Air interval type friction nanometer generator

A nano-generator and air-spacer technology, applied in the fields of textile, micro-nano technology and electronics, can solve the problems of limited service life of springs, affecting the flexibility of devices, and reducing the effective area of upper and lower friction surfaces, so as to improve service life and stability. , the effect of increasing the effective contact area and improving the electrical output performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

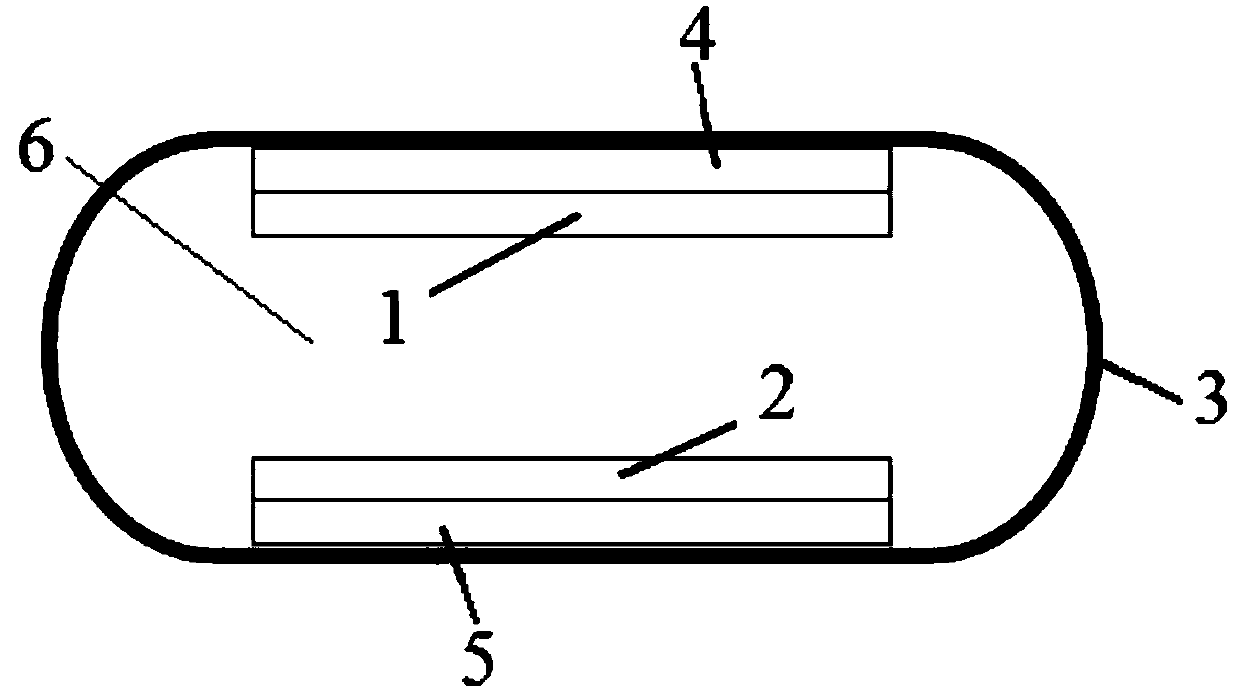

[0017] Embodiment 1. TPE is selected as the external high elastic material, which is synthesized from PP, compatibilizer, antioxidant, dispersant and the like. Use PTFE film (8*8cm 2 , thickness 0.4cm) and PA film (8*8cm 2 , thickness 0.4cm) were used as the first friction layer and the second friction layer, and copper foil was adhered to the back of the two materials as the electrode material. Then stick it on the inner surface of TPE, and seal the edge with hot pressing, pay attention to keep a certain amount of air inside, and ensure that the first friction layer and the second friction layer are facing each other up and down after sealing. Under the action of an external force of 60N, the first friction layer and the second friction layer come into contact and separate, and the output voltage can reach 300V, and the output voltage does not attenuate significantly after 10,000 cycles of testing.

Embodiment 2

[0018] Embodiment 2. select PVC as external material for use, select PDMS film (8*8cm for use) 2 , thickness 0.4mm) and PA plain fabric (8*8cm 2 , The total fabric density 100T—refers to the total number of warp yarns and weft yarns per unit length (1 inch) is 100) as the first friction layer and the second friction layer respectively. The electrode material of the PDMS film is copper, and considering the adhesion between the fabric and the electrode, the conductive silver paste with good affinity with the fabric is selected as the raw material, and the screen printing method is used to coat the back of the PA fabric, and then on the surface of the PA fabric. Dry in an oven at 120°C for 2 hours to form a silver electrode. Then paste the two friction layers with the electrode layer on the inner surface of the PVC sealing structure respectively, and seal it with hot pressing, pay attention to keep a certain amount of air inside, and ensure that the first friction layer and the ...

Embodiment 3

[0019] Embodiment 3. directly select commercially available PVC film to make tubular thing as external support material, select PA plain weave fabric (8*8cm 2 , total fabric density 240T) and PTFE film (8*8cm 2 , thickness 0.4mm) as the first friction layer and the second friction layer. The silver paste with good adhesion to the fabric was selected as the electrode material, and the silver paste was coated on the back of the fabric by screen printing, and baked at 120°C for 2 hours to form a uniform silver electrode with extremely low resistivity. Copper foil is selected as the electrode of PTFE film. Adhere the two friction layers with the electrodes attached to the upper and lower layers of the inner surface of the PVC tube respectively, fill in a certain amount of air and seal it. After sealing, ensure that the first friction layer and the second friction layer are facing each other up and down. Under the action of an external force of 60N, the first friction layer and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com