Maca coffee producing device and method

A technology of coffee and maca, which is applied in the direction of coffee extraction, etc., can solve problems such as complicated process, and achieve the effect of simple process, preventing enzymatic hydrolysis, and uniform product particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

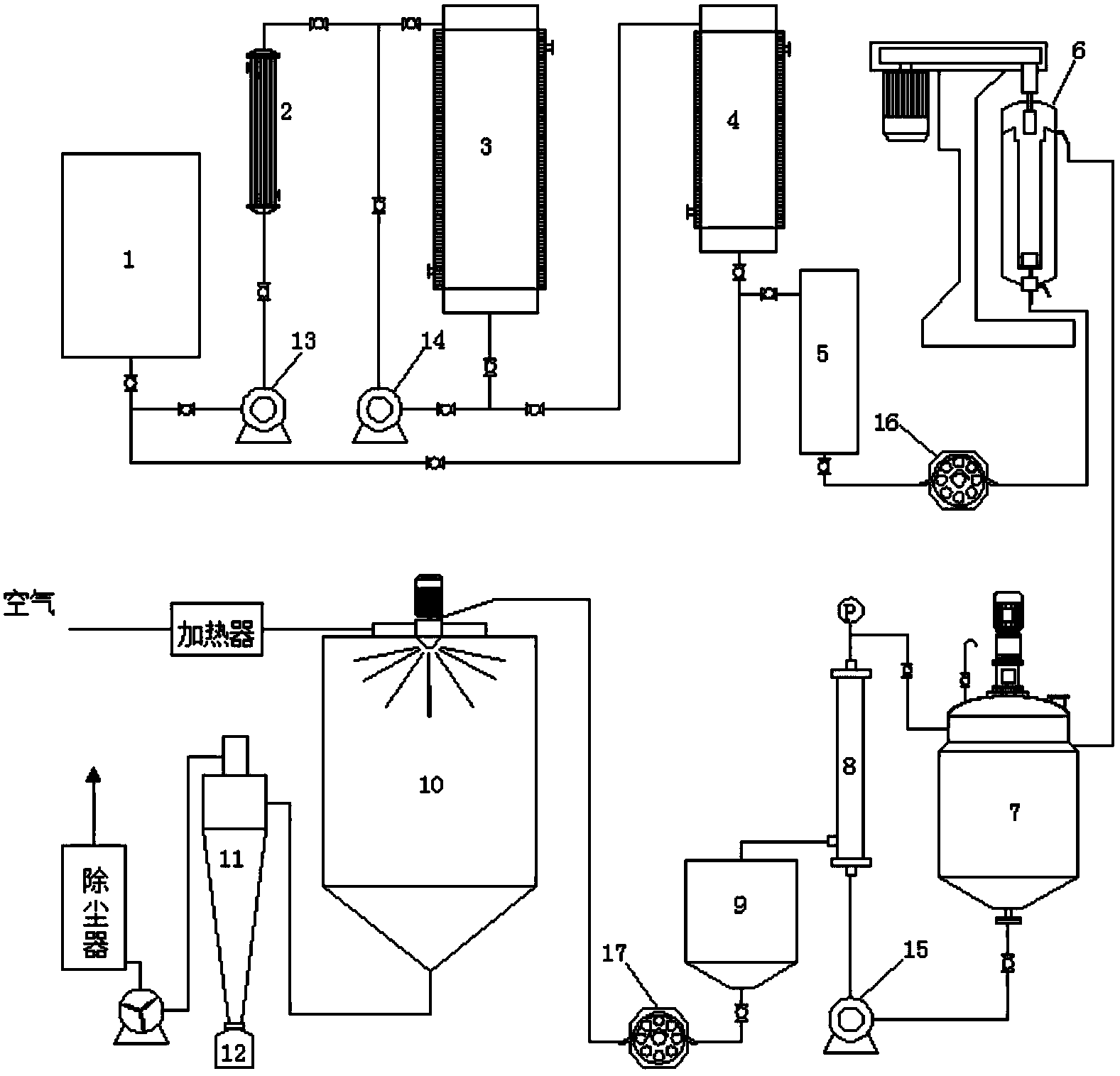

[0035] A device for producing maca coffee, characterized in that it comprises a water storage tank 1, a first booster pump 13, a preheater 2, an extraction tank 3, a cooling tank 4, an extraction liquid receiving tank 5, a centrifuge 6, a stirring Tank 7, microfiltration membrane equipment 8, microfiltrate receiving tank 9, spray drier 10, cyclone separator 11 and product collection tank 12 are connected sequentially through pipelines, between the feed port and the discharge port of the extraction tank 3 Through circulation pump 14 communication. A first peristaltic pump 16 and a second peristaltic pump 17 are provided between the extract receiving tank 5 and the centrifuge 6, and between the microfiltrate receiving tank 9 and the spray dryer 10, respectively. A second booster pump 15 is provided between the stirring tank 7 and the microfiltration membrane device 8 .

