Method for preparing classifying porous aluminum oxide nano heat insulating material

A technology of alumina nanometer and hierarchical porosity, which is applied in the direction of alumina/hydroxide preparation, nanostructure manufacturing, nanotechnology, etc., can solve the problems of nano-alumina impurities, restrictions on widespread promotion, complex process, etc., and achieve low cost , The process is simple and environmentally friendly, and the effect of low thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

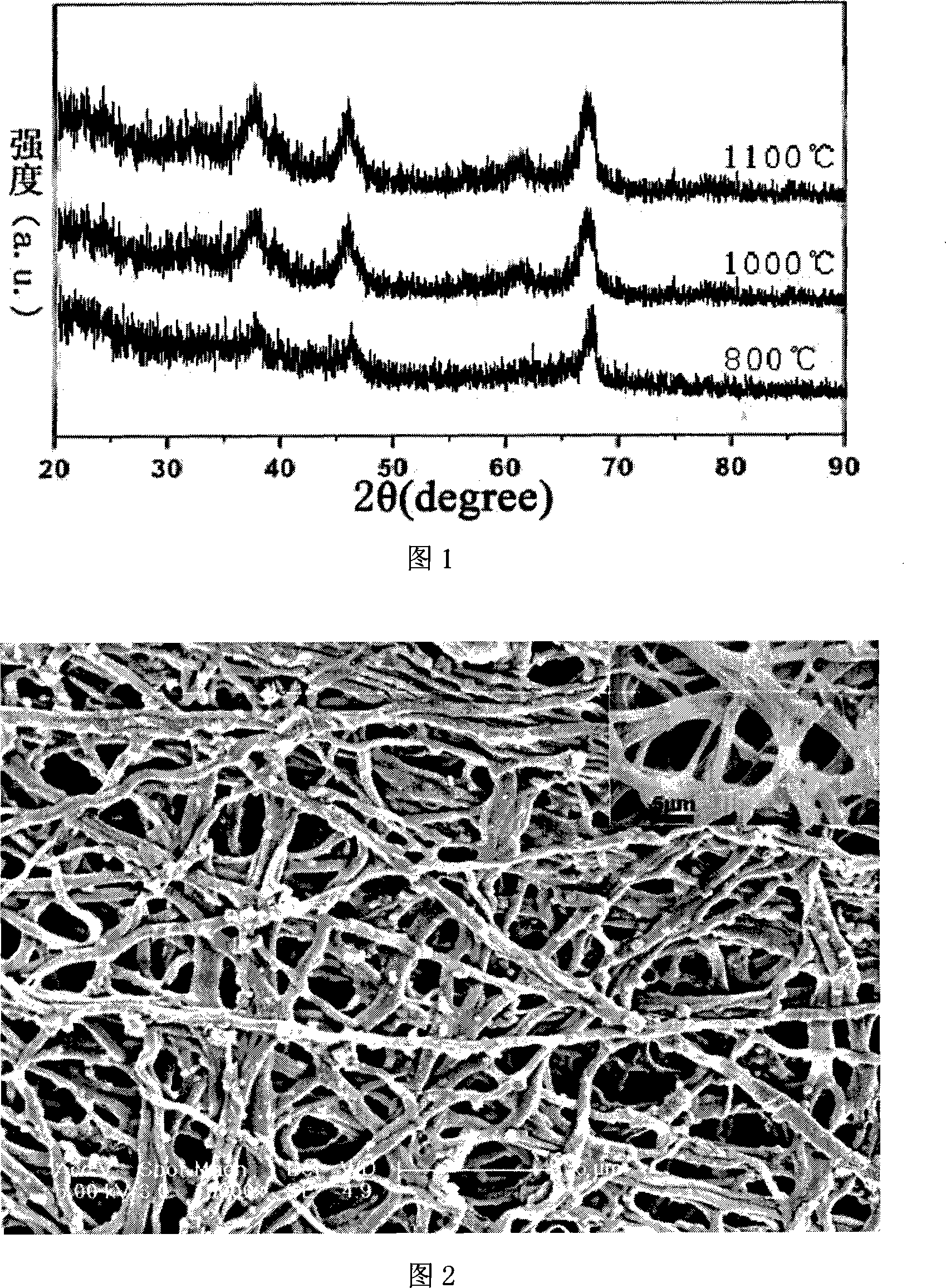

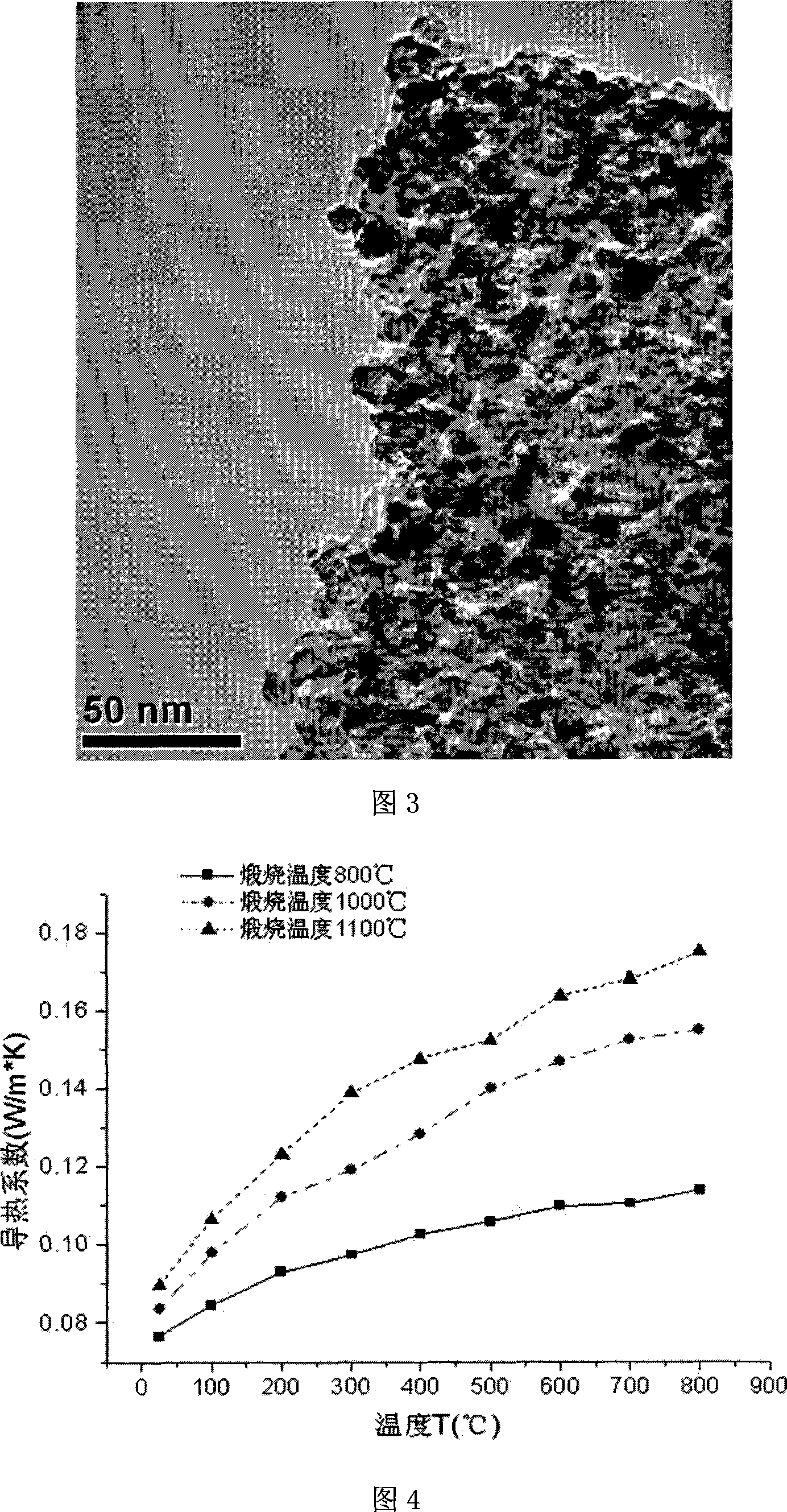

Embodiment 1

[0021] Select fresh poultry eggs, remove the liquid content, rinse the eggshells with clean water, soak in 1M hydrochloric acid solution for about 10 minutes to peel off the egg film, rinse thoroughly with clean water and deionized water three times, remove and blow at room temperature Dry in the air; take 2g of the above-mentioned clean and dry biological material egg film that has been treated, add the solution obtained by slowly adding 250g of distilled water to the aluminum chloride solution system (25g of crystalline aluminum chloride under constant stirring, and mix with 1M NaOH Adjust the solution to pH = 4) after soaking for 24 hours, take it out, dry it at 50°C for 2 hours, put it into the induction cooker and heat it to 800°C at a heating rate of 20°C / min and keep it at a constant temperature for 2 hours, then stop heating. Remove after cooling to room temperature. The resulting white flake-like substance is a ceramic material with a hierarchical porous network struc...

Embodiment 2

