Patents

Literature

183results about How to "Affect the filtering effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

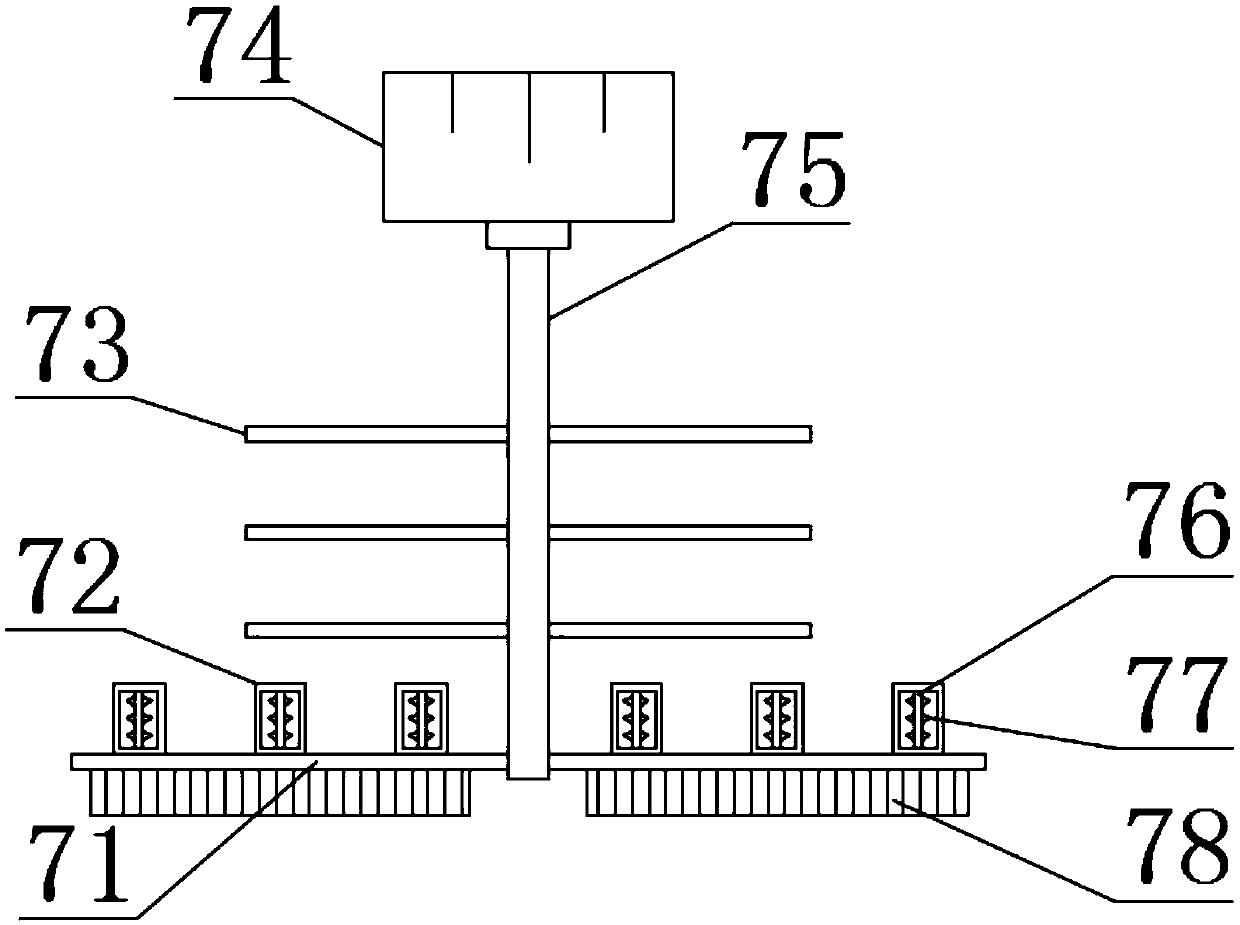

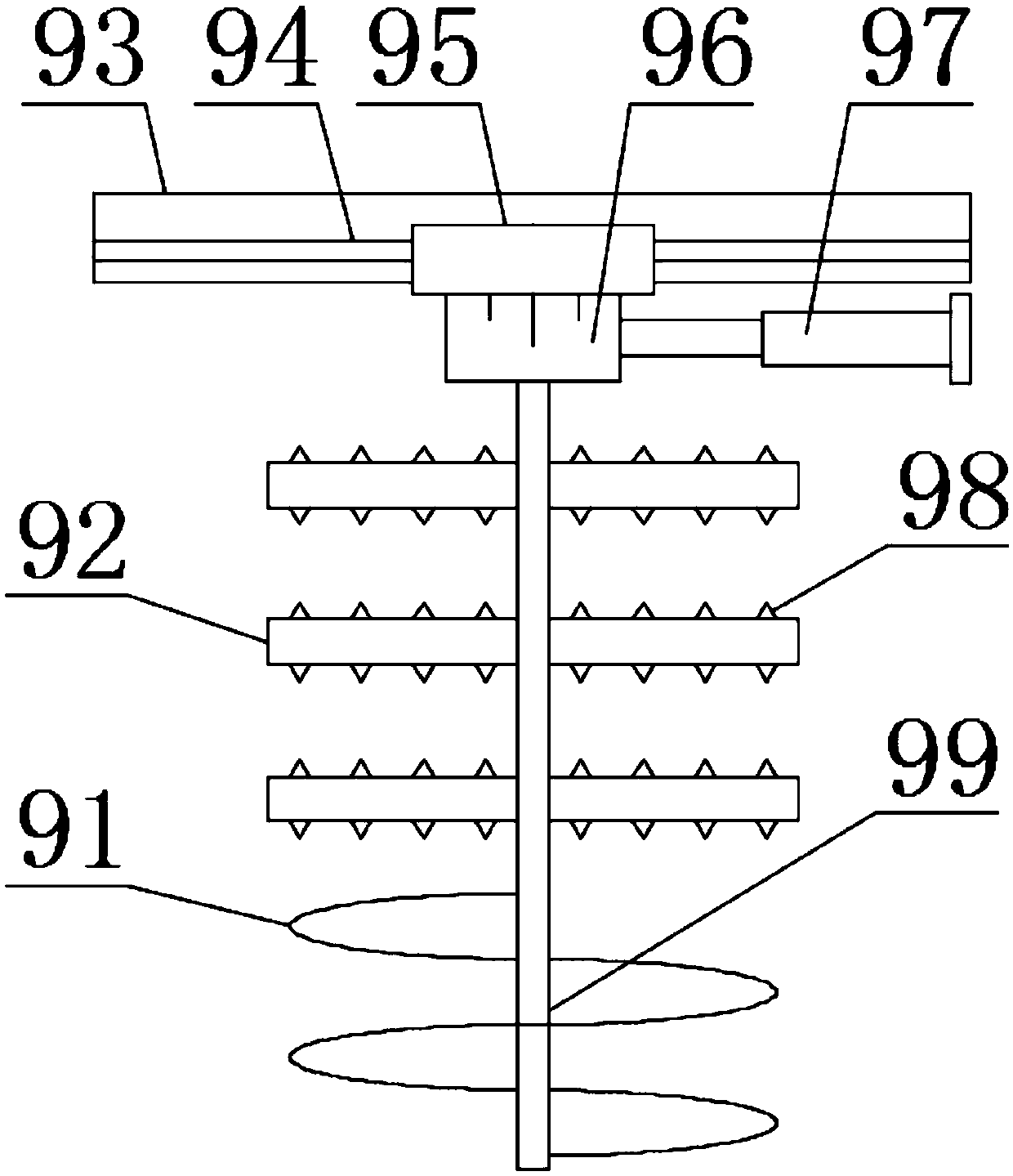

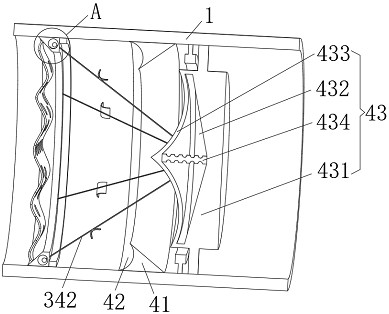

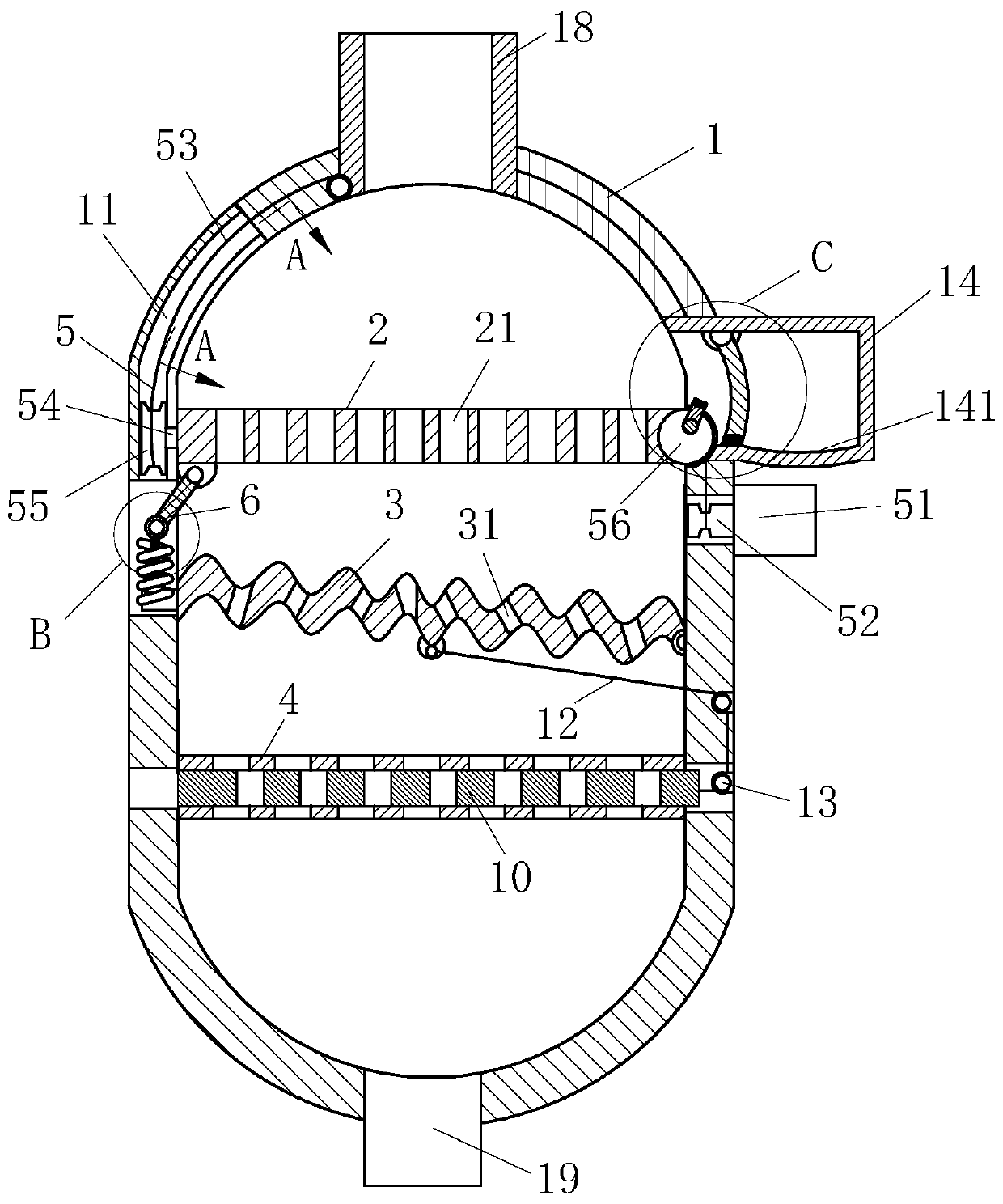

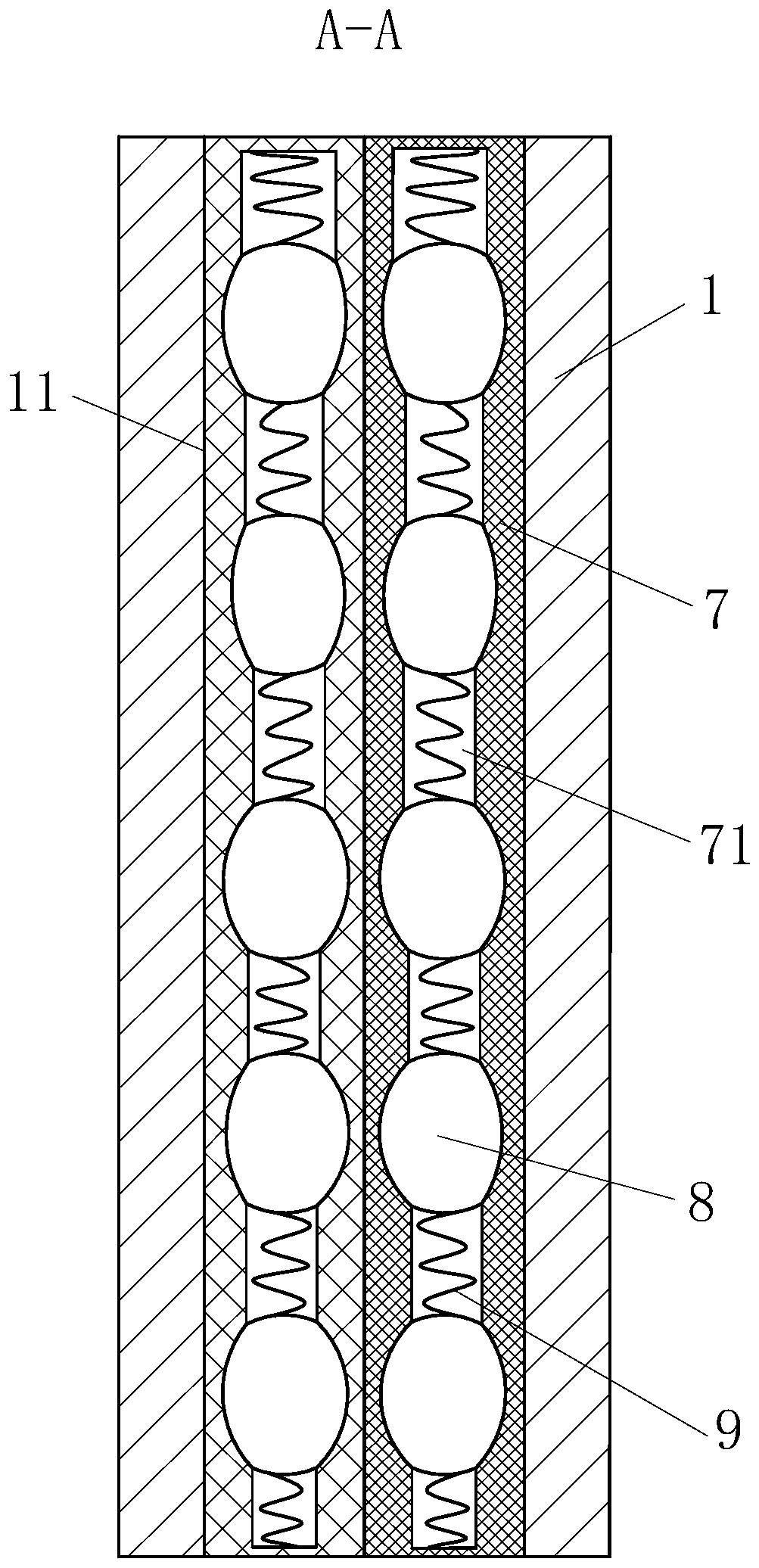

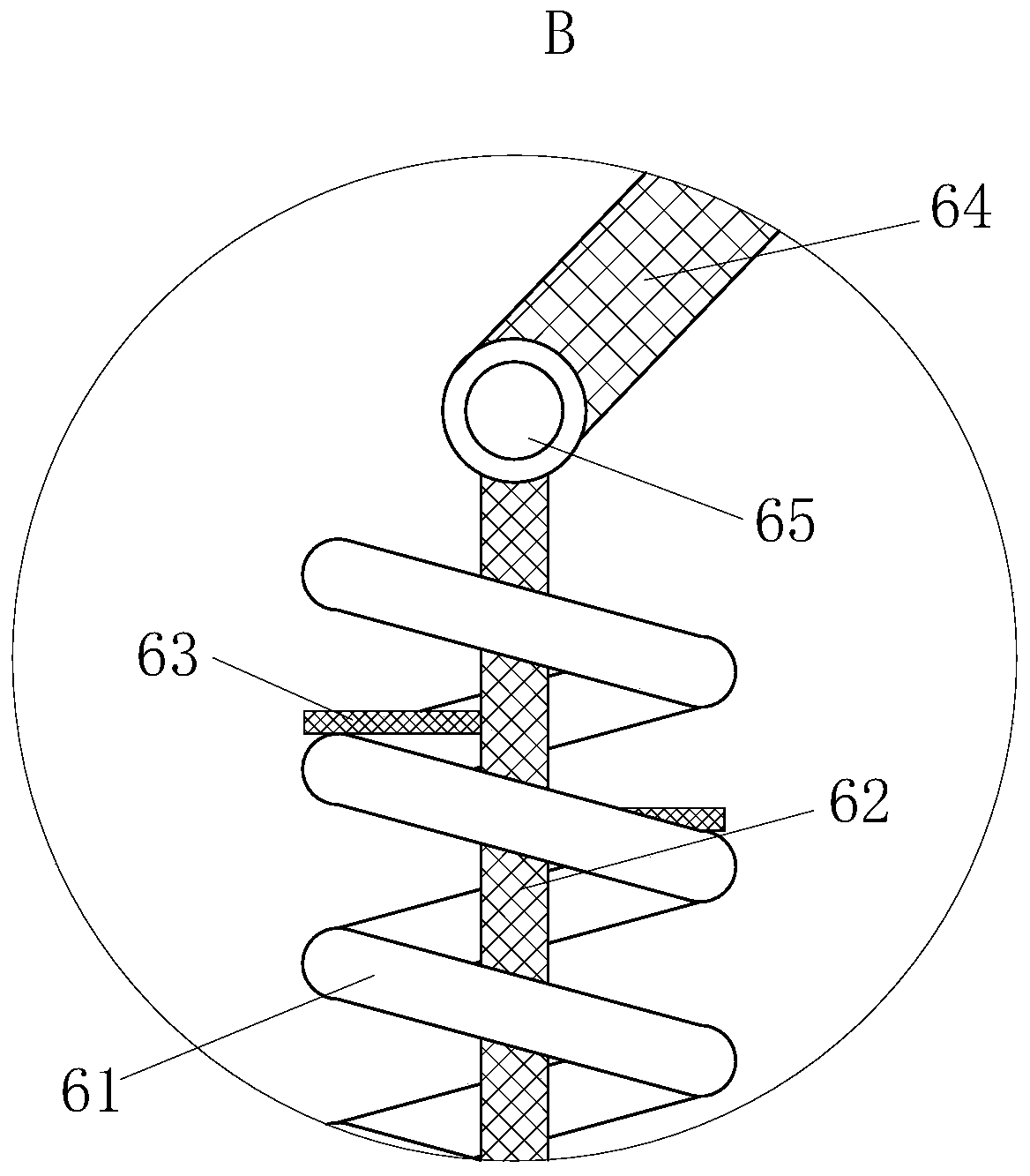

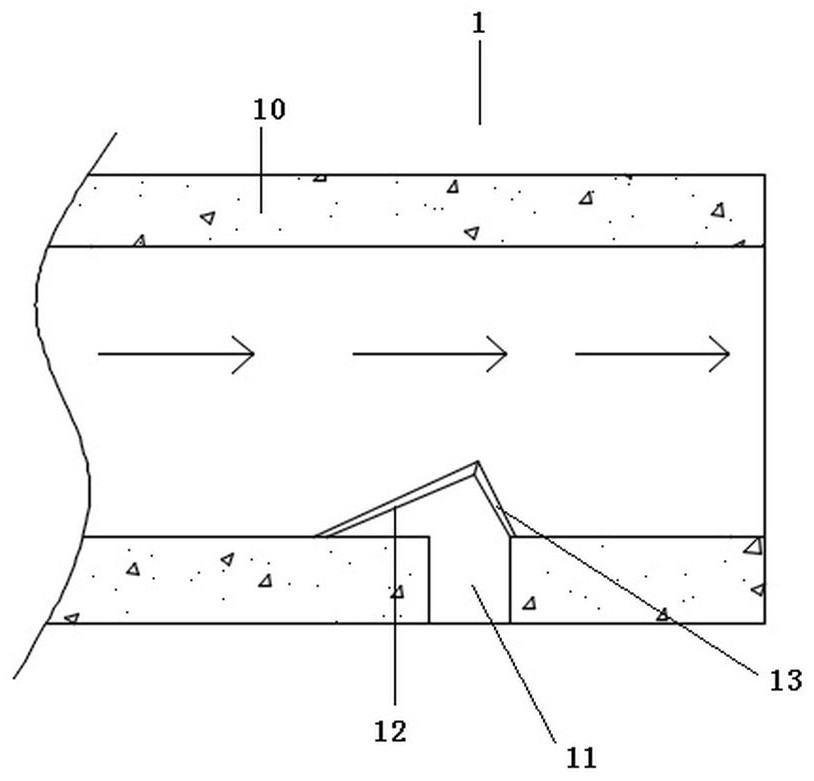

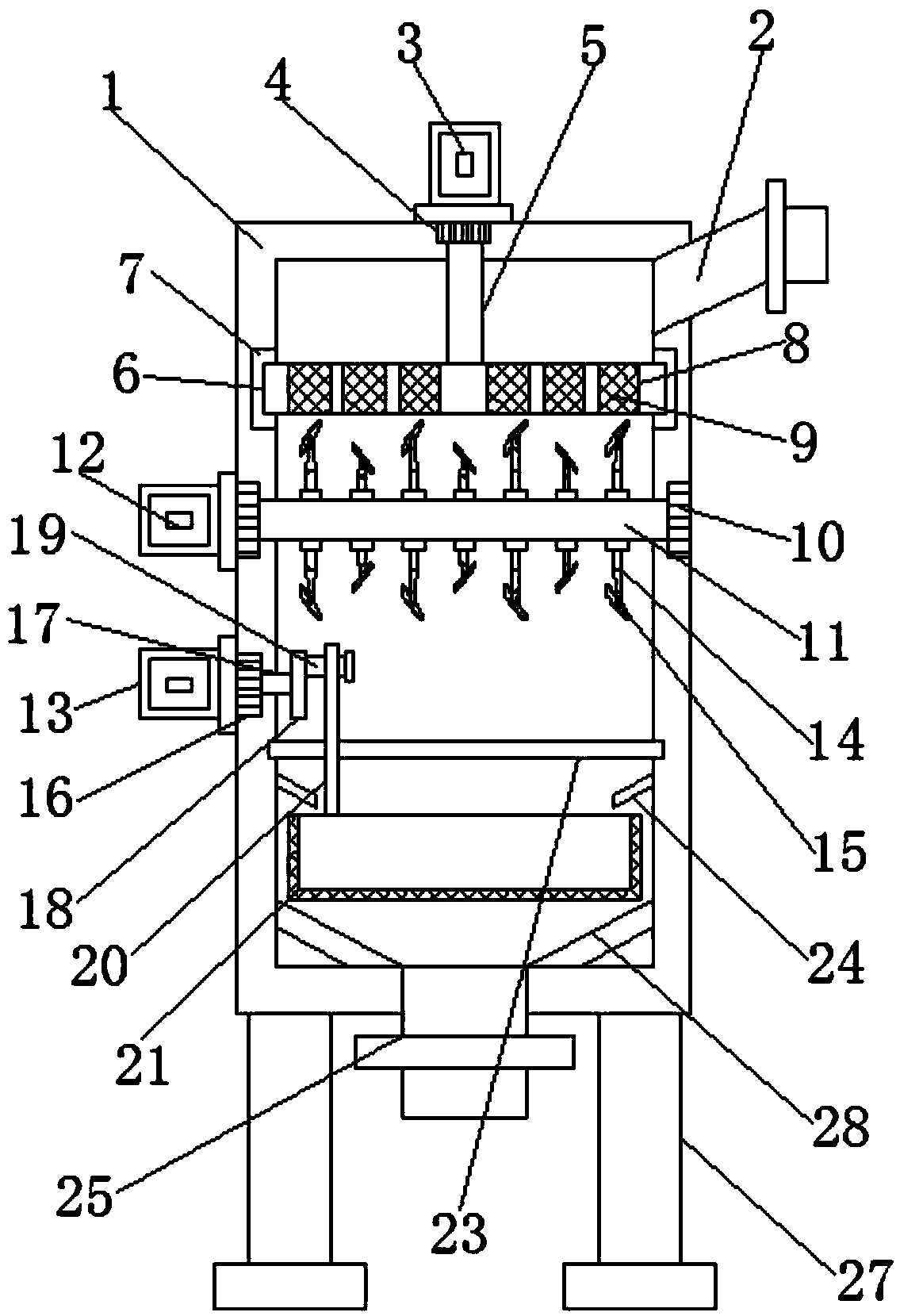

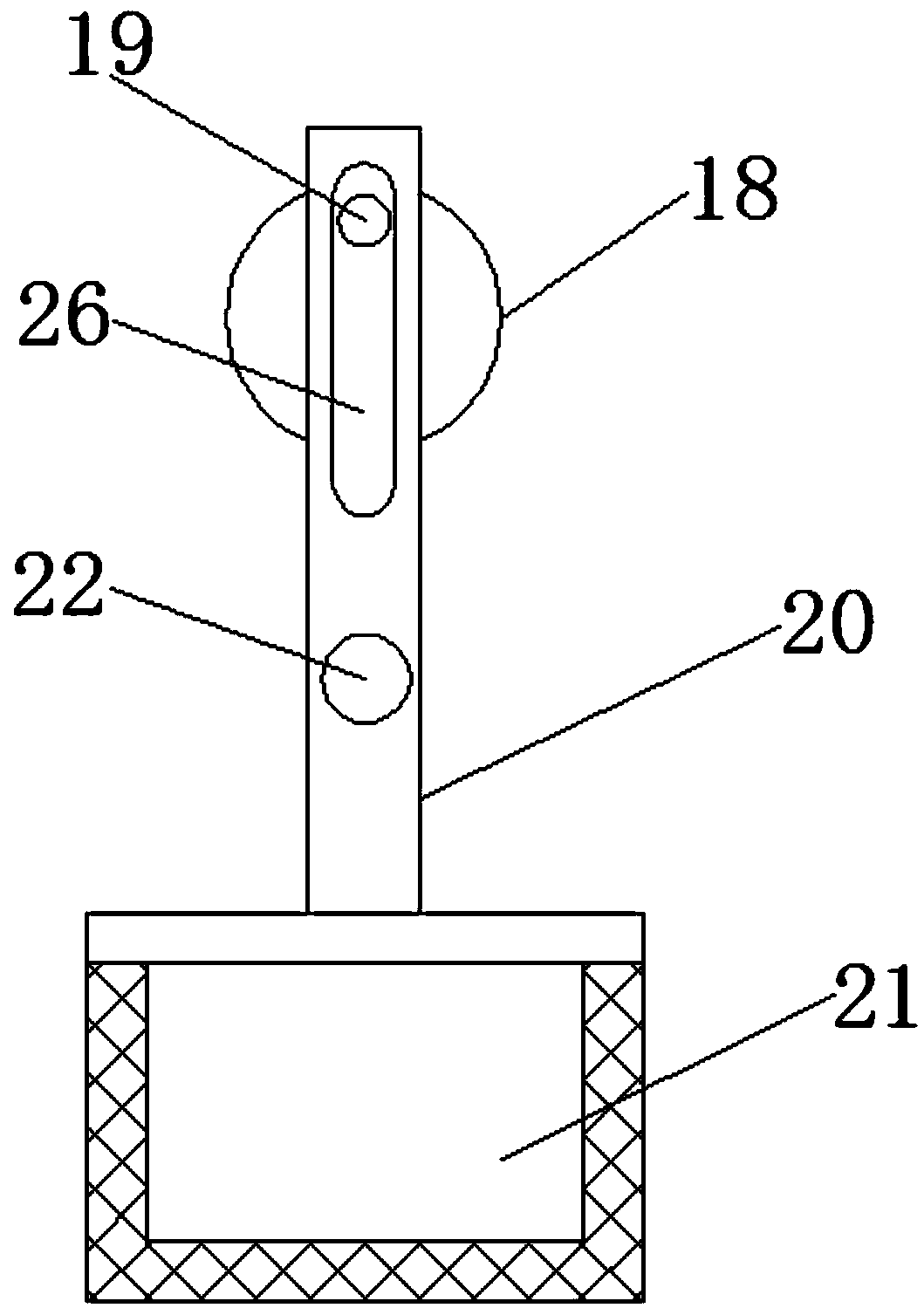

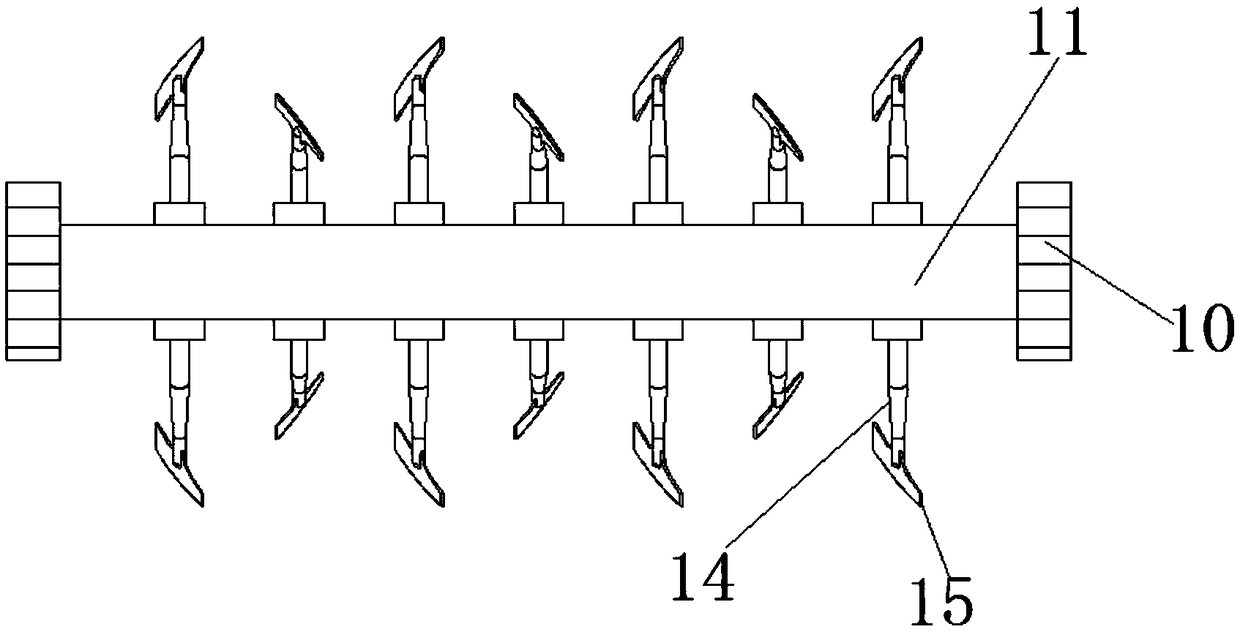

Waste gas purification equipment with functions of particulate matter removal and air pressure adjustment

InactiveCN107670424AAffect the filtering effectImprove practicalityDispersed particle filtrationTransportation and packagingInternal pressureParticulates

