Preparation method of polydimethylsiloxane film, polydimethylsiloxane film prepared by the method and application thereof

A polydimethylsiloxane film and polydimethylsiloxane technology are applied in the field of polymer films, which can solve the problems of low output performance of triboelectric generators, and achieve the advantages of improving electrical output performance and improving negative charge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

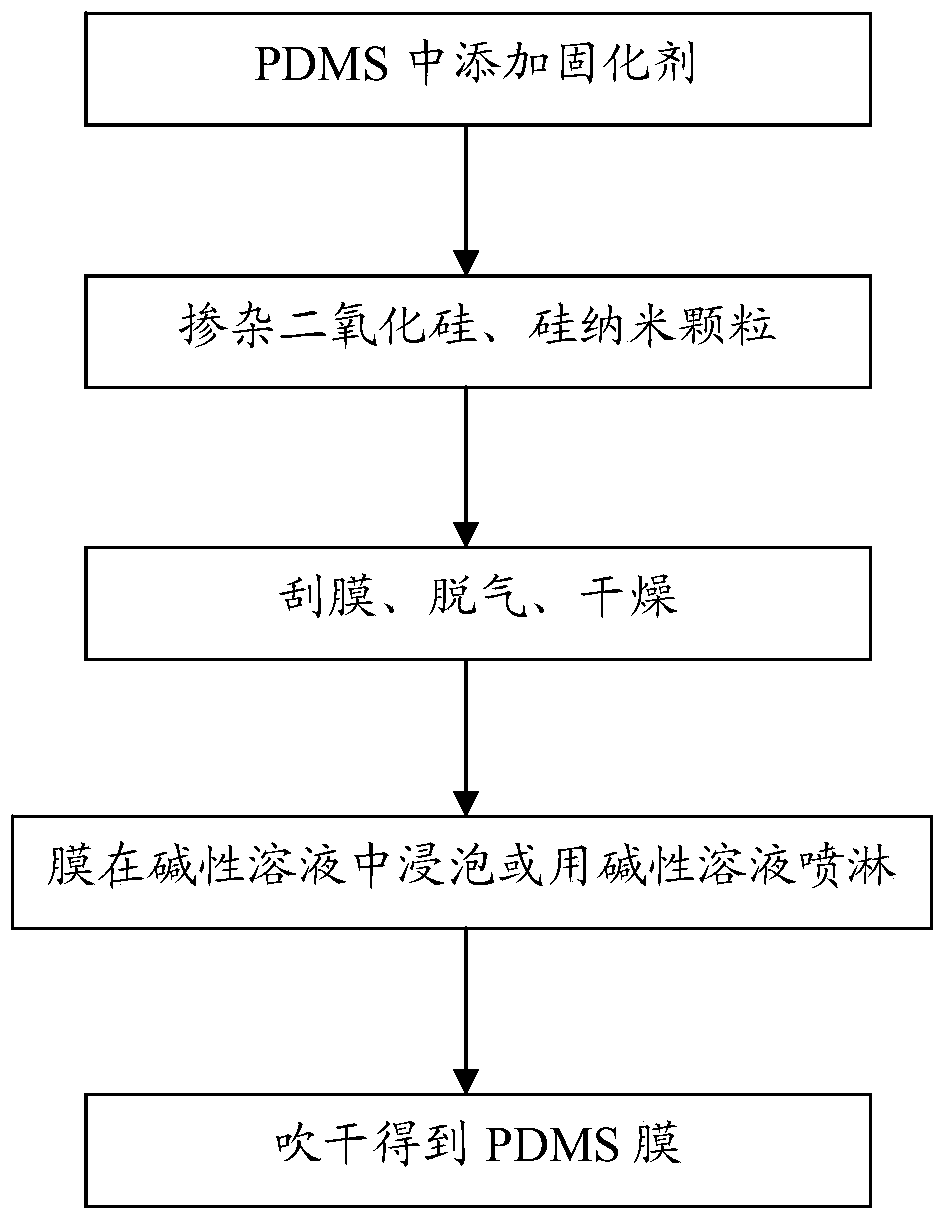

[0018] The invention provides a method for preparing a polydimethylsiloxane (PDMS) film, and the polydimethylsiloxane film prepared by the method can be used for a triboelectric generator, a microfluidic chip, and the like. Combine below figure 1 The method of the present invention will be described. Method of the present invention comprises the steps:

[0019] (1) Add a curing agent to the polydimethylsiloxane, and stir to obtain a mixture. Wherein, the polydimethylsiloxane used in the present invention is commercially available, for example, the model of Sylgard 184 produced by Dow Corning Corporation of the United States. Conventional commercially available curing agents (eg, vulcanizing agents) can be used in the present invention, for example, the model of Sylgard 184 produced by Dow Corning Corporation of the United States. The mass ratio of the polydimethylsiloxane to the curing agent is 1:1-20:1, preferably 10:1.

