Poultry egg shell-membrane separation equipment

A shell-membrane separation and equipment technology is applied in the field of poultry egg and egg shell processing equipment, which can solve the problems of high equipment cost, complex process, and difficulty in large-scale production, and achieves low equipment cost and operating cost, simple process, and easy large-scale production. the effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

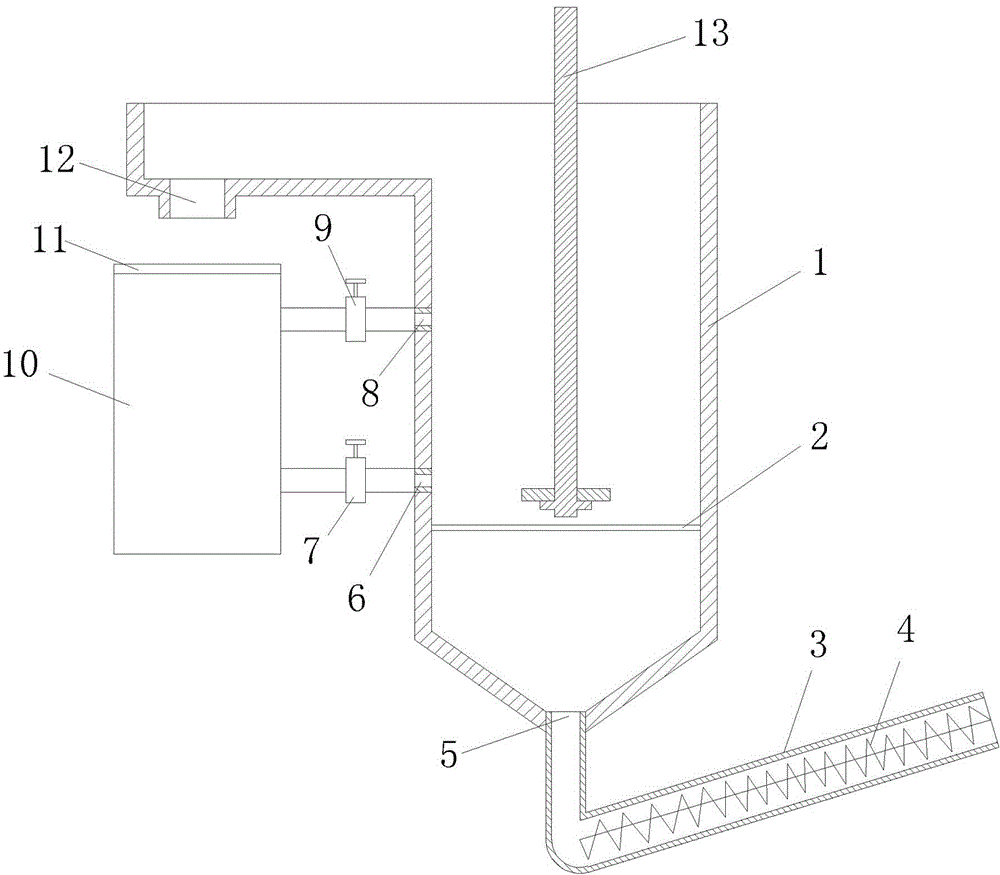

[0014] Such as figure 1 Shown, be the specific embodiment of a kind of poultry eggshell membrane separation equipment of the present invention, in this embodiment, poultry eggshell membrane separation equipment comprises cylinder body 1, and water is injected in cylinder body 1, and the eggshell after the fragmentation is fed by cylinder body 1 The top opening is poured into the cylinder body 1, the membrane outlet 12 is arranged on the side wall of the cylinder body 1 top, the shell outlet 5 is arranged on the bottom of the cylinder body 1, and the stirring device 13 for stirring the shell membrane to separate from each other is installed in the cylinder body 1, The stirring device 13 may be a stirrer with blades installed at the lower end, and the stirring device 13 is a common mechanism in the field, and will not be described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com