Preparation method and application of titanium dioxide/carbon nanoflower composite PDMS film

A titanium dioxide and carbon nanotechnology, applied in triboelectric generators, coatings and other directions, can solve the problems of insufficient and limited output performance of frictional conversion of dielectric properties, and achieve the enhancement of interface polarization effect, improvement of dielectric properties, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

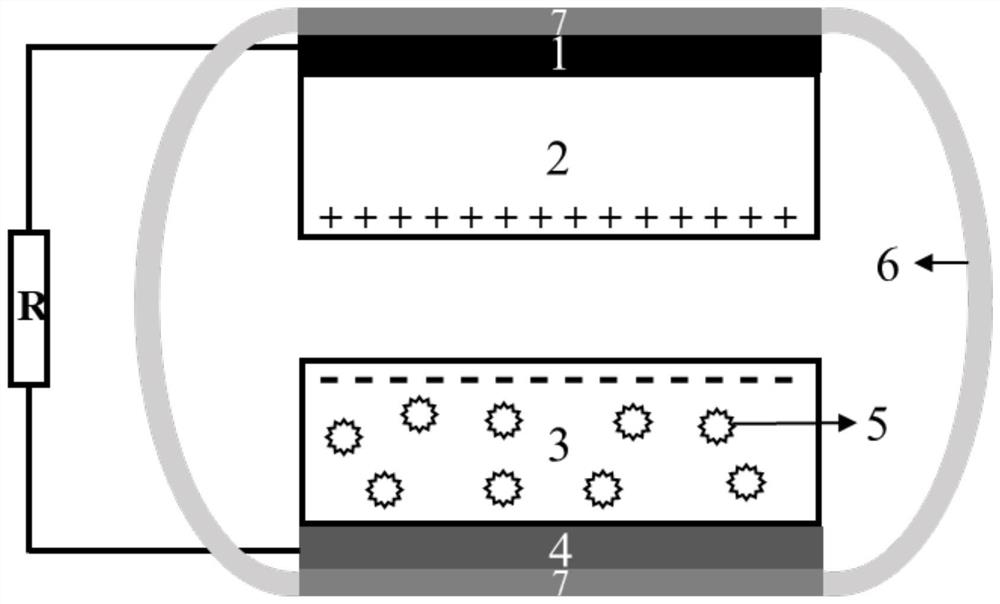

[0045] In this example, titanium dioxide / carbon nanoflowers are used as filler, PDMS is used as matrix material, and a high-performance triboelectric energy conversion device is prepared by adopting the method used in the present invention.

[0046] The specific operation steps are as follows:

