Holocellulose-based friction nano-generator

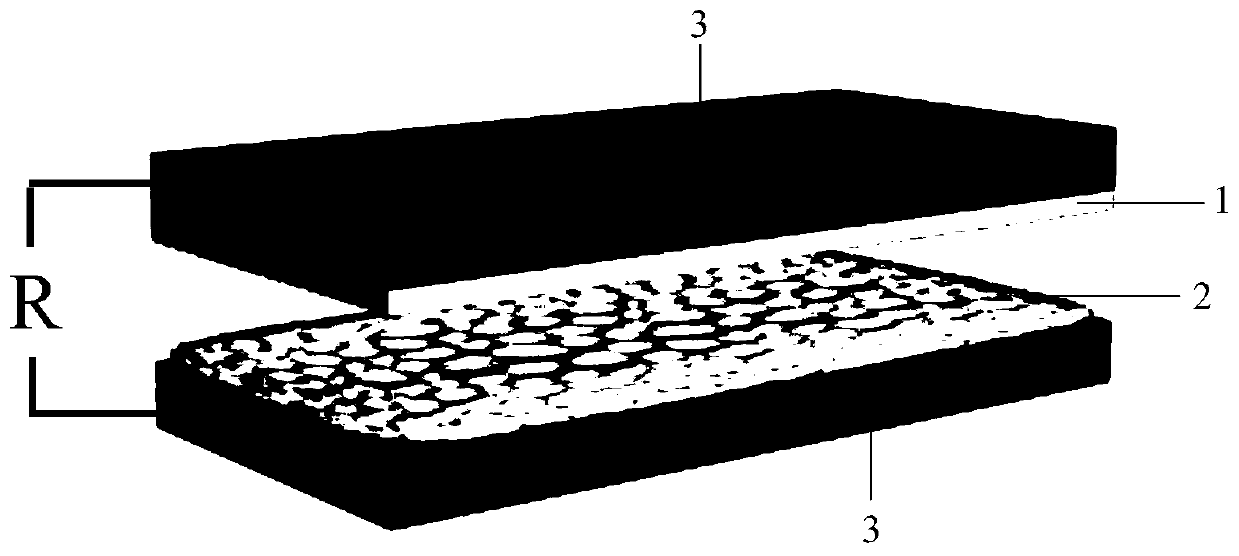

A nano-generator and whole cellulose technology, applied in triboelectric generators, fiber processing, plant fibers, etc., can solve the problem of limited ability to generate surface charges, and achieve high electrical output performance, simple structure, and wide application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of cation-modified cellulose nanofibril-based airgel membrane:

[0023] Step 1: Add glycidyltrialkylammonium chloride to the cellulose nanofibril aqueous solution at a mass ratio of 10% to the cellulose nanofibril, stir magnetically at 60°C for 4 hours, and dilute with 5 times deionized water , then vacuum filtered, and washed 3 times, and the product was dried at 65°C;

[0024] Step 2: Prepare the cationically modified cellulose nanofibrils obtained in Step 1 into an aqueous solution with a concentration of 1 wt%, add a small amount of epichlorohydrin (EPI), and react in LiOH / urea solution to prepare a hydrogel , and then freeze-dried to obtain an airgel, and then pressed under a pressure of 1Mpa to obtain an airgel film with a thickness of 5mm.

[0025] (2) Preparation of cellulose nanofibril-based airgel membrane:

[0026] The cellulose nanofibrils were formulated into an aqueous solution with a concentration of 1 wt%, added a small amount of epichl...

Embodiment 2

[0031] (1) Preparation of cation-modified cellulose nanofibril-based airgel membrane:

[0032] Step 1: Add glycidyltrialkylammonium chloride to the cellulose nanofibril aqueous solution at a mass ratio of 30% to the cellulose nanofibril, stir magnetically at 65°C for 5 hours, and dilute with 5 times deionized water , then vacuum filtered, and washed 3 times, and the product was dried at 65°C;

[0033] Step 2: The cationically modified cellulose nanofibrils obtained in Step 1 are made into an aqueous solution with a concentration of 1 wt%, adding a small amount of epichlorohydrin (EPI), and reacting in LiOH / urea solution to prepare a hydrogel , and then freeze-dried to obtain an airgel, and then pressed under a pressure of 1.3Mpa to obtain an airgel film with a thickness of 10mm.

[0034] (2) Preparation of cellulose nanofibril-based airgel membrane:

[0035] The cellulose nanofibrils were made into an aqueous solution with a concentration of 1wt%, added a small amount of epi...

Embodiment 3

[0040] (1) Preparation of cation-modified cellulose nanofibril-based airgel membrane:

[0041] Step 1: Add glycidyltrialkylammonium chloride to the cellulose nanofibril aqueous solution at a mass ratio of 50% to the cellulose nanofibril, stir magnetically at 70°C for 6h, and dilute with 5 times deionized water , then vacuum filtered, and washed 3 times, and the product was dried at 65°C;

[0042] Step 2: The cationically modified cellulose nanofibrils obtained in Step 1 are made into an aqueous solution with a concentration of 1 wt%, adding a small amount of epichlorohydrin (EPI), and reacting in LiOH / urea solution to prepare a hydrogel , and then freeze-dried to obtain an airgel, and then pressed under a pressure of 1.5Mpa to obtain an airgel film with a thickness of 15mm.

[0043] (2) Preparation of cellulose nanofibril-based airgel membrane:

[0044] The cellulose nanofibrils were made into an aqueous solution with a concentration of 1wt%, added a small amount of epichlor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com