[0020] (2) Doping negatively charged micro-nano pa...

Embodiment 1

[0034]1. Preparation of Polydimethylsiloxane Membrane

[0035] Add a curing agent (Dow Corning 184) to polydimethylsiloxane (Dow Corning), and stir to obtain a mixture, wherein the mass ratio of polydimethylsiloxane to curing agent is 10:1. Doping silicon dioxide particles with a particle diameter of 200nm-500nm into the mixture, the doping amount is 7% by weight, and mixing uniformly to obtain polydimethylsiloxane slurry. The polydimethylsiloxane slurry was doctor-coated on the template, and the film was degassed under vacuum to remove air bubbles in the film, and then baked in a drying oven at 70° C. for 2 hours. Then, the membrane was immersed in ammonia water with a concentration of 1 mol / L for 800 seconds. Then the membrane was cleaned with deionized water and dried with inert gas to obtain a polydimethylsiloxane membrane with a thickness of 300 μm.

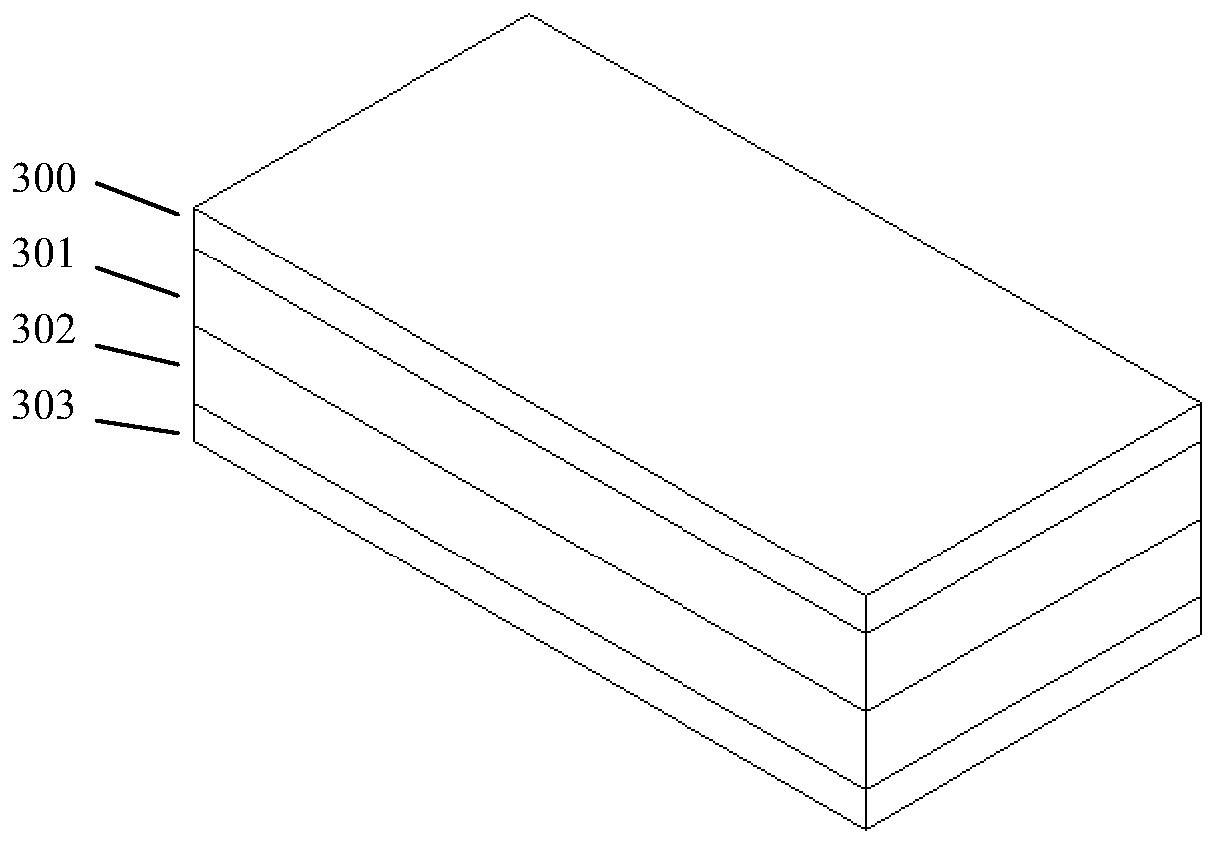

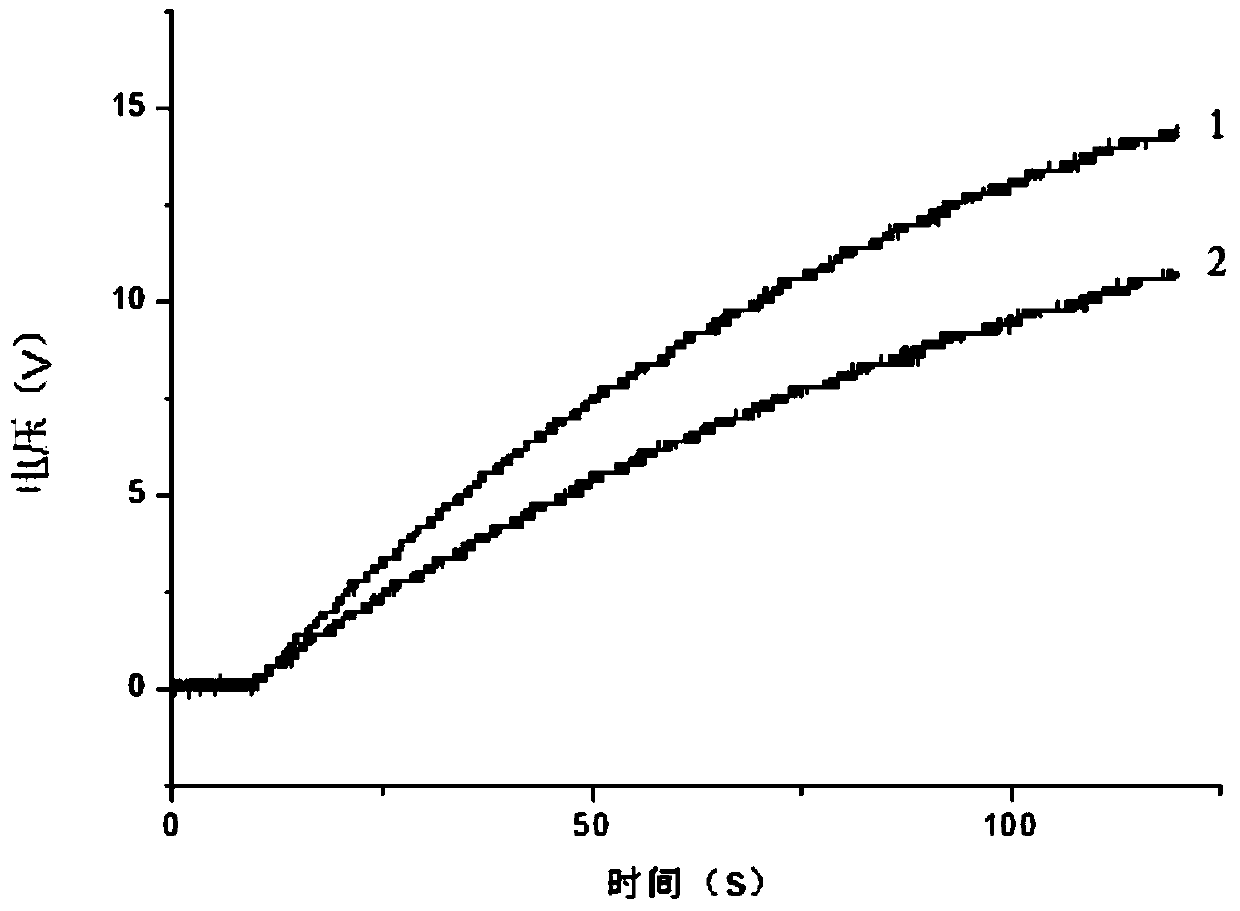

[0036] 2. Preparation of Friction Generator

[0037] The above-mentioned polydimethylsiloxane film is used as the first...

Embodiment 2

[0039] 1. Preparation of Polydimethylsiloxane Membrane

[0040] Add curing agent (Dow Corning 184) to polydimethylsiloxane (Dow Corning) and stir evenly to obtain a mixture, wherein the mass ratio of polydimethylsiloxane to curing agent is 1:1. Doping silicon dioxide particles with a particle diameter of 10nm-300nm into the mixture, the doping amount is 5% by weight, and mixing uniformly to obtain polydimethylsiloxane slurry. The polydimethylsiloxane slurry was doctor-coated on the template, and the film was degassed under vacuum to remove air bubbles in the film, and then baked in a drying oven at 50° C. for 5 hours. Then, the membrane was immersed in ammonia water with a concentration of 0.01 mol / L for 1000 seconds. Then the membrane was cleaned with deionized water and dried with inert gas to obtain a polydimethylsiloxane membrane with a thickness of 300 μm.

[0041] 2. Preparation of Friction Generator

[0042] The above-mentioned polydimethylsiloxane film is used as th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com