Method of preparing polyethylene glycol and protein fiber combined artificial cardiac valve

An artificial heart valve, protein fiber technology, applied in heart valve, medical science, prosthesis, etc., to achieve the effect of satisfying durability, preventing calcification, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

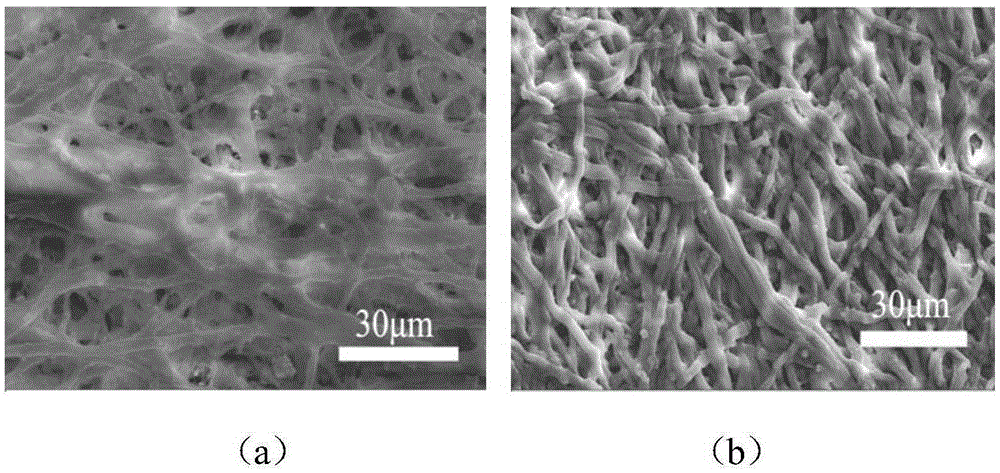

[0030] Raw materials and requirements: fresh egg membrane, polyethylene glycol, acryloyl chloride, triethanolamine (TEOA), eosin (EosinY), PBS solution, ethanol, N-vinylpyrrolidone (NVP), 40% sodium bisulfite solution, Ultrapure water (all chemical reagents are of analytical grade).

[0031] PEGDA synthesis: Polyethylene glycol diacrylate (PEGDA) is prepared by reacting polyethylene glycol (PEG) with acryloyl chloride;

[0032] Egg film treatment: remove the egg yolk and egg white in raw eggs, carefully peel off the egg film from the air cell of the egg, wash it with deionized water for 3 times, soak the egg film in acetic acid with a concentration of 8mol / L, and treat it at 4°C for 12 hours , washed three times with deionized water. Afterwards, a semicircular sample with a diameter of 12 mm was cut and soaked in a PEGDA white light pre-gelling solution with a concentration of 20% by mass for 30 minutes at room temperature;

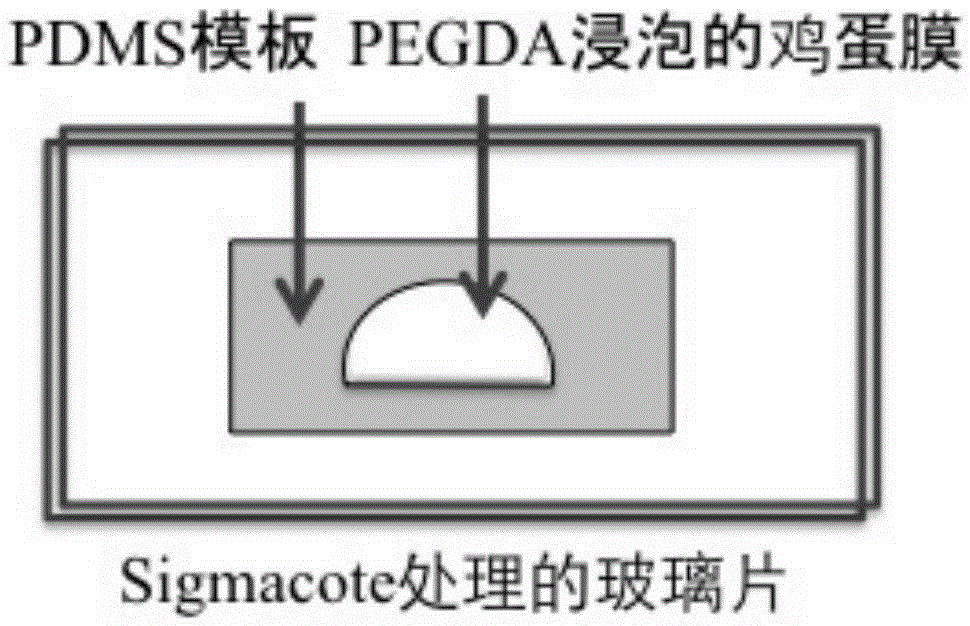

[0033] PDMS template production: prepare a 0.6mm ...