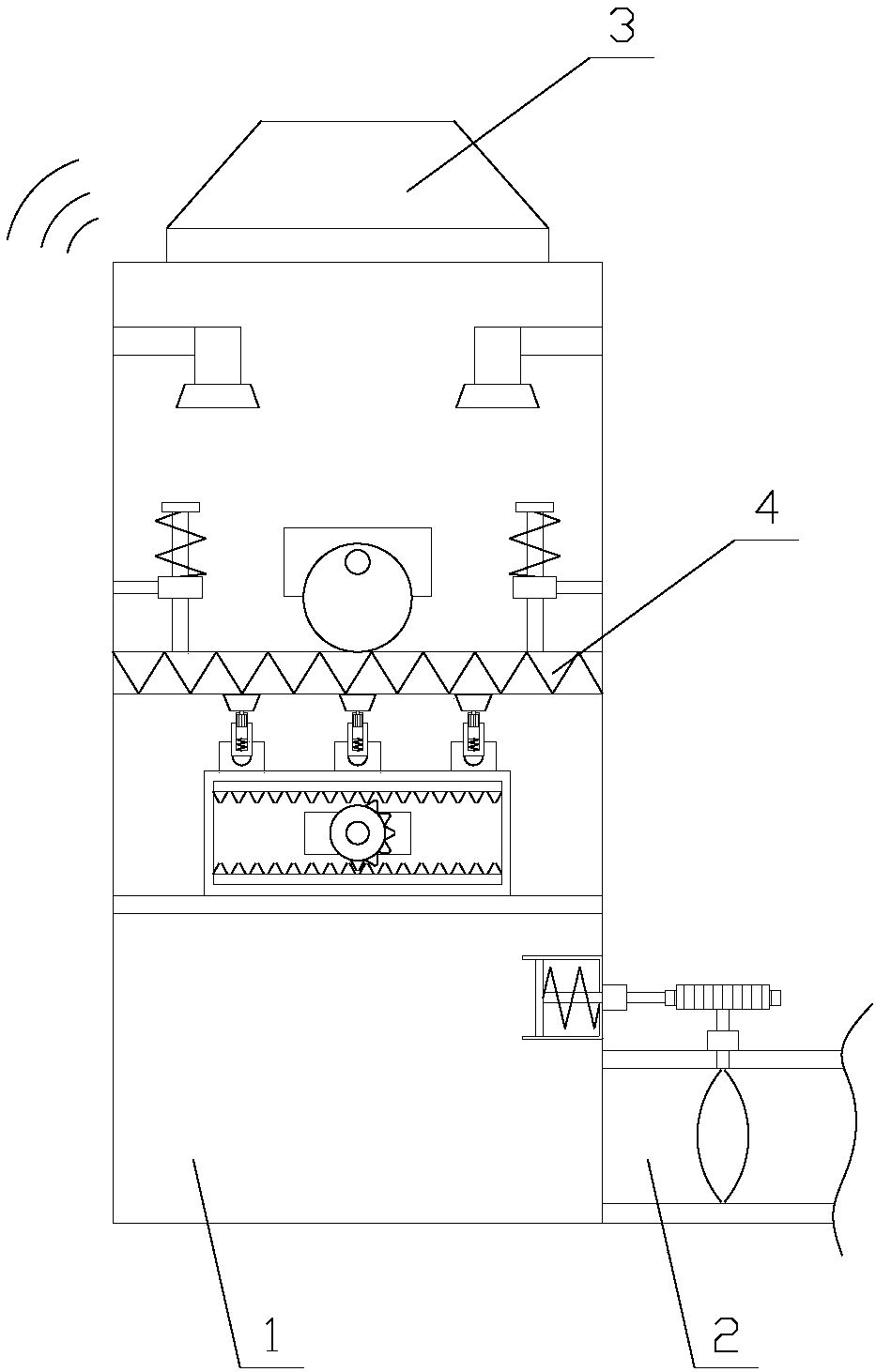

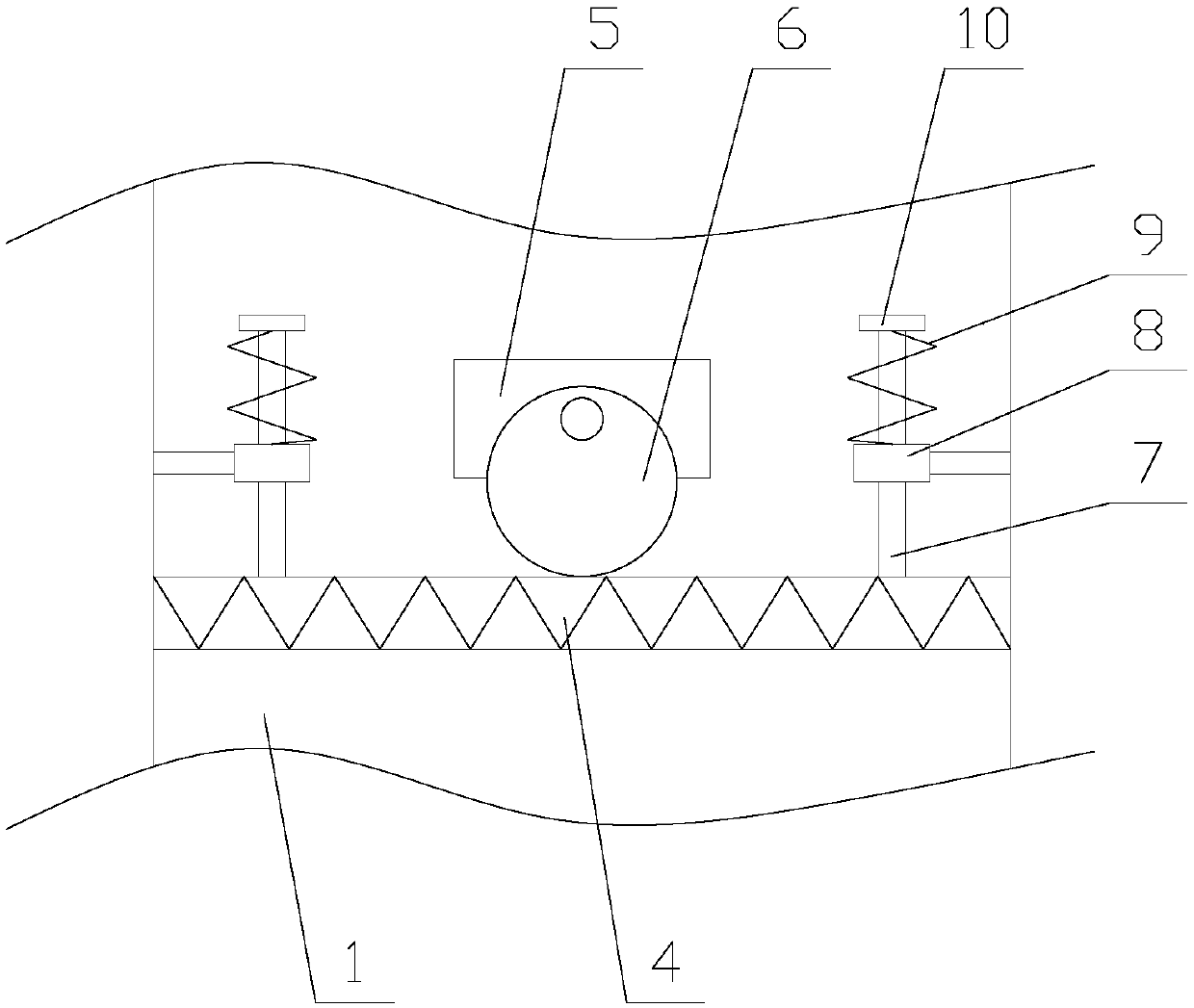

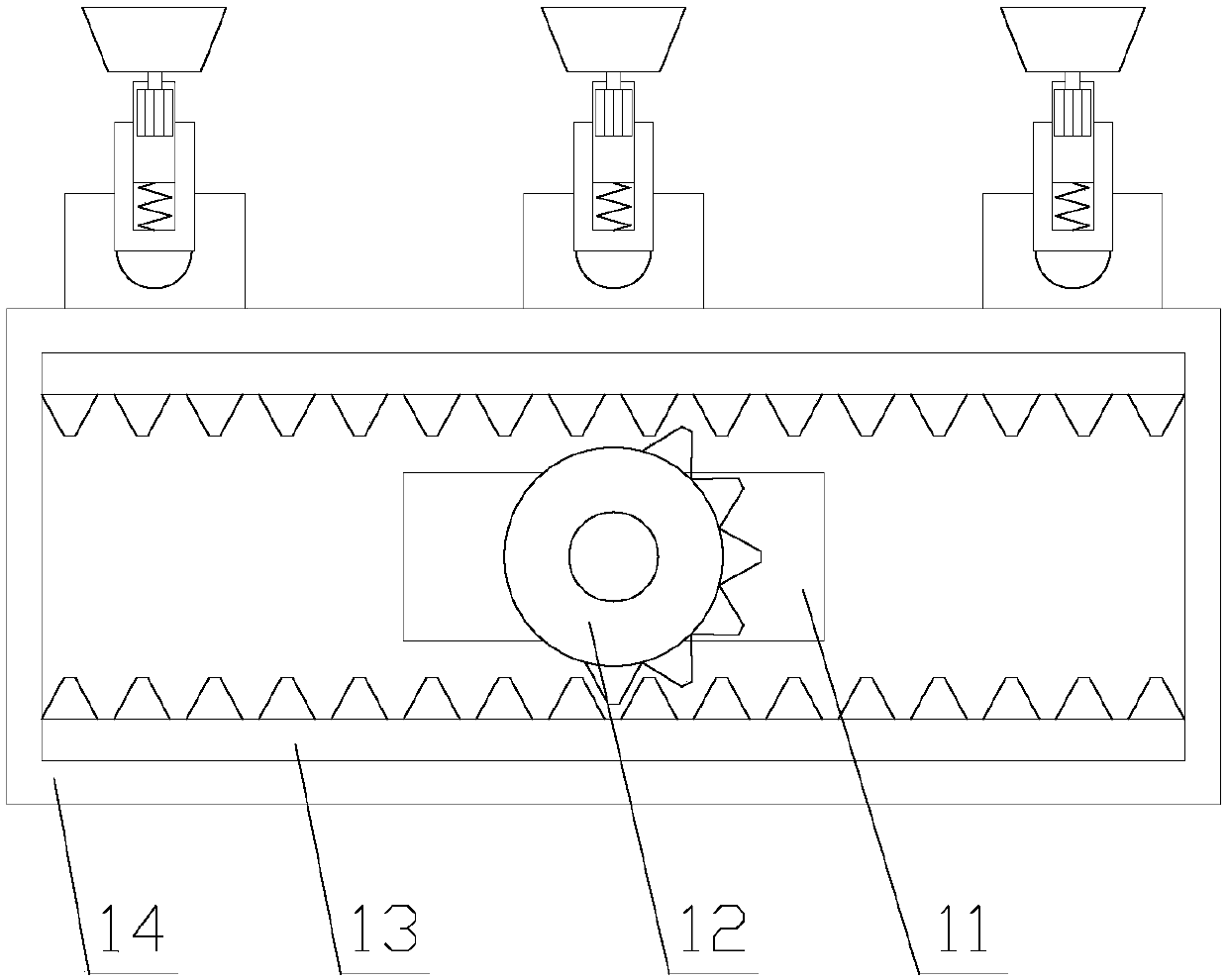

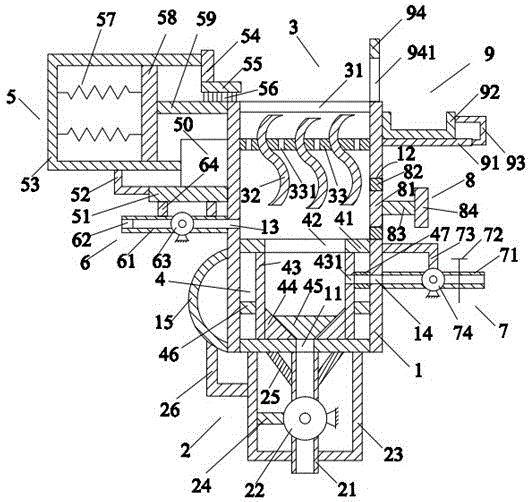

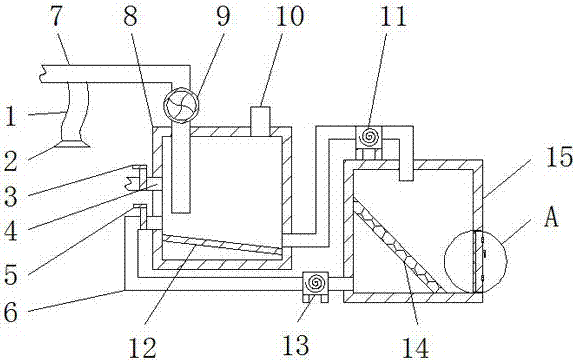

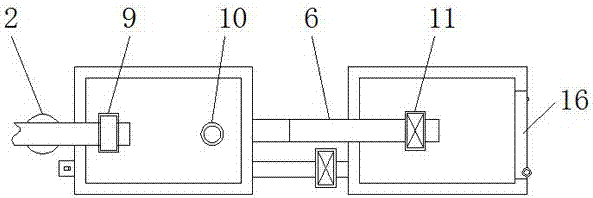

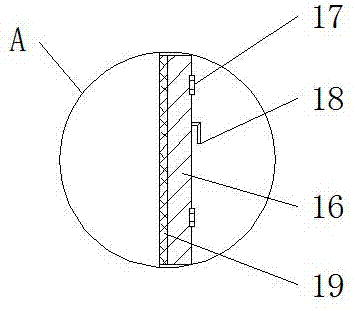

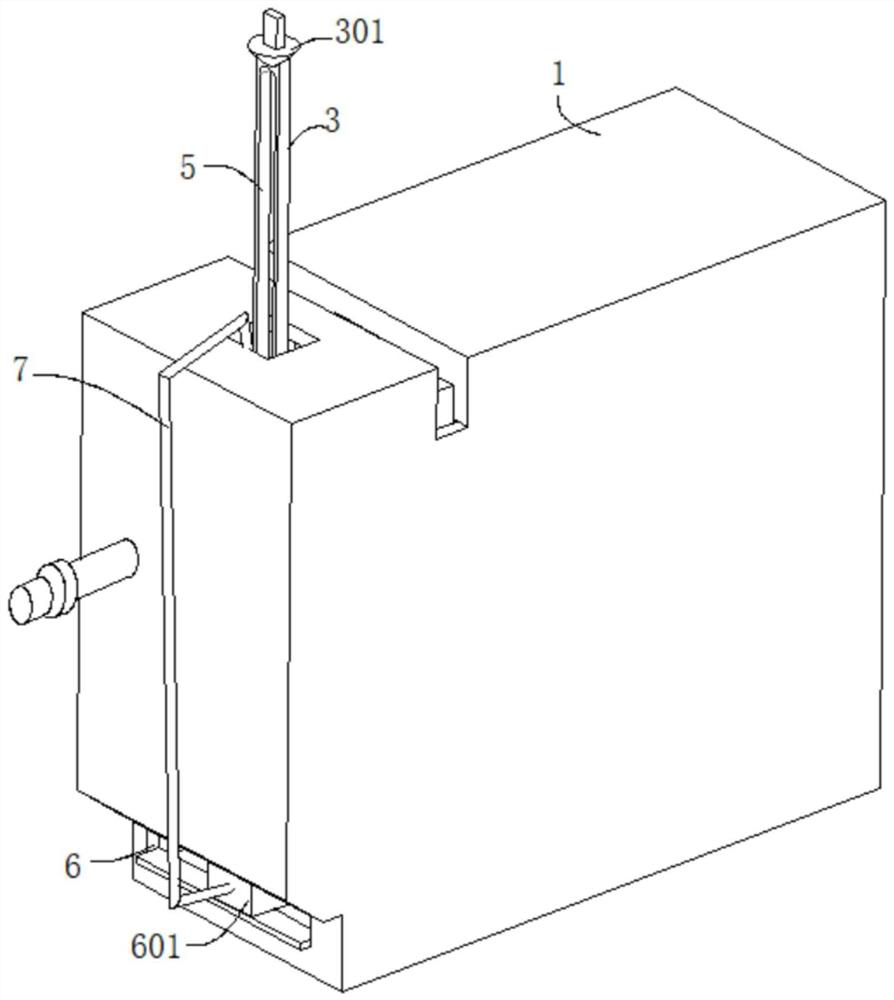

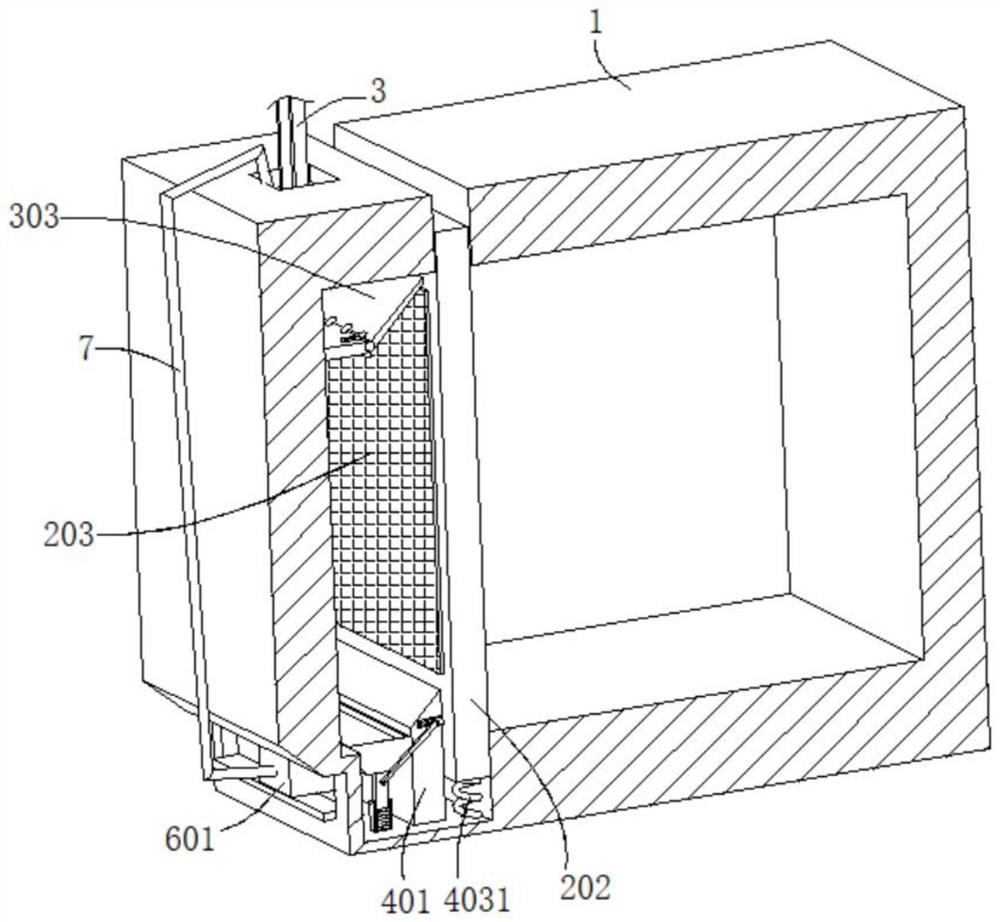

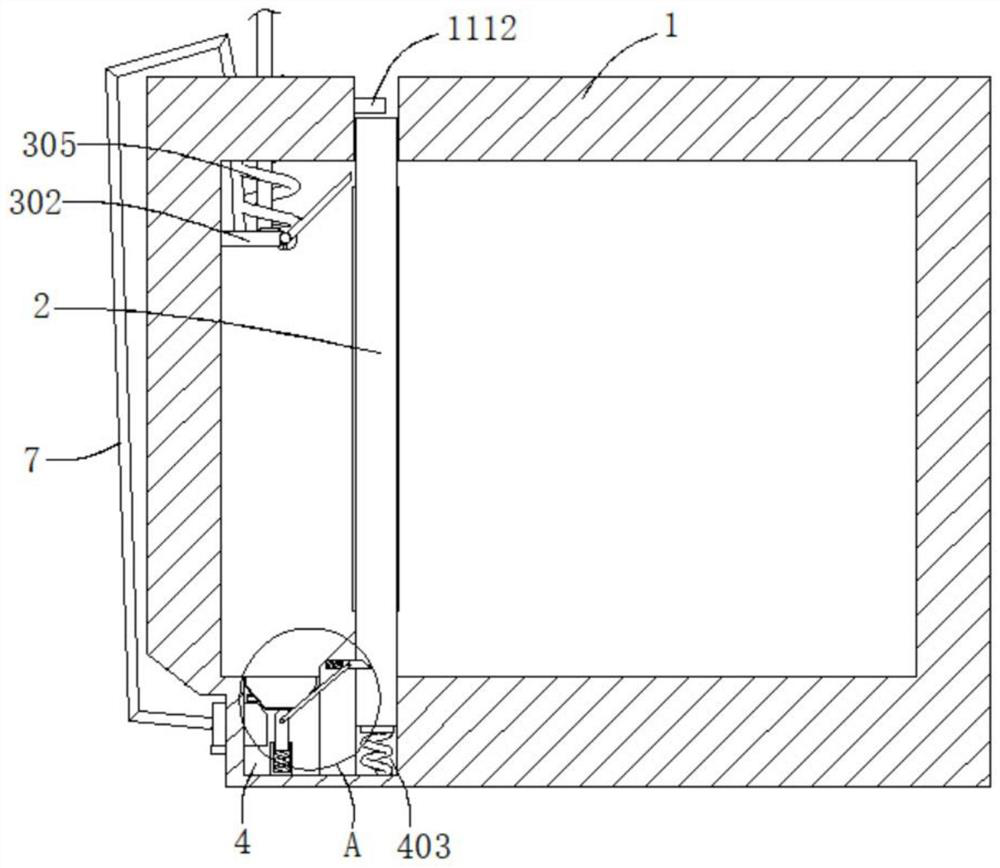

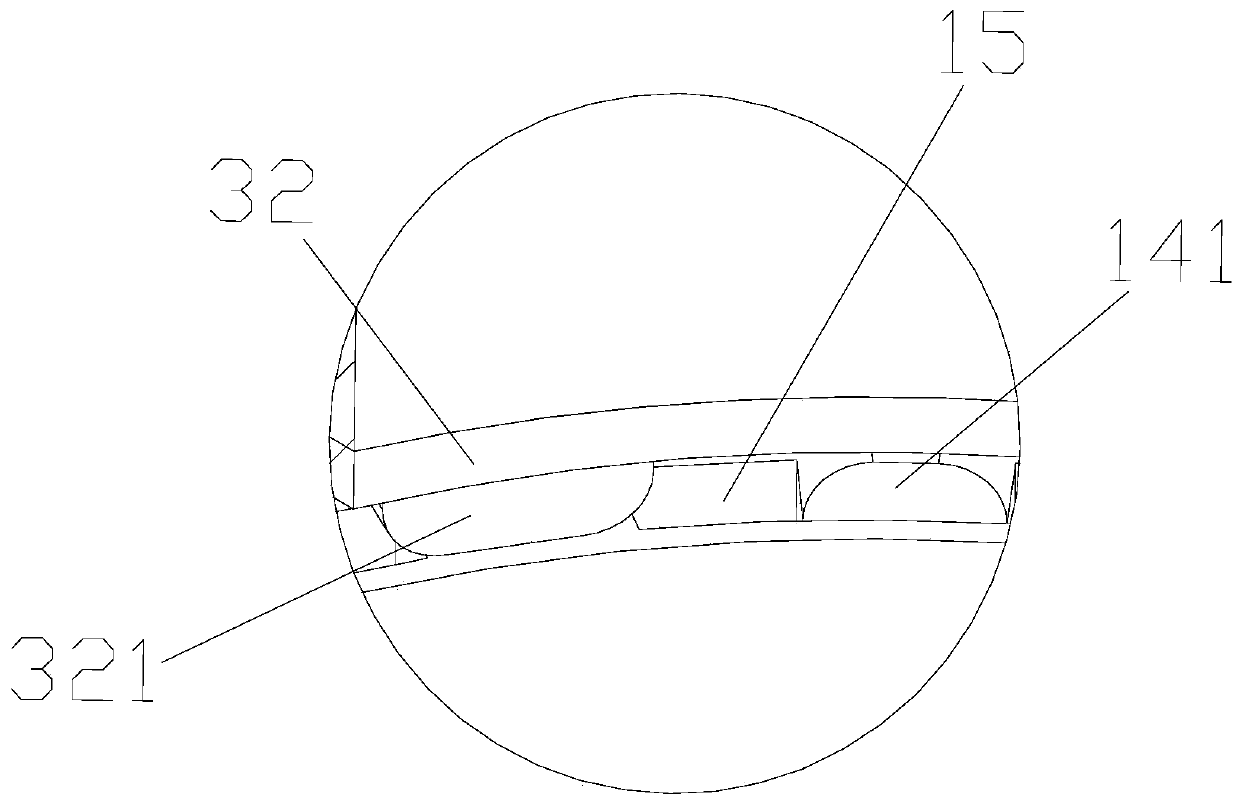

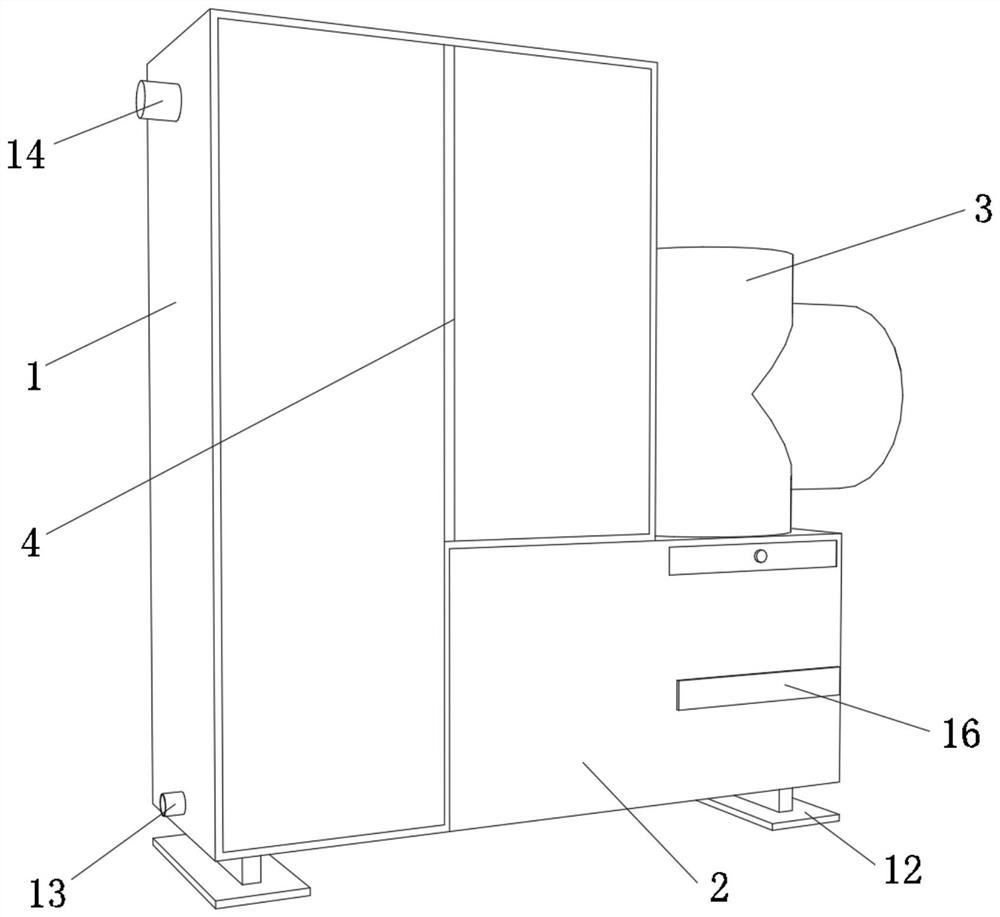

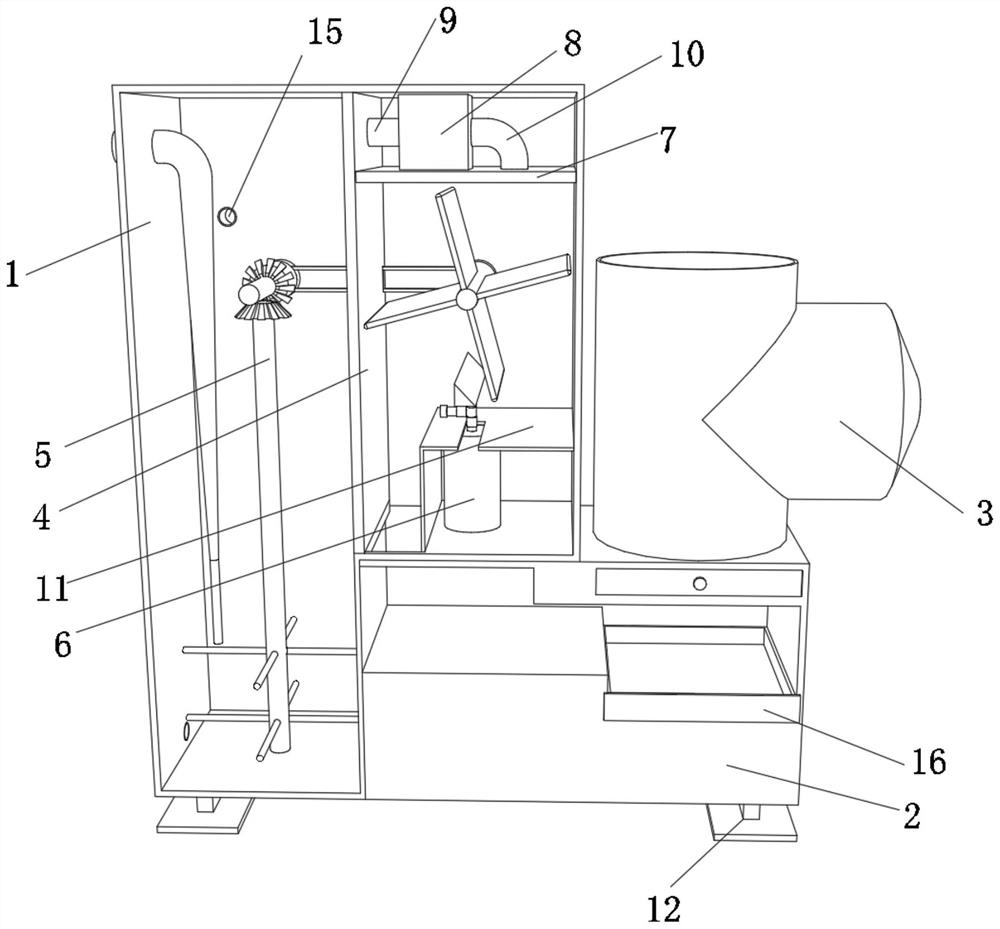

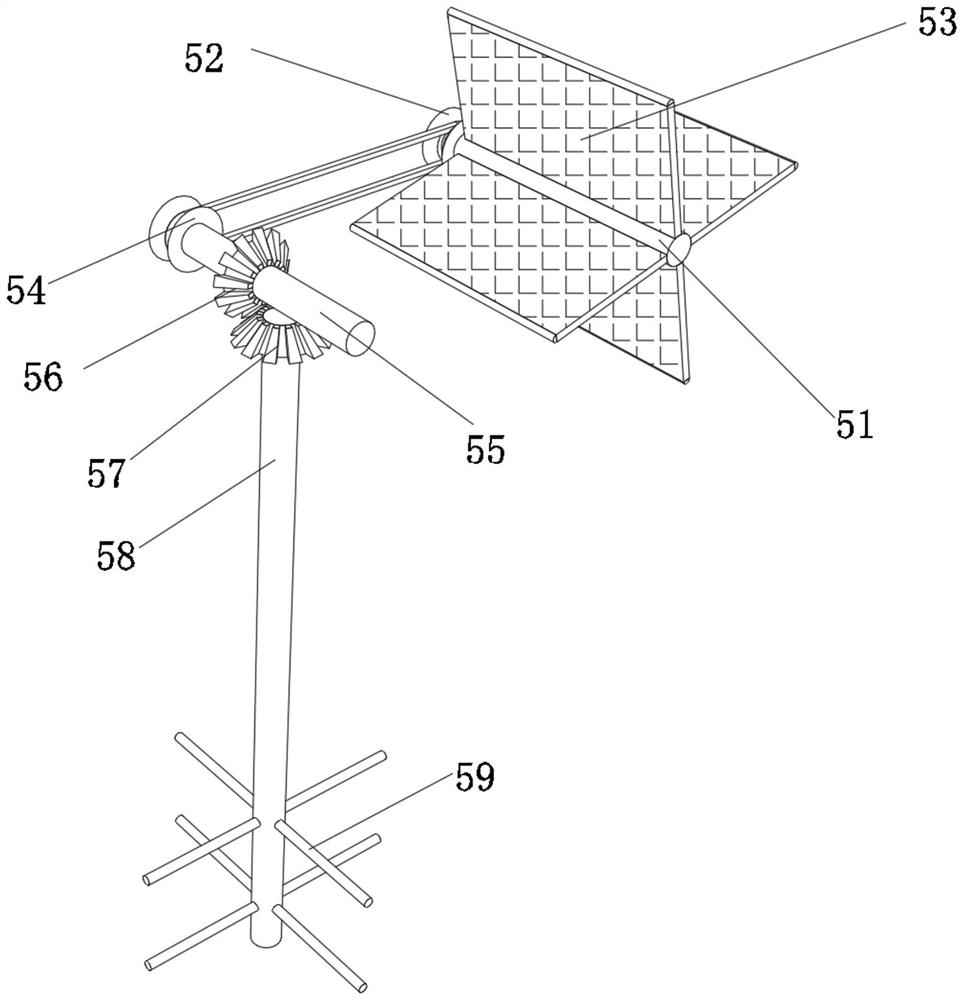

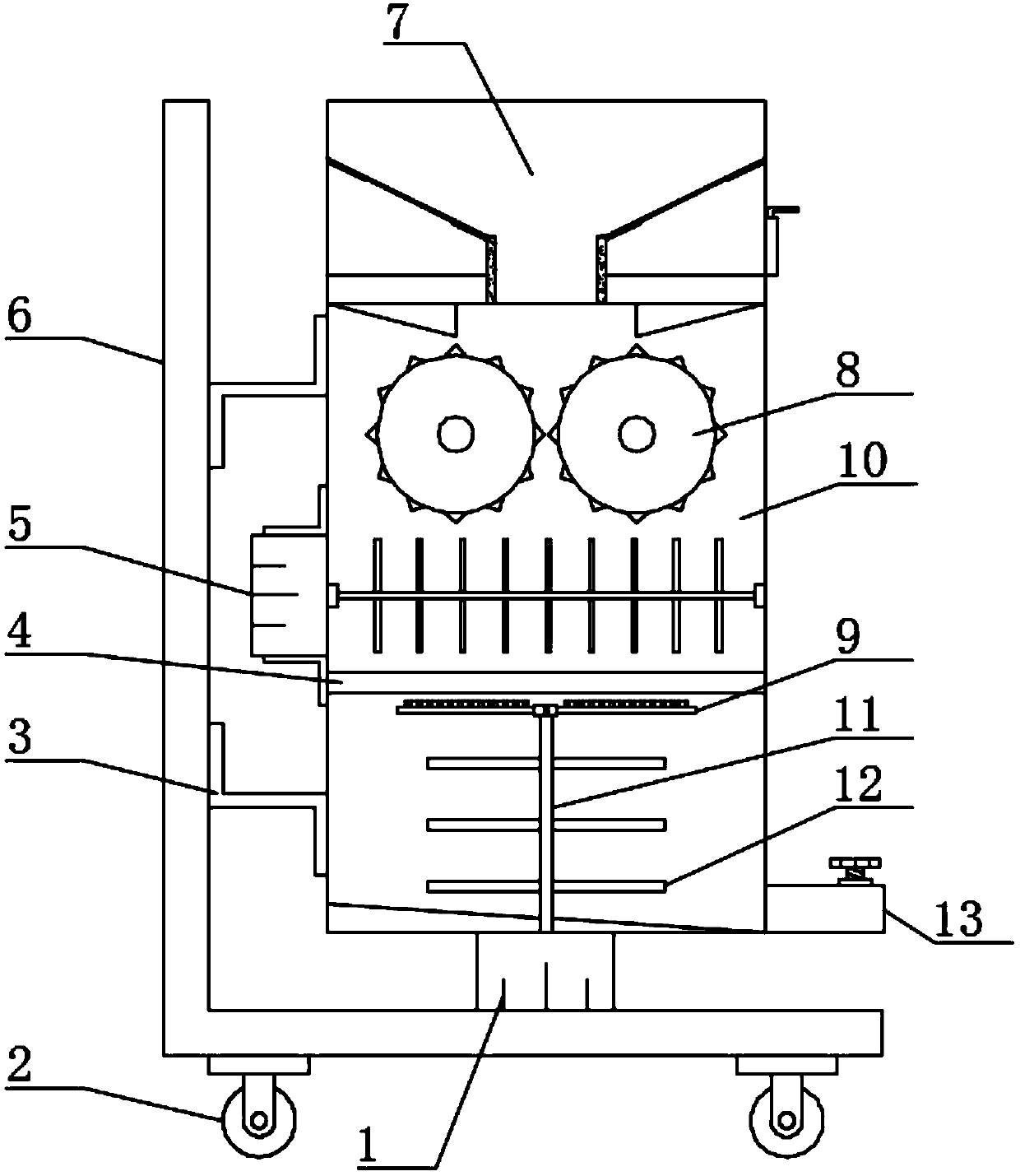

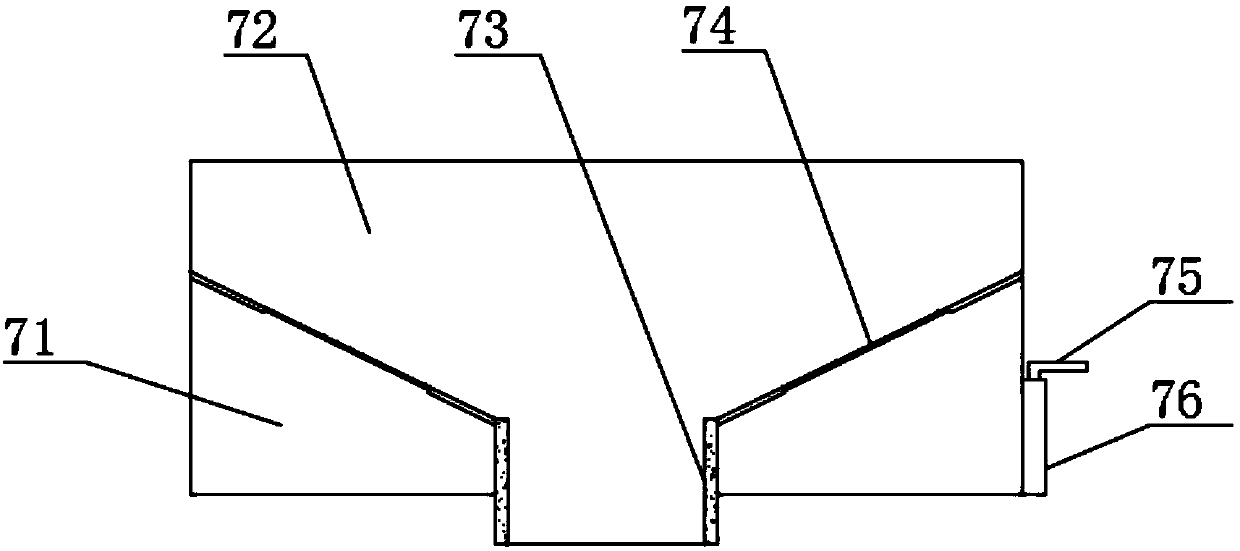

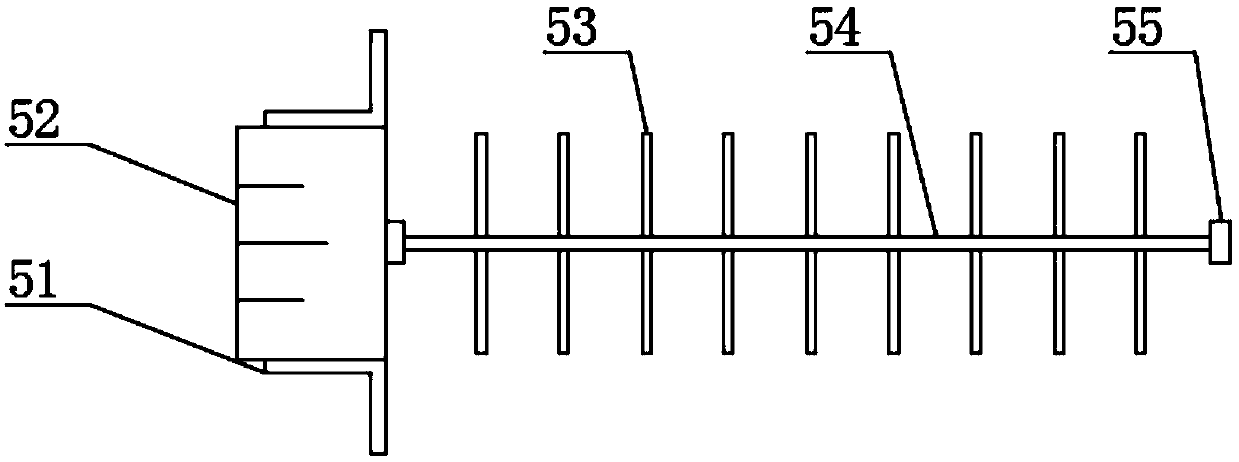

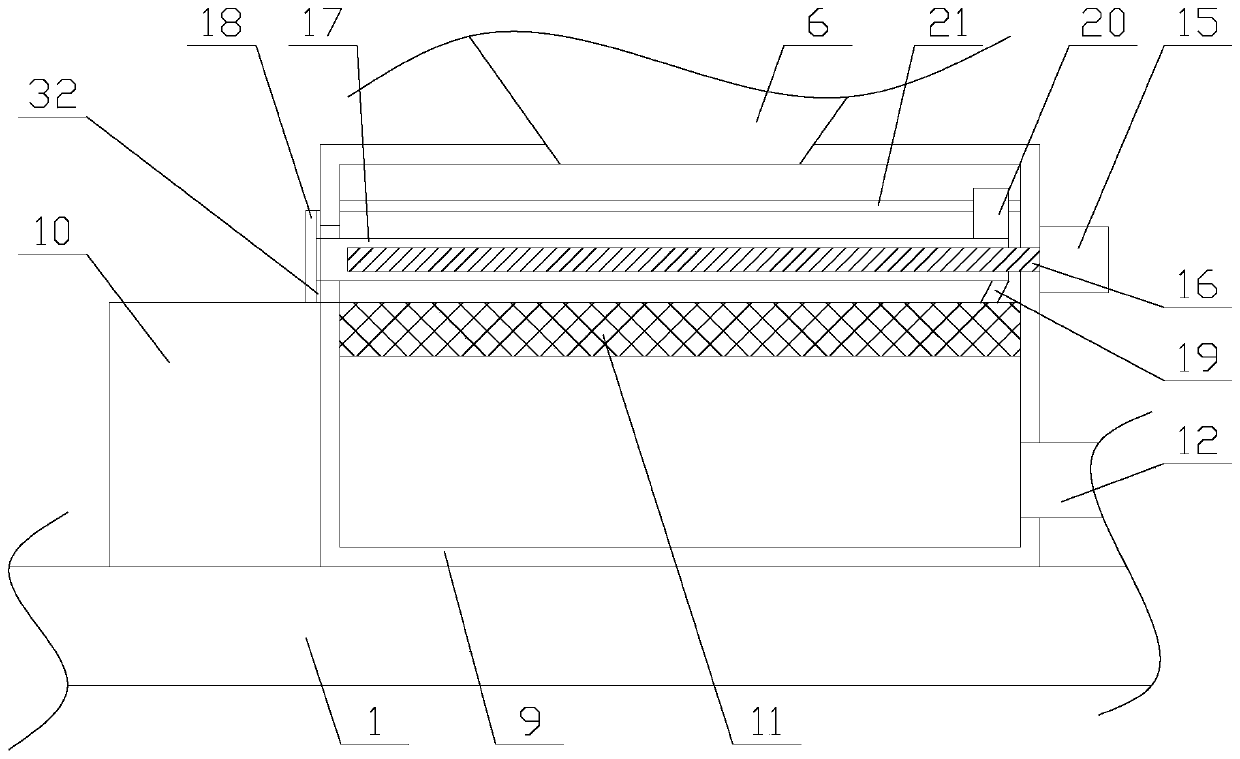

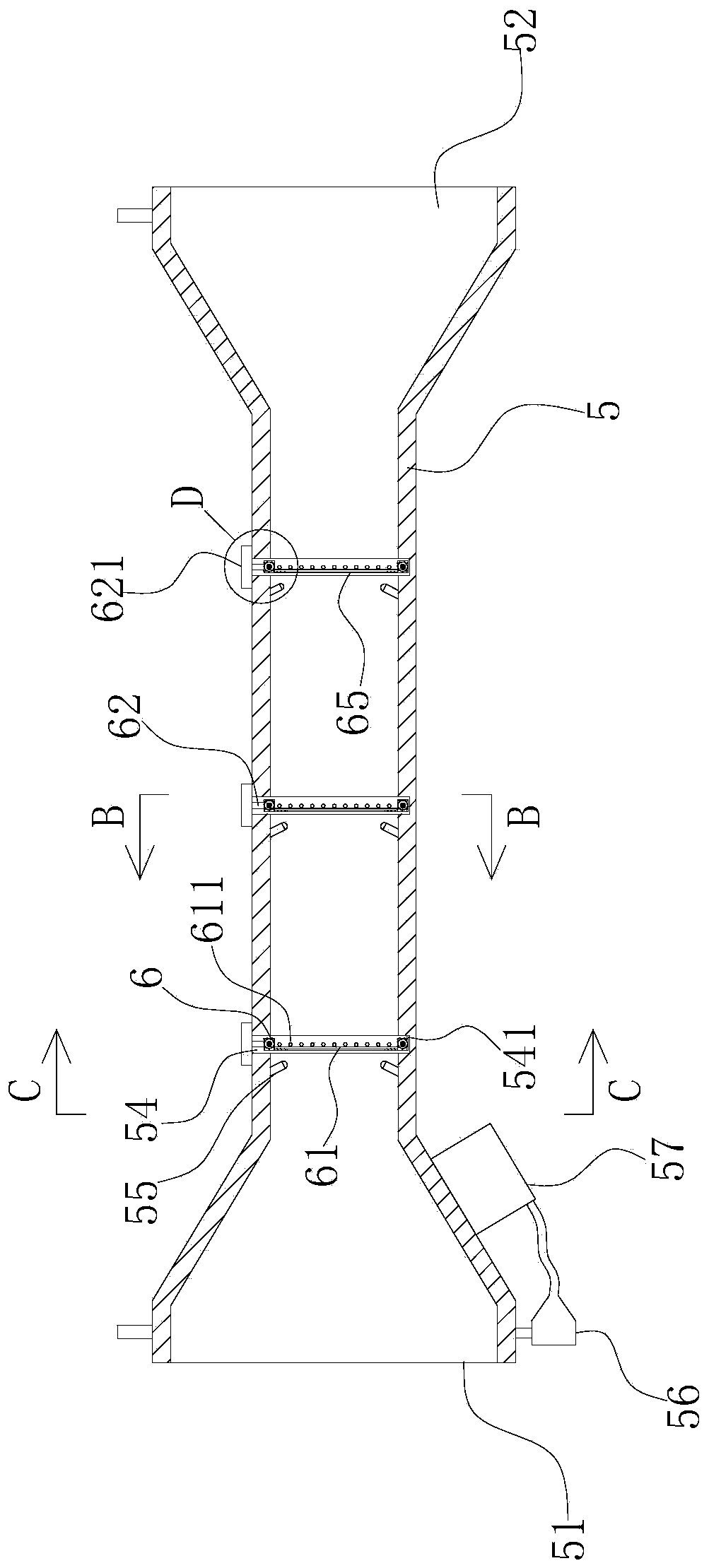

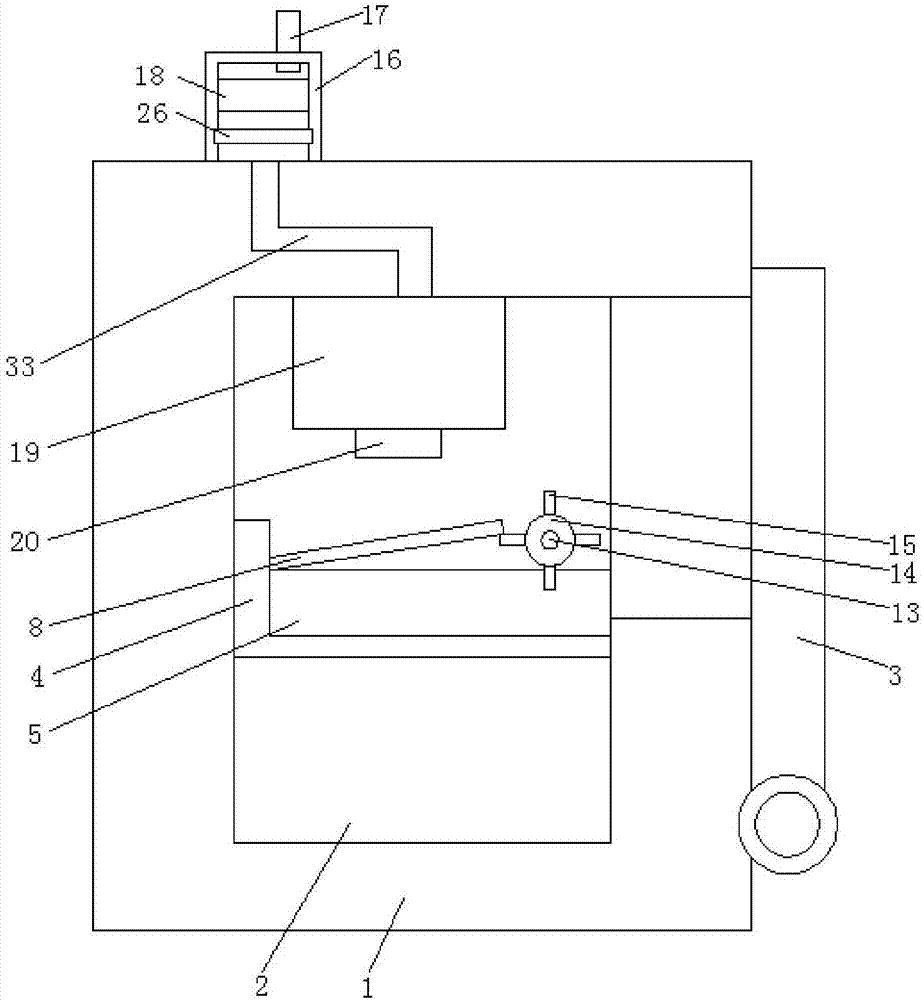

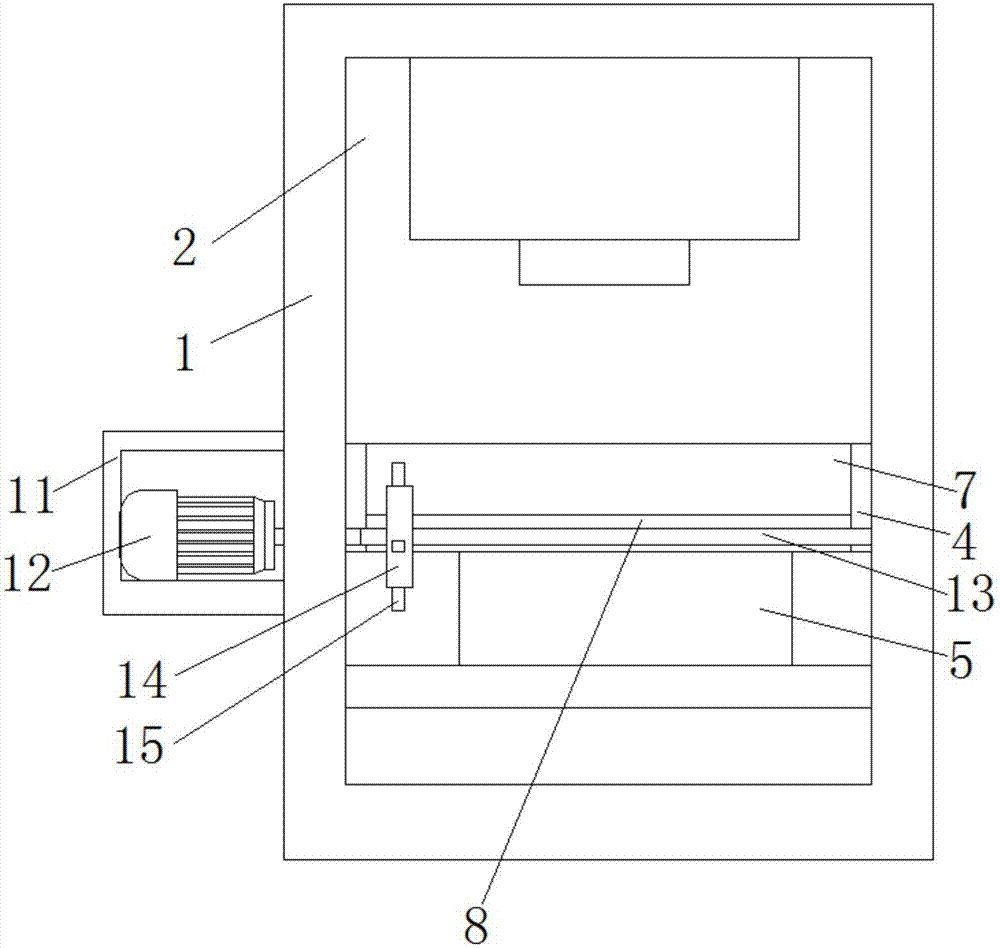

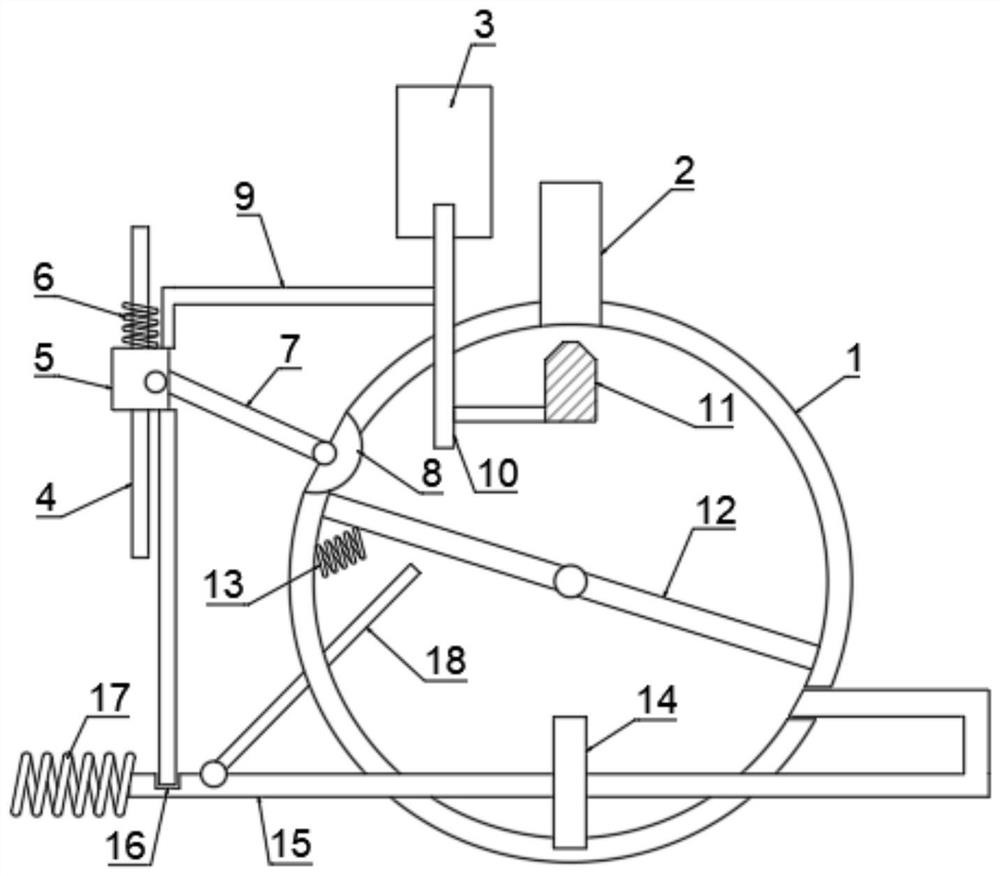

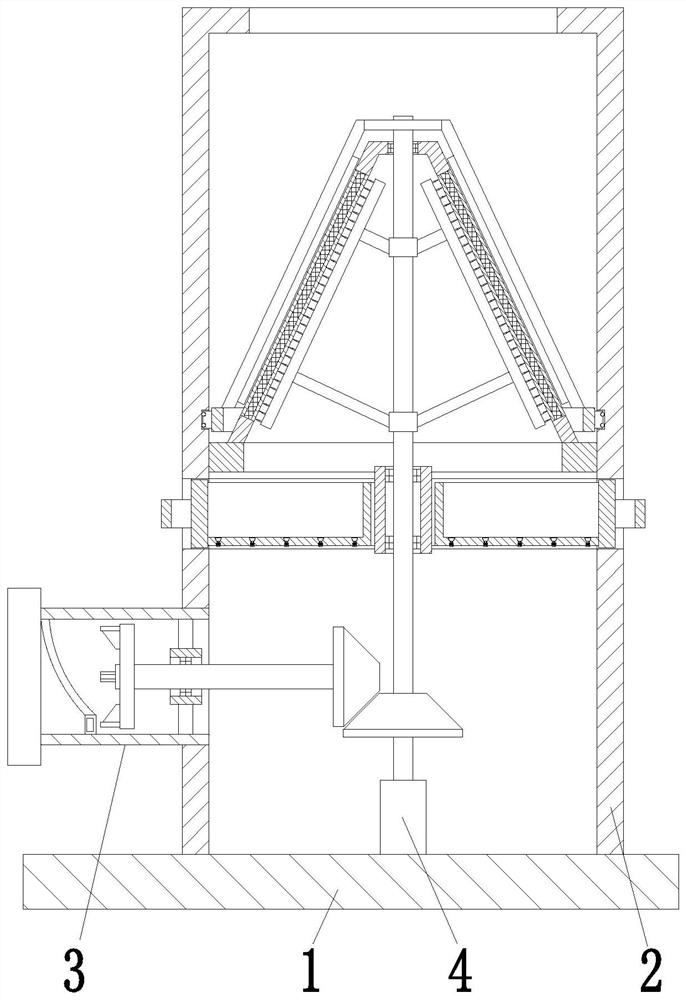

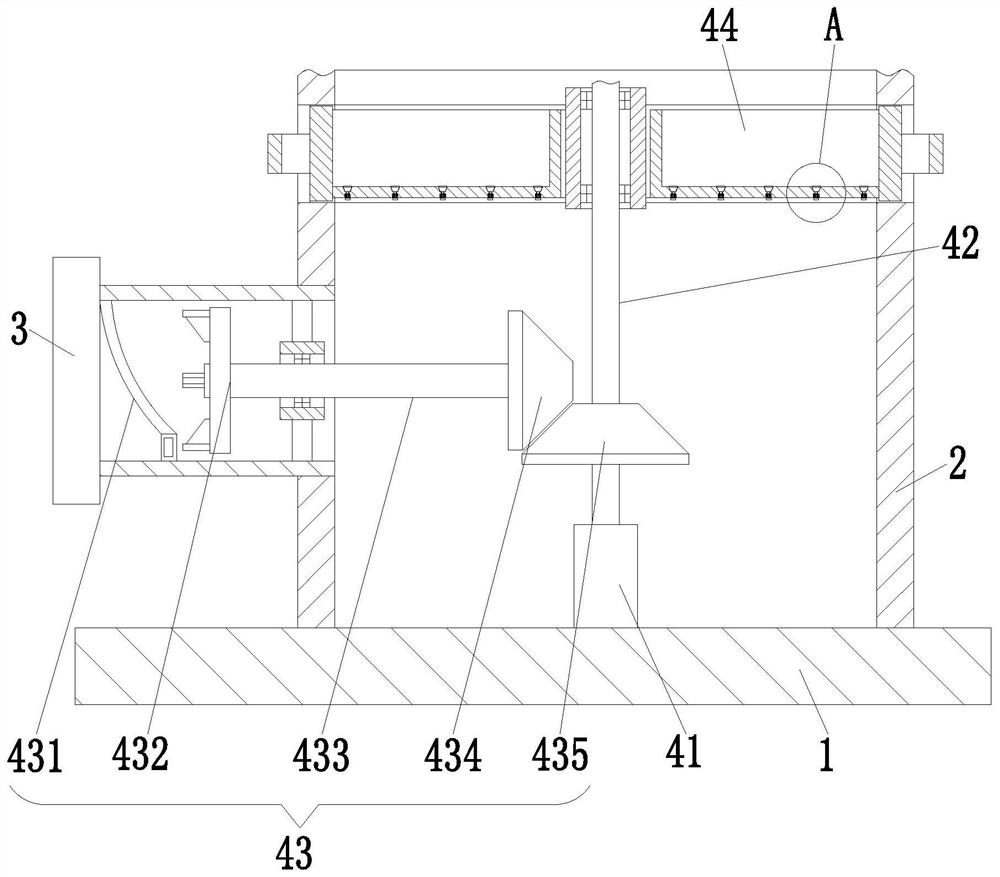

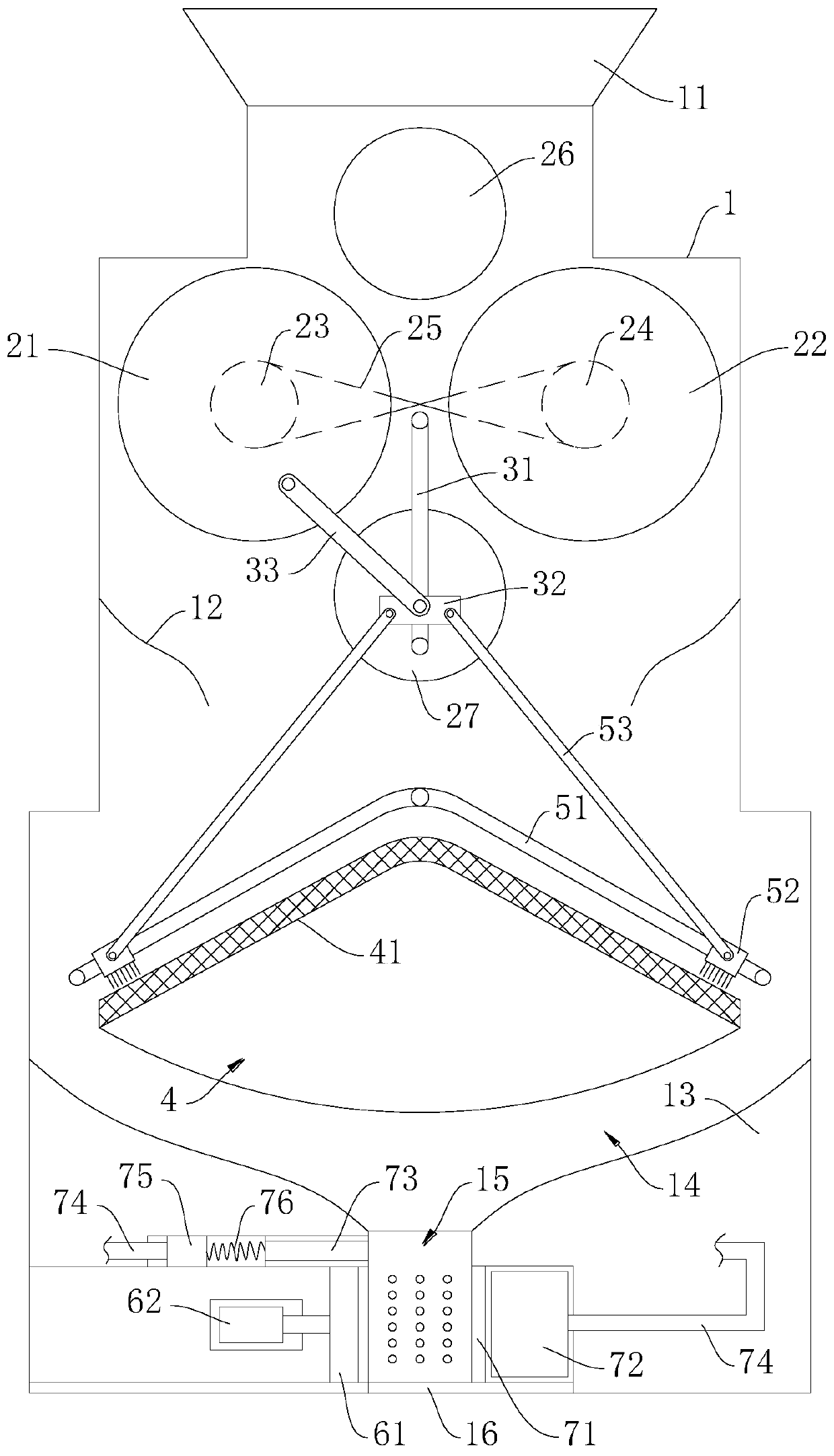

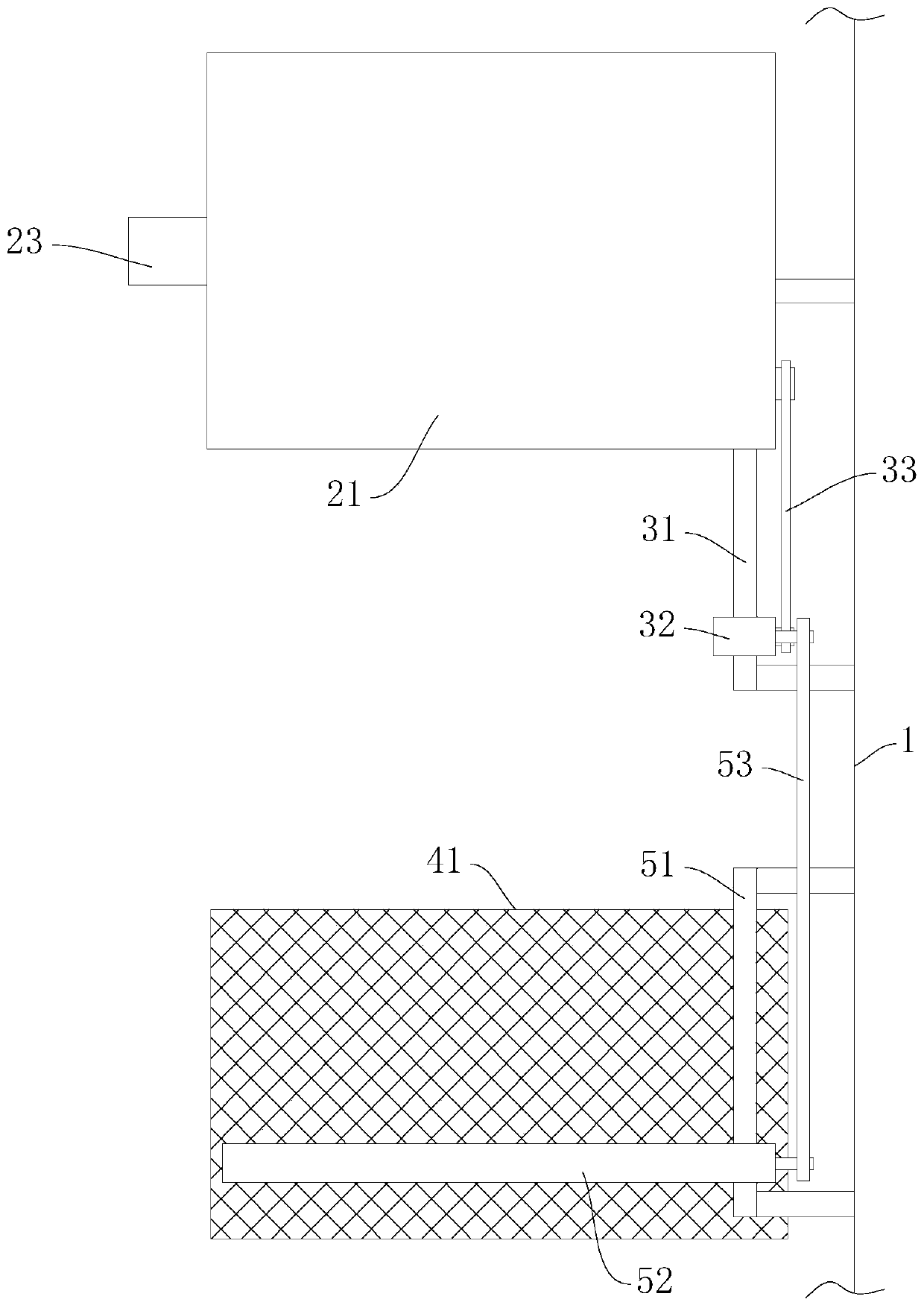

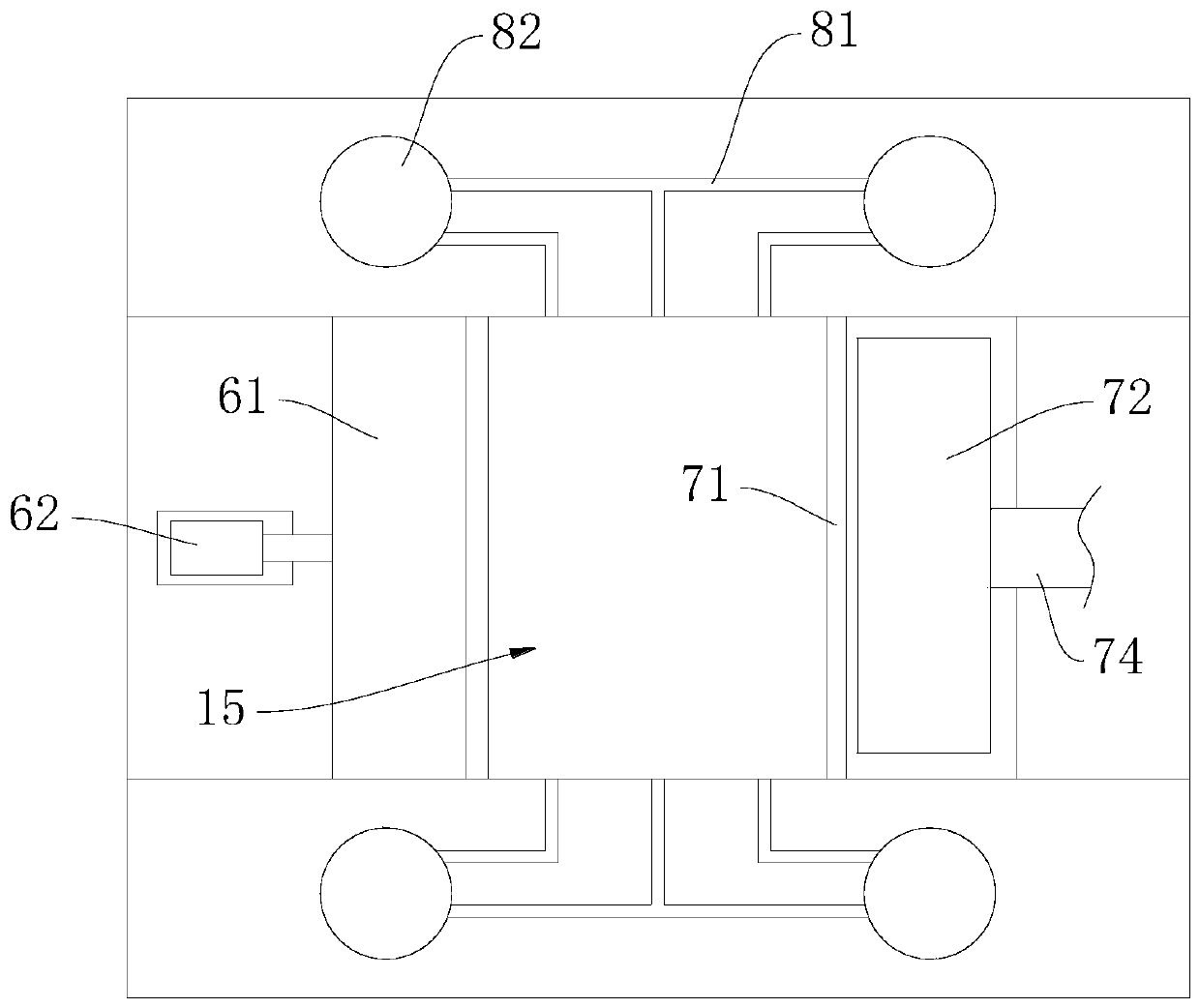

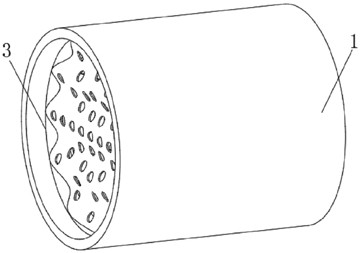

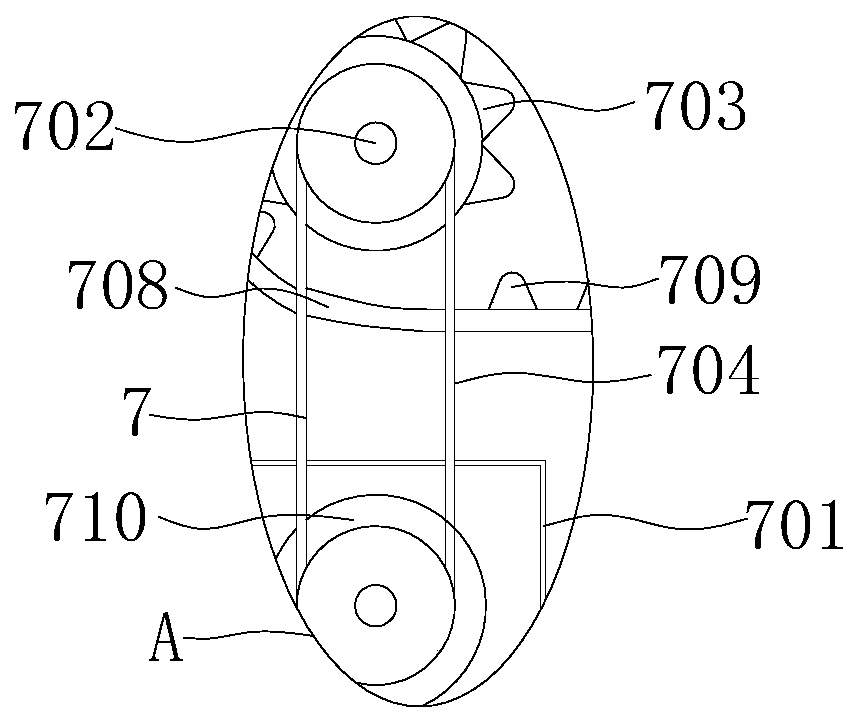

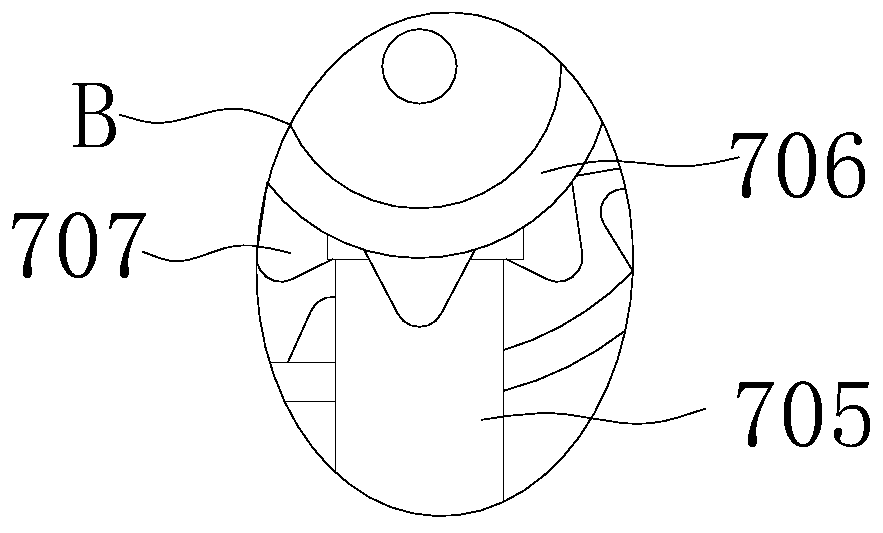

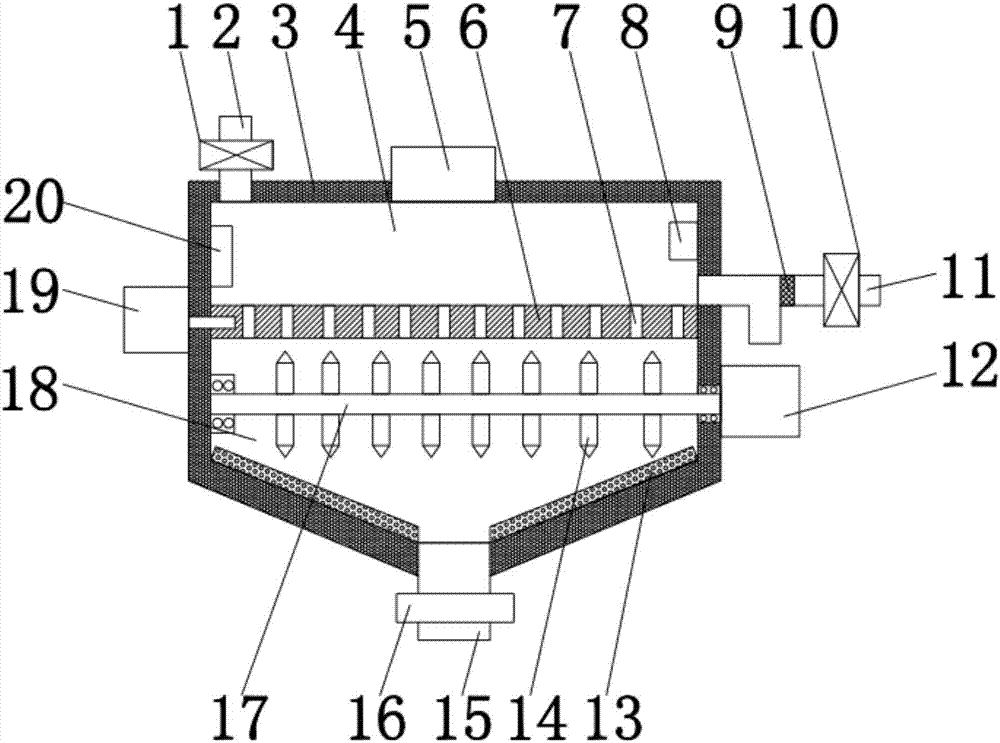

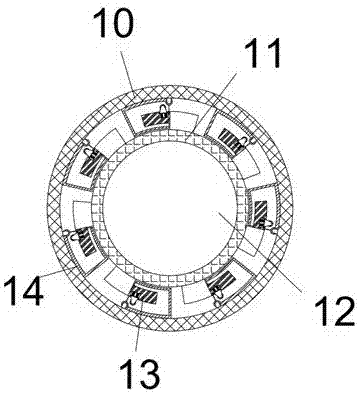

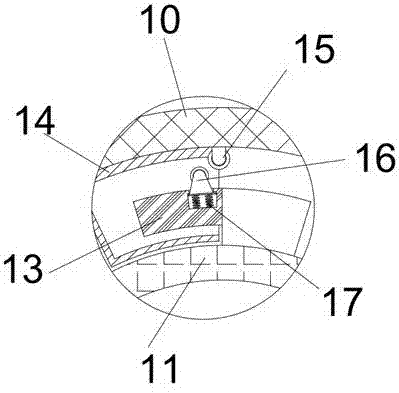

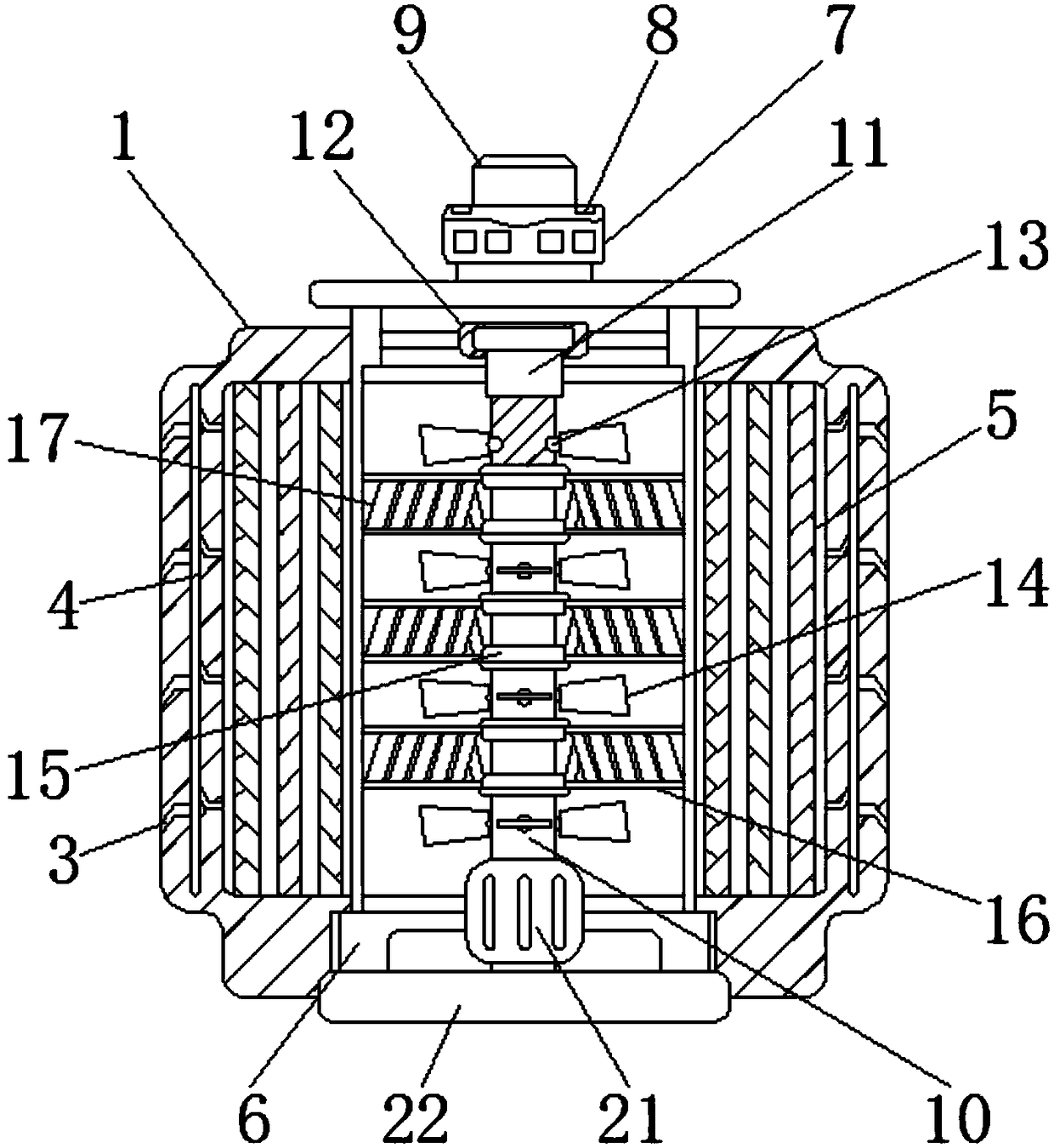

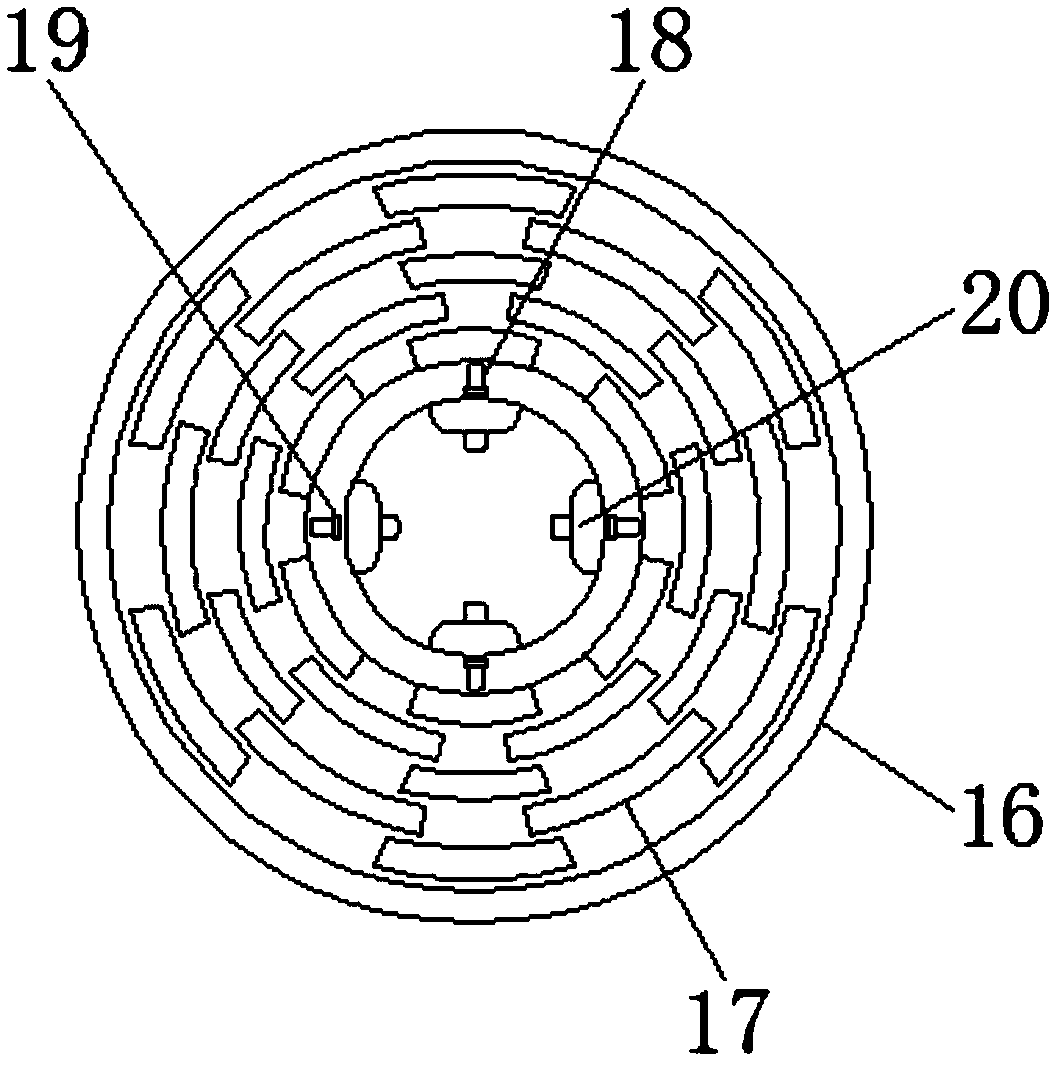

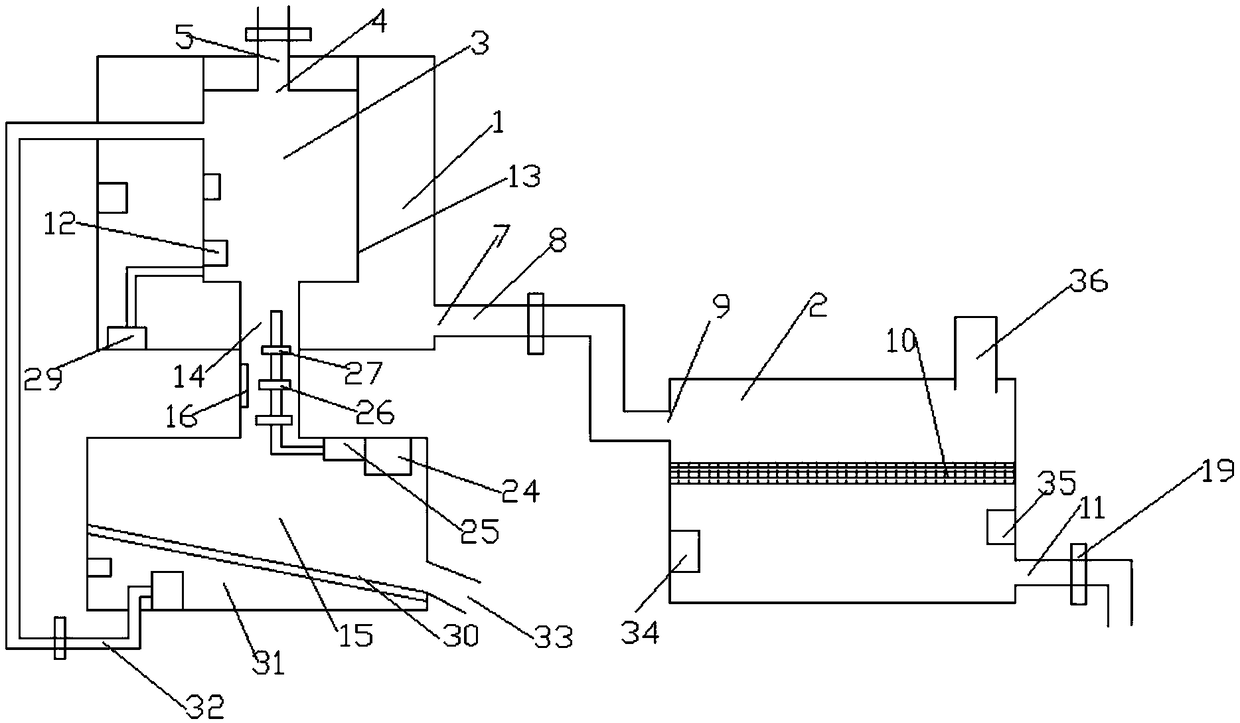

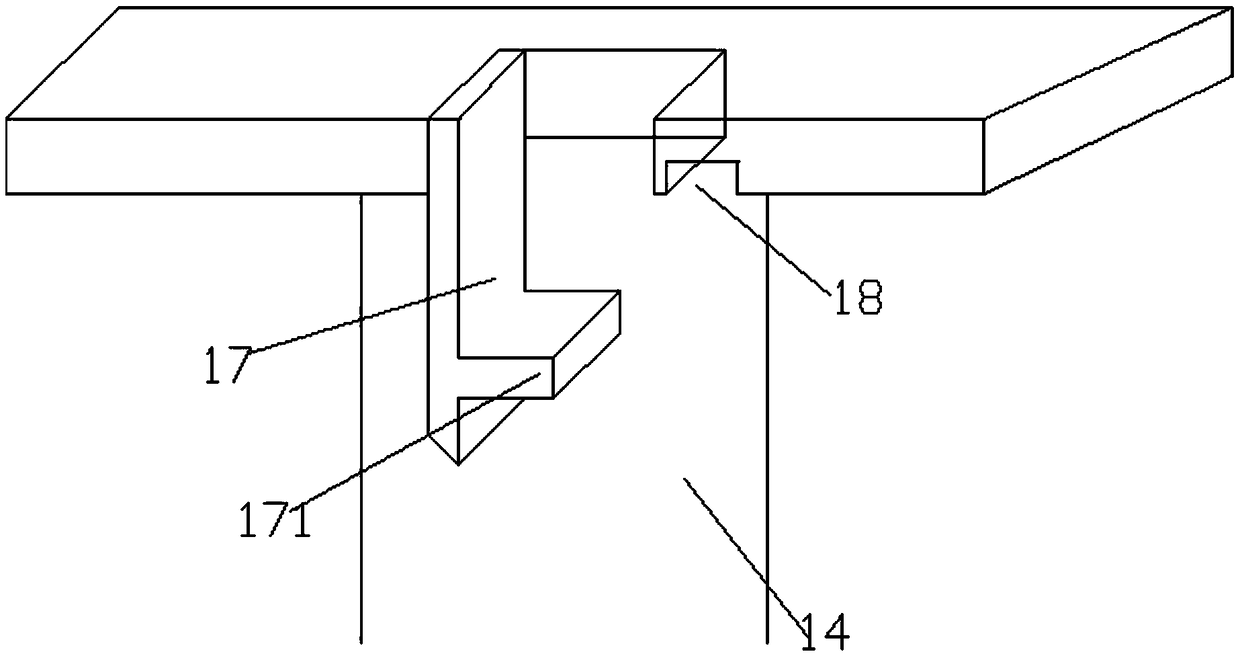

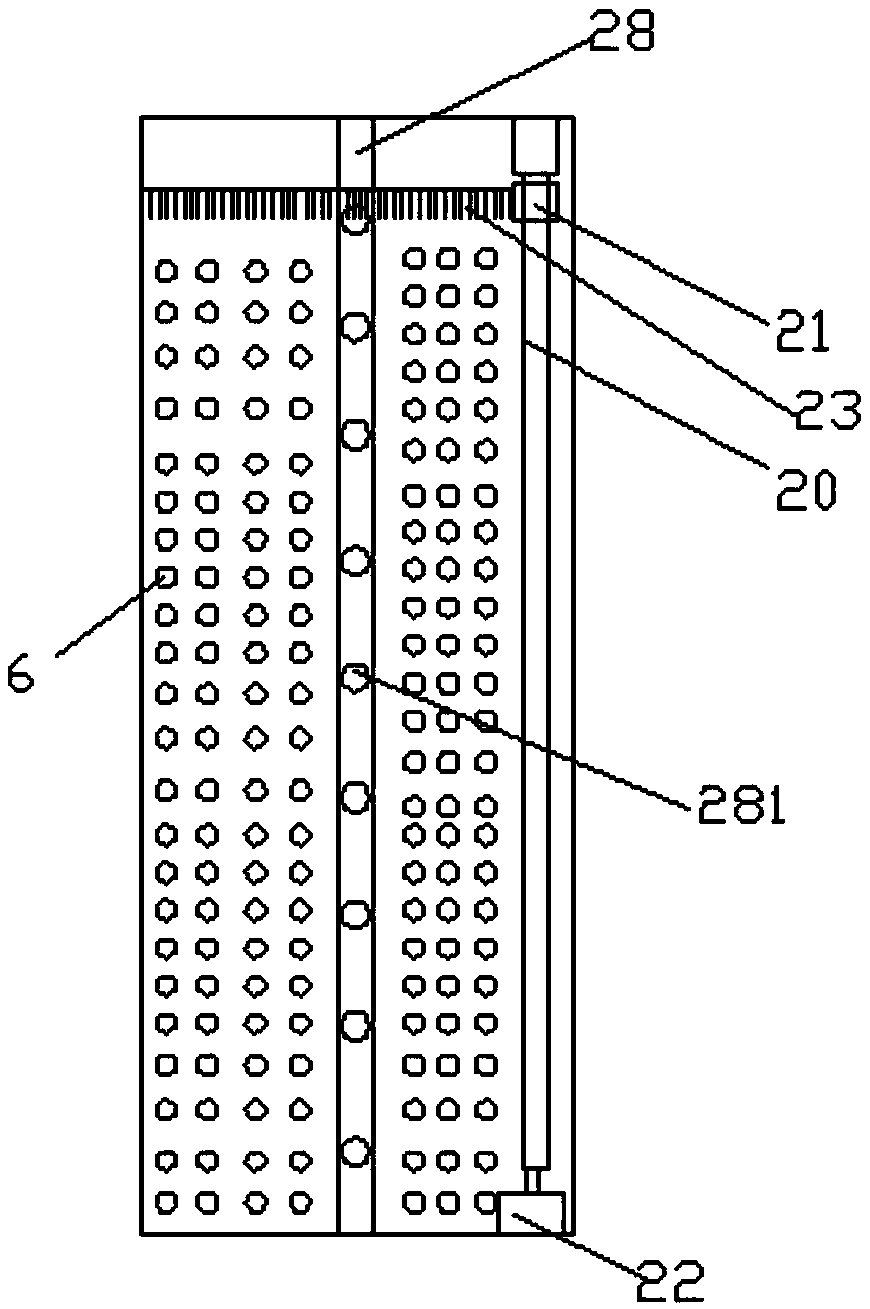

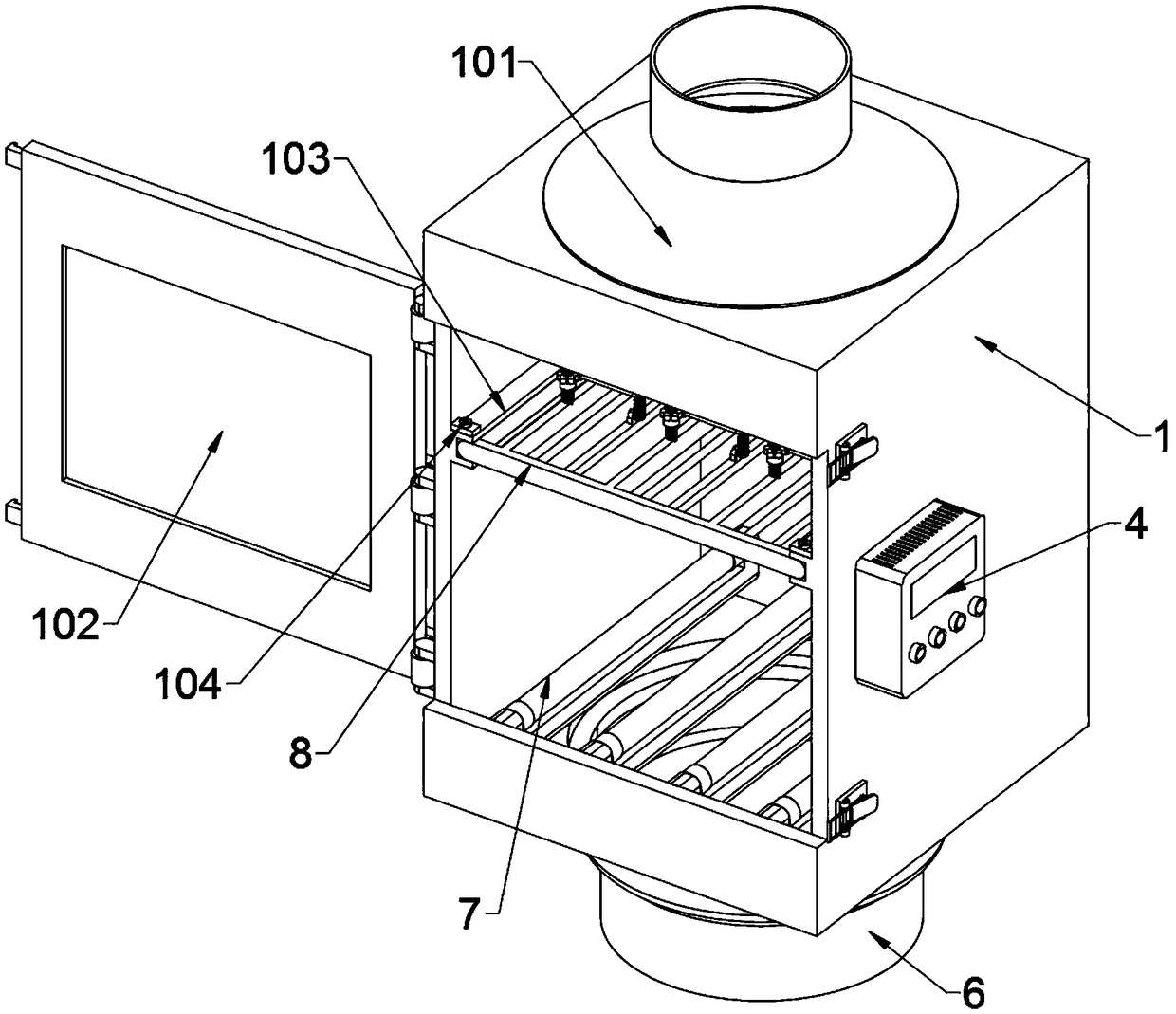

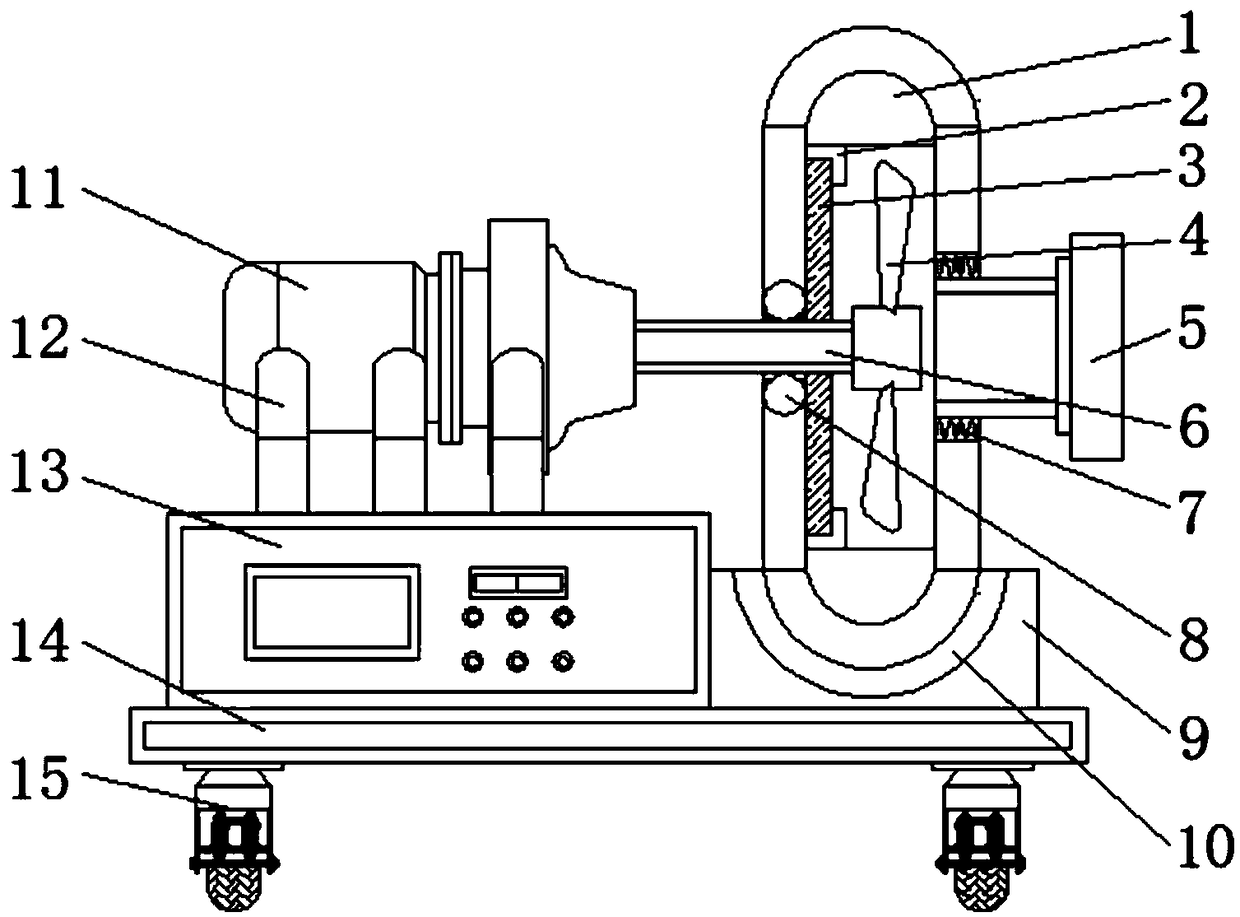

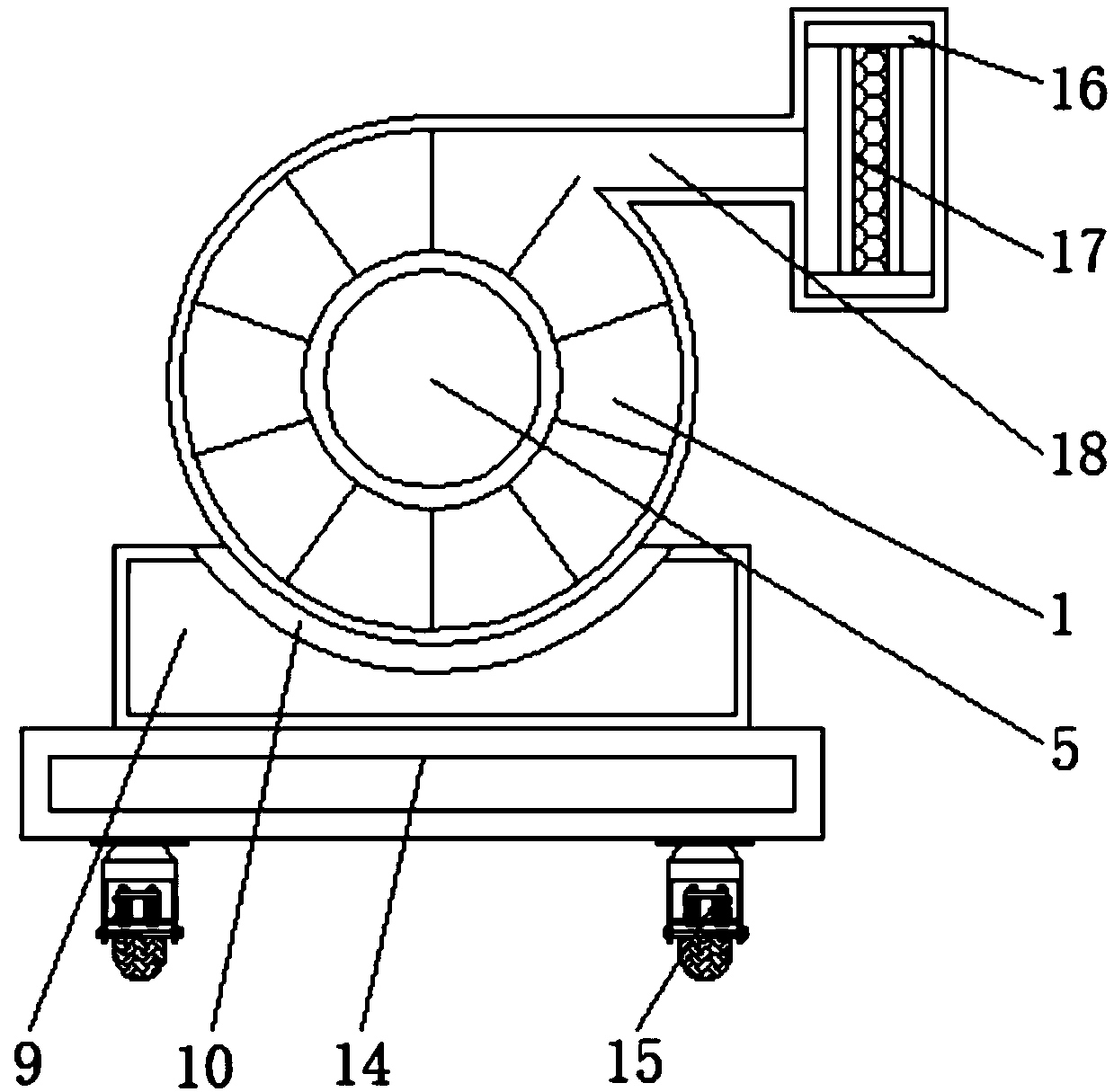

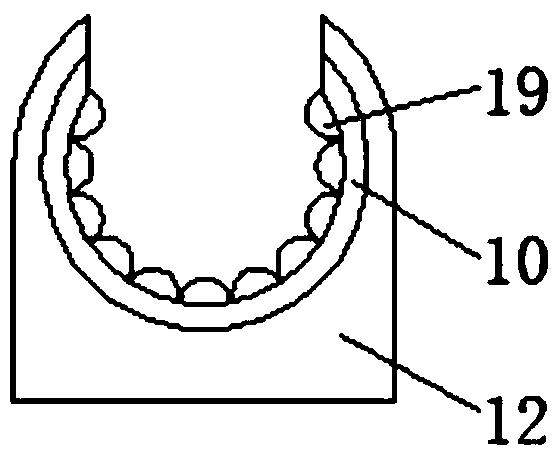

The invention relates to waste gas purification equipment with functions of particulate matter removal and air pressure adjustment. The waste gas purification equipment comprises a main body, an air inlet pipe, an air outlet, a filter screen, a clearing mechanism and an adjusting mechanism. The clearing mechanism comprises a vibration assembly and a cleaning assembly; the vibration assembly comprises a first motor, a drive wheel and two vibration units; the cleaning assembly comprises a reciprocating unit and a telescopic unit; the adjusting mechanism comprises a detection assembly and a rotation assembly. According to the waste gas purification equipment with the functions of particulate matter removal and air pressure adjustment, through the clearing mechanism, the filter screen is vibrated up and down and cleaned, and solid particulate matters are prevented from blocking the filter screen to influence a waste gas filtration effect; through the adjusting mechanism, the internal pressure intensity of the main body can be detected, a waste gas flow amount in an air inlet is adjusted, so that the influence of excessive air pressure on an inner structure of the main body is reduced,and a protection effect is achieved; therefore, the practicability and the reliability of the waste gas purification equipment are improved.