Embodiment 2

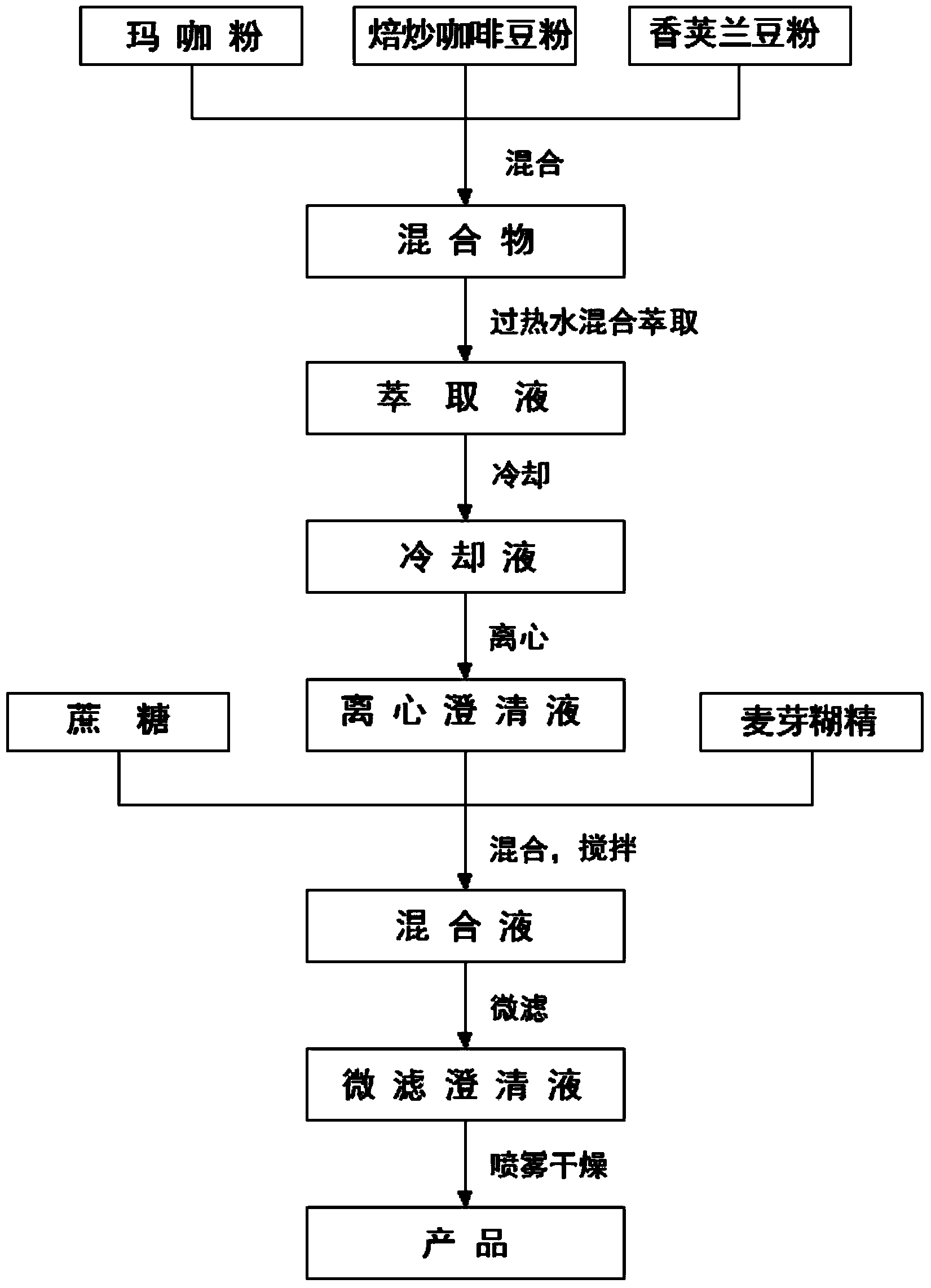

[0037] A kind of preparation method of functional maca coffee, step and condition thereof are as follows:

[0038] Step 1, superheated water preparation:

[0039] The pure water is pressurized to 5MPa by increasing the pump, and then the pure water enters the preheater and is preheated to 130°C.

[0040] Step 2. Mixed extraction with superheated water

[0041] Put 15 parts of crushed maca powder, 15 parts of roasted coffee bean powder, and 3 parts of vanilla bean powder into the superheated water extraction kettle, then pass the preheated superheated water into the extraction tank, when the temperature And when the pressure reaches 150°C and 6Mpa, turn on the circulation pump, turn off the booster pump, and carry out circulation extraction for 2 hours.

[0042] Step 3. Cooling and Filtration

[0043] After the extraction, turn off the circulation pump, then discharge the extract to the cooling tank, and cool it to 35°C, then centrifuge through a 200-mesh tube centrifuge to ...

Embodiment 3

[0049] A preparation method of functional Maca coffee, except for the following differences, other steps and process conditions thereof are the same as in Example 2:

[0050] (1) Step 1 (preparation of superheated water): boost pressure is 8Mpa, preheating temperature is 150°C.

[0051] (2) Step 2 (mixed extraction with superheated water): the parts by weight of maca powder, roasted coffee bean powder, and vanilla bean powder are respectively: 22 parts, 23 parts, 4 parts, and the superheated water extraction temperature is 180 ℃, extraction pressure 10Mpa, extraction time: 1.0h.

[0052] (3) Step 4 (adding auxiliary materials, stirring and dissolving): the added auxiliary materials are sucrose and maltodextrin, and the parts by weight are: 3 parts and 4 parts respectively.

[0053] (4) Step 5 (microfiltration and drying): 21.6 parts of maca coffee products were obtained, and the extraction recoveries of maca polysaccharides, alkaloids, and glucosinolates were 97.4%, 97.6%, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com