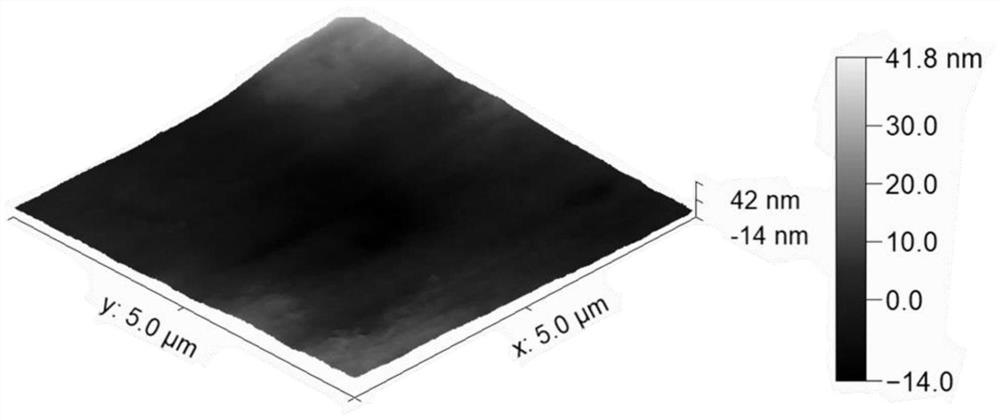

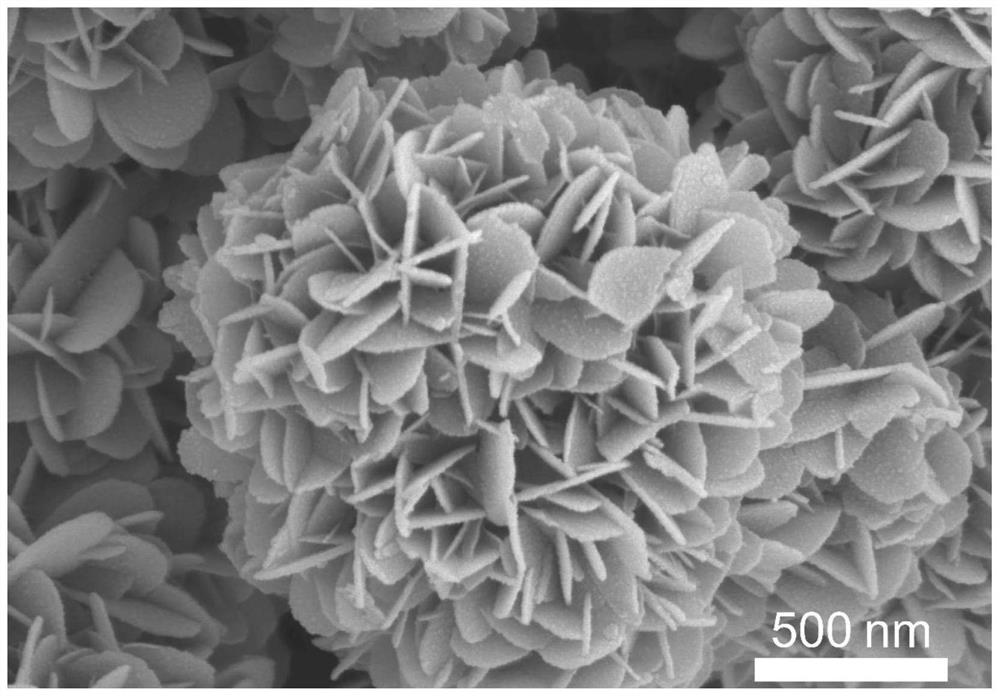

[0047](1) Add 2ml of titanyl sulfate dropwise into 23ml of glycerol and 41ml of ethanol solution; stir at room temperature for 1 hour to obtain a clear solution, which is placed in a 100ml reactor and reacted at 110°C for 48h. After the reaction, the white powder was obtained by centrifugation, washed with water and ethanol, and then dried in an oven at 60°C to obtain the titanium glycerol salt precursor. Then the titanium glycerol salt precursor was placed in a muffle furnace and calcined at 330 °C for 1 h with a heating rate of 1 °C / min. Then it was placed in a tube furnace and calcined at 575° C. for 2 h under the protection of argon, with a heating rate of 2° C. / min. Titanium dio...

Embodiment 2

[0052] In this example, titanium dioxide / carbon nanoflowers are used as filler, PDMS is used as matrix material, and a high-performance triboelectric energy conversion device is prepared by adopting the method used in the present invention.

[0053] The specific operation steps are as follows:

[0054] (1) Add 2ml of titanyl sulfate dropwise into 23ml of glycerol and 41ml of ethanol solution; stir at room temperature for 1 hour to obtain a clear solution, which is placed in a 100ml reactor and reacted at 110°C for 48h. After the reaction, the white powder was obtained by centrifugation, washed with water and ethanol, and then dried in an oven at 60°C to obtain the titanium glycerol salt precursor. Then the titanium glycerol salt precursor was placed in a muffle furnace and calcined at 330 °C for 1 h with a heating rate of 1 °C / min. Then it was placed in a tube furnace and calcined at 575° C. for 2 h under the protection of argon, with a heating rate of 2° C. / min. Titanium di...

Embodiment 3

[0059] In this example, titanium dioxide / carbon nanoflowers are used as filler, PDMS is used as matrix material, and a high-performance triboelectric energy conversion device is prepared by adopting the method used in the present invention.

[0060] The specific operation steps are as follows:

[0061] (1) Add 2ml of titanyl sulfate dropwise into 23ml of glycerol and 41ml of ethanol solution; stir at room temperature for 1 hour to obtain a clear solution, which is placed in a 100ml reactor and reacted at 110°C for 48h. After the reaction, the white powder was obtained by centrifugation, washed with water and ethanol, and then dried in an oven at 60°C to obtain the titanium glycerol salt precursor. Then the titanium glycerol salt precursor was placed in a muffle furnace and calcined at 330 °C for 1 h with a heating rate of 1 °C / min. Then it was placed in a tube furnace and calcined at 575° C. for 2 h under the protection of argon, with a heating rate of 2° C. / min. Titanium di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com