Owner:孙洪军

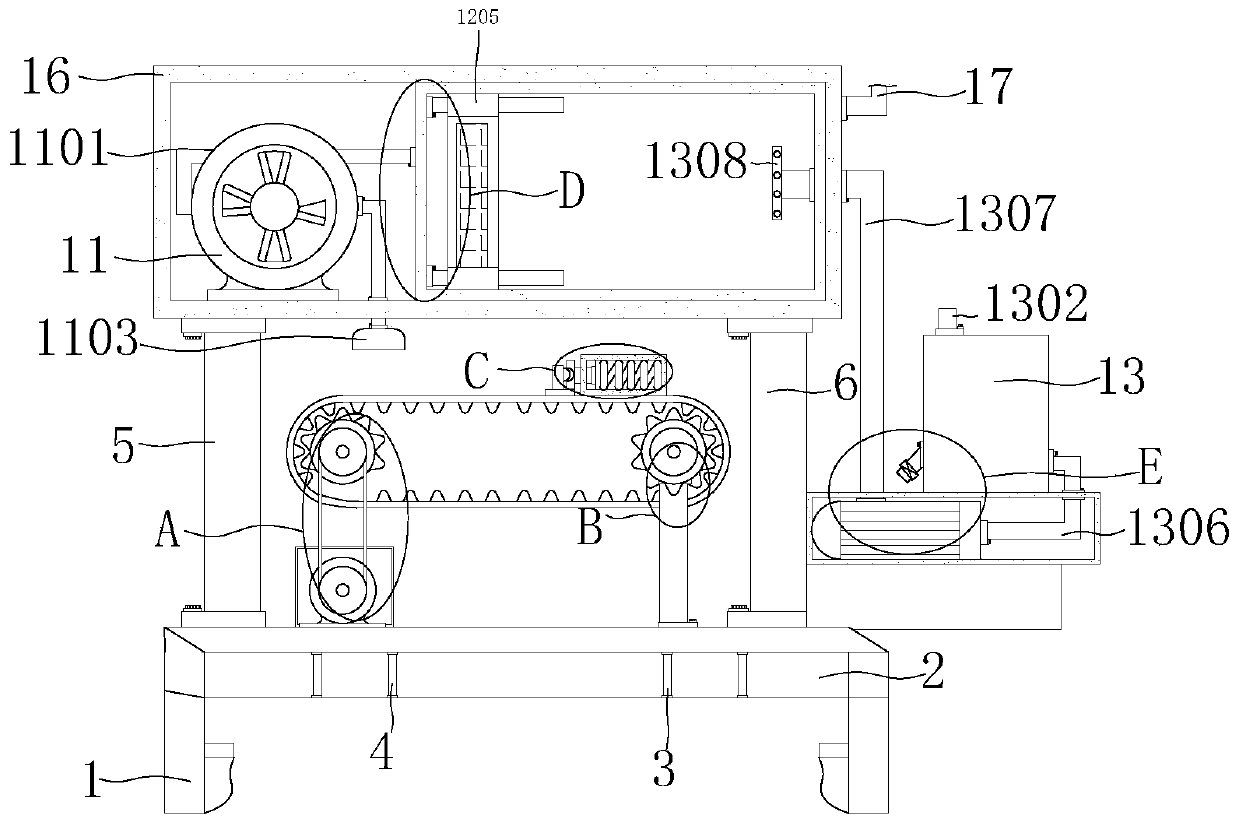

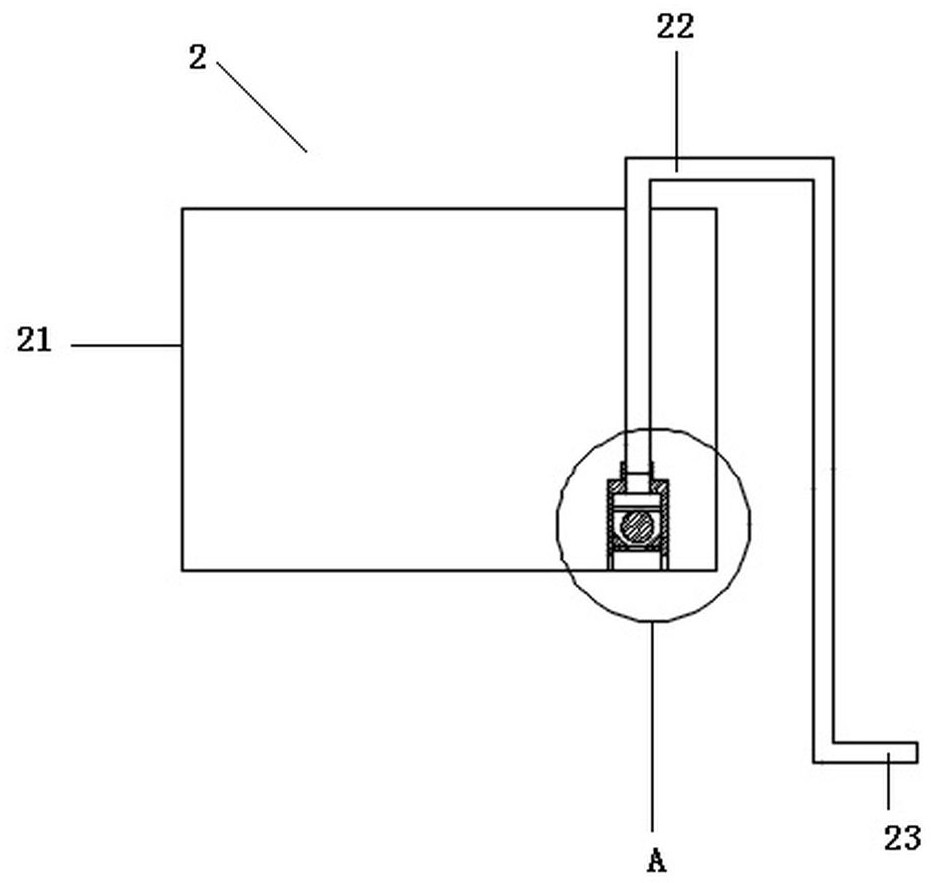

Air purifying device facilitating clearing of dust

ActiveCN105477944AEasy to useSimple structureCombination devicesDispersed particle filtrationBristleFixed frame

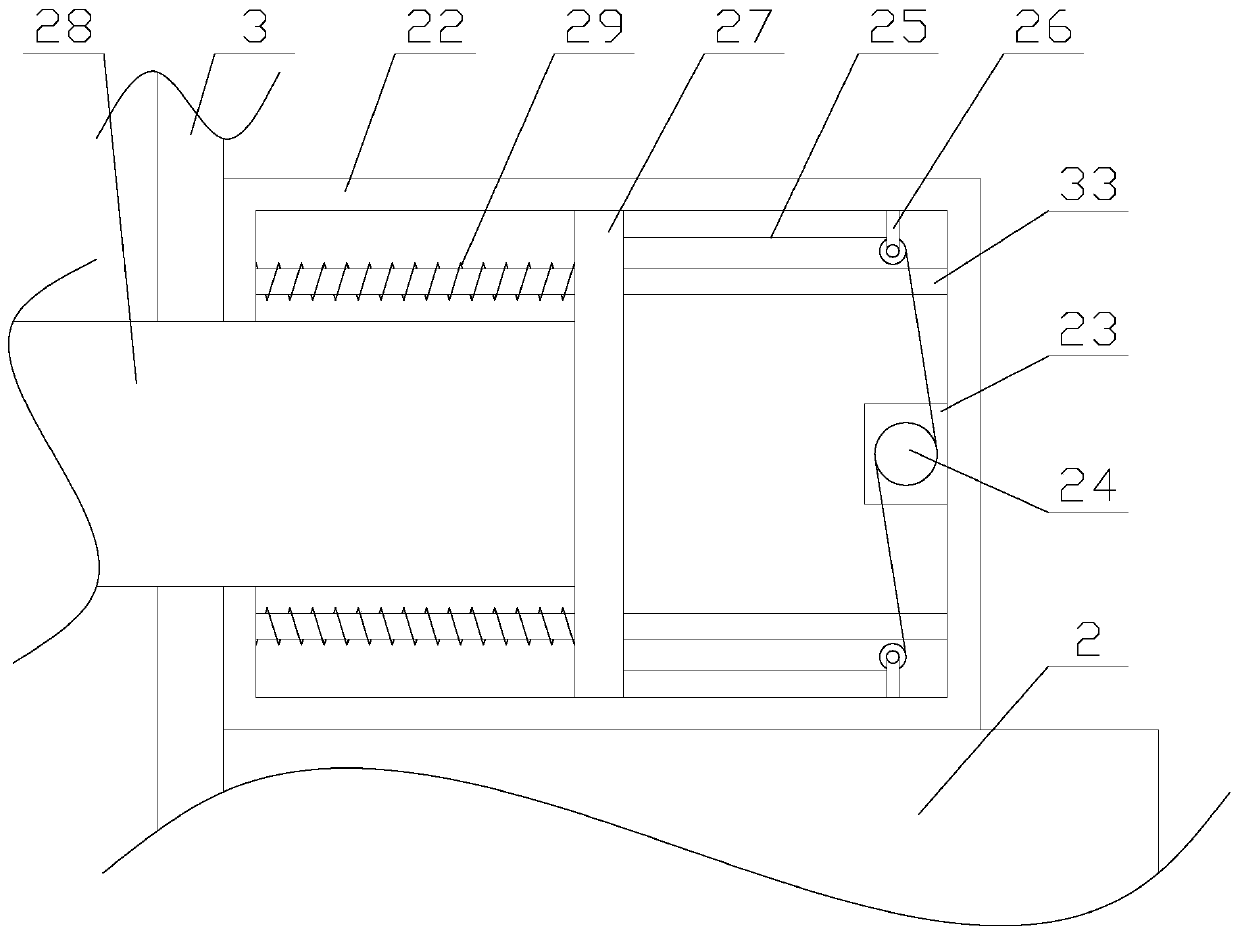

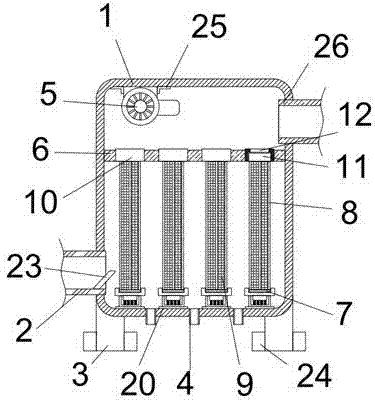

An air purifying device facilitating clearing of dust comprises a frame body, an air outlet device, a first filtering device, a second filtering device, a first sweeping device, an air blowing device, a water inlet device, a blocking device and a collection device, wherein a first through hole, a second through hole, a third through hole, a fourth through hole and a holding ring are arranged on the frame body; the air outlet device comprises an air outlet pipe, a first fan, a fixing frame, a first fixing rod, first oblique rods and a first support; the first filtering device comprises a first filter net, first bent rods and a first fixing plate; the second filtering device comprises a second fixing plate, a second filter net, first supporting rods, concentrating blocks, first cross rods, a sponge block and a first pipeline; the first sweeping device comprises a supporting plate, a second support, a moving frame, a first connection rod, a second cross rod, bristles, first springs, a first vertical rod, a third cross rod and an air cylinder. Dust on the filter nets of the air purifying device can be cleared completely, and dust can be prevented from accumulating on the filter nets.

Owner:六安同辉智能科技有限公司

Stone processing and dust-removal device

InactiveCN107029495AAffect the filtering effectAdd controlUsing liquid separation agentSeparation devicesStone dustEngineering

The invention discloses a dust removal device for stone material processing, which comprises a dust suction port, a first valve, a fan, a second water pump and a handle. The dust suction port is sealed and connected to the lower end of a dust suction arm, and the first valve is sealed by a water pipe. Connected to the left side of the dust removal chamber, the inner bottom surface of the dust removal chamber is provided with a deflector, the fan is sealed and connected with the dust removal chamber through a smoke pipe, the first water pump is arranged on the top of the filter chamber, and the second water pump It is sealed and connected to the left side of the filter chamber through a water pipe, and