Tin dioxide thin film and silicon heterojunction solar battery

A tin dioxide and silicon heterojunction technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low efficiency, the problem of passivation of the back electrode of the battery is not well solved, and the cost of indium oxide films is high. Achieve the effects of low industrialization cost, improved electrical output performance, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

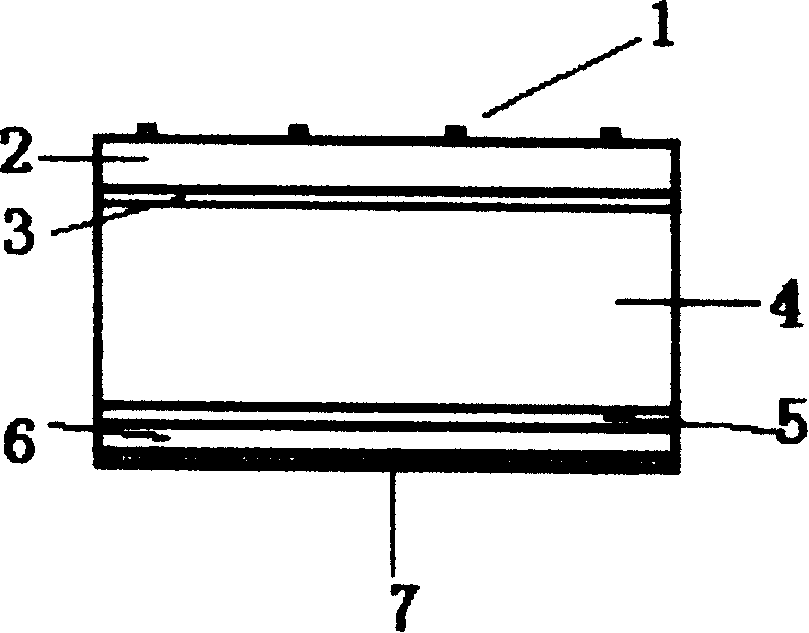

[0030] The n-type silicon substrate 4 selects n-type Czochralski monocrystalline silicon wafers with a resistivity of 1 Ωcm. The silicon wafers are (100) oriented, polished on one side, and have a thickness of 250 μm. The effective area of the solar cell obtained is 2×2 cm 2 , the thickness of the fluorine-doped tin dioxide layer 2 is 76nm, the thicknesses of the intrinsic amorphous silicon film 5 and the phosphorus-doped amorphous silicon film 6 are 3nm and 30nm respectively, and the thickness of the silicon dioxide layer 3 is 2nm. The performance test results of the battery are: AM1.5, 100mW / cm 2 Under the irradiation of standard light intensity, the efficiency of the heterojunction solar cell prepared by this process reaches 14.2%, the open circuit voltage reaches 590mV, the short circuit current reaches 36mA, and the fill factor reaches 67%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com