[0023] Select fresh poultry eggs, remove the liquid content, rinse the eggshell with clean water, put it into 1M hydrochloric acid solution for about 10 minutes to peel off the egg film, rinse it fully with clean water and deionized water three times, remove it and blow it at room temperature. Dry in the air; take 2g of the above-mentioned clean and dry biological material egg film that has been treated, add the solution obtained by slowly adding 250g of distilled water to the aluminum chloride solution system (25g of crystalline aluminum chloride under constant stirring, and mix with 1M NaOH Adjust the solution to pH = 4) after soaking for 24 hours, take it out, dry it at 50°C for 2 hours, put it into the induction cooker and heat it to 1000°C at a heating rate of 25°C / min and keep it at a constant temperature for 1.5 hours. Remove after cooling to room temperature. The resulting white flake-like substance is a ceramic material with egg-film hierarchical porous network struct...

Embodiment 3

[0025] Select fresh poultry eggs, remove the liquid content, rinse the eggshell with clean water, put it into 1M hydrochloric acid solution for about 10 minutes to peel off the egg film, rinse it fully with clean water and deionized water three times, remove it and blow it at room temperature. Dry in the air; take 2g of the above-mentioned clean and dry biological material egg film that has been treated, add the solution obtained by slowly adding 250g of distilled water to the aluminum chloride solution system (25g of crystalline aluminum chloride under constant stirring, and mix with 1M NaOH Adjust the solution to pH = 4) after soaking for 24 hours, take it out, dry it at 50°C for 2 hours, put it into the induction cooker and heat it to 1100°C at a heating rate of 30°C / min and keep it at a constant temperature for 1 hour. Remove after cooling to room temperature. The resulting white flake-like substance is a ceramic material with egg-film hierarchical porous network structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com