the inside of the filter chamber is connected with the fixing bolts of the filter plate, and the right side of the filter chamber is sealed with the decontamination door through a rotating hinge, and the handle is arranged on the outside of the decontamination door. surface. The stone processing dust removal device is equipped with deflectors to facilitate the discharge of sewage at the bottom of the dust removal chamber. The filter plate filters out impurities in the sewage. The decontamination door can regularly clean the dust inside the filter chamber to prevent too much dust after filtering from affecting the filter chamber. filter effect.

Owner:林彩红

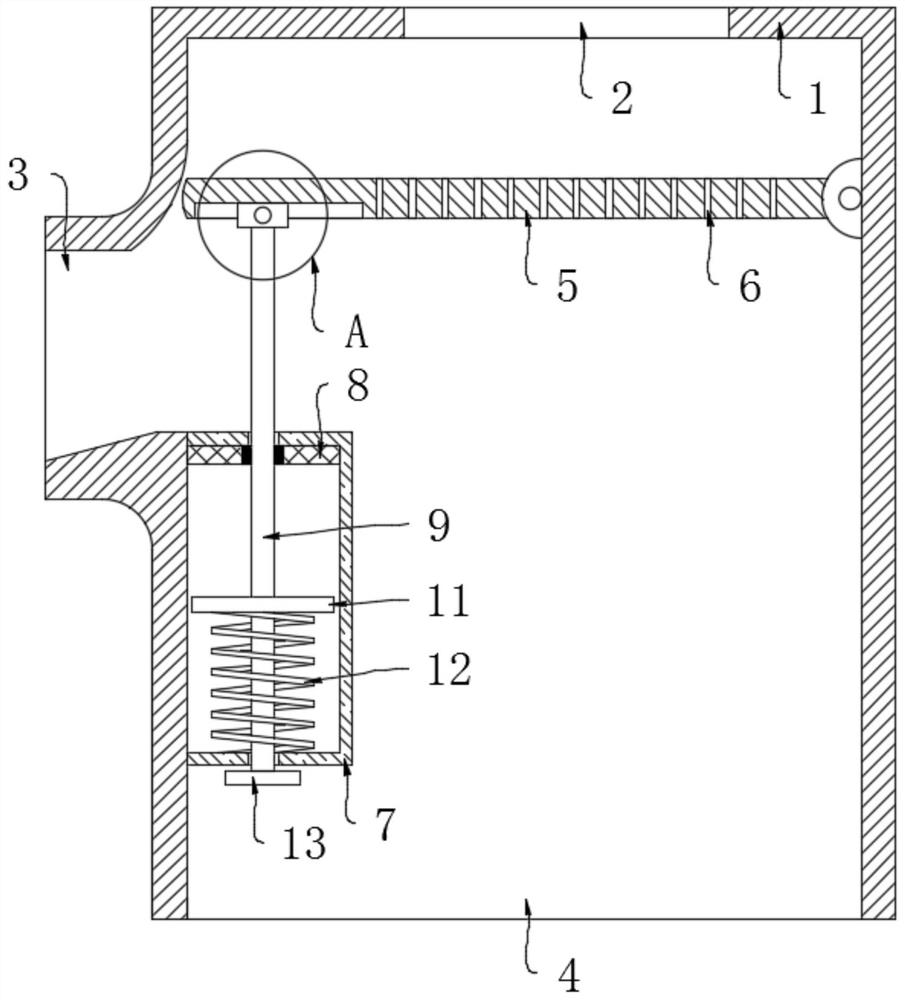

Filter plate cleaning device for wastewater treatment and use method

InactiveCN111804026AAffect the filtering effectEasy to assemble and disassembleStationary filtering element filtersMechanical engineeringScreen filter

The invention discloses a filter plate cleaning device for wastewater treatment and a using method, and belongs to the technical field of wastewater treatment. The invention discloses a filter plate cleaning device for wastewater treatment. Wastewater treatment tank, a filter screen plate is detachably connected into the wastewater treatment box, the top of the wastewater treatment box is movablyconnected with a moving rod, the top of the moving rod is rotationally connected with a first bevel gear, the end, away from the first bevel gear, of the moving rod is connected with a moving plate, the moving plate is slidably connected to the inner wall of the wastewater treatment box, the outer wall of the moving rod is sleeved with a first elastic element, the first elastic element is connected between the wastewater treatment box and the moving plate, the outer wall of the moving plate is connected with a scraper, the scraper movably abuts against the outer wall of the filter screen plate, and a first groove is dug in the bottom of the wastewater treatment box. Impurities attached to the outer wall of the filter screen plate are removed through the scraper blade, the filter screen plate is prevented from being blocked, the filter screen plate is detachably connected into the box body, the filter screen plate is convenient to disassemble and assemble, and the filter screen plate can be further cleaned.

Owner:绍兴市晟途环保科技有限公司

Neodymium-iron-boron magnet manufacturing process

ActiveCN110233042AAffect the filtering effectImprove filtering effectSievingScreeningEngineeringMoisture

