Bionic degradable friction nano-generator and preparation method thereof

A nano-generator, friction material technology, applied in the direction of friction generator, wind energy power generation, ocean energy power generation, etc., can solve the problems of non-conformity, poor material degradability, high preparation cost, and achieve good flexibility and friction performance, preparation The effect of improved efficiency and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

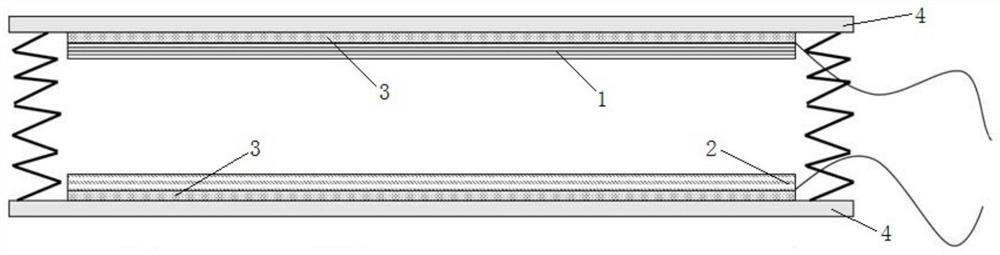

[0030] Example 1. Preparation of a biomimetic degradable triboelectric nanogenerator

[0031] Cut the bamboo into 1mm, 2mm, 3mm, and 4mm thick slices respectively, and then splicing these slices of different thicknesses into 5cm×5cm squares, using them as the negative electrode friction material and the aluminum film as the positive electrode friction material to make a simple Triboelectric nanogenerators, compared with their open circuit voltages, found that 2mm thick bamboo flakes performed better.

[0032] bamboo thickness 1mm 2mm 3mm 4mm 5mm Open circuit voltage 60V 80V 65V 50V 20V

[0033] Therefore, in the present embodiment, a 2mm thick sheet is selected to carry out the follow-up test, and the specific process is as follows:

[0034] 1) Cut the bamboo into 2mm thick slices, and then cut the slices into 5mm wide strips;

[0035] 2) Weaving the thin strips of bamboo fibers into a 10cm×10cm bamboo fiber cloth by using a plain weave meth...

Embodiment 2

[0045] Example 2. Preparation of a biomimetic degradable triboelectric nanogenerator

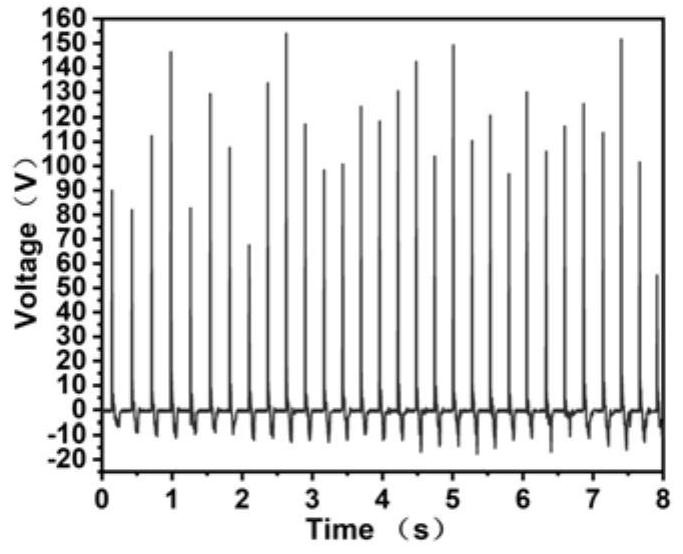

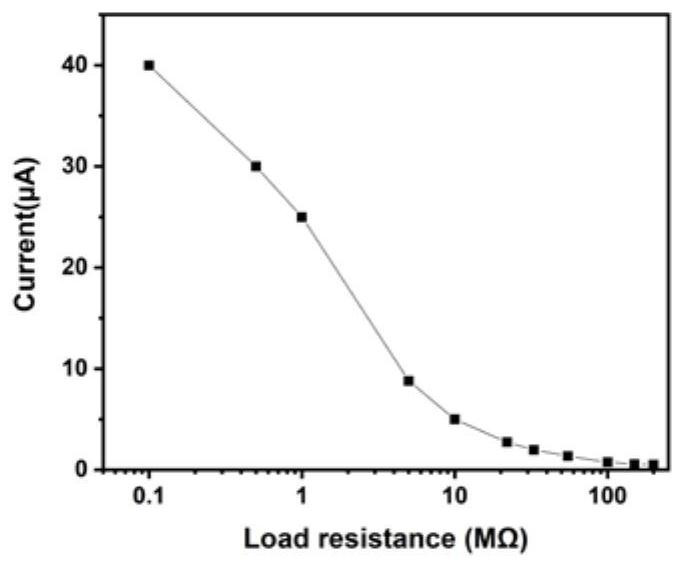

[0046] The difference between the second embodiment and the first embodiment is that the size of the prepared bamboo fiber cloth positive electrode material and the cotton cloth negative electrode material is 8cm×8cm, and the remaining conditions are the same as those in the first embodiment, and the sizes of the positive and negative electrode friction materials are different. , will cause the difference in friction area, and then the power generation performance of the triboelectric nanogenerator will also change. After testing, the maximum open circuit voltage and maximum output power of the triboelectric nanogenerator under this size are 133V and 1.8mW, respectively.

Embodiment 3

[0047] Embodiment 3. Preparation of a biomimetic degradable triboelectric nanogenerator

[0048] The difference between Embodiment 3 and Embodiment 1 is that the size of the prepared bamboo fiber cloth positive electrode material and cotton cloth negative electrode material is 5cm×5cm, and the remaining conditions are the same as those in Embodiment 1. After testing, the friction under this size is the same. The maximum open circuit voltage of the nanogenerator is 100V.

[0049] The following table lists the maximum open circuit voltage of the triboelectric nanogenerators prepared in the three examples. It can be intuitively known from the table that the size of the bamboo fiber cloth positive electrode material and the cotton cloth negative electrode material is 10cm×10cm. The maximum open circuit voltage of the machine is the highest, which also proves that the difference in the friction area will cause the electrical performance to change significantly.

[0050] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com