Manufacturing method of high integration-level flexible film thermoelectric cell

A flexible thin-film, thermoelectric battery technology, applied in the field of thermoelectricity, can solve the problems of low battery integration and large thin-film batteries, and achieve the effect of improving electrical output performance and integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

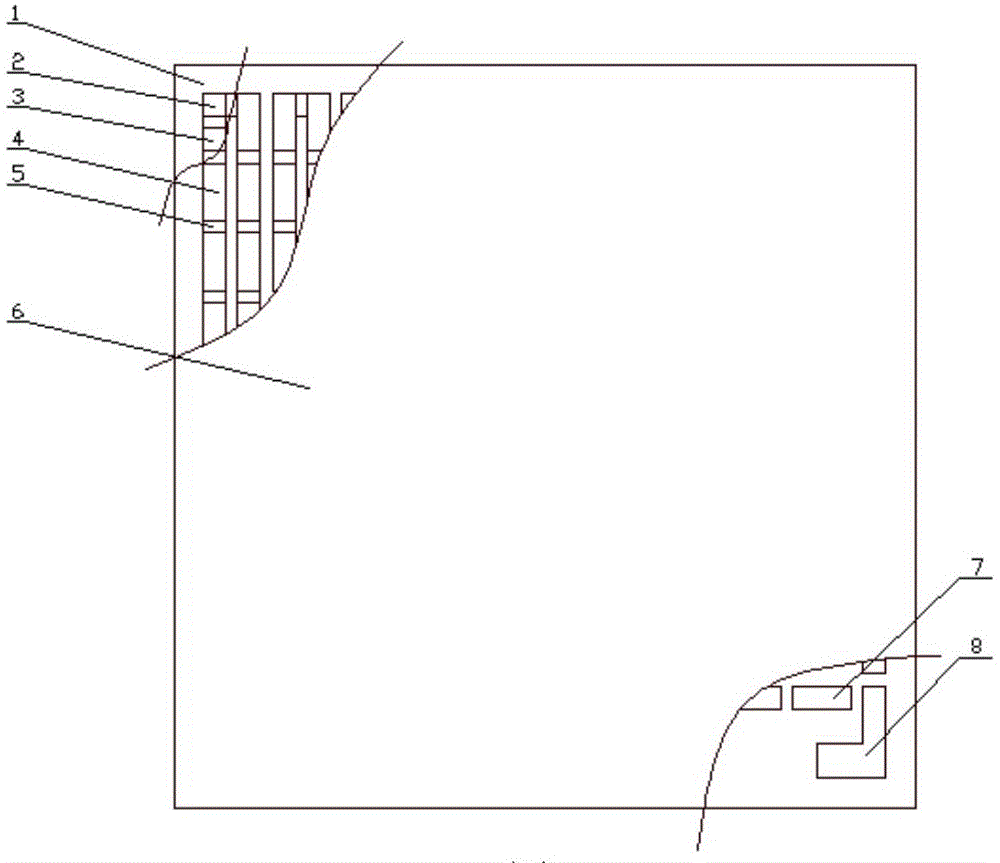

[0038] Step 1: Make a photolithography mask:

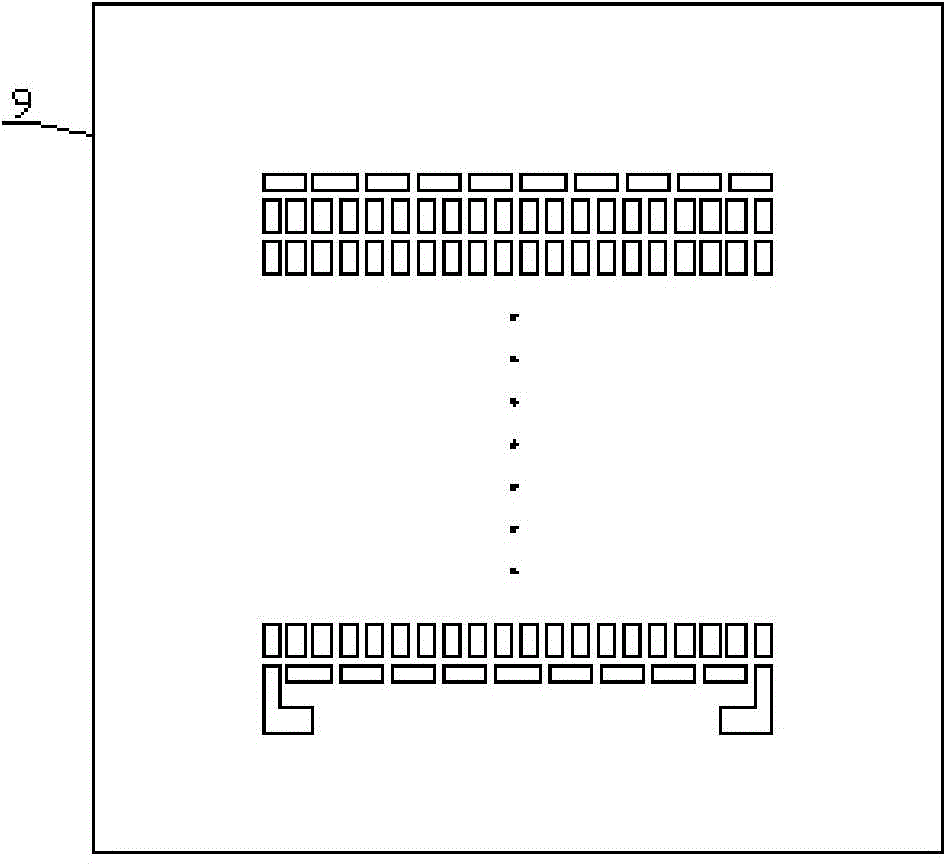

[0039] According to the production of 200 hot-end conductive layer micro-areas, 200 N-type thermoelectric monomer micro-areas, 200 P-type monomer micro-areas, 30 cold-end conductive interlayer insulating layer micro-areas, and 199 cold-end conductive layers Take the highly-integrated flexible thin-film thermoelectric battery of the micro-zone and the two cold-end conductive layer output port micro-zones as an example; use quartz glass with a thickness of 2.5mm and an area of 4 inches to make them respectively image 3 As shown, there are 199 rectangular figures as cold-end conductive layer micro-regions and 2 symmetrical L-shaped figures as cold-end conductive layer micro-region photolithography mask templates for cold-end conductive layer output port micro-regions 9, Figure 4 There are 200 square figures shown as N / P type thermoelectric monomer micro-region photolithography mask 10, Figure 5 As shown, there are 30 rectangula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com