Flexible wearable friction nanometer power generator with comprehensive multi-mode mechanical energy collecting functions

A nano-generator and multi-mode technology, applied in the direction of friction generators, etc., can solve the problems of unable to collect electric energy output, electrostatic energy can not be effectively used, etc., to achieve the effect of expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

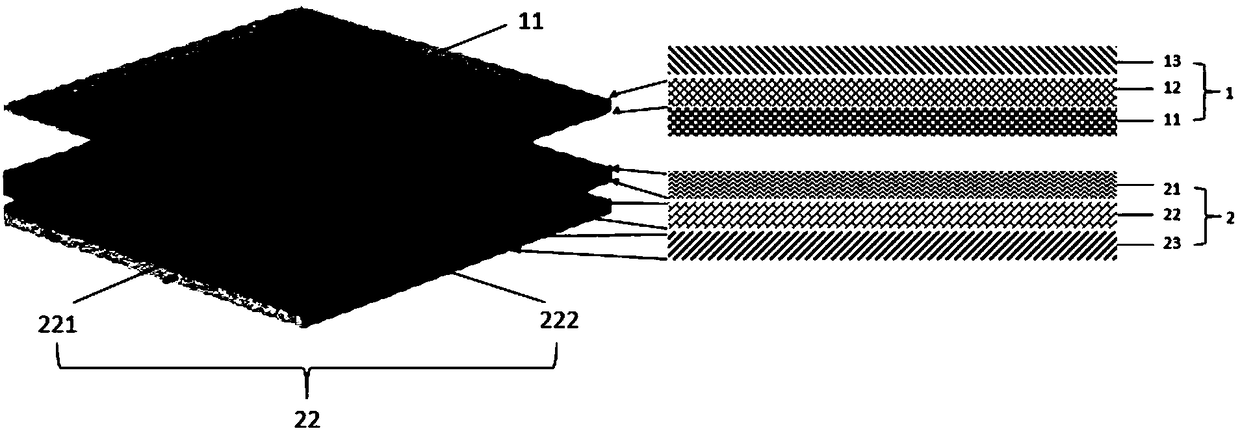

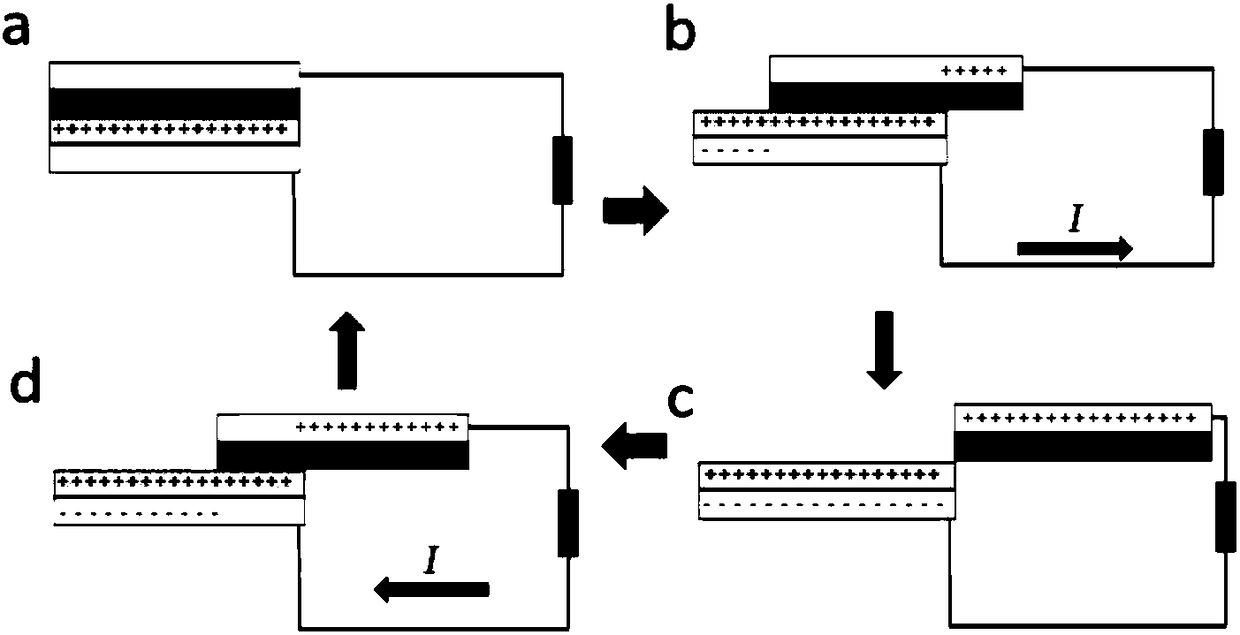

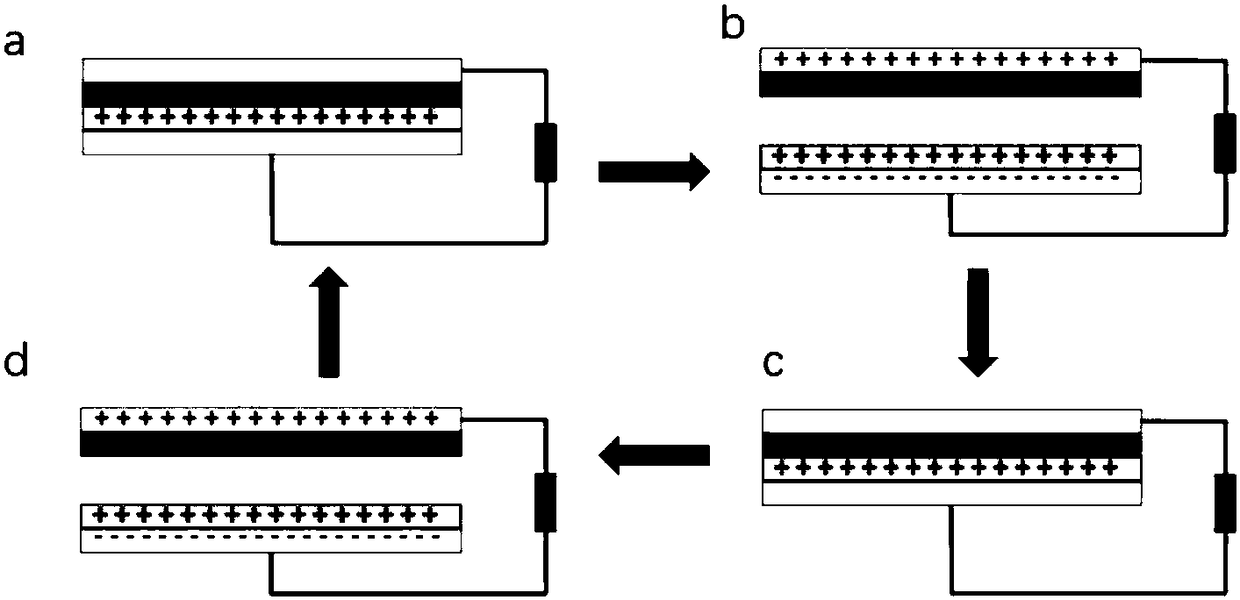

[0034] The specific implementation manners of the present invention will be described in detail below in conjunction with the drawings and technical solutions.

[0035] In the present invention, the orientation words used, such as "up", "down", "left", "right", etc., are only referring to the direction of the drawings; Inside the structure, "outside" refers to the outside of the structure; "normal external force" means that the external force or component of the external force is perpendicular to the friction surface, and "tangential external force" means that the external force or component of the external force is parallel to the friction surface.

[0036] The "triboelectrode series" mentioned in the present invention refers to the sorting of materials according to their ability to attract charges. When two materials are rubbed or contacted, the negative charge will pass through the friction surface from the material with more positive polarity in the triboelectrode series. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com