Alloy nano-catalyst, preparation method thereof and fuel cell

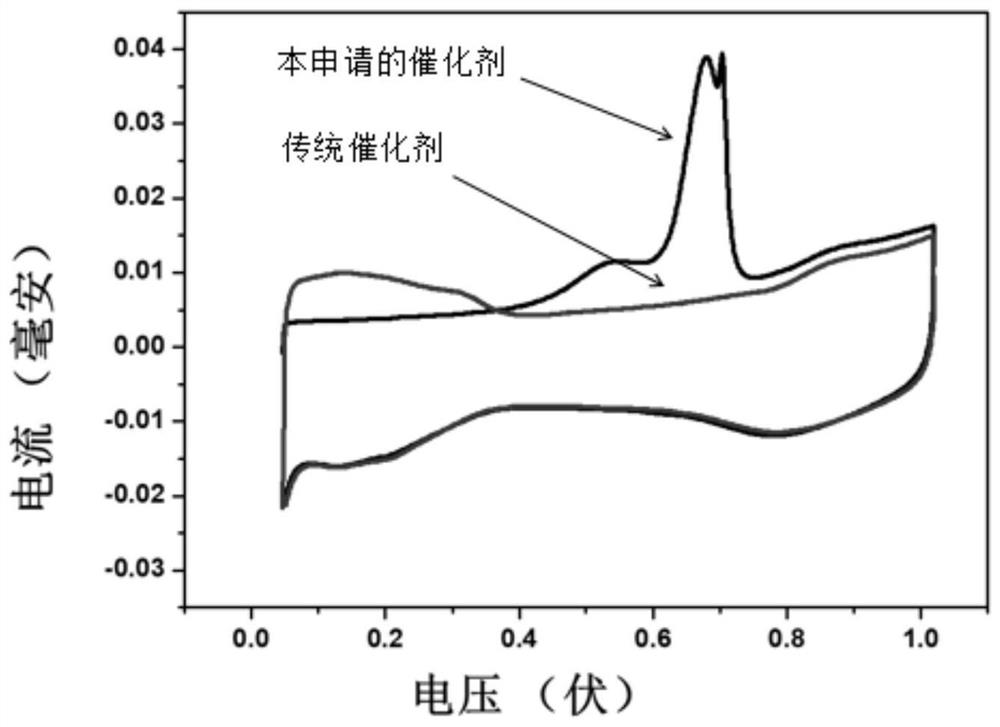

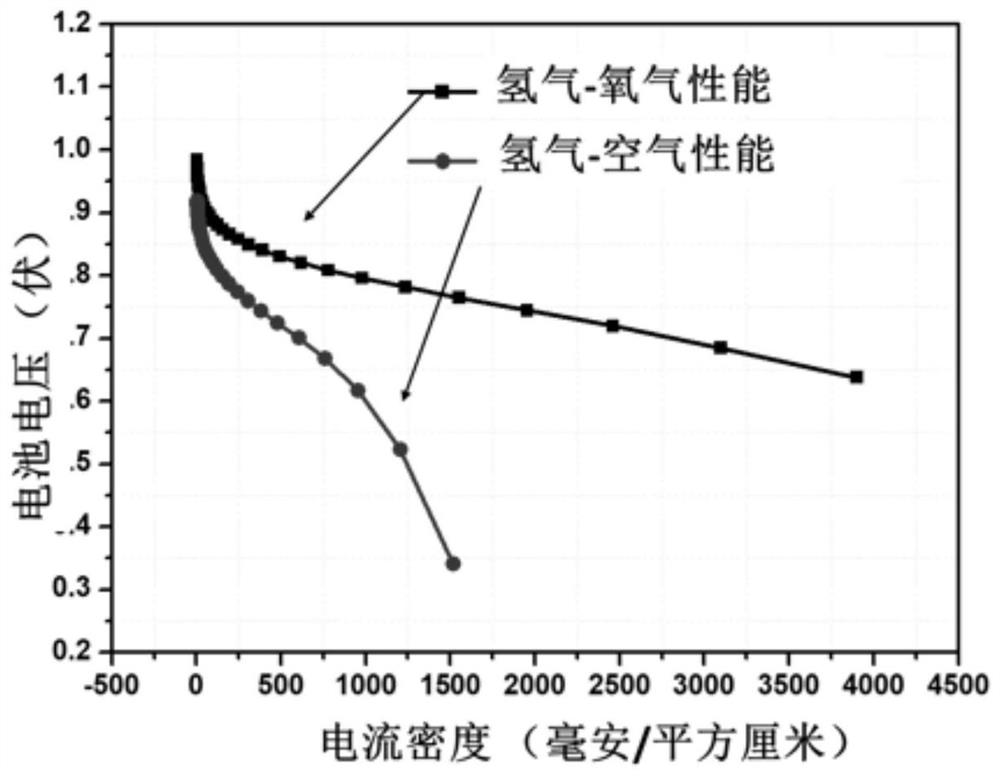

A nano-alloy, fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor catalytic activity and weak stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] In a second aspect, the application provides a method for preparing an alloy nanocatalyst, comprising the steps of:

[0038] S01. In the protective gas, provide a reductive shape-oriented organic solvent, mix the metal precursor and the organic solvent to obtain a first mixed solution, and heat-treat the first mixed solution to obtain a metal colloid;

[0039] S02. mixing metal colloid and carbon-based carrier dispersion to obtain alloy nanocatalyst;

