Growth factor-loaded micro-nano composite membrane

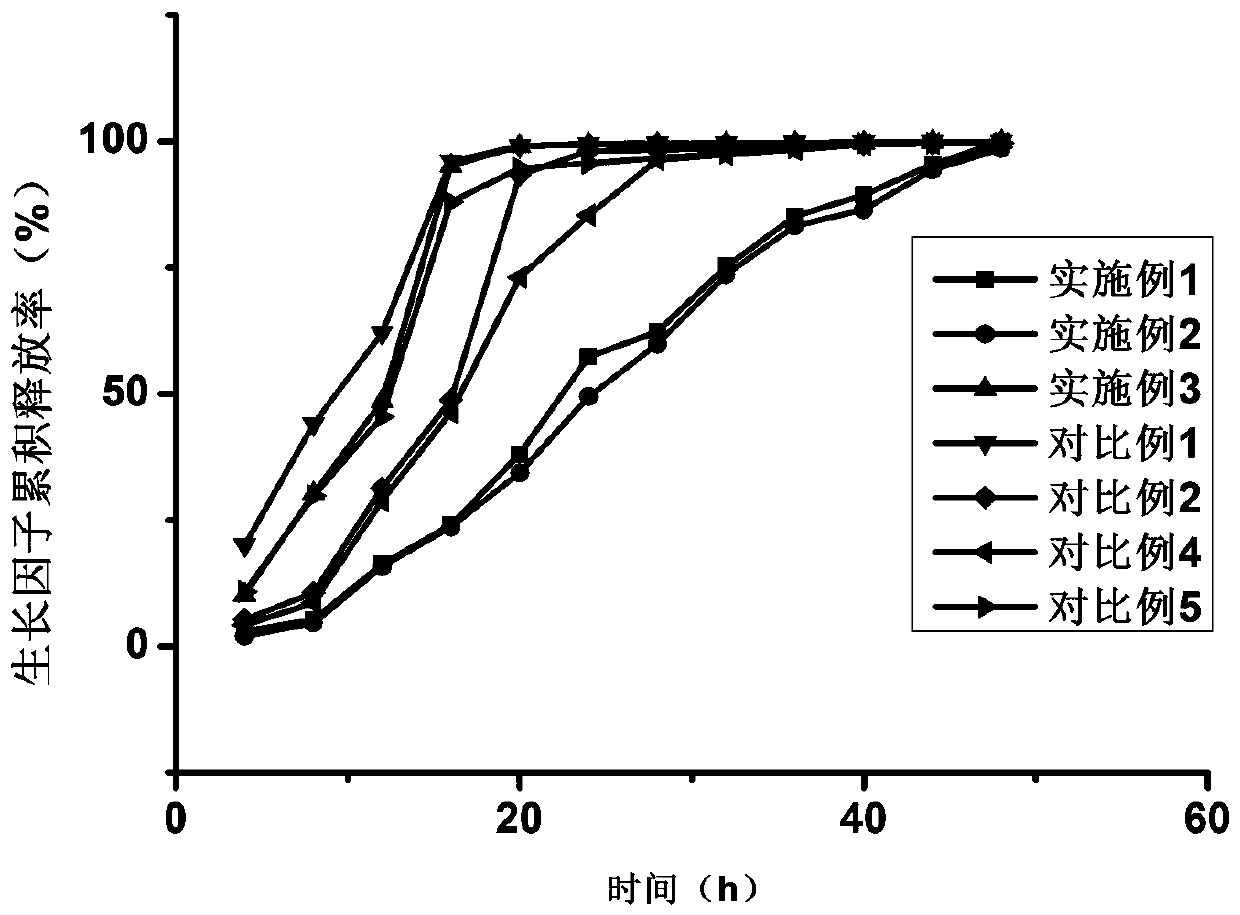

A growth factor, micro-nano technology, applied in filament/wire forming, coating, medical science, etc., can solve the problems of growth factor activity, inability to achieve biological effects, reduced stability, etc., and achieve good sustained release behavior , maintain activity and exist stability, improve the effect of existence stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]A micro-nano composite film loaded with growth factors is composed of eggshell membranes loaded with growth factors, a protein film, a hydrophilic nanofiber layer and a hydrophobic nanofiber layer, which uses the eggshell membrane as the direct carrier of growth factors, and at the same time The protein is deposited as a coating layer on the surface of the eggshell membrane loaded with growth factors by salting out to form a protein film, and then the hydrophilic nanofiber membrane and the hydrophobic nanofiber membrane are sequentially wrapped on the surface of the protein membrane by electrospinning technology Obtain; the protein film adopts poultry egg white to obtain through salting out deposition; Its specific preparation method comprises the following steps:

[0036] (1) Preparation of protein film@eggshell membrane loaded with growth factors:

[0037] 11) Take fresh goose eggs, clean them, immerse them in sodium hydroxide solution for sterilization and disinfectio...

Embodiment 2

[0047] A micro-nano composite film loaded with growth factors is composed of eggshell membranes loaded with growth factors, a protein film, a hydrophilic nanofiber layer and a hydrophobic nanofiber layer, which uses the eggshell membrane as the direct carrier of growth factors, and at the same time The protein is deposited as a coating layer on the surface of the eggshell membrane loaded with growth factors by salting out to form a protein film, and then the hydrophilic nanofiber membrane and the hydrophobic nanofiber membrane are sequentially wrapped on the surface of the protein membrane by electrospinning technology Obtain; the protein film adopts poultry egg white to obtain through salting out deposition; Its specific preparation method comprises the following steps:

[0048] (1) Preparation of protein film@eggshell membrane loaded with growth factors:

[0049] 11) Take fresh goose eggs, clean them, immerse them in sodium hydroxide solution for sterilization and disinfecti...

Embodiment 3

[0059] A micro-nano composite film loaded with growth factors is composed of eggshell membranes loaded with growth factors, a protein film, a hydrophilic nanofiber layer and a hydrophobic nanofiber layer, which uses the eggshell membrane as the direct carrier of growth factors, and at the same time The protein is deposited as a coating layer on the surface of the eggshell membrane loaded with growth factors by salting out to form a protein film, and then the hydrophilic nanofiber membrane and the hydrophobic nanofiber membrane are sequentially wrapped on the surface of the protein membrane by electrospinning technology Obtain; the protein film adopts poultry egg white to obtain through salting out deposition; Its specific preparation method comprises the following steps:

[0060] (1) Preparation of protein film@eggshell membrane loaded with growth factors:

[0061] 11) Take fresh goose eggs, clean them, immerse them in sodium hydroxide solution for sterilization and disinfecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com