The invention discloses a neodymium-iron-boron magnet manufacturing process. The neodymium-iron-boron magnet manufacturing process comprises the following steps that a, smelting:, loading is performedfirstly and then vacuumizing to be less than 1 Pa is carried out, the low-power heating is started, heating while air extracting is performed, the moisture of the gas in an adsorption state is gradually de-absorbed and extracted along with temperature rise until the furnace burden is generally dark and red, a valve is closed and argon is injected, and power-increasing temperature rise is carriedout until the furnace burden is completely molten, five minutes of refining is carried out, the power is reduced after refining is completed and pouring is carried out, and then cooling is carried outafter pouring is finished; b, powder preparing: the neodymium-iron-boron particles are put into a jet mill to perform high-speed collision, so that the particles are subjected to high-speed collisionto form powder, the formed powder is collected and put into a screening machine to be screened, and impurities in the magnetic powder are removed; c, forming; d, sintering; e, machining, wherein theneodymium-iron-boron magnet obtained after sintering is a blank, and further machining is required to obtain products with different dimensions, sizes and shapes; f, surface treatment; and g, finishedproduct inspection and packaging are carried out.

Owner:ZHEJIANG SHEENSEN MAGNETICS TECH CO LTD

Efficient automatic waste gas treatment method

ActiveCN113019042ATo achieve the purpose of dust removalAffect the effect of dust removalCombination devicesDispersed particle filtrationParticulatesWater source

The invention relates to waste gas treatment, and discloses an efficient automatic waste gas treatment method. The treatment method is based on waste gas treatment equipment. The treatment equipment comprises a water tank, a bottom box is welded to the surface of the water tank, a dust removal mechanism is arranged in the bottom box, a vertical plate is welded in the water tank, a crushing mechanism is arranged on the rear wall of the water tank, a spraying mechanism is arranged on the bottom wall of the water tank and located on the right side of the vertical plate, and the right side of the vertical plate is fixedly connected with the inner wall of the water tank through a transverse plate. According to the waste gas treatment equipment with a dust removal function and the use method thereof, waste gas can be subjected to preliminary dust removal through a water source to reduce the existence rate of dust in the waste gas, then the waste gas is conveyed into the bottom box and a dust removal pipe through an air pump, the waste gas subjected to dust removal through a water adsorption method is filtered again through a filter screen, a filter plate and a filter box, and therefore, particulate matters in the waste gas are reduced again, and the purpose of removing dust from the waste gas is achieved.