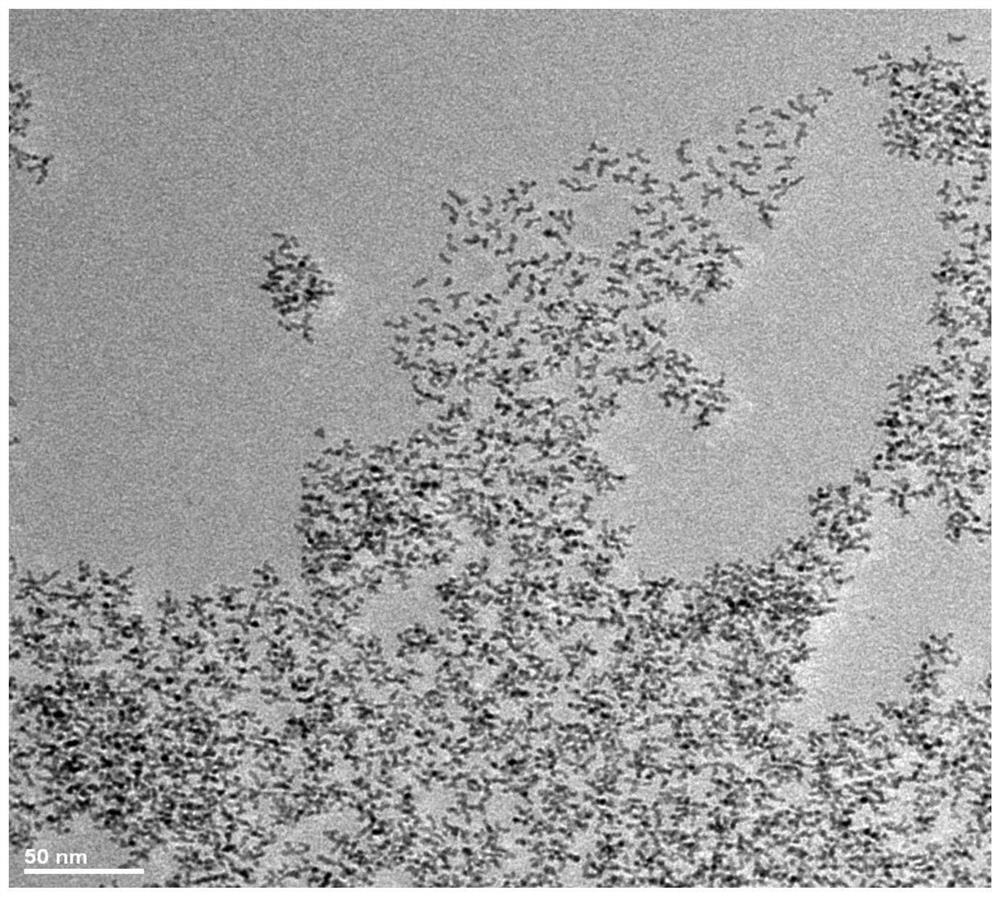

[0040] Wherein, the alloy nanocatalyst includes a carbon-based support and worm-like alloy nanoparticles adsorbed on the surface of the carbon-based support.

[0041] The preparation method is simple and easy to operate, and the alloy nanocatalyst of the worm-like alloy nanoparticles adsorbed on the surface of the carbon-based support can be prepared by only two steps. In the preparation process, no other polymers need to be added, and the reaction process is simple. The reaction conditions are mild, suitable for large-s...

Embodiment 1

[0065] A PtNi / C alloy nano-catalyst, the alloy nano-catalyst includes a carbon-based carrier, and alloy nanoparticles adsorbed on the surface of the carbon-based carrier, the alloy nano-particles are worm-like.

[0066] The preparation method of PtNi / C alloy nano catalyst comprises the steps:

[0067] in N 2 In the protective gas, mix the metal precursor and the organic solvent to obtain the first mixed liquid, wherein the metal precursor is 50 mL of H with a concentration of 1.4 mg / mL 2 PtCl 6 ·6H 2 O and Ni(NO) 3 The mixed solution of organic solvent is the oleylamine solution of 150mL;

[0068] Heat the first mixed solution in an oil bath to 100-110°C, heat up to 200-230°C and reflux for 2-5 hours, the color of the solution gradually changes from light yellow to dark brown, and a stable metal Pt colloidal solution is obtained;

[0069] Provide carbon black powder with a mass of 280 mg and an average particle size of 50 nm, mix it with 100 mL of n-hexane solution, and p...

Embodiment 2

[0074] A PtNi / C alloy nano-catalyst, the alloy nano-catalyst includes a carbon-based carrier, and alloy nanoparticles adsorbed on the surface of the carbon-based carrier, the alloy nano-particles are worm-like.

[0075] The preparation method of PtNi / C alloy nano catalyst comprises the steps:

[0076] in N 2 In the protective gas, mix the metal precursor and the organic solvent to obtain the first mixed liquid, wherein the metal precursor is 50 mL of Pt(acac) with a concentration of 1.4 mg / mL 2 and Ni(acac) 2 The mixed solution of organic solvent is the oleylamine solution of 150mL;

[0077] Heat the first mixed solution in an oil bath to 100-110°C, heat up to 200-230°C and reflux for 2-5 hours, the color of the solution gradually changes from light yellow to dark brown, and a stable metal Pt colloidal solution is obtained;

[0078] Provide carbon black powder with a mass of 280 mg and an average particle size of 50 nm, mix it with 100 mL of n-hexane solution, and perform u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com