Preparation method of fabric-based portable flexible pressure sensor

A pressure sensor and fabric technology, applied in the direction of sensors, instruments, measuring force, etc., can solve the problems that it is difficult to further improve the output performance of the friction nanogenerator, the equipment is expensive, and the process is complicated, so as to improve the electrical output performance, the equipment is simple, and the process easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

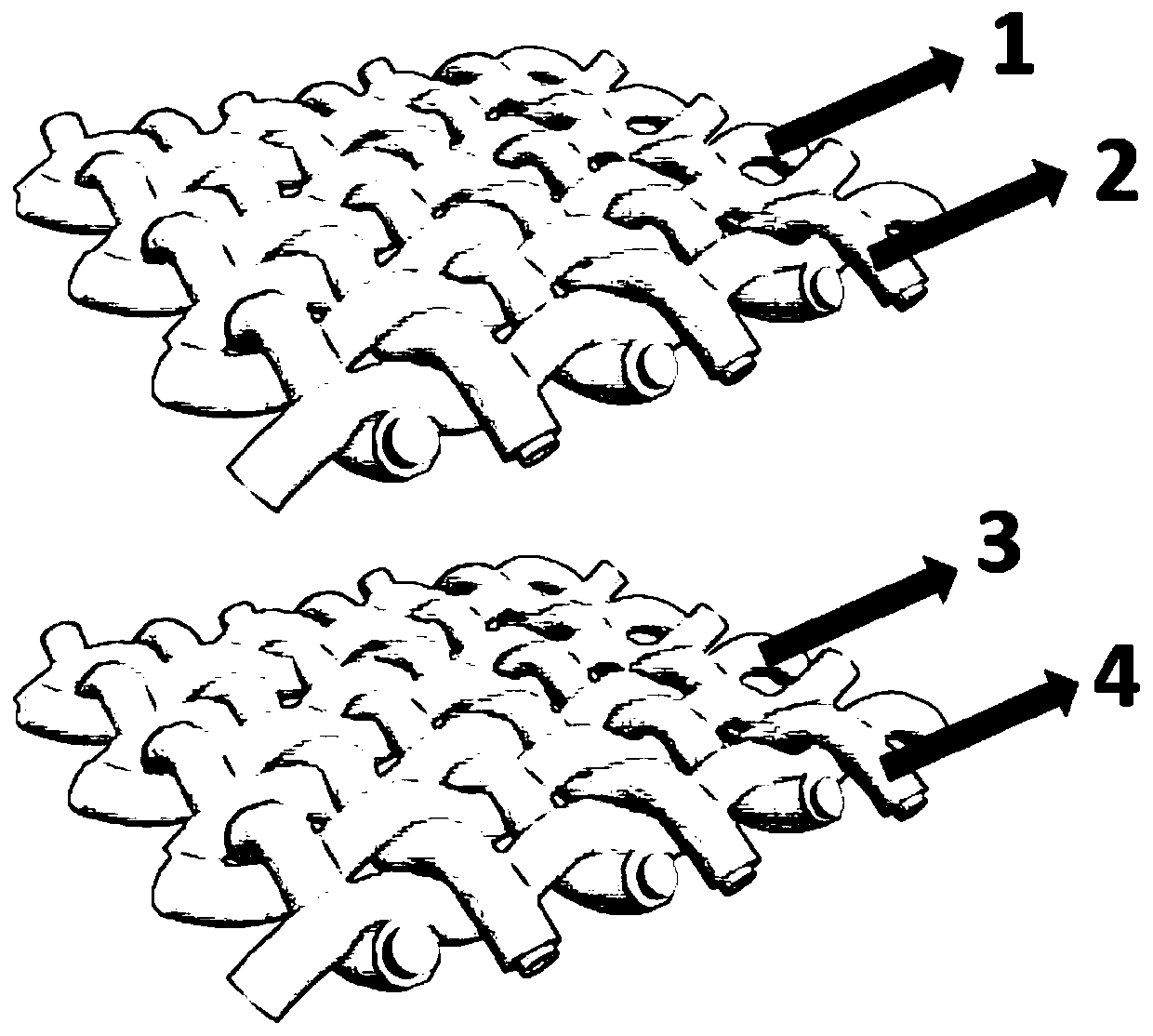

[0043] A preparation method of a fabric-based portable flexible pressure sensor, the specific steps are:

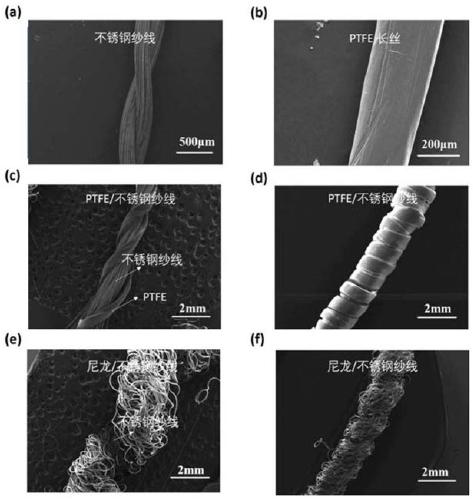

[0044] Step 1: Prepare triboelectrically positive wrapping yarn, use nylon filament to coat stainless steel yarn to form triboelectrically positive wrapping yarn, wherein, the wrapping process is realized by electric motor, and stainless steel yarn is used as an electrode ;

[0045] Step 2: Prepare triboelectrically negative wrapping yarn, use PTFE filaments to coat stainless steel yarn to form triboelectronegative wrapping yarn, wherein, the wrapping process is realized by electric motor, and stainless steel yarn is used as an electrode ;