Embodiment 2

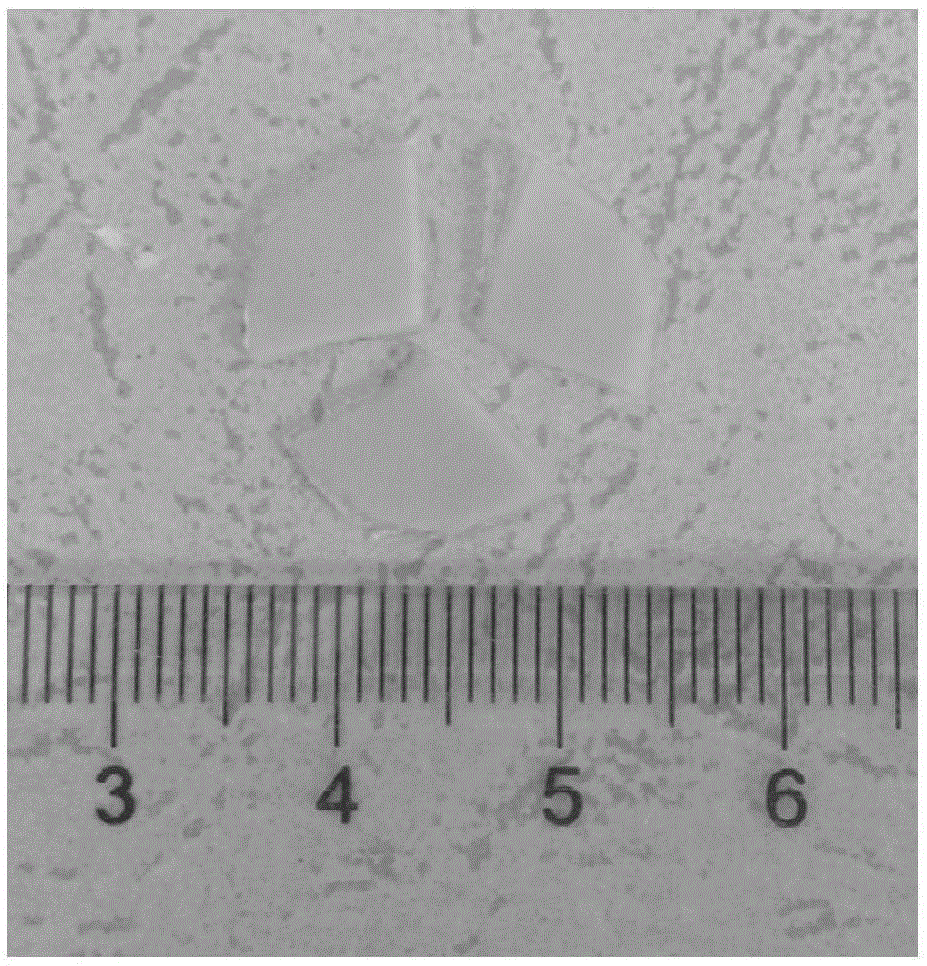

[0038] In this example, a semicircular model with a size of 12 mm (diameter) × 0.6 mm (thickness) will be prepared in the PDMS template, and 6 layers of processed egg membranes will be selected to fill the PDMS template, and the rest are the same as in Example 1. The elastic modulus of the artificial heart valve is 3.43MPa and the elongation rate reaches 43% as measured by the static tensile test.

Embodiment 3

[0040] In this example, a semicircular model with a size of 12 mm (diameter) × 0.6 mm (thickness) will be prepared in the PDMS template, and 4 layers of processed egg membranes will be selected to fill the PDMS template, and the rest are the same as in Example 1. The elastic modulus of the artificial heart valve is 3.30MPa and the elongation rate reaches 35% as measured by the static tensile test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com