Marine micro-plastic collecting device

A collection device and microplastic technology, applied in seawater treatment, separation methods, and cleaning of open water surfaces, can solve problems such as low collection efficiency, prolong collection time, and reduce the effective water area of collection, so as to reduce resistance and avoid The impact of the water flow is too large and the effect of increasing the sailing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

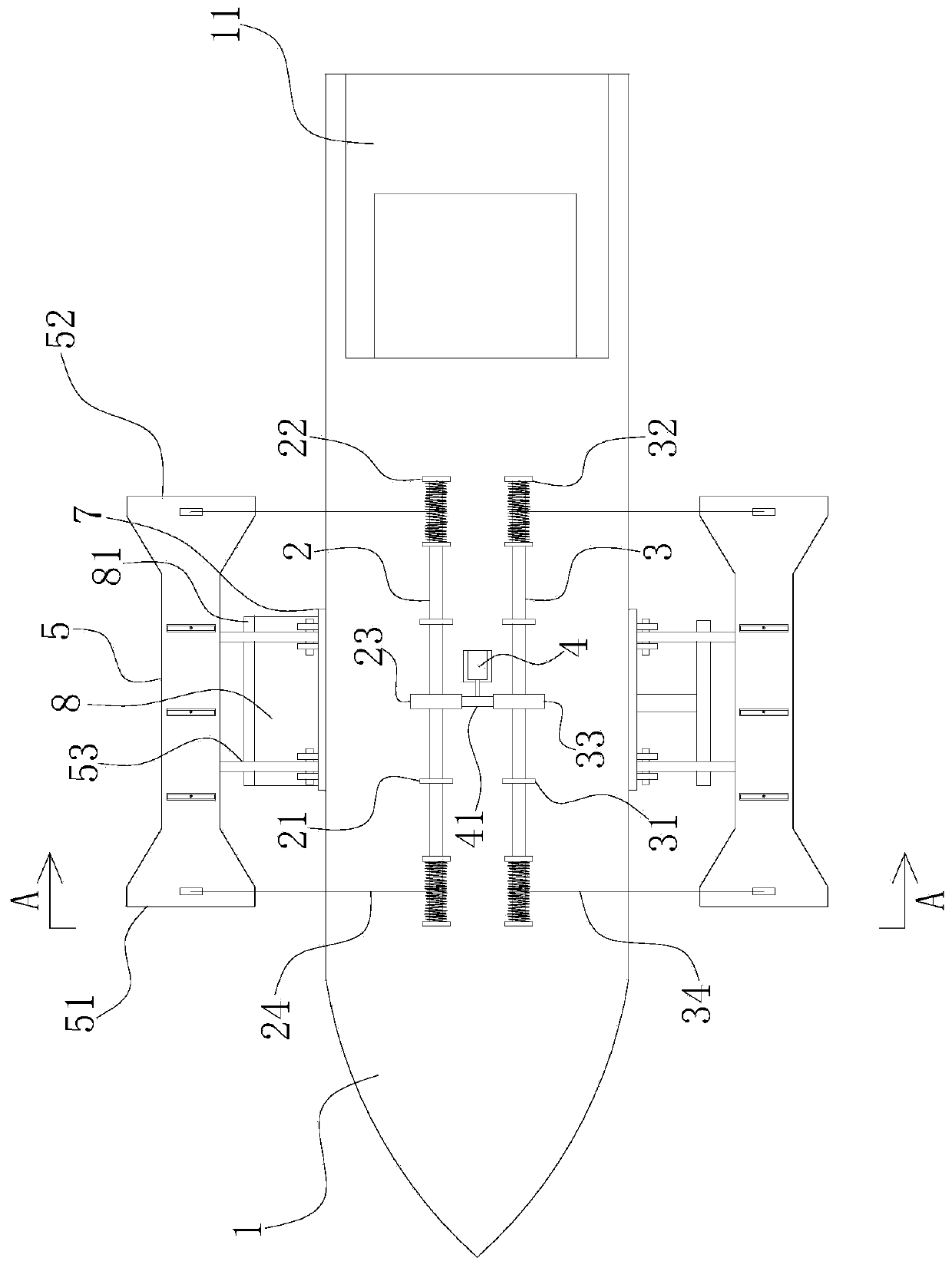

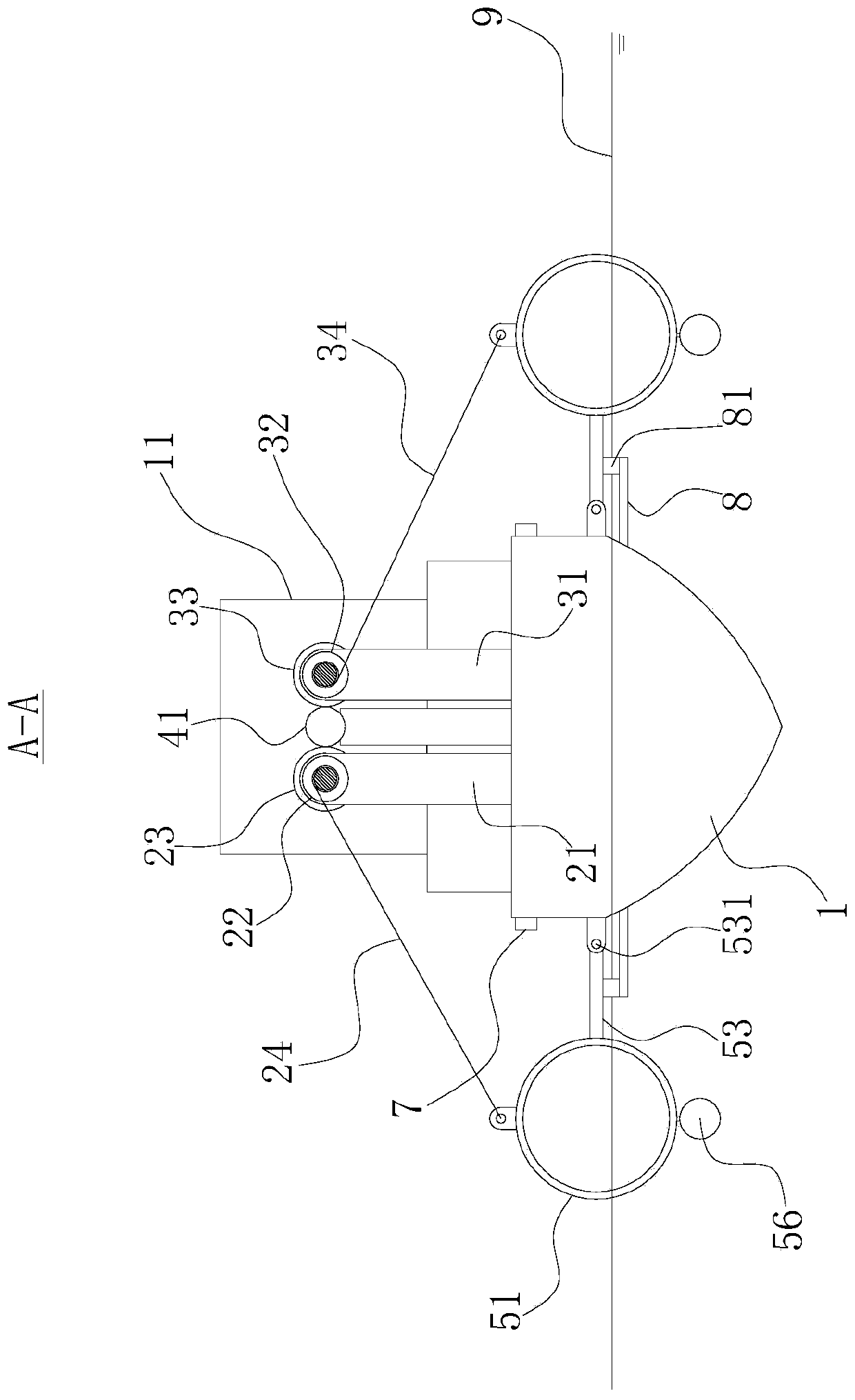

[0052] Such as Figures 1 to 8 As shown, a marine microplastic collection device includes a hull 1, two circular tubes 5 and a rotating mechanism.