Owner:湖南利苍环保科技有限公司

Traditional Chinese medicine blender having impurity removing function

InactiveCN109092184AAffect production qualityStir wellTransportation and packagingRotary stirring mixersBiochemical engineeringImpurity

The invention discloses a traditional Chinese medicine blender having an impurity removing function. The traditional Chinese medicine blender comprises a supporting plate, wherein a stirring cylinderis arranged above the supporting plate, a supporting frame is welded at the connecting position of the supporting plate and the stirring cylinder, a second motor is arranged at the middle position ofthe lower surface of the stirring cylinder and is provided with a first transmission rod, two sides of the first transmission rod are provided with stirring rods, a filter screen is arranged above thefirst transmission rod, a smashing roller is arranged at the top end of the stirring cylinder, the bottom end of the stirring cylinder is provided with a discharging pipe, and a screening mechanism is arranged above the stirring cylinder. The screening mechanism is arranged on the traditional Chinese medicine blender, a user can screen impurities mixed in medicinal materials through the screeningmechanism and accordingly removes the impurities mixed in medicinal materials, and accordingly the left impurities are prevented from affecting the production quality of the traditional Chinese medicine blender.

Owner:ZHENGZHOU RENHONG PHARMA CO LTD

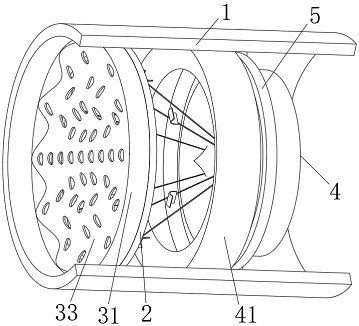

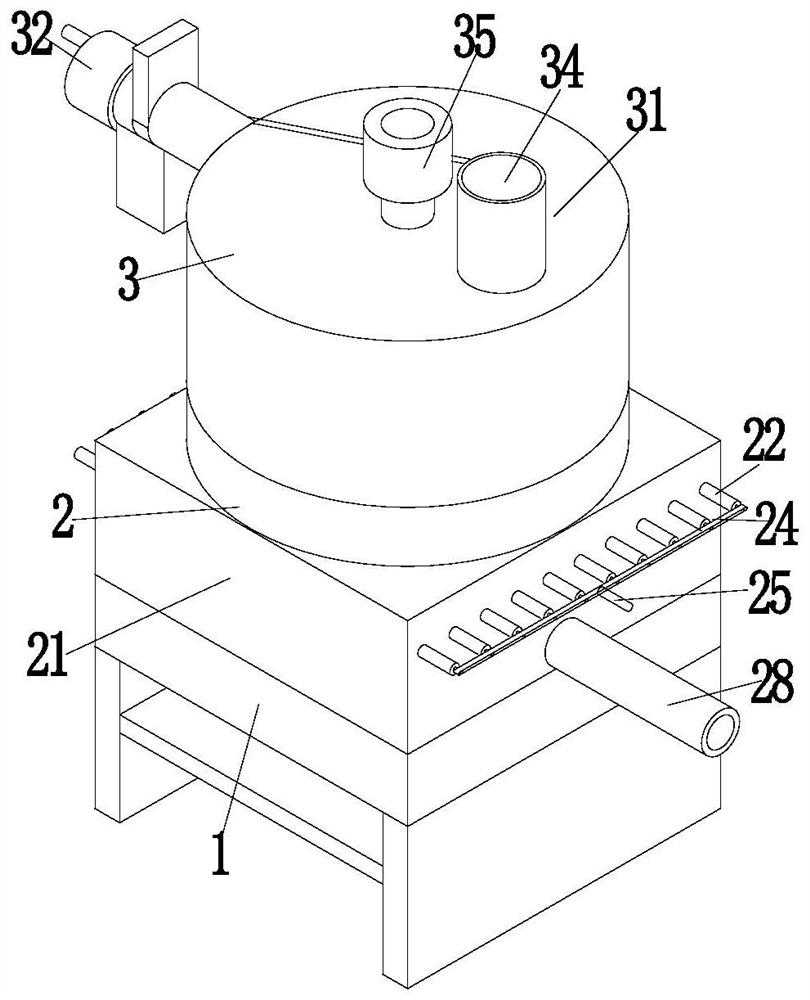

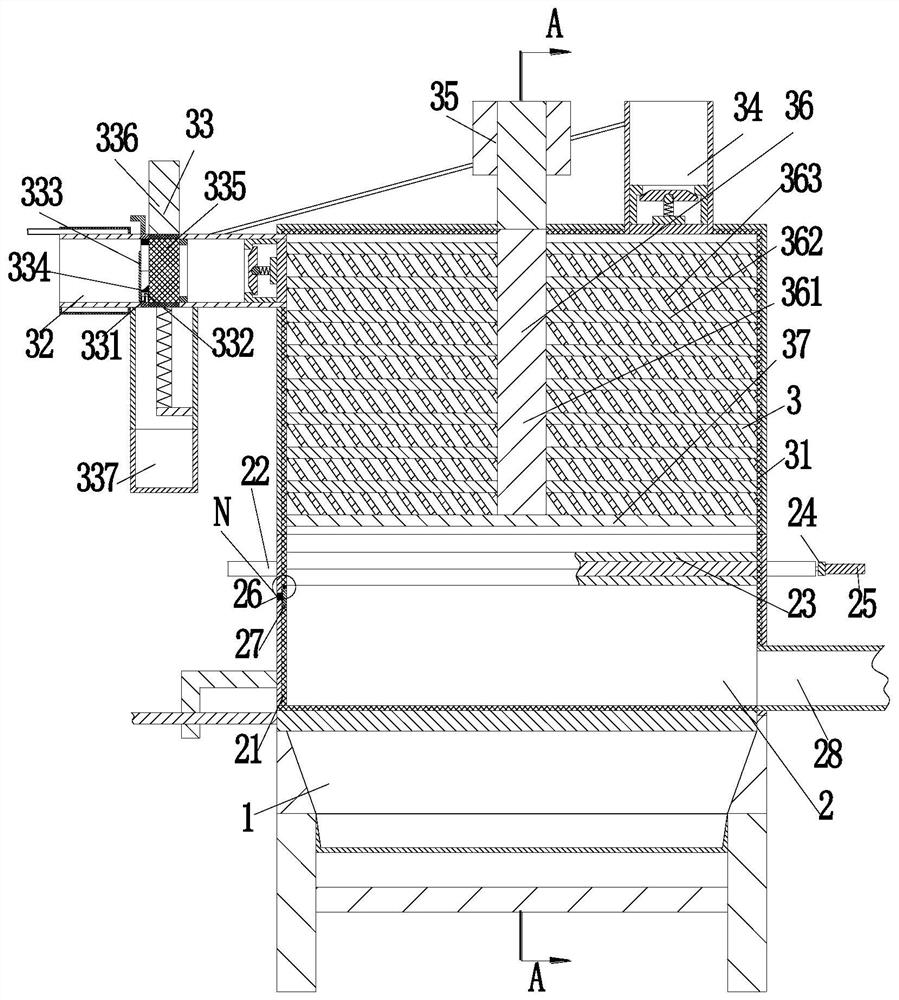

Efficient water-saving ore washing device for ore concentration

InactiveCN110125071AImprove practicalityAffect the filtering effectMultistage water/sewage treatmentCleaning using liquidsWater savingWater spray

The invention relates to an efficient water-saving ore washing device for ore concentration. The efficient water-saving ore washing device for ore concentration comprises a body, a filter drum, a feeding pipe, a discharge pipe, a base plate, a water spraying device and two supports. A recycling mechanism includes a recovery box, a waste box, a filter net, a material pushing assembly and a water pumping assembly. The material pushing assembly comprises a first motor, a lead screw, a sleeve, a push plate, and a sealing plate, and the moving mechanism comprises two fixing boxes, wherein each fixing box is internally provided with a moving component. Each moving component comprises a driving unit, a moving plate, a moving rod and two springs. The efficient water-saving ore washing device for ore concentration recycle clear water by means of the recycling mechanism, the function of water saving can be achieved, and the environmental protection property of the equipment is improved; and by means of the moving mechanisms, the filter drum can be driven to move, so that ore materials shake to make full contact with water, and the cleaning effect is improved.

Owner:薄士霞

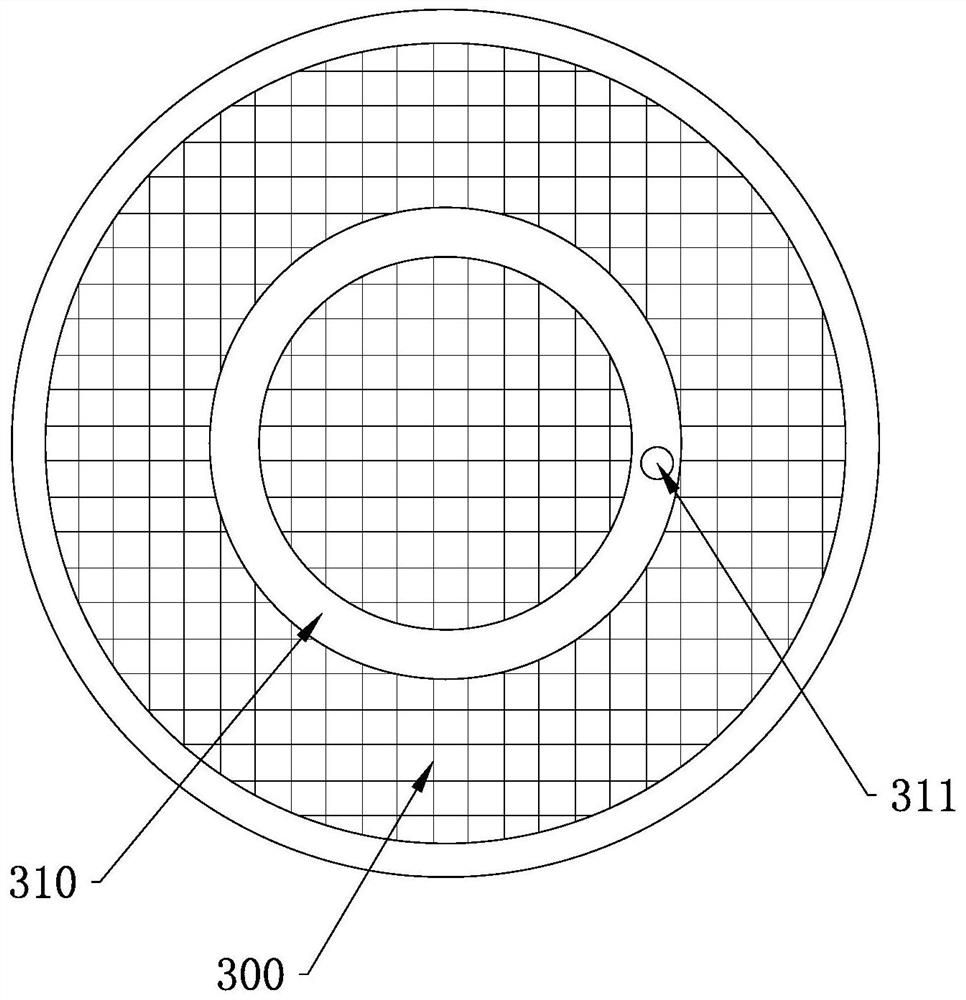

Marine micro-plastic collecting device

InactiveCN110639245AReduce resistanceIncrease sailing speedWater cleaningSeawater treatmentHull structureMechanical engineering

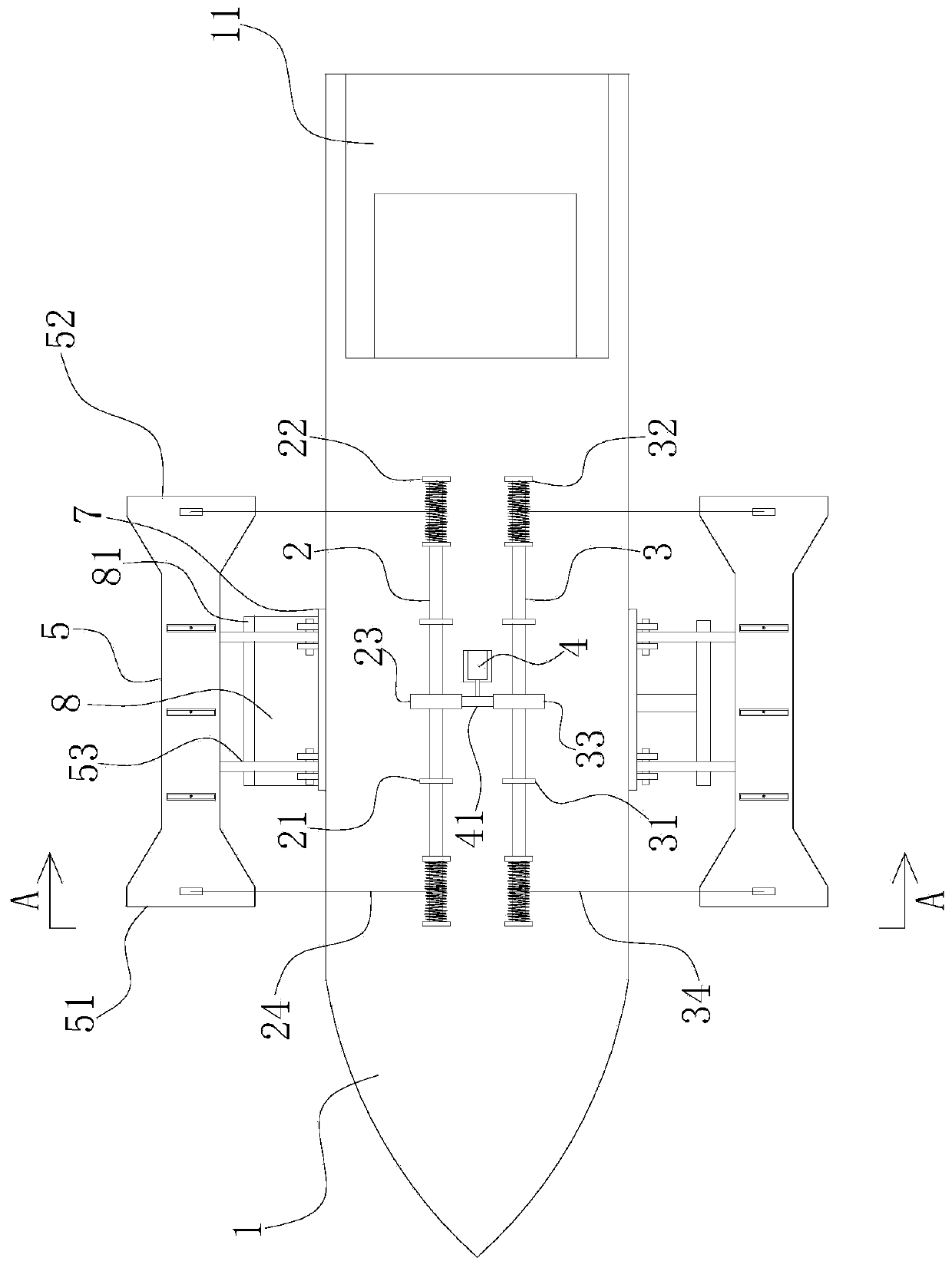

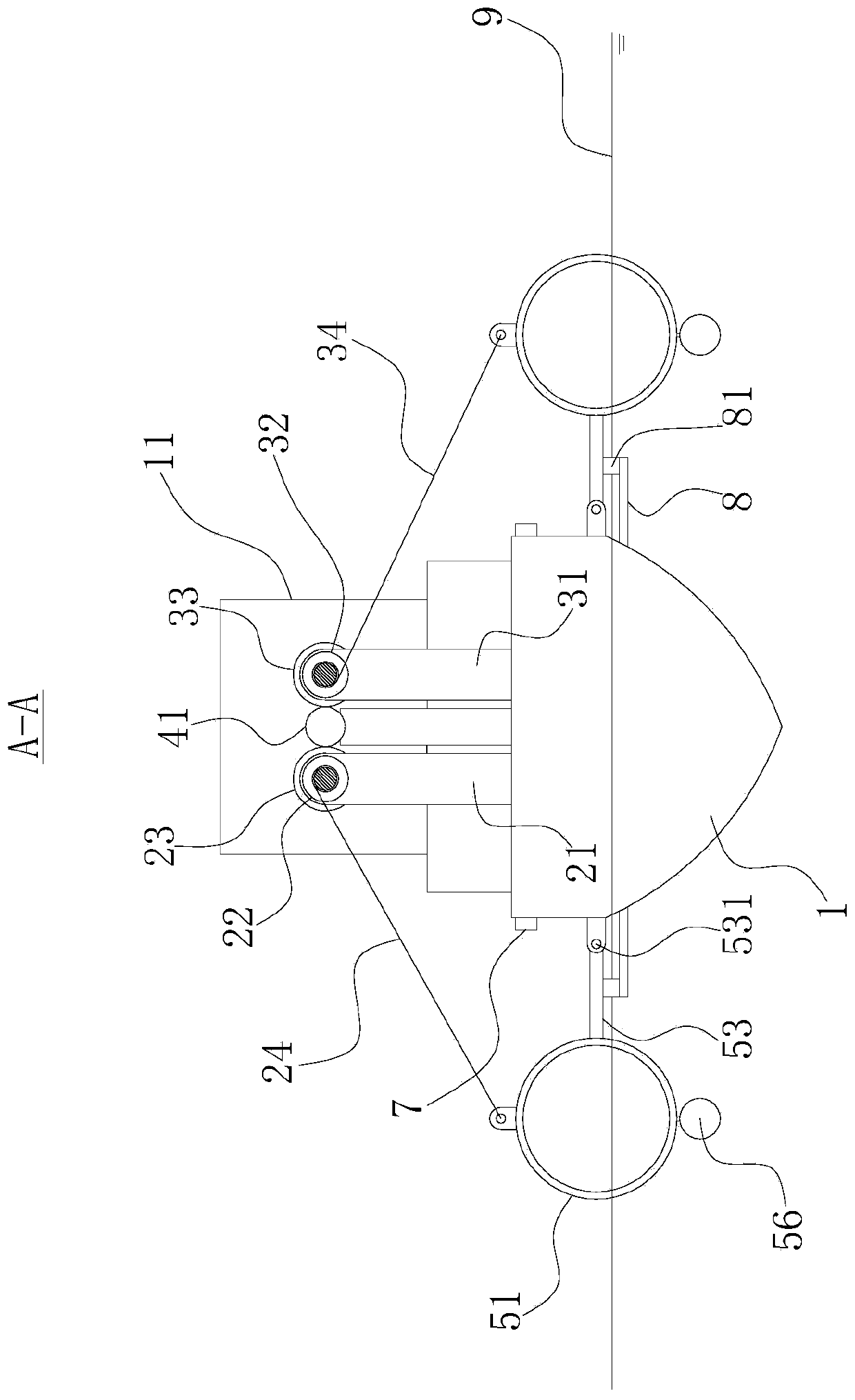

The invention provides a marine micro-plastic collection device, and belongs to the technical field of micro-plastic collection. The device comprises a ship body, two circular pipes and a rotating mechanism, the two circular pipes are respectively located at the left side and the right side of the ship body correspondingly, the length directions of the two circular pipes are consistent with the length direction of the ship body, every circular pipe is horizontally provided with supporting rods, the free ends of the supporting rods are hinged to the ship body, a water inlet is arranged at one end, close to the head of the ship body, of every circular pipe, a water outlet is arranged at one end, close to the tail of the ship body, of each circular pipe, three filtering mechanisms are sequentially arranged in every circular pipe from the corresponding water inlet to the corresponding water outlet, the three filtering mechanisms can sequentially filter micro-plastics from large to small, the rotating mechanism is arranged on the ship body structure, and the rotating mechanism can drive the two round pipes to rotate in the same direction and in the opposite directions at the same time.The device can quickly collect the micro-plastics in the ocean, and is simple and efficient.

Owner:ZHEJIANG OCEAN UNIV

Cotton fluffing machine with dust collection function

InactiveCN107385566ATo achieve the purpose of loose cotton woolService life effectFibre cleaning/opening machinesFiberEngineering

The invention discloses a cotton bouncing machine with a dust-absorbing function, comprising a casing, an accommodating cavity is opened inside the casing, one side of the accommodating cavity is open, and one side of the inner wall of the accommodating cavity is inlaid with a fixing cavity A placing box is placed on the top of the fixing plate, and the placing box is placed above the fixing plate. In the present invention, when the cotton-bombing machine is working, the exhaust fan in the exhaust air works by arranging the cooperation of the exhaust pipe and the dust-removing box, so that the air in the cotton-bombing machine is extracted, and when the air in the inner cavity of the cotton-bombing machine is extracted At the same time, the cotton waste will be filtered through the dust box and the dust box, and discharged through the exhaust pipe, so as to achieve the vacuuming of the cotton bomber and prevent the cotton waste waste from being adsorbed on the inner wall of the accommodation cavity. affect the service life.

Owner:秦泽坤

Self-cleaning anti-blocking filter screen

PendingCN112403058ARealize self-cleaningAffect the filtering effectStationary filtering element filtersWater storageWater storage tank

The invention discloses a self-cleaning anti-blocking filter screen which comprises a filter screen body rotatably mounted in a mounting groove, a reset spring is fixedly connected between the end ofthe filter screen body and the inner wall of the mounting groove, a water inlet pipe is connected to the upper side wall of the mounting groove, and a guide rod is arranged on the outer side of the mounting groove. The outer wall of the guide rod is slidably sleeved with a sliding block, the outer wall of the upper end of the guide rod is sleeved with a telescopic spring, the two ends of the telescopic spring are fixedly connected with the upper side wall of the sliding block and the outer wall of the guide rod respectively, a through opening is formed in the outer wall of the mounting groove,an arc-shaped block slides in the through opening, and a connecting rod is rotatably connected to the outer side wall of the arc-shaped block. When too many impurities exist on the filter screen, a water outlet pipe is triggered to move upwards through rotation of the filter screen, water in a water storage tank flows out to flush the filter screen, meanwhile, a movable plate moves to open a discharge port, self-cleaning of the filter screen is achieved, and the situation that the filtering effect is affected due to too many impurities on the filter screen is avoided.