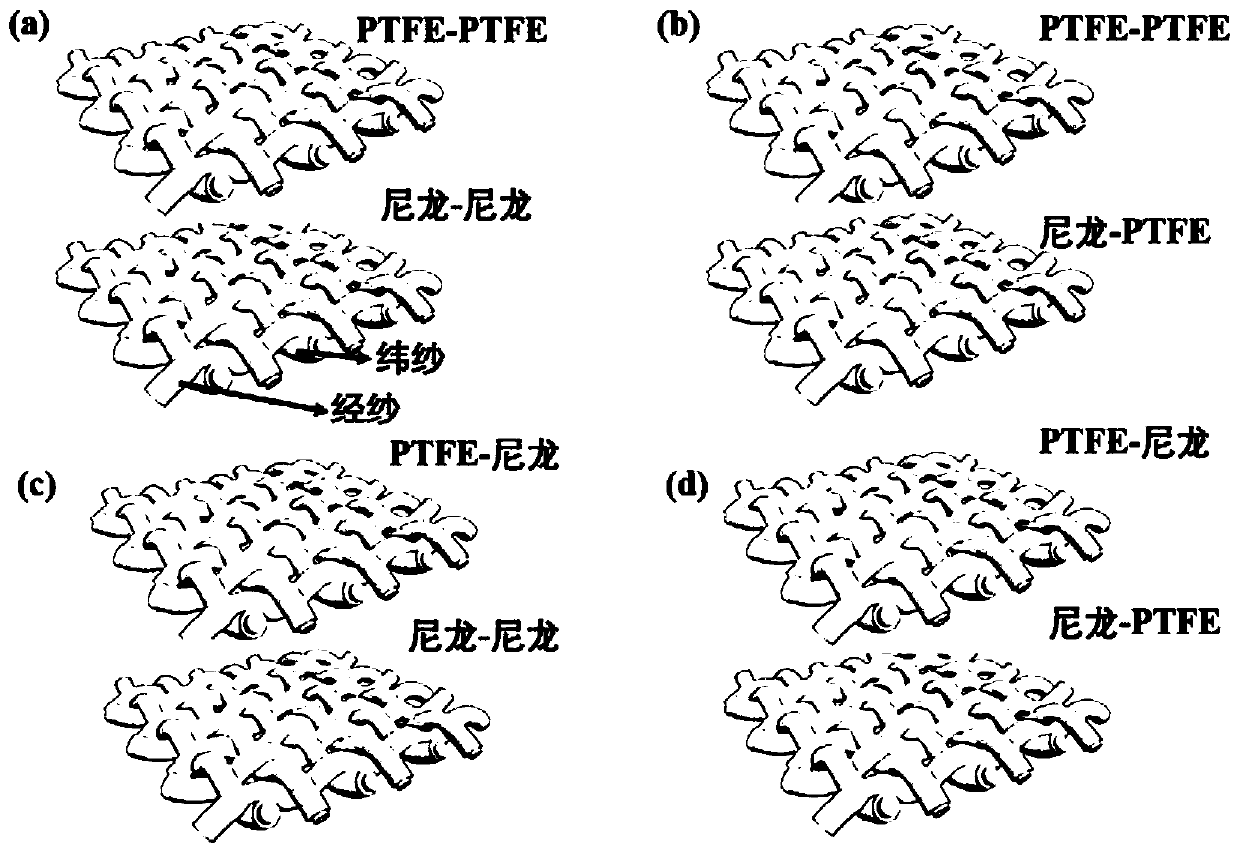

[0046] Step 3: use the triboelectrically positive wrapping yarn obtained in step 1 as the weft yarn, and the nylon yarn and the PTFE filament as the warp yarn to weave by hand to form two corresponding triboelectrically positive woven fabrics;

[0047] Step 4: using the triboelectric negative wrapping yarn obtained in step 2 as weft...

Embodiment 2

[0052] A preparation method of a fabric-based portable flexible pressure sensor, the specific steps are:

[0053] Step 1: Prepare triboelectrically positive wrapping yarn, use nylon filament to coat stainless steel yarn to form triboelectrically positive wrapping yarn, wherein, the wrapping process is realized by electric motor, and stainless steel yarn is used as an electrode ;

[0054] Step 2: Prepare triboelectrically negative wrapping yarn, use PTFE filaments to coat stainless steel yarn to form triboelectronegative wrapping yarn, wherein, the wrapping process is realized by electric motor, and stainless steel yarn is used as an electrode ;

[0055] Step 3: using the triboelectrically positive wrapping yarn obtained in step 1 as the weft yarn, and the PTFE filament as the warp yarn to weave by hand to form a corresponding triboelectrically positive fabric;

[0056] Step 4: using the triboelectric negative wrapping yarn obtained in step 2 as the weft yarn, and the nylon y...

Embodiment 3

[0060] A preparation method of a fabric-based portable flexible pressure sensor, the specific steps are:

[0061] Step 1: Prepare triboelectrically positive wrapping yarn, use nylon filament to coat stainless steel yarn to form triboelectrically positive wrapping yarn, wherein, the wrapping process is realized by electric motor, and stainless steel yarn is used as an electrode ;

[0062] Step 2: Prepare triboelectrically negative wrapping yarn, use PTFE filaments to coat stainless steel yarn to form triboelectronegative wrapping yarn, wherein, the wrapping process is realized by electric motor, and stainless steel yarn is used as an electrode ;

[0063] Step 3: using the triboelectrically positive wrapping yarn obtained in step 1 as the weft yarn, and the PTFE filament as the warp yarn to weave by hand to form a corresponding triboelectrically positive fabric;

[0064] Step 4: using the triboelectric negative wrapping yarn obtained in step 2 as the weft yarn, and the nylon y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com