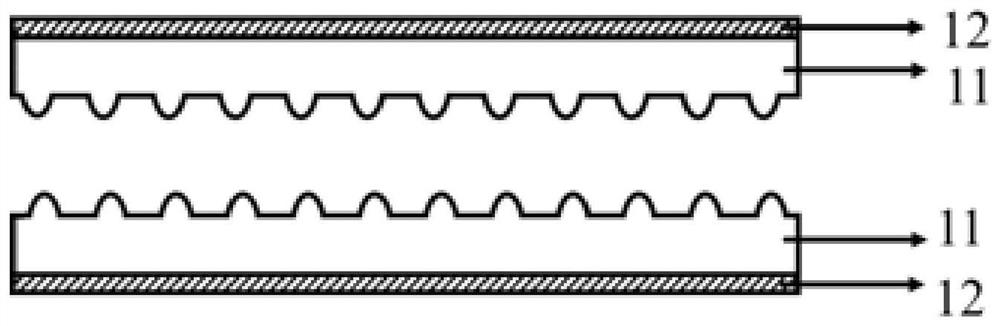

[0068] This embodiment provides a fully degradable triboelectric nanogenerator, the preparation method of which is as follows:

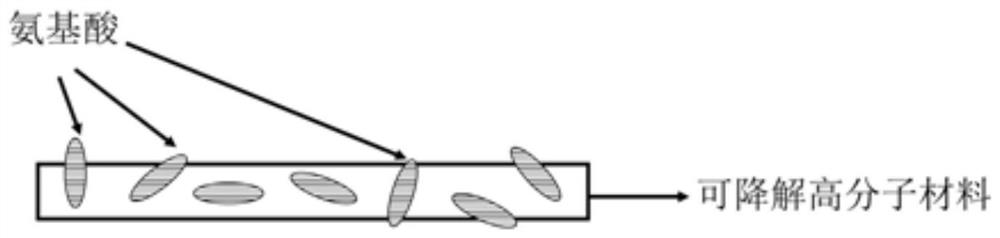

[0069] (1) Preparation of the first amino acid composite material layer: first prepare an acetic acid solution with a volume fraction of 1%, then add sodium alginate powder into the acetic acid solution, and stir well to obtain a homogeneous solution with a mass fraction of 3%. Next, add glycine powder into the sodium alginate solution so that the mass ratio of glycine to sodium alginate in the mixed solution is 1.2:1, and stir well and evenly. Finally, the obtained mixed solution was poured into a clean glass plate, left standing at 25°C to remove air bubbles, and then placed in a vacuum oven at 60°C for 12 hours to obtain a flat first amino acid composite material layer with a thickness of 300 μm. Its schematic diagram is as follows figure 1 shown.

[0070] (2) Preparation of the second amino acid composite material layer: firstly, the polyvinyl ...

Embodiment 2

[0075]This embodiment provides a fully degradable triboelectric nanogenerator, the preparation method of which is as follows:

[0076] (1) Preparation of the first amino acid composite material layer: adding silk fibroin to deionized aqueous solution, centrifuging to remove impurities after fully dissolving, and obtaining a silk fibroin aqueous solution with a mass fraction of 10%. Next, add lysine powder into the silk fibroin aqueous solution so that the mass ratio of serine and silk fibroin in the mixed solution is 0.35:1, and stir well and evenly. Finally, the obtained mixed solution was poured into a clean glass plate, left standing at 25°C to remove air bubbles, and then placed in a vacuum oven at 60°C for 18 hours to obtain a flat first amino acid composite material layer with a thickness of 800 μm.

[0077] (2) Preparation of the second amino acid composite material layer: firstly, the polyvinyl alcohol polymer material was added to the deionized aqueous solution, heate...

Embodiment 3

[0082] This embodiment provides a fully degradable triboelectric nanogenerator, the preparation method of which is as follows:

[0083] (1) Preparation of the first amino acid composite material layer: gelatin was added into a deionized aqueous solution, fully dissolved and then centrifuged to remove impurities to obtain an aqueous gelatin solution with a mass fraction of 8%. Next, add glutamine powder into the gelatin aqueous solution so that the mass ratio of glutamine and gelatin in the mixed solution is 0.8:1, and stir well and evenly. Finally, the obtained mixed solution was poured into a clean glass plate, left standing at 25°C to remove air bubbles, and then placed in a vacuum oven at 40°C for 24 hours to obtain a flat first amino acid composite material layer with a thickness of 80 μm.

[0084] (2) Preparation of the second amino acid composite material layer: firstly, the polyoxyethylene polymer material was added to the deionized aqueous solution, heated to 90° C. an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com