Owner:李明锋

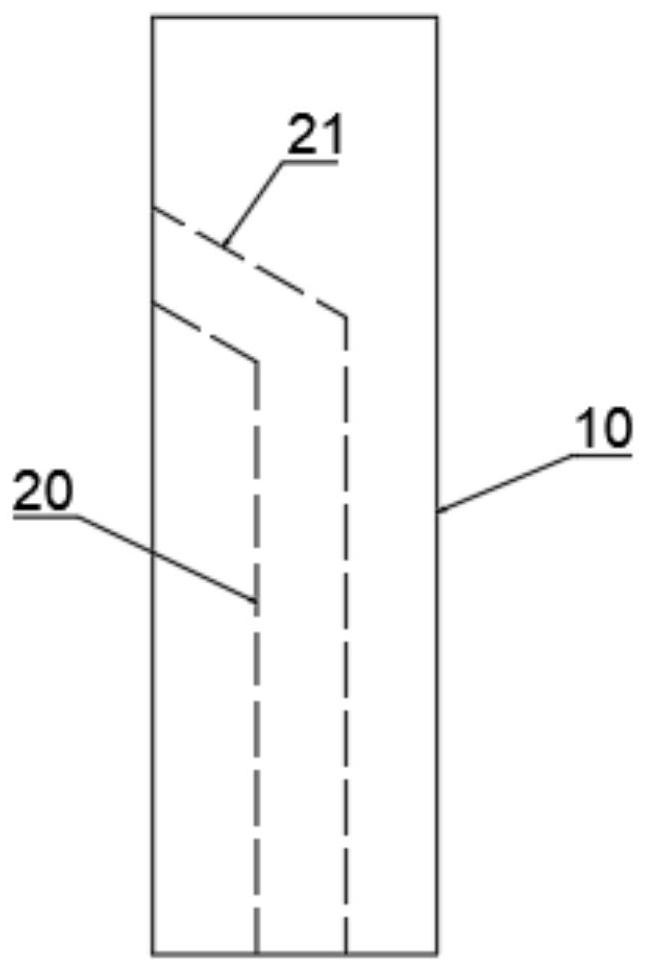

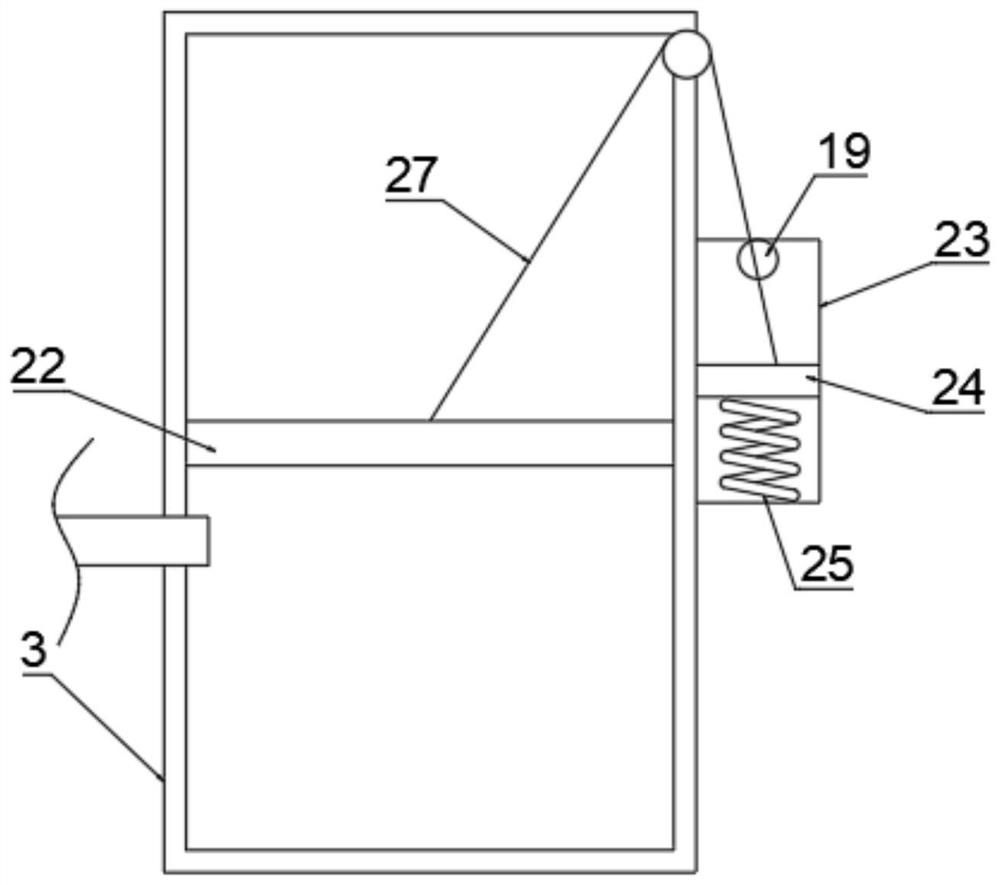

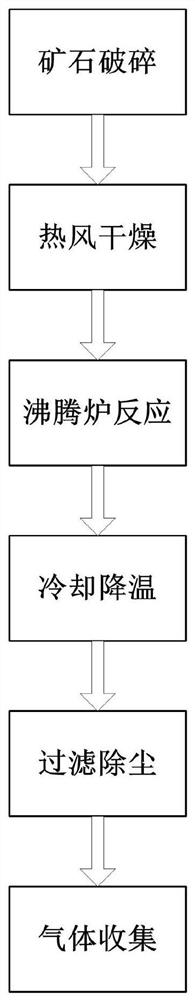

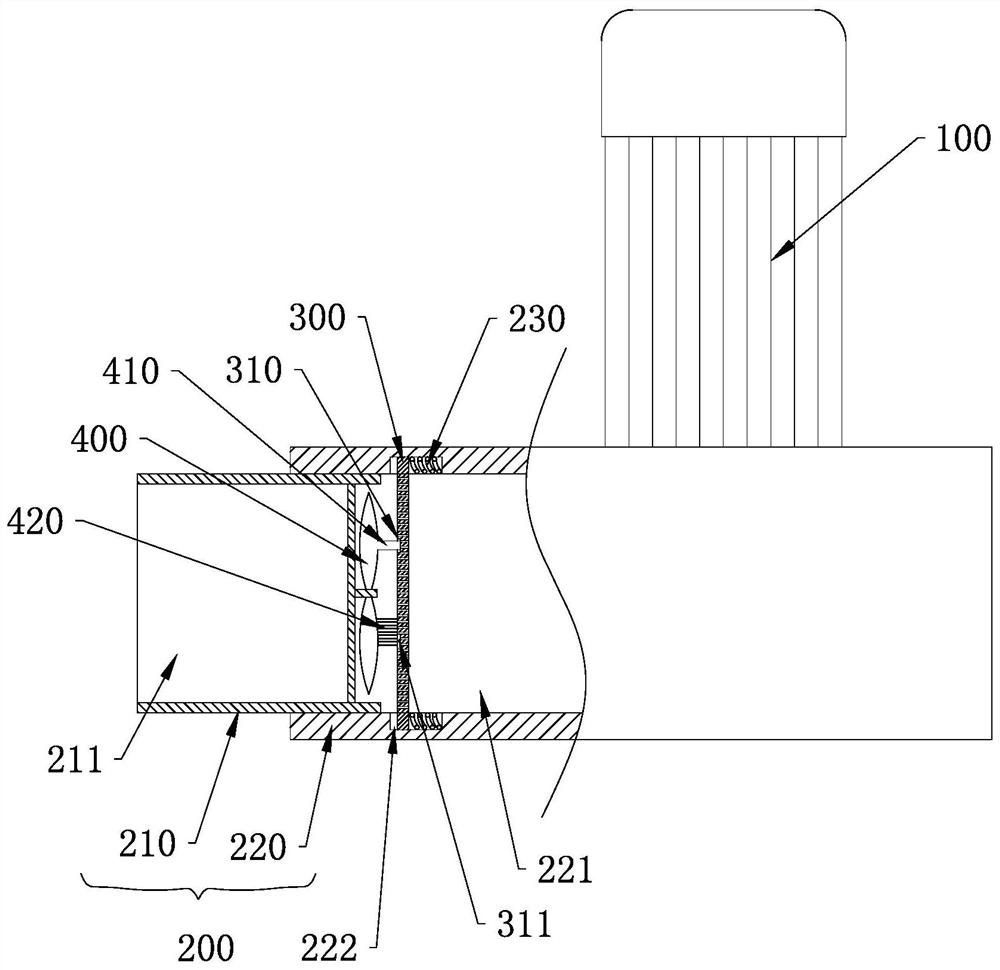

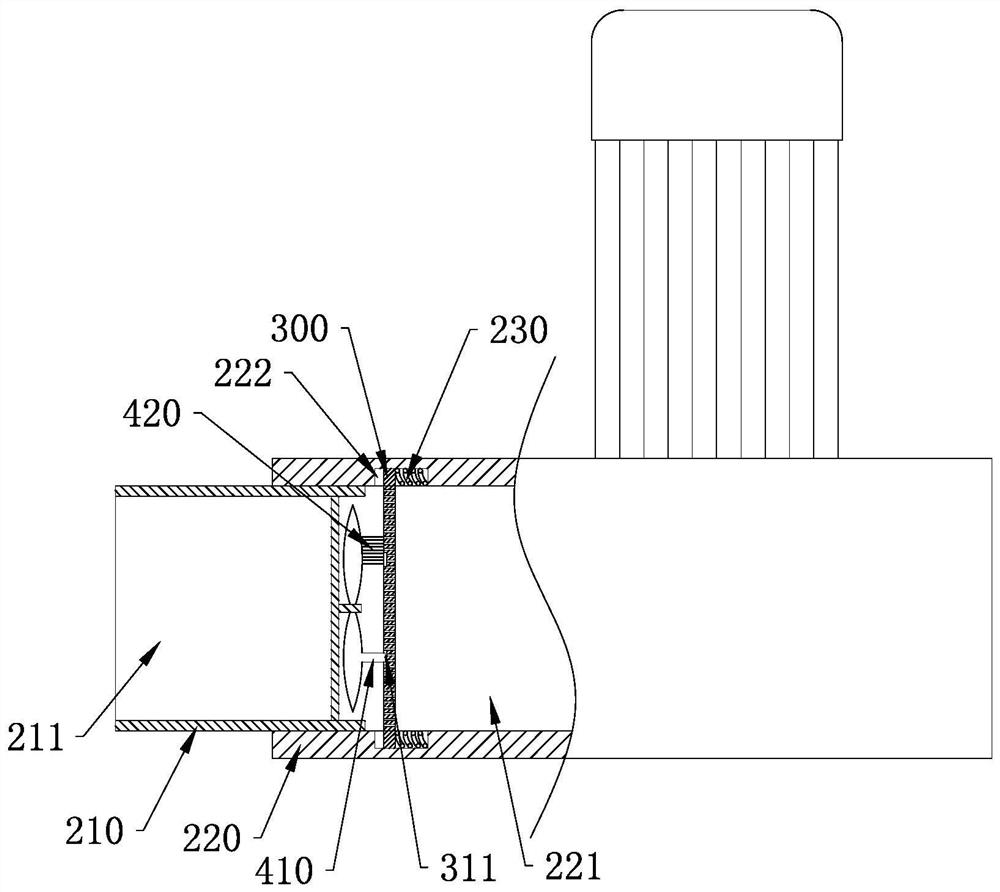

Pretreatment process for preparing industrial concentrated sulfuric acid

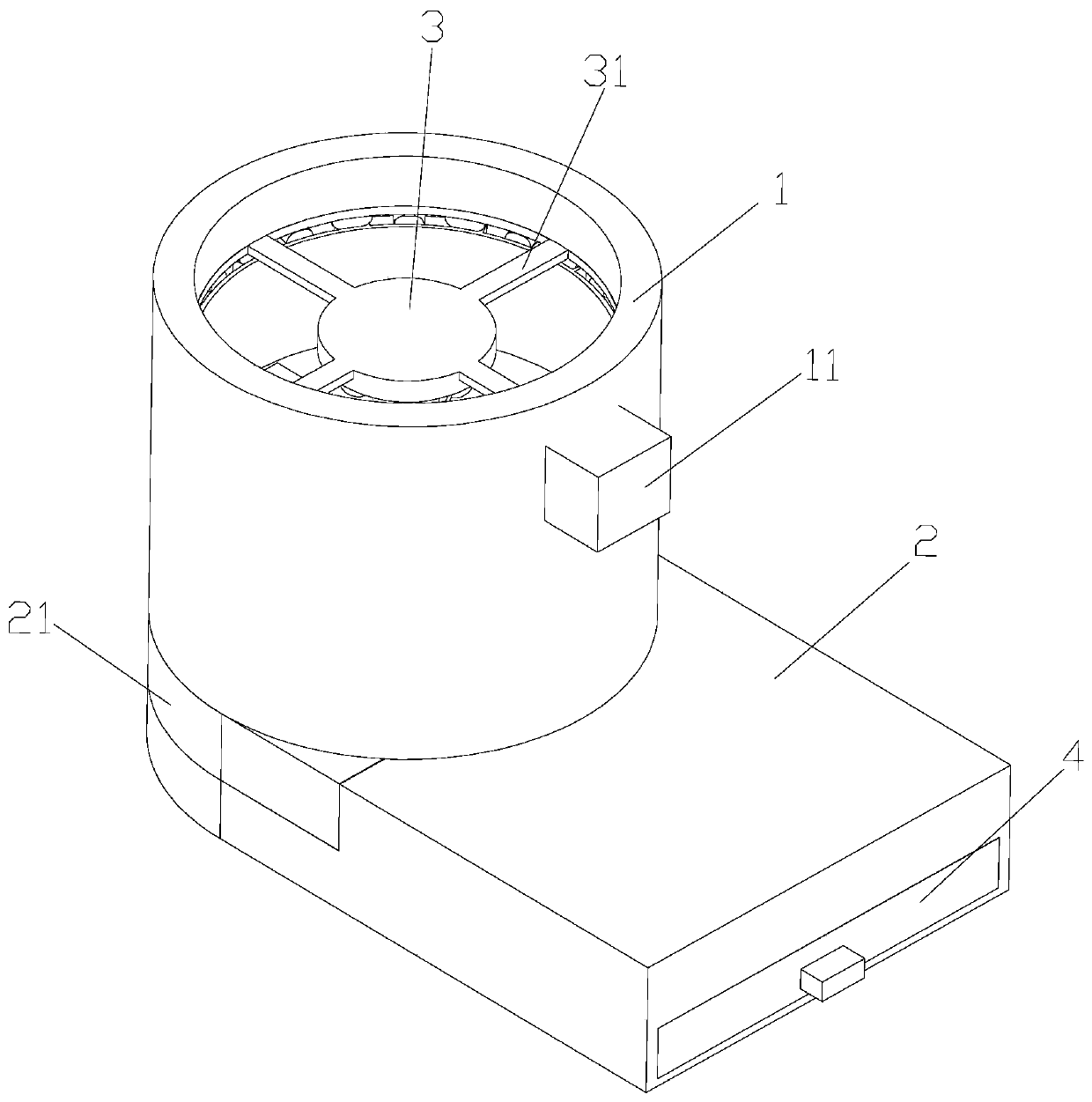

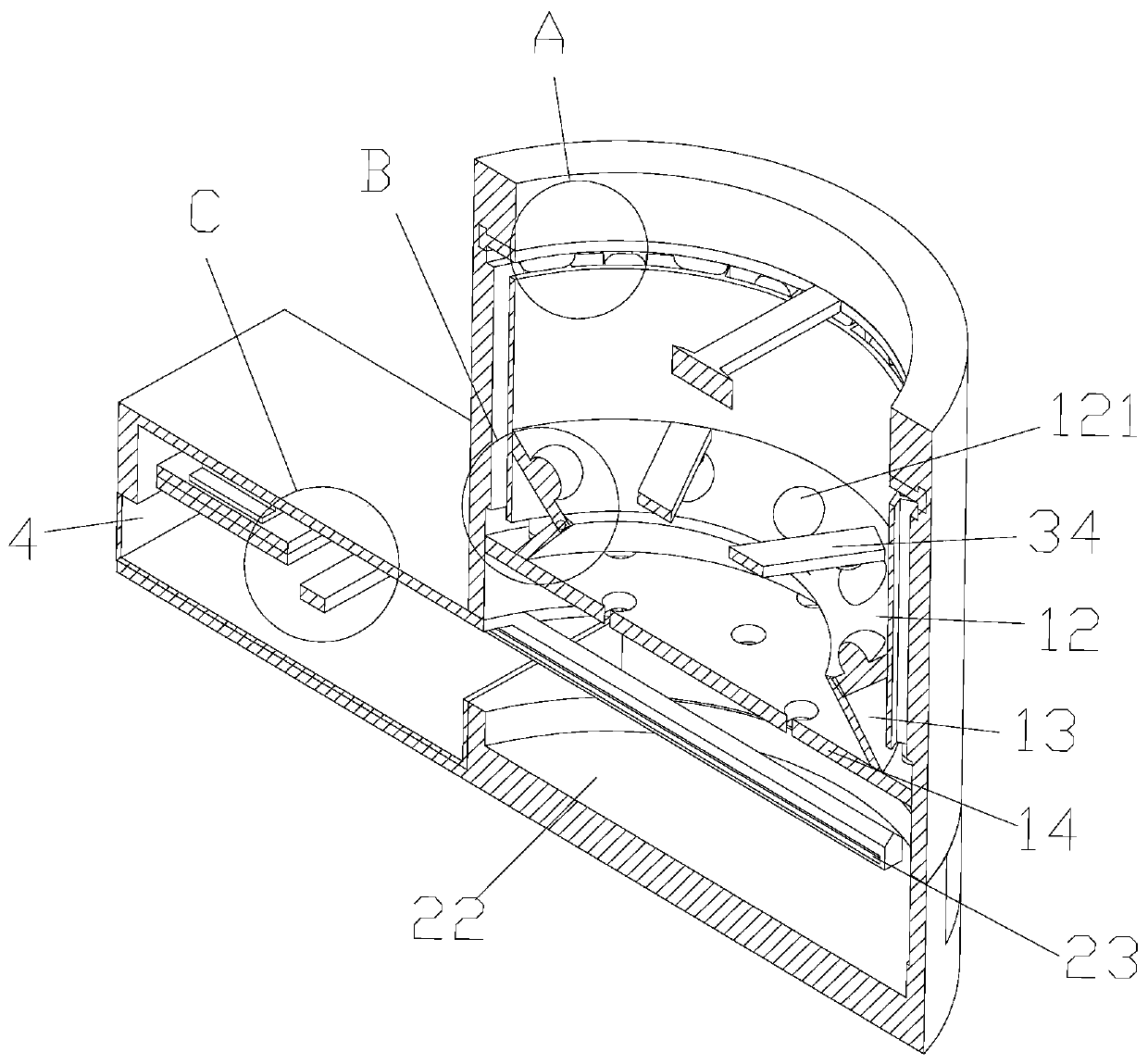

ActiveCN111617568AAffect the preparation effectEffective filteringDispersed particle filtrationTransportation and packagingPipeRoasting

The invention relates to a pretreatment process for preparing industrial concentrated sulfuric acid, which comprises a bottom plate, a shell frame, an air inlet pipe and a filtering device. The shellframe is arranged at the upper end of the bottom plate, the shell frame is of a cylindrical hollow structure, the air inlet pipe is arranged at the lower end of the left side of the shell frame, and the filtering device is arranged in the shell frame. The pretreatment process can solve the problems as follows: when existing equipment is used for filtering gas generated after pyrite roasting, the filtering effect is poor, the filtering is incomplete, impurities in the gas cannot be effectively and completely removed, the impurities are prone to blocking filter screen holes, and the gas filtering effect is affected; and meanwhile, when existing equipment filters gas generated after pyrite roasting, the filtered impurities cannot be effectively collected, the collected impurities are inconvenient to clean, and the using effect of the equipment is affected.

Owner:ANHUI HUAERTAI CHEM IND

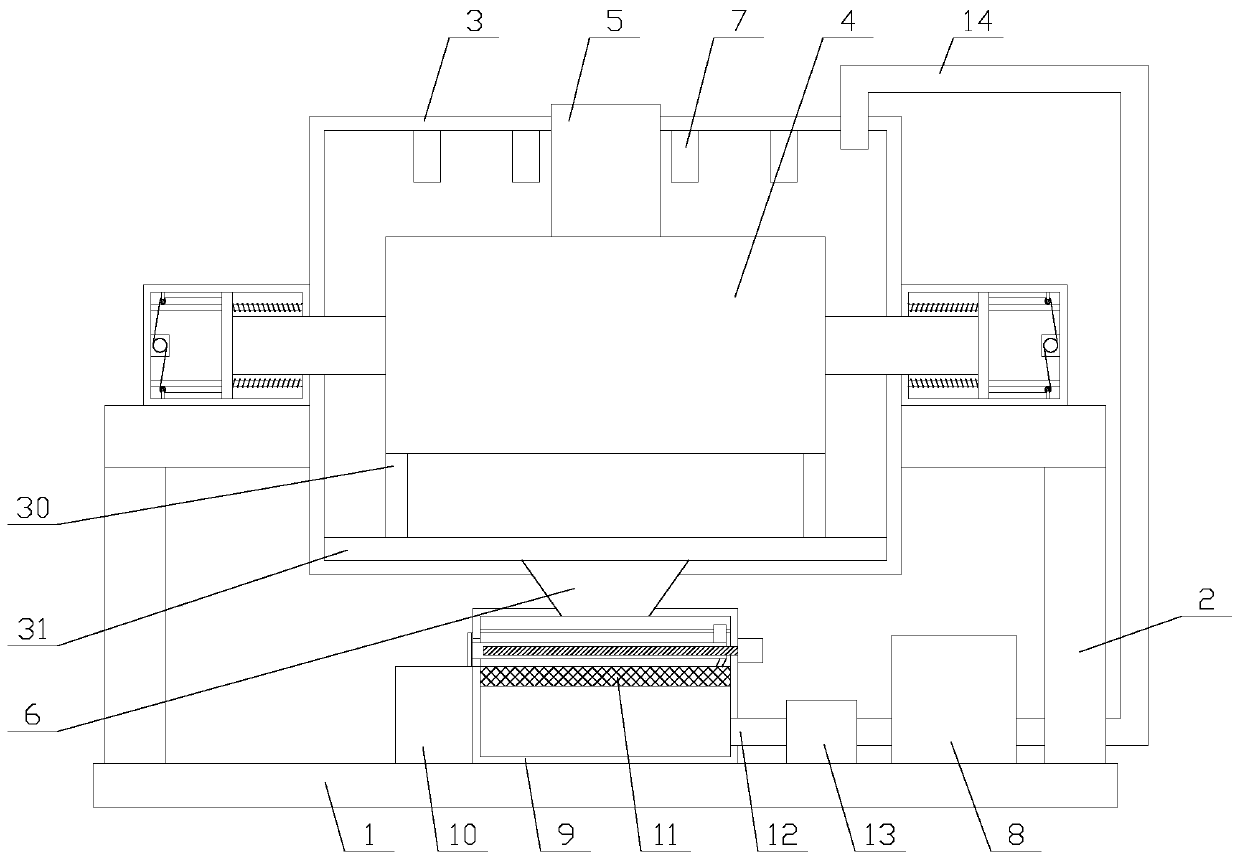

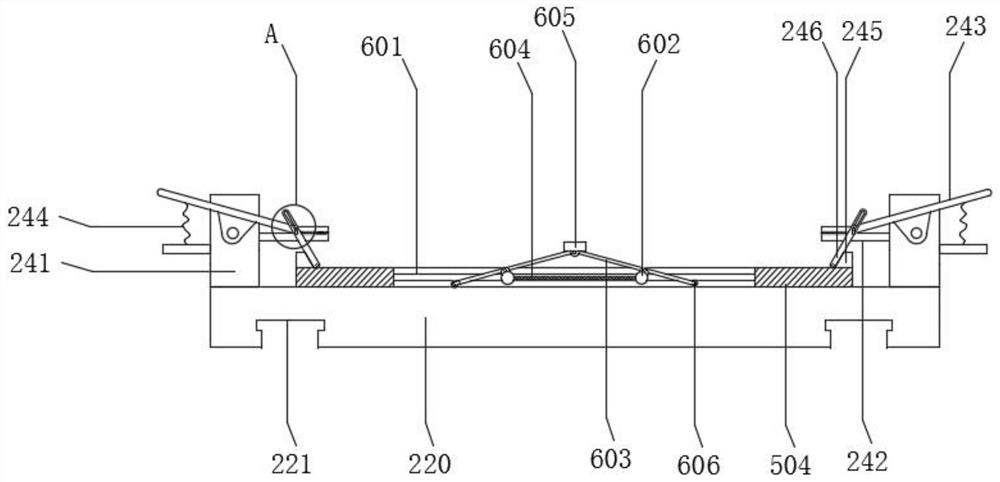

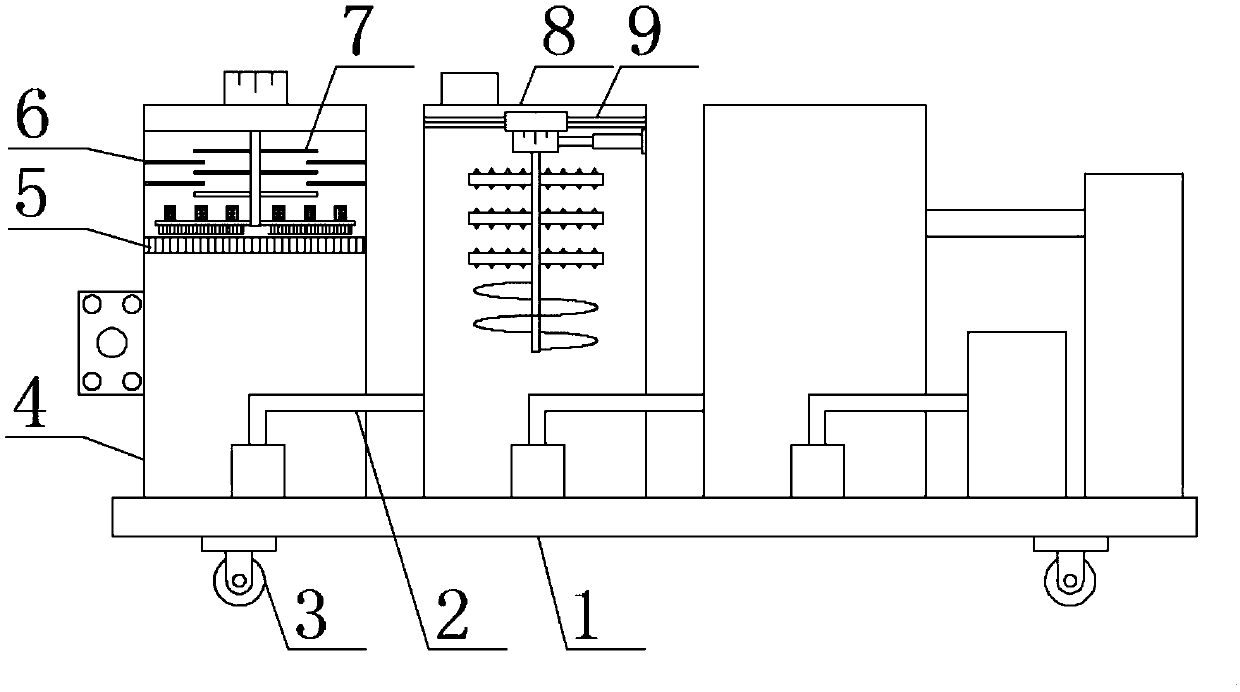

Automatic stripping and laser drilling equipment for LCP flexible circuit board

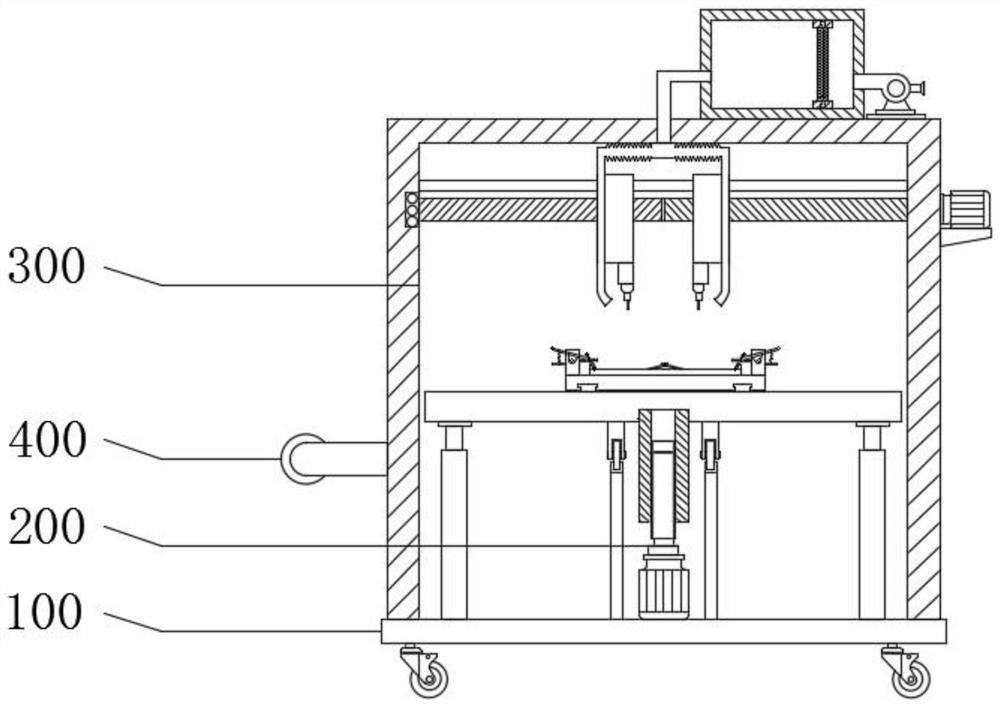

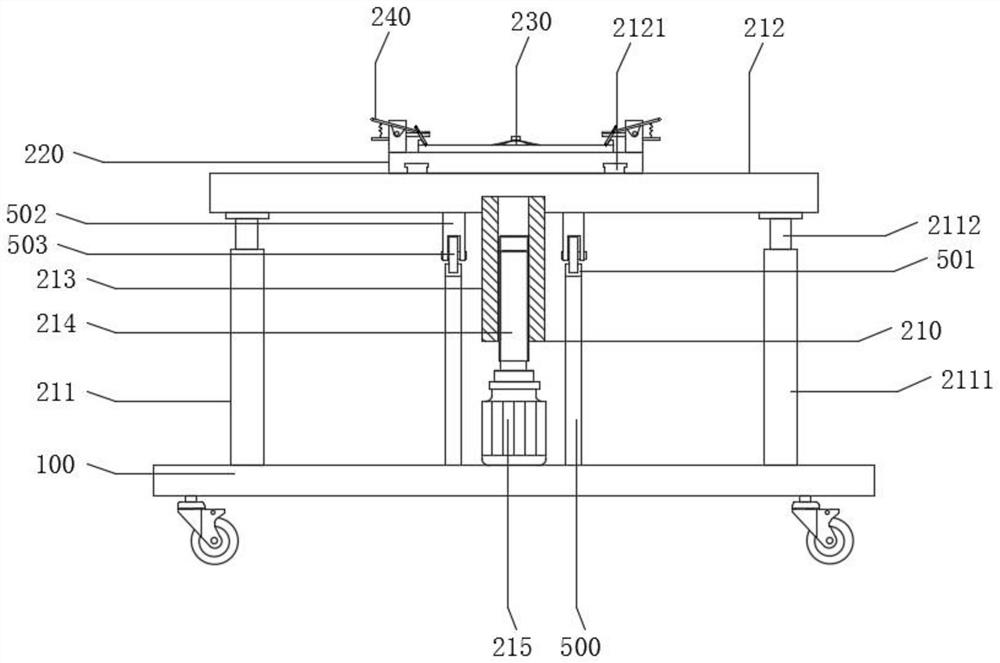

InactiveCN113385841AStripping to achieveNo need for manual operationDispersed particle filtrationWelding/cutting auxillary devicesFlexible circuitsStructural engineering

The invention provides automatic stripping and laser drilling equipment for an LCP flexible circuit board, and belongs to the technical field of circuit board machining. The laser drilling equipment for the LCP flexible circuit board comprises a base, a fixing assembly and a laser drilling assembly. The fixing assembly comprises a lifting piece, a sliding table, an electric push rod and a clamping piece. The sliding table is driven by the lifting piece to descend, in the descending process, a jacking column moves along with the sliding table, when a supporting roller at the lower end of the jacking column makes contact with a supporting guide rail at the upper part of a supporting column, the supporting guide rail generates supporting force on the supporting roller and the jacking column, and along with downward movement of the sliding table, the jacking column jacks a stripping plate upwards, the drilled LCP flexible circuit board on the sliding table is ejected through the stripping plate, stripping of the LCP flexible circuit board is achieved, manual stripping is not needed, and the production efficiency is greatly improved.

Owner:聂三磊

Waste mineral oil recovery and reutilization device with cleaning function

ActiveCN109609179AAffect the filtering effectAvoid cloggingTransportation and packagingRotary stirring mixersForeign matterFuel tank

The invention discloses a waste mineral oil recovery and reutilization device with a cleaning function, belonging to the technical field of waste treatment. The waste mineral oil recovery and reutilization device comprises a supporting base plate, a cleaning mechanism and a stirring mechanism, wherein one end of the upper surface of the supporting base plate is provided with an oil storage box; the supporting base plate and the oil storage box are fixedly connected in a welded manner; the top end of the oil storage box is provided with a filter net; one side of the oil storage box is providedwith a stirring box; the connection position of the oil storage box and the stirring box is provided with a first oil pipe; and the stirring box and the supporting base plate are fixedly connected ina welded manner. According to the invention, the cleaning mechanism is arranged on the waste mineral oil recovery and reutilization device, a user can remove foreign matters accumulated on the filternet through brush plates of the cleaning mechanism, so the foreign matters are prevented from continuous accumulation to affect the filtering effect of the filter net; moreover, the user can crush theforeign matters in the oil storage box through crushing cutters of the cleaning mechanism, so the filter net is prevented from generating blockage due to excessively large volume of the foreign matters.

Owner:山东卓泰油脂科技有限公司

Squeezing device for prinsepia utilis royle oil

ActiveCN110696413AAffect the filtering effectLow costFatty-oils/fats productionPressesEngineeringMechanical drive

The invention discloses a squeezing device for prinsepia utilis royle oil and belongs to the technical field of food processing equipment. The squeezing device comprises a machine box. The top of a box body of the machine box is provided with a feed inlet. A first pressing roller and a second pressing roller are symmetrically arranged on the lower side of the feed inlet and rotate downwards on theadjacent sides thereof so as to form a squeezing channel, so that prinsepia utilis royle nut materials enter the squeezing channel to be squeezed and be conveyed downwards. A first sliding rod is vertically arranged on the side face of one side of the first pressing roller and is fixedly connected to the side wall of an inner cavity of the machine box. A first slider is slidably connected to thefirst sliding rod. The squeezing device has the beneficial effects that a second slider and a cleaning brush are arranged, a residual oil cake mixture on a strainer and stuck oil cakes are cleaned away, and the conditions that net holes of the strainer are blocked, and the filtration effect of the strainer is influenced are avoided. A mechanical transmission mechanism is arranged, so that the pressing rollers are in transmission linkage with the cleaning brush on the second slider, a plurality of purposes are achieved through one power device, cost is lowered, and work efficiency is improved.

Owner:西昌市金粮山粮油食品有限公司

Urban domestic sewage discharge monitoring device

ActiveCN113914433AAffect emission efficiencySlow down the flow of waterFatty/oily/floating substances removal devicesSewerage structuresWater flowEngineering

The invention discloses an urban domestic sewage discharge monitoring device, and relates to the technical field of sewage discharge. The urban domestic sewage discharge monitoring device comprises a fixed cylinder, wherein a fixed ring is fixedly arranged in a position, near the left end, of the inner wall of the fixed cylinder; a filtering mechanism is arranged in a position, near the left end, inside the fixed cylinder; a speed reducing mechanism is arranged in a position, near the right end, in the fixed cylinder; a monitoring part is fixedly arranged in a position, near the right end, inside the fixed cylinder through a fixing column; the filtering mechanism comprises an elastic ring, an annular cavity, an elastic filtering piece and a movable part; the elastic ring is fixedly arranged on the left side of the fixed ring; and the outer surface of the elastic ring is connected with the inner wall of the fixed cylinder. According to the urban domestic sewage discharge monitoring device, the filtering mechanism and the speed reducing mechanism are arranged, impurities on one side of the elastic filtering piece are shaken off, the condition that the sewage discharge efficiency is affected by impurity accumulation is avoided, the water flow speed on the outer side of the monitoring part is slowed down, and the monitoring part works normally.

Owner:江苏海峡环保科技发展有限公司

Water pump with self-cleaning function

ActiveCN113074109AAffect the filtering effectAvoid enteringPositive displacement pump componentsLiquid fuel engine componentsWater flowEngineering

The invention discloses a water pump with a self-cleaning function, comprising a pump body and a filter device. The filter device comprises a shell; a water inlet channel is formed in the shell; a filter screen is arranged in the water inlet channel and divides the water inlet channel into a raw water cavity and a purified water cavity; a mounting groove is formed in the inner wall of the shell; the filter screen is arranged in the mounting groove; an elastic member is further arranged in the mounting groove; turbulent flow fan blades are arranged in the raw water cavity; pushing protrusions are arranged on the turbulent flow fan blades; an annular sliding rail is arranged on the filter screen; protruding points are arranged on the annular sliding rail; the turbulent flow fan blades are impacted by water flow to rotate so as to drive the pushing protrusions to slide along the annular sliding rail; and the pushing protrusions drive the filter screen to vibrate in the mounting groove when crossing the protruding points. The turbulent flow fan blades are impacted by the water flow, so that the pushing protrusions on the turbulent flow fan blades push the filter screen to vibrate in the mounting groove, large-particle impurities attached to the filter screen are vibrated off, and the situation that the filter screen is blocked by the large-particle impurities and the filtering effect of the filter screen on the water flow is influenced is prevented.

Owner:ZHEJIANG WEIBANG LEISURE ARTICLE

Chemical engineering filter can

ActiveCN109772009AImprove filtering effectFacilitates centralized cleaning operationsMoving filtering element filtersCompound (substance)Filter effect

The invention belongs to the technical field of chemical engineering equipment, and particularly relates to a chemical engineering filter can. The can comprises an outer can body; the outer can body is internally provided with a first filtering plate, a corrugated metal plate and a second filtering plate; the first filtering plate is arranged on the upper end of the inside of the outer can body through a swing unit, and a first filtering hole is formed in the first filtering plate; the corrugated metal plate is connected to the lower end of the first filtering plate through a shaking unit, anda second filtering hole is formed in the corrugated metal plate; a third filtering plate is disposed on the lower end of the corrugated metal plate, and a third filtering hole is formed in the secondfiltering plate; though the first filtering plate and the corrugated metal plate, when the first filtering plate is swung, the corrugated metal plate is driven to shake by the shaking unit, debris ofexcessively large volumes are filtered and collected at the end of the first filtering plate, and the corrugated metal plate is subjected to secondary filtration in a fluid to prevent a particulate material from accumulating on the first filtering plate and the corrugated metal plate and affecting the filtering effect.

Owner:苏州吉态来胺生物科技有限公司

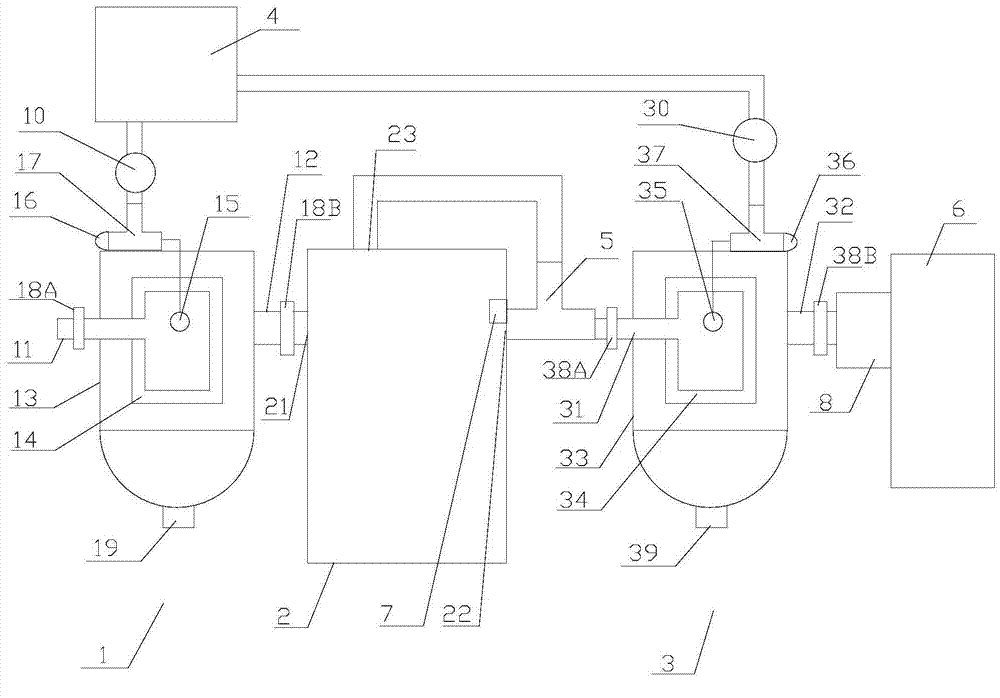

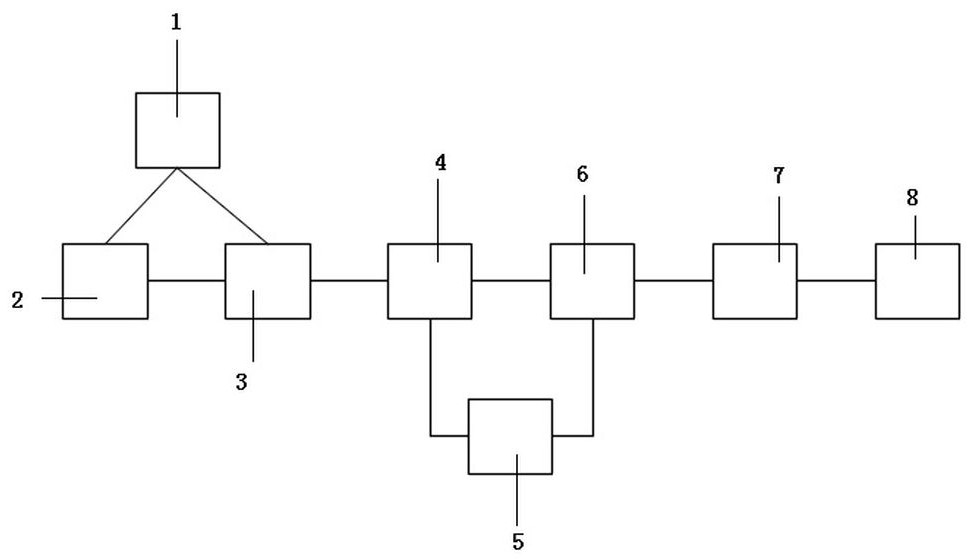

Multistage filtering type natural gas compressor

InactiveCN104711060AImplement loop compressionGuaranteed compressionGaseous fuelsEngineeringSpherical form

The invention discloses a multistage filtering type natural gas compressor which comprises a first filtering device, a cylinder, a second filtering device, a cleaning solution storage tank, a first three-way valve, a gas storage device and a control module, wherein the first filtering device comprises a first suction pump, a first inlet pipe, a first outlet pipe, a first shell, a first filter element, a first spherical shower nozzle, a first fan and the first three-way valve; the second filtering device comprises a second suction pump, a second inlet pipe, a second outlet pipe, a second shell, a second filter element, a second spherical shower nozzle, a second fan and a second three-way valve. According to the multistage filtering type natural gas compressor, uncompressed gas is filtered to be purified by the first filtering device, and the compressed gas is filtered to be further purified and compressed by the second filtering device.

