Samarium isotope minisize cell and manufacturing method thereof

A micro-battery and isotope technology, which is applied in the fields of obtaining electric energy from radioactive sources, nuclear engineering, and the application of radioactive source radiation. It can solve the problems of low output power and low short-circuit current, achieve good electrical output performance, and the preparation method is safe and reliable. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

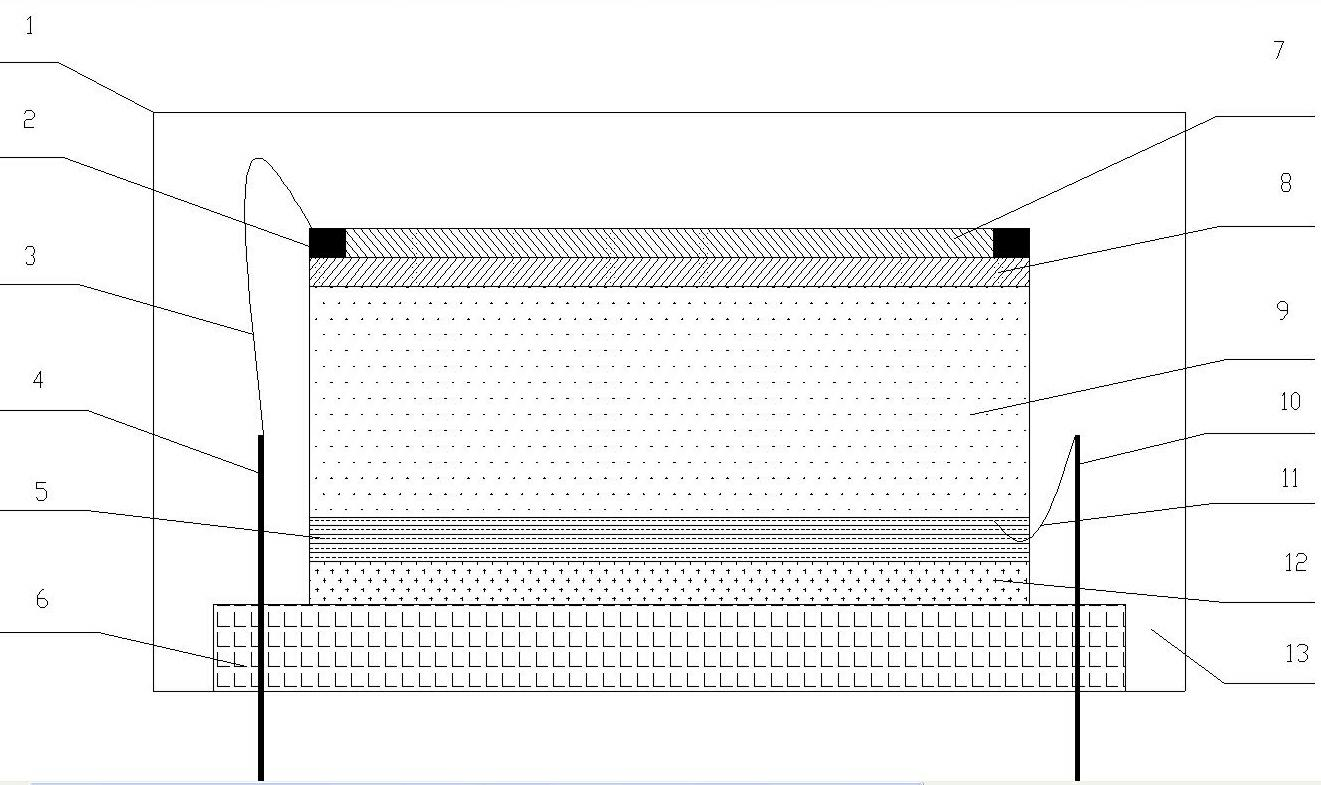

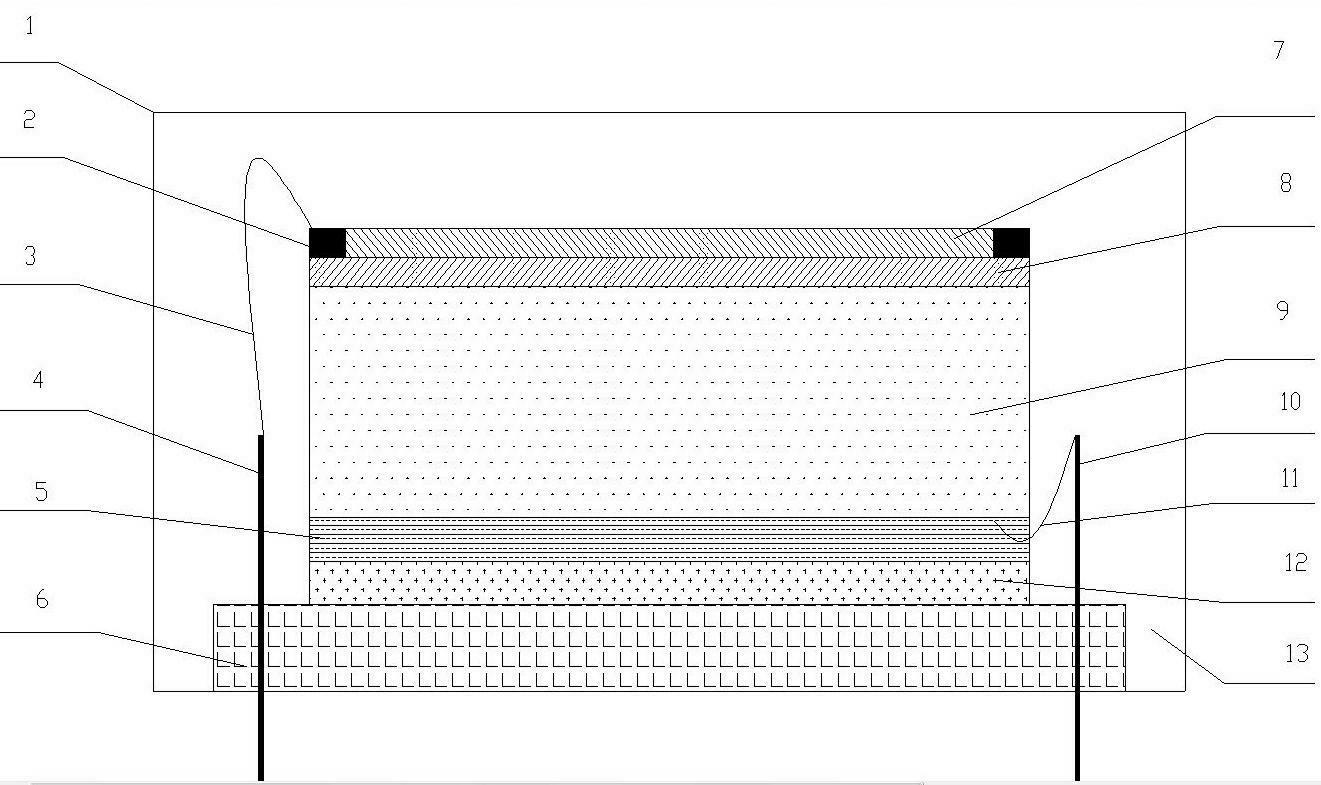

[0026] The content of the present invention will be further described below in conjunction with the accompanying drawings.

[0027] figure 1 It is a structural schematic diagram of a samarium isotope micro-battery of the present invention. figure 1 Among them, the samarium isotope micro-battery of the present invention contains a transduction unit and accessory parts, and the transduction unit includes samarium-151 radiation source sheet 7, Si 3 N 4 Layer 8, silicon-based PN junction 9; accessory components include outer package layer 1, ring electrode 2, positive lead 3, positive electrode 4, gold layer 5, base 6, negative electrode 10, negative lead 11, ceramic sheet 12, inner package Layer 13; its connection relationship is, Si 3 N 4 Layer 8 is located on the upper surface of the silicon-based PN junction 9; the ring electrode 2 is on the Si 3 N 4 Epitaxy of layer 8; samarium-151 radiation source sheet 7 is fixed on Si by inner encapsulation layer 13 3 N 4 The upp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com