Flue gas desulfurization and denitrification treatment method for coal-fired power plant

A technology for desulfurization and denitrification and treatment methods, which is applied in the field of flue gas desulfurization and denitrification treatment in coal-fired power plants, and can solve problems such as affecting filtration quality, increasing processing costs, and blocking filter plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

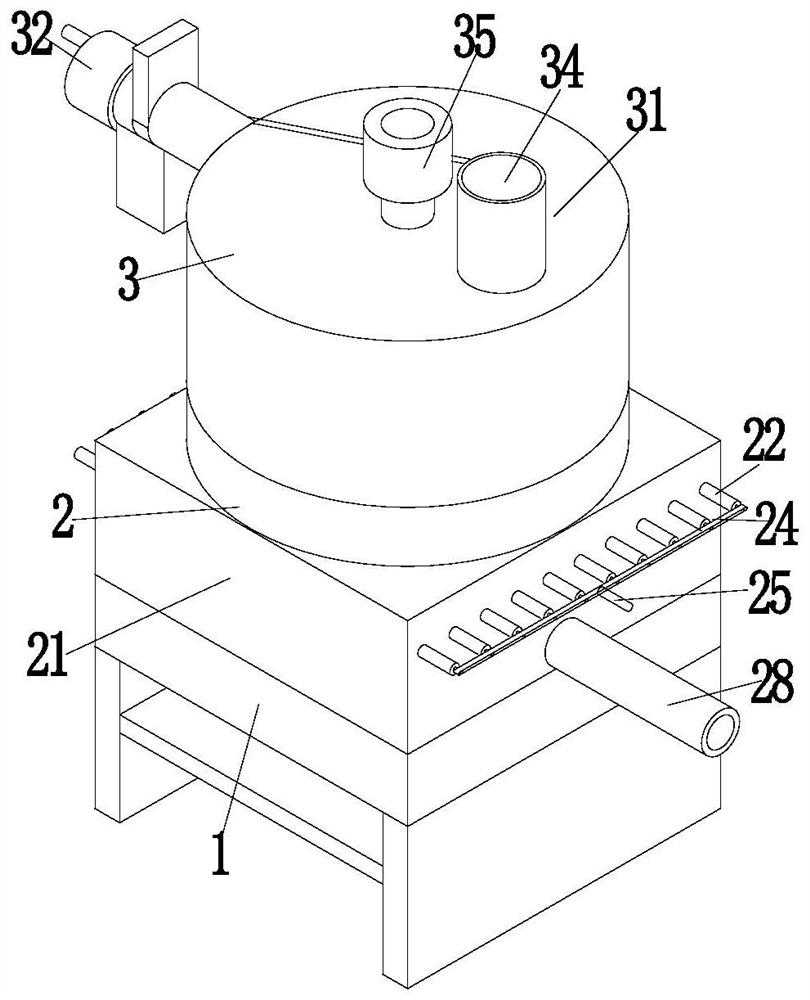

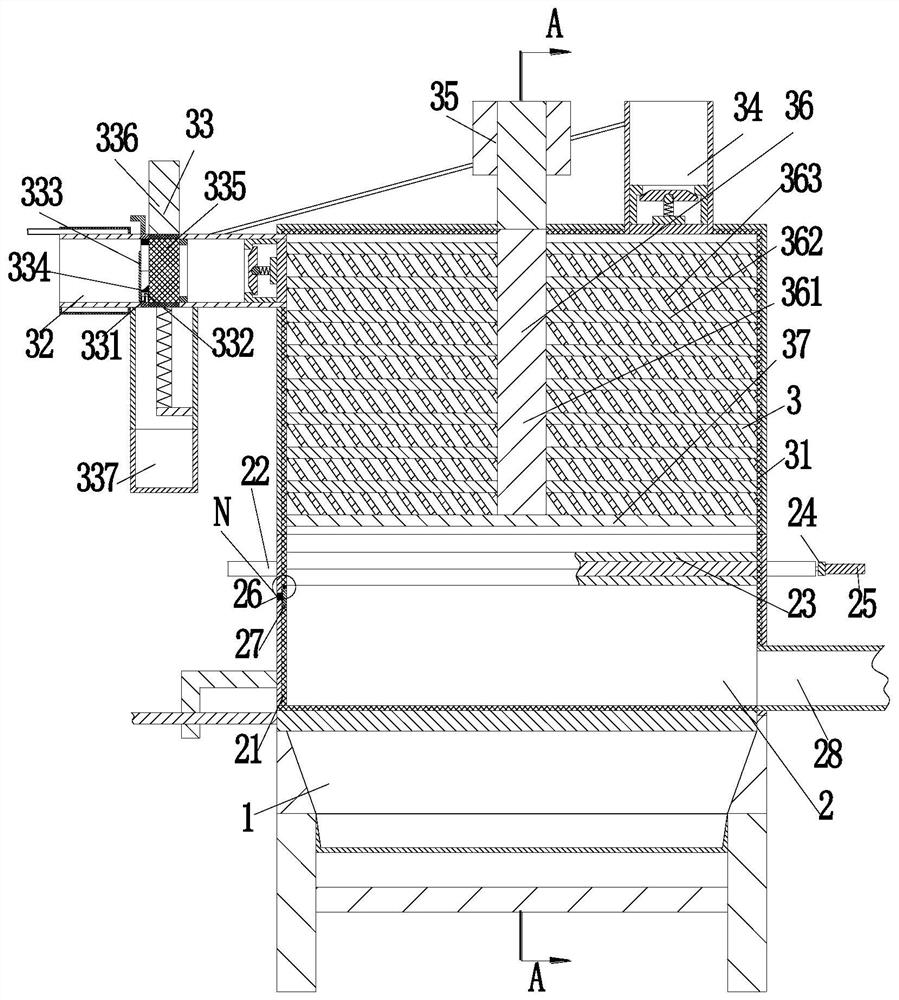

[0038] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 7 , to further elaborate the present invention.

[0039] A coal-fired power plant flue gas desulfurization and denitration treatment method, which uses a coal-fired power plant flue gas desulfurization and denitration treatment equipment, the coal-fired power plant flue gas desulfurization and denitrification treatment equipment includes a workbench 1, a collection device 2 and a treatment Device 3, the specific method when using the above-mentioned flue gas desulfurization and denitrification treatment equipment in coal-fired power plants to desulfurize flue gas is as follows:

[0040] S1. Introduce gas: pass the flue gas into the equipment, cool and filter, separate the solid particle impurities in the cooled flue gas from the flue gas, and collect the solid particle impurities;

[0041] S2. Gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com