Owner:安徽寅时压缩机制造有限公司

Flue gas desulfurization and denitrification treatment method for coal-fired power plant

ActiveCN111603918AReduced service lifeReduce the use effectGas treatmentDispersed particle filtrationElectric machineryProcess engineering

The invention relates to a flue gas desulfurization and denitrification treatment method for a coal-fired power plant. A workbench, a collecting device and a treatment device are included. The collecting device is fixedly installed at the upper end of the workbench. The treatment device is fixedly mounted at the upper end of the collecting device. The treatment device comprises a treatment tank, an air inlet pipe, a filter frame, a feeding pipe, a motor, a stirring frame and a valve. According to the invention, the flue gas is primarily filtered through the treatment device, a filtering part is cleaned, the problem that the service life and using effect of the filtering part are reduced due to too many impurities accumulated on the surface of the filtering part is prevented, and the flue gas can completely react with a reagent; and the reacted liquid is filtered through the collecting device, the surface of a filtering plate is cleaned, so that the situation in which the filtering plate is blocked and the filtering effect is influenced due to the fact that too many sediments are accumulated on the surface of the filtering plate is prevented.

Owner:深圳妈湾电力有限公司

Conveying device having dust removal function and capable of conveniently fixing garments for garment production

InactiveCN110934368AEasy to operateEasy to useMechanical cleaningPressure cleaningManufacturing engineeringDust control

The invention discloses a conveying device having a dust removal function and capable of conveniently fixing garments for garment production, and relates to the technical field of garment production.The conveying device comprises support legs, and a panel is arranged above the supporting legs; the panel is fixedly connected with the supporting legs, wherein the number of the supporting legs is four. Drawers are slidingly mounted on the outer surface of the front side of the panel, wherein the number of the drawers is four; a first support and a second support are welded to the top of the panel, a box body is arranged above the panel, the first support and the second support are fixedly connected with the box body, a second shell is fixedly arranged in the box body, a conveying mechanism is arranged above the panel, and a fixing mechanism is arranged above the panel. The device is convenient to operate, the working intensity of workers can be reduced, meanwhile, the situation that theworking efficiency is reduced is avoided, the time cost is effectively saved, the working efficiency is improved to a certain degree, and the effect is obvious.

Owner:湖州拉姆蕾姆服饰有限公司

Discharging device of traditional Chinese medicine pill making machine

InactiveCN107411966AUniform temperatureImprove qualitySievingScreeningPulp and paper industryFilter effect

The invention discloses a discharge device of a traditional Chinese medicine pill making machine, which comprises a filter sieve plate, a vibrating motor, a heating block, a circulation fan and a first exhaust fan. Screening and filtering, so as to screen out the unqualified pills, improve the overall quality of the pills, use the vibration motor to vibrate and drive the vibration of the filter sieve plate to speed up the speed of pill screening, and set the heating block for the pills in the screening bin Heating and drying are carried out to prevent the high humidity of the pills from sticking to the filter sieve plate so as to affect the effect of the filter sieve on the filtration of the pills. The circulating fan is used to blow air in the screening chamber to achieve uniform temperature in the screening chamber, thus realizing For the uniform drying of the pills in the screening bin, the first exhaust fan is used to discharge the moisture generated by drying the pills in the screening bin through the dehumidification pipe, thereby speeding up the drying speed of the pills in the screening bin.

Owner:SHENZHEN ZHIHUI QIANXIAN TECH CO LTD

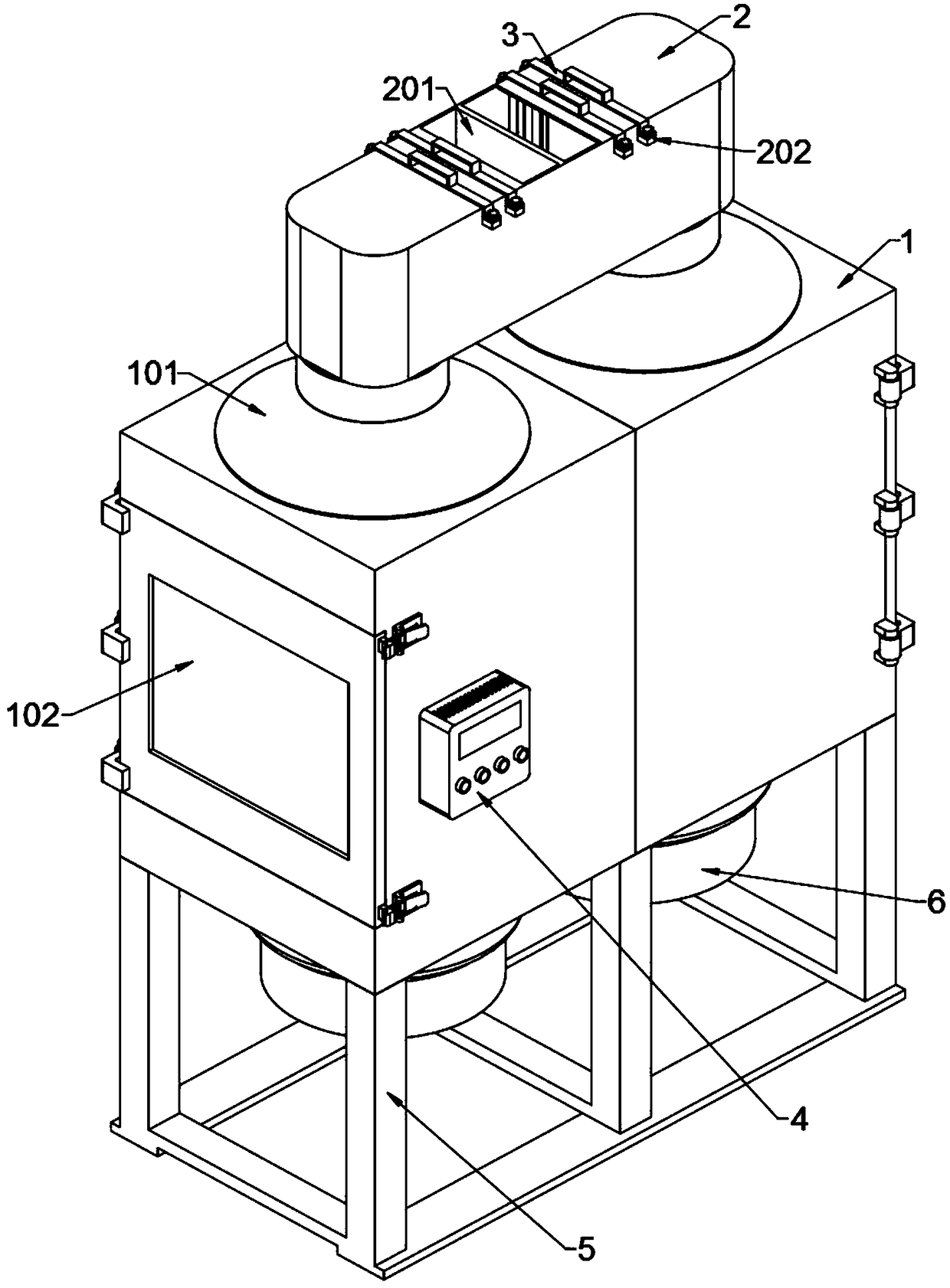

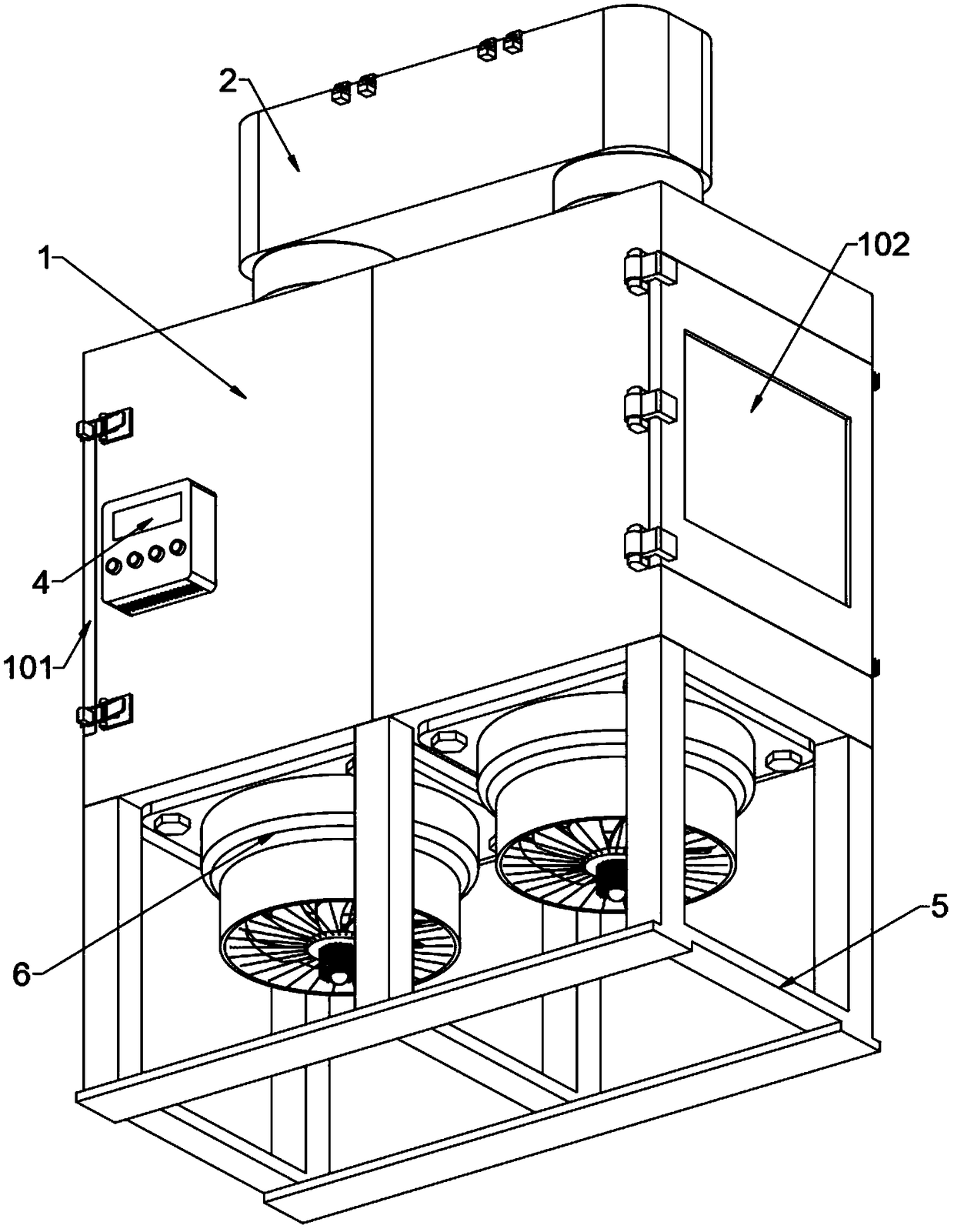

Bag type air dust remover convenient to clean

ActiveCN107569938ATo achieve the purpose of circulationAffect the filtering effectDispersed particle filtrationEngineeringWaste material

The invention discloses a bag type air dust remover convenient to clean. The bag type air dust remover comprises a tank body and an air inlet pipe, wherein the air inlet pipe is mounted at the bottomof the left side of the tank body, and the bottom end of a first spring is connected with the inner wall of an insertion block. According to the bag type air dust remover, the air circulating in the tank body is realized by virtue of the pumping of an air pump, waste gas blown into an air inlet can be filtered by virtue of a bag body, is conveyed to the upper part of a top plate through a throughhole in a first groove steel and is finally exhausted through an air outlet; falling waste materials filtered by the bag body can flow out of the tank body through a waste residue hole, and therefore,the normal operation of dust removal is influenced; and the insertion block is connected with a second pulley through the first spring, and when the insertion block needs to be plugged out of a slot,a first pulley can rotate relative to the second pulley to press down the second pulley into the insertion block, so that the phenomenon that the insertion block cannot be plugged out of the slot dueto the clamping caused by the over-clamping between the first pulley and the second pulley is prevented.

Owner:JIANGSU SENZE ENVIRONMENTAL PROTECTION ENG TECH

Drying and dust-proofing method for air filter element

InactiveCN108159793AAffect the filtering effectAvoid wastingDispersed particle filtrationTransportation and packagingAir filterDrive motor

The invention discloses a drying and dust-proofing method for an air filter element. The transmission speed range of a power structure in the air filter element is controlled through adjusting fan blades, the fan blades can be rotated and turned over through steel balls in order to adjust the direction and the tilt angle of the fan blades, a drive motor in a drive motor storage sleeve is started to perform test run on a rotating shaft, a speed measurement device is used to perform sensitive speed measurement on the wind power at the fan blades in every segment in order to keep the wind speed in a reasonable range, the air filter element is arranged in an apparatus, a mounting tube is connected with the motor, a fixed sleeve compacts the mounting tube through a sealing gasket to avoid air leakage at the connecting position, a positioning ring is connected with other devices to guarantee stable connection, the apparatus officially starts to work after the whole air filter element is mounted, air goes through pores in an outer protection tube and an inner isolation wall plate and enters the filter element, and the outer protection tube and the inner isolation wall plate play a role indust water proofing while supporting, protecting and reinforcing the whole air filter element.

Owner:浙江安吉铭瑞汽车销售有限公司

Sewage reuse purification system

InactiveCN109368834AImprove availabilityReduce the impactWater treatment parameter controlSpecific water treatment objectivesDistributed filteringSewage discharge

The invention discloses a sewage reuse purification system, and relates to the field of sewage purification. The sewage reuse purification system comprises a sewage purification device and a controller; the sewage purification device comprises a precipitating chamber and a purification chamber; a filter chamber is formed in the precipitating chamber; a first water inlet is formed in the filter chamber and provided with a sewer pipe; the sewer pipe penetrates through the top of the precipitating chamber to be connected to the first water inlet; evenly-distributed filter holes are formed in theside wall of the filter chamber; the precipitating chamber communicates with the interior of the filter chamber through the filter holes; and a water outlet is formed in the lower part of the precipitating chamber and provided with a water discharging pipe, and the other end of the water discharging pipe is connected to the purification chamber. According to the sewage reuse purification system, sewage is purified at multiple stages, the utilization degree of the purified sewage is increased, meanwhile, a sewage discharging structure is contained in a sewage purification device, and thus precipitate after sewage purification can be directly discharged.

Owner:HEFEI MINZHONGYIXING SOFTWARE DEV CO LTD

Green building rainwater collecting and discharging system

ActiveCN111705866ALow costImprove processing efficiencyFatty/oily/floating substances removal devicesSewerage structuresWater storageRainwater harvesting

The invention discloses a green building rainwater collecting and discharging system, and relates to the technical field of rainwater collecting devices. The green building rainwater collecting and discharging system comprises a rainwater flow channel, wherein the outlet end of the rainwater flow channel is connected with a flushing water storage pool and a primary filtering water pool; the wateroutlet end of the flushing water storage pool is positioned above the primary filtering water pool; the outlet end of the primary filtering water pool is connected with a rainwater filtering and settling pool, and a rainwater discarding device is arranged between the primary filtering water pool and the rainwater filtering and settling pool; the rainwater discarding device is further connected with the rainwater filtering and settling pool through a rainwater purifying device; and the outlet end of the rainwater filtering and settling pool is connected with a backflow pool, and a plurality ofrainwater collecting pools are arranged between the rainwater filtering and settling pool and the backflow pool. According to the green building rainwater collecting and discharging system, rainwatermetal in the initial stage of rainfall is collected and then treated through the rainwater discarding device, the cost of agent treatment is reduced, and the overall treatment efficiency is improved.

Owner:上海原构设计咨询有限公司

Sewage pretreatment equipment for sewage treatment plant

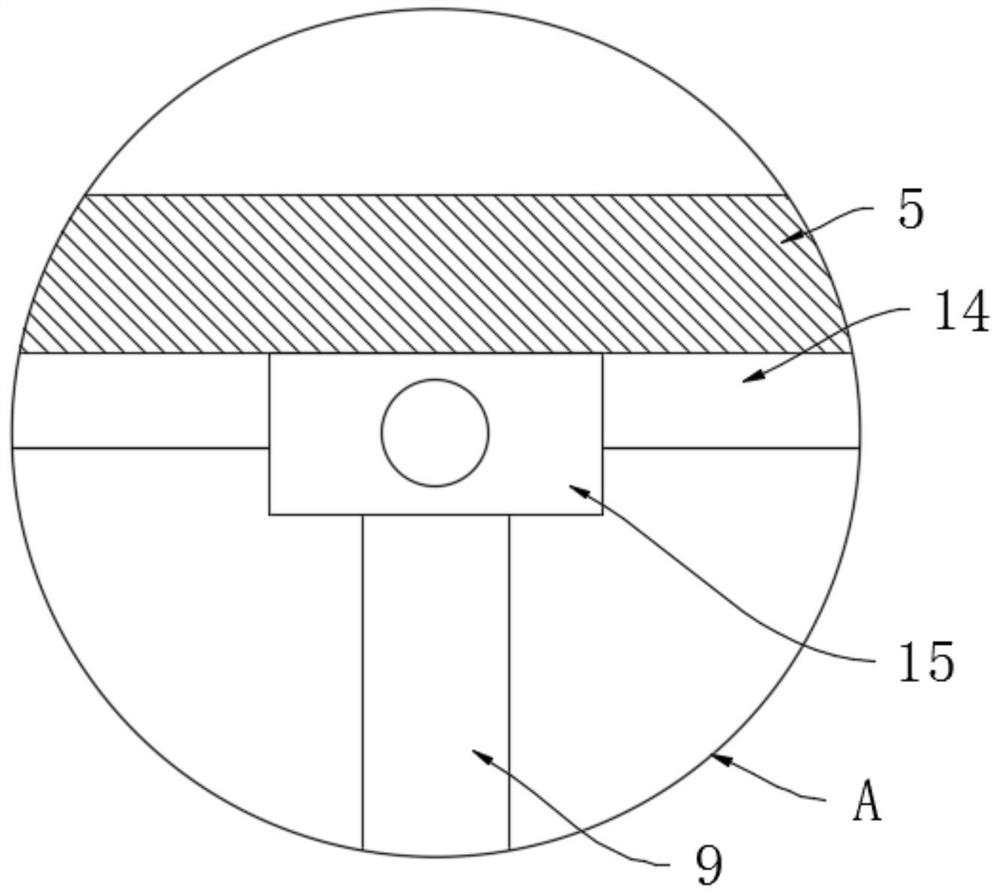

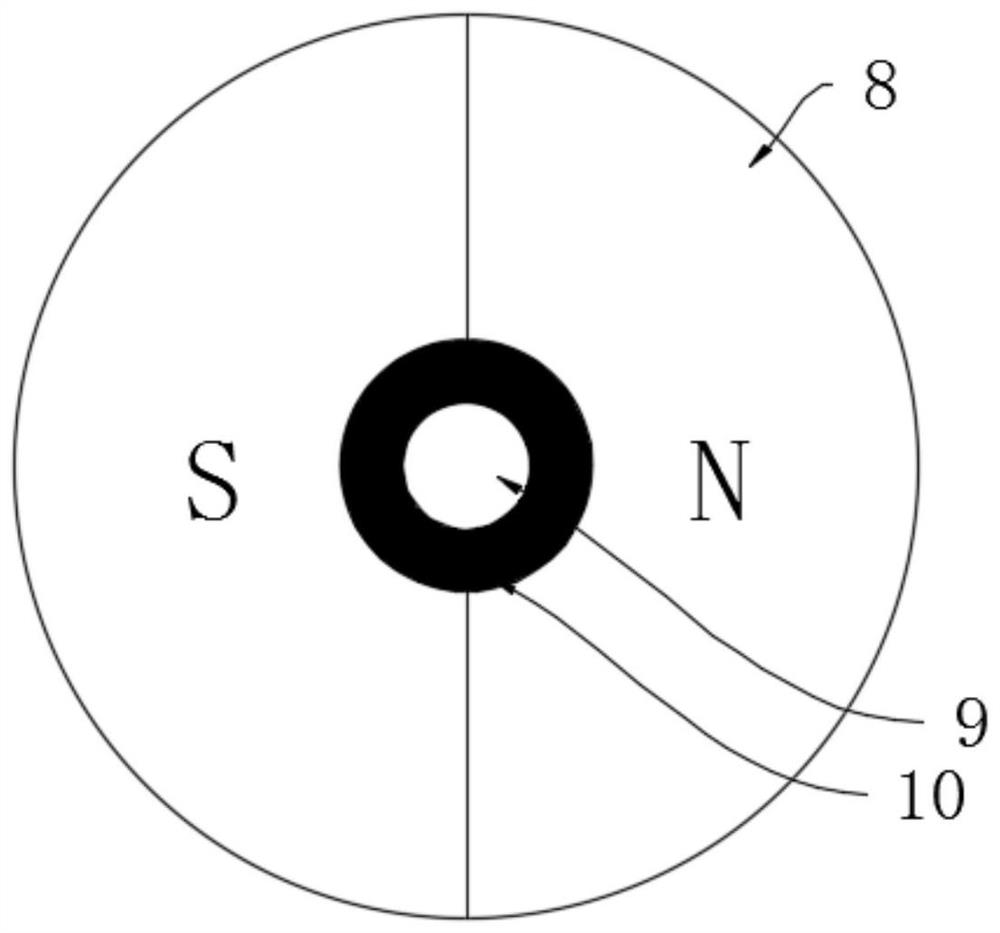

InactiveCN111804042AReduce investmentContinuously workingMoving filtering element filtersSewageSewage treatment

The invention discloses sewage pretreatment equipment for a sewage treatment plant. The equipment comprises a tank body, wherein a water inlet is formed in the upper end surface of the tank body; a slag discharging opening is formed in the side wall of the tank body; a water outlet is formed in the lower end surface of the tank body; a rotating plate is rotationally connected to the inner wall ofthe side, away from the slag discharging opening, of the tank body through a pin shaft; a plurality of water permeable holes opposite to the water inlet are evenly formed in the rotating plate; a plurality of control mechanisms are symmetrically arranged between the rotating plate and the inner wall of the tank body; and each control mechanism comprises a mounting box fixedly connected to the inner wall of the side, close to the slag discharging opening, of the tank body. The first permanent magnet disc and the second permanent magnet disc are arranged; sewage can be continuously filtered by utilizing potential energy of sundries on the upper end face of the rotating plate, the sundries on the upper end face of the rotating plate are discharged into the slag discharging opening, input of manpower and external electric power energy sources is not needed, input of manpower resources is reduced, energy conservation and environmental protection are achieved, continuous work can be achieved, and the using effect is good.

Owner:宋卫校

Self-service multi-book sterilization machine for libraries

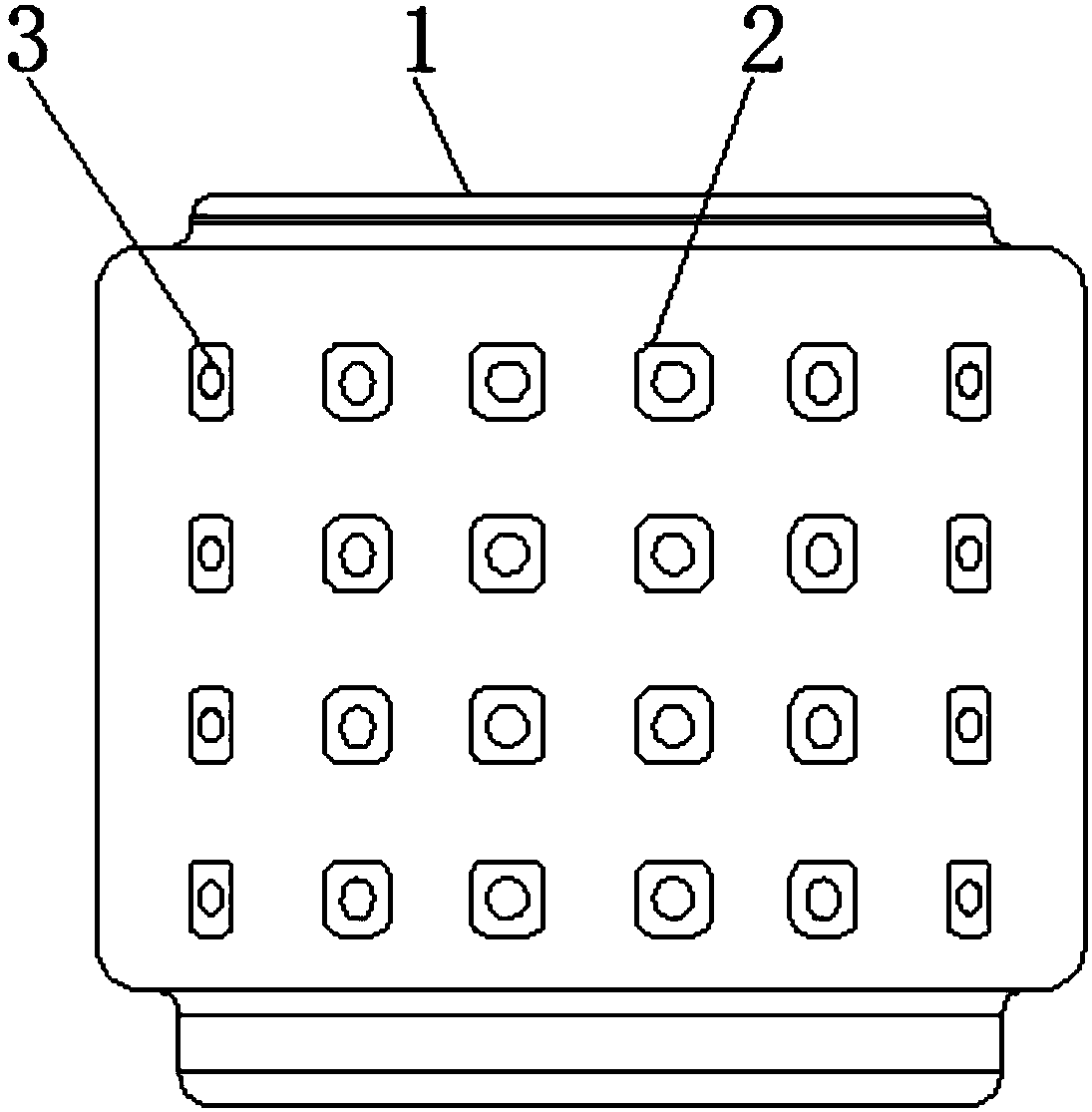

ActiveCN108785699AEasy to cleanEasy to replaceDispersed particle filtrationTransportation and packagingEngineeringHooking

The invention provides a self-service multi-book sterilization machine for libraries. The self-service multi-book sterilization machine comprises quincuncial nuts, dust collection filter screens and shackles. An integral sterilization frame of the self-service multi-book sterilization machine is squarely arranged, left and right slide rods of the sterilization frame are of half-cylinder structures, and three book supporting, compressing and positioning devices are sequentially arrayed and welded inside the sterilization frame from left to right; two hooking lug plates are supported and weldedon the left side and the right side of an end surface of the outer side of a connecting pressure plate of each compressing frame in a protruded manner, the tails of two tension springs are rotationally hooked in center hanging holes of every two corresponding hooking lug plates, every two shackles are symmetrically welded on the top surface of a corresponding book positioning plate and correspondto the two corresponding hooking lug plates, the heads of every two corresponding tension springs are hooked inside the two corresponding shackles, and each compressing frame is tensioned and positioned by the two corresponding tension springs. The self-service multi-book sterilization machine has the advantages that the self-service multi-book sterilization machine is provided with two bent backup plates, the sterilization frame can be constrained by the two bent backup plates from sliding, and accordingly the problem of trouble in secondary insertion due to the fact that an existing sterilization frame is separated from two rails due to interference sliding can be solved.

Owner:WUHU LINGMENG E COMMERCE CO LTD

Combustion fan used for ceramic wall and floor tile production

InactiveCN109185199AAffectAvoid shakingPump componentsPump installationsCombustionPulp and paper industry

The invention discloses a combustion fan used for ceramic wall and floor tile production. The combustion fan comprises a housing, blades and an air inlet pipe; a clamping groove is formed in the surface of the inner wall of the housing, and the interior of the clamping groove is connected with a silencing block; the clamping groove and the silencing block are elastically connected in manner of clamping; the bottom ends of the blades are connected with a rotating shaft; and the blades are located at the right side of the silencing block. Compared with an existing common combustion fan used forceramic wall and floor tile production, the combustion fan used for ceramic wall and floor tile production is capable of performing silencing treatment on noise produced during operation of the combustion fan, so that noise pollution caused to the environment is reduced, and environmental protection property of the combustion fan is improved; moreover, vibration reduction can be performed on the combustion fan so as to reduce vibration produced during use of the combustion fan; and meanwhile, air entering into the combustion fan can also be filtered so as to prevent the phenomenon that the interior of the combustion fan is blocked due to the fact that impurities in the outside air enter into the combustion fan.

Owner:罗会保

Flour filtering device for fine dried noodle production

InactiveCN108787439AControl the feeding amountAffect the filtering effectSievingTransportation and packagingEngineeringFilter effect

The invention discloses a flour filtering device for fine dried noodle production. The flour filtering device comprises a filtering box, a feeding pipeline is fixedly inlaid in the side face of the filtering box, a first motor is fixedly connected to the top of the filtering box, the top of the inner wall of the filtering box is fixedly connected with a first bearing, the output shaft of the firstmotor is fixedly connected with the inner wall of the first bearing, and a rotating shaft is fixedly connected to the interior of the first bearing. The flour filtering device for the fine dried noodle production is provided with a feeding tray, through holes and a filter screen, so that the feeding amount of flour can be effectively controlled, the filtering effect of the filtering box can be prevented from being influenced by too much one-time feeding amount of the flour; and a stirring shaft, a connecting rod and stirring blades are arranged, the flour can be stirred, the flour can be turned over inside the filtering box, so that impurities inside the flour can be separated from the flour; and a screening frame, a disc and a swing rod are arranged, and the flour can be turned over in the screening frame, the flour is screened and filtered, so that the screening effect of the flour is enhanced.

Owner:蒙城于氏德霖食品科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com