Immobilized enzyme carrier, immobilized enzyme and preparation method

An immobilized enzyme carrier, immobilized enzyme technology, applied to biochemical equipment and methods, fixed on or in inorganic carriers, fixed on/in organic carriers, etc., can solve the problem of unsatisfactory reusability, Difficulty in recovery and reuse, obstacles to large-scale application, etc., to achieve good operational stability, good activity recovery rate, and good enzyme loading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] 1. Preparation of immobilized enzyme carrier

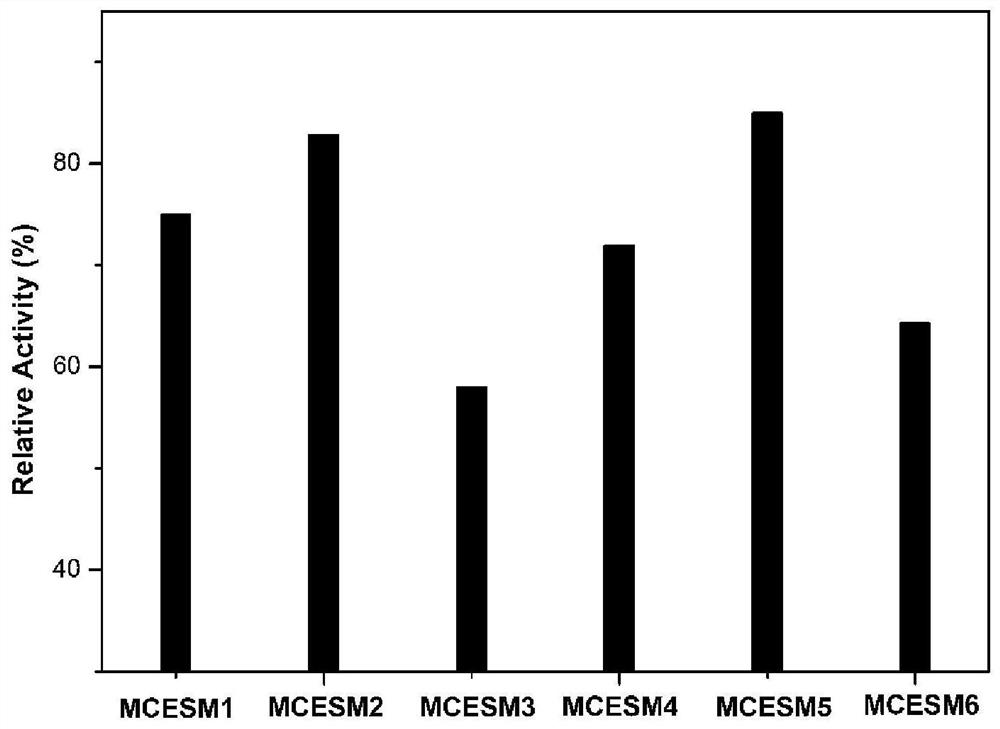

[0049] 1.1 Effect of ESMP on the performance of immobilized enzyme carrier

[0050] 0.5g Fe 3 o 4 (Preparation conditions refer to Fe in MCESM1 3 o 4 Preparation method) and 20 mL filtered chitosan solution (3.5% mass concentration) were stirred at room temperature for 1 h, and 10% sodium hydroxide solution (25% ethanol: 75% water, v / v) was added dropwise thereto to obtain Large particles were washed sequentially with deionized water, ethanol solution (50% ethanol: 50% water, v / v) and deionized water until neutral. The resulting large particles were incubated at 50°C in 20mmol / L genipin solution, rinsed with deionized water after 5h, and the BG and Fe 3 o 4 / CS was added to a 10mL reactor at a mass ratio of 1:8, β-glucosidase was added to 1mL PBS buffer (pH7.0) and incubated at 4°C for 3h, and Fe was collected under the action of a magnetic field. 3 o 4 / CS / ESMP@BG. The measured enzyme activity was 52.4%.

[0051]...

Embodiment 1

[0066] Embodiment 1: magnetic chitosan eggshell membrane (Fe 3 o 4 / CS / ESMP) comprises the following steps:

[0067] Step 1: dissolving chitosan powder in 2% (w / v) acetic acid aqueous solution, stirring at 50° C. for 4 h to obtain a 0.035 g / mL chitosan solution, and then filtering it with gauze. In 20mL containing FeCl 2 4H 2 O 0.89g, FeCl 3 ·6H 2 In O 2.42g aqueous solution, the 2% (w / v) acetic acid aqueous solution of chitosan (deacetylation degree ≥ 85%, viscosity is 50mPa.s) that the mass percent concentration after adding 20mL filter wherein is 0.035g / mL , stirred at room temperature for 1 h, added 1.4 g ESMP to it, mixed and stirred for 2 h, then raised the temperature to 80 ° C, added ammonia water as a precipitant, stirred for 1 h, and then added dropwise 10% sodium hydroxide solution (25% ethanol : 75% water, v / v), the obtained large particles were washed with deionized water, ethanol (50% ethanol: 50% water, v / v) and deionized water successively until neutral. ...

Embodiment 2

[0069] Embodiment 2: Preparation of immobilized β-glucosidase

[0070] The BG prepared by embodiment 1 and Fe 3 o 4 / CS / ESMP was added to the 10mL reactor according to the mass ratio of 1:8, and β-glucosidase was added to 1mL PBS buffer (pH 7.0) and incubated at 4°C for 3h, and the β-glucosidase was immobilized on the cross-linked substrate. After the particles were loaded, all samples were washed with sodium phosphate buffer solution at pH 7.0 until no protein was detected, and Fe was collected under the action of a magnetic field. 3 o 4 / CS / ESMP@BG.

[0071] In order to further confirm the prepared Fe 3 o 4 In the presence of the target β-glucosidase on / CS / ESMP, our detection of Fe 3 o 4 / CS / ESMP and Fe 3 o 4 / CS / ESMP@BG performed confocal laser scanning microscopy (CLSM) analysis with fluorescein isothiocyanate-labeled Fe 3 o 4 Confocal microscopy analysis of / CS / ESMP@BG see Figure 6 . From Figure 6 In the sample morphology images shown in panels A and C, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com