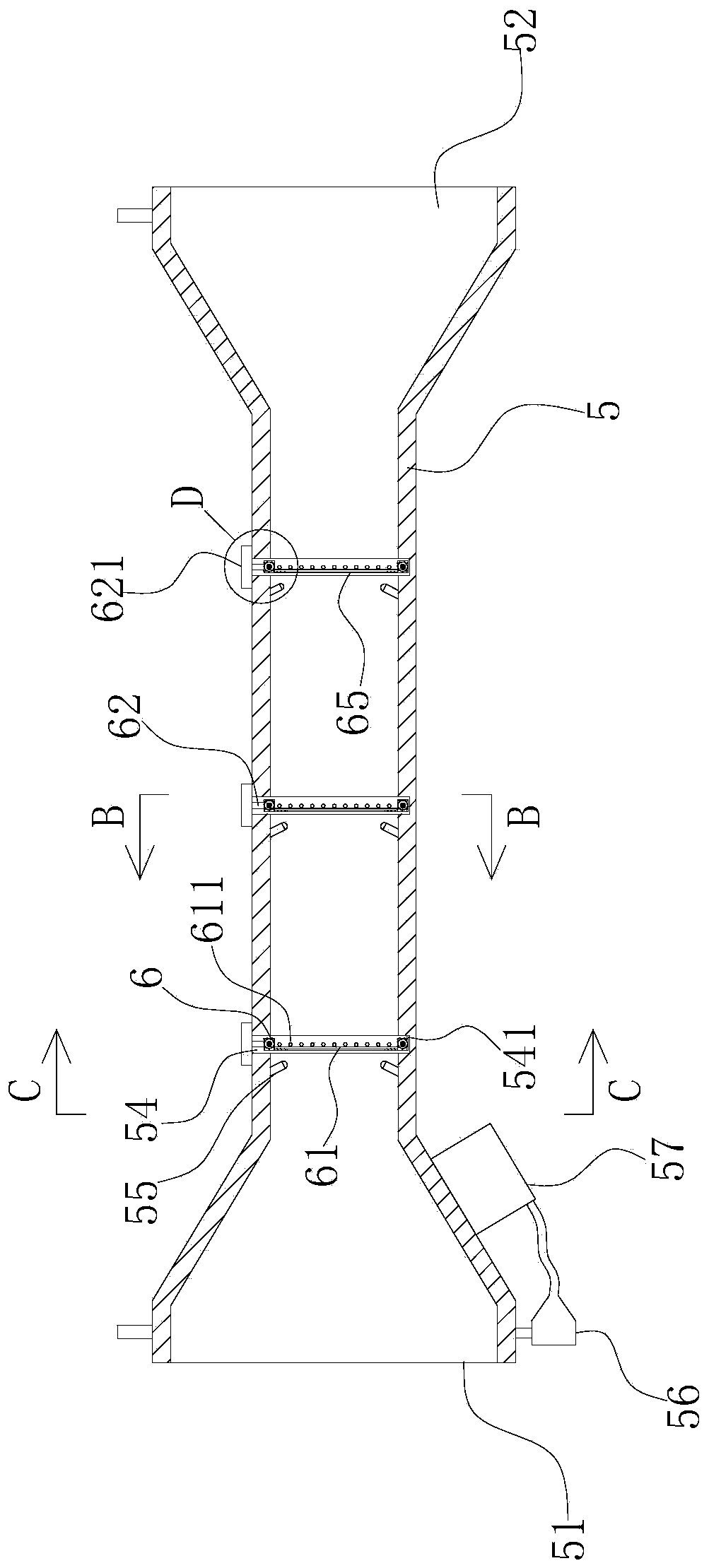

[0053] The two circular tubes 5 are respectively located on the left and right sides of the hull 1, and the length direction of the two circular tubes 5 is consistent with the length direction of the hull 1. Two support rods 53 are fixed on the two circular tubes 5. One end of the support rod 53 away from the round pipe 5 is hinged on the hull 1 through a hinge shaft 531, the end of the round pipe 5 near the bow of the hull 1 is the water inlet 51, and the end of the round pipe 5 near the tail of the hull 1 is Water outlet 52, three filter mechanisms are arranged in sequence ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com