Sewage pretreatment equipment for sewage treatment plant

A sewage pretreatment and sewage treatment plant technology, applied in the direction of filtration separation, separation method, mobile filter element filter, etc., can solve the problems of poor applicability, insufficient energy saving and environmental protection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

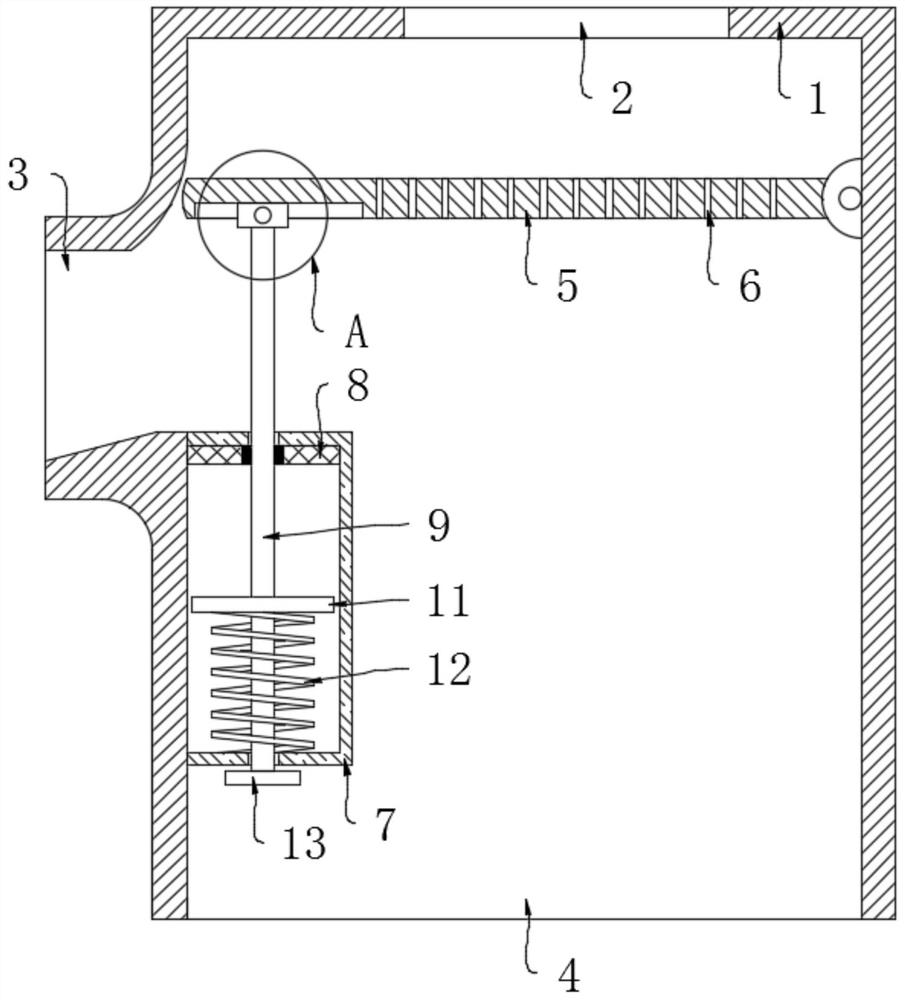

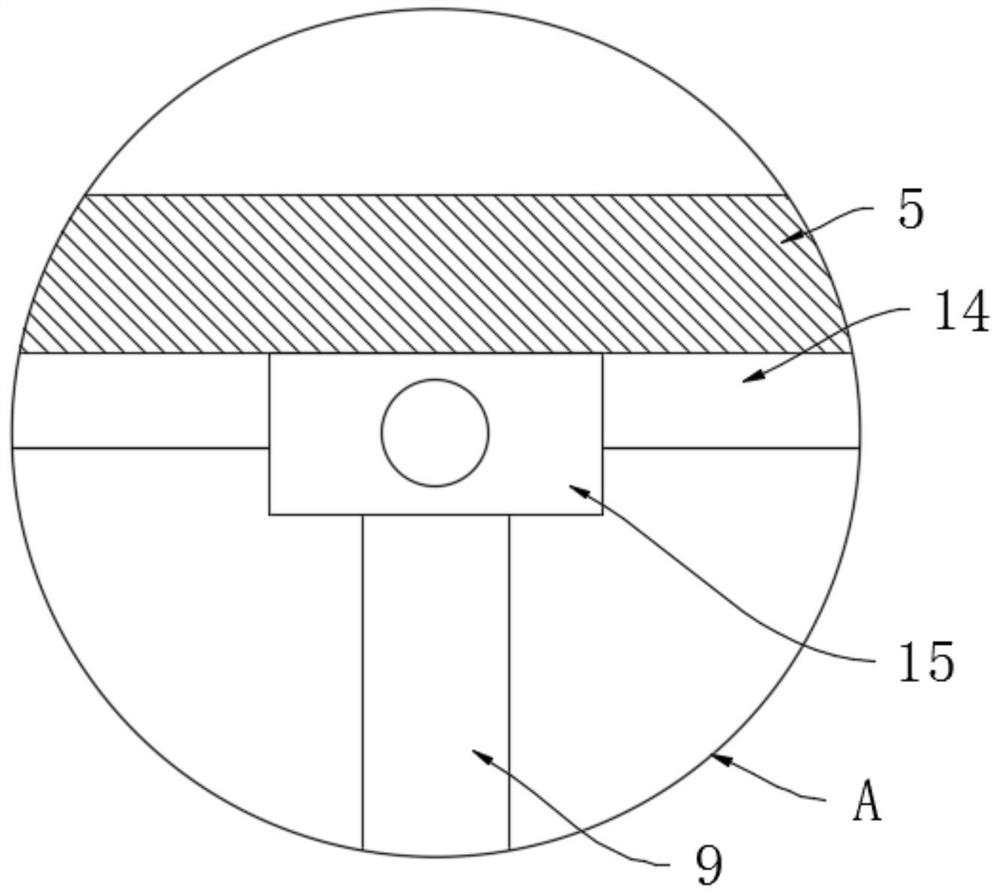

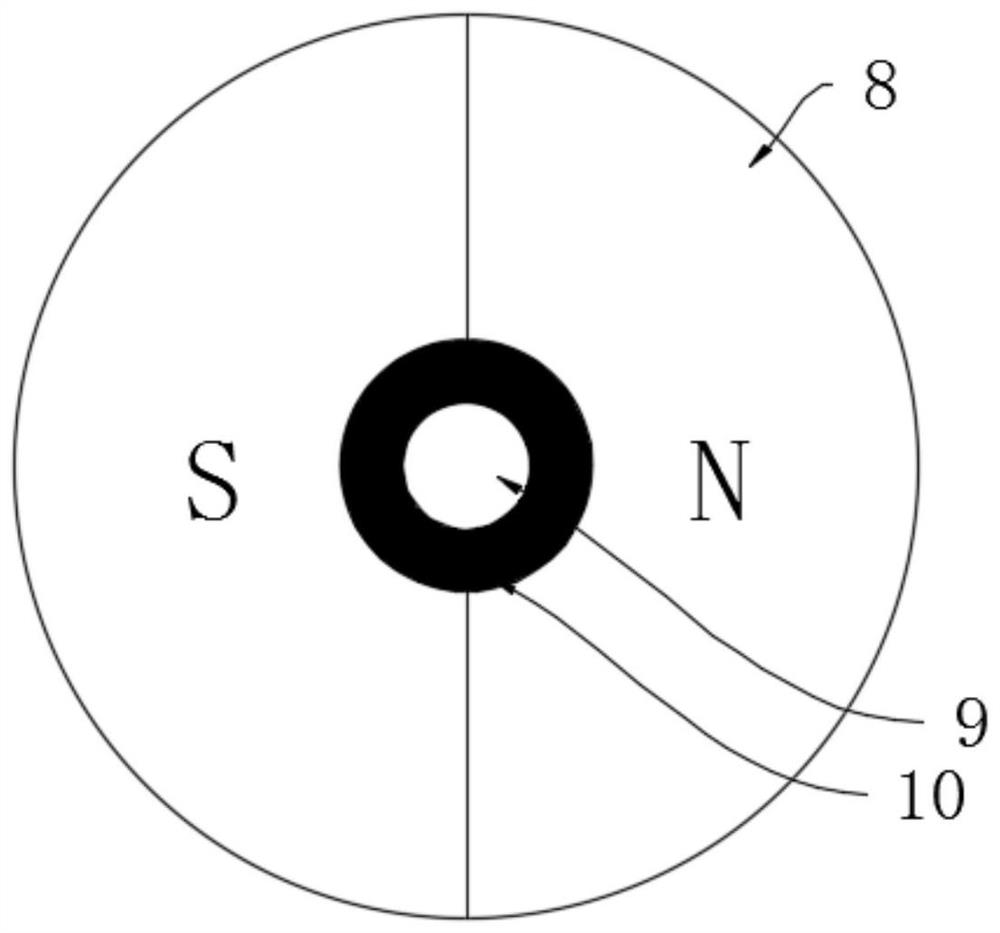

[0020] refer to Figure 1-3 , a kind of sewage pretreatment equipment for sewage treatment plants, comprising a box body 1, a water inlet 2 is opened on the upper end surface of the box body 1, a slag discharge port 3 is opened on the side wall of the box body 1, and a drain outlet 4 is opened on the lower end surface of the box body 1 , the inner wall of the box body 1 away from the slag discharge port 3 is connected to the rotary plate 5 through the rotation of the pin shaft, and the end of the rotary plate 5 close to the slag discharge port 3 and the top of the slag discharge port 3 are chamfered, and the rotary plate A plurality of water permeable holes 6 opposite to the water inlet 2 are evenly opened on the 5, and the plurality of water permeable holes 6 and the water inlet 2 are located on the side close to the pin shaft, and the water falling from the water inlet 2 to the rotating plate 5 falls on the The rotating plate 5 is close to the side of the pin shaft to form a...

Embodiment 2

[0024] Compared with the prior art, the difference between this embodiment and the embodiment is that: slide rails 16 are symmetrically arranged on the rotating plate 5, and each slide rail 16 is elastically connected with a counterweight 18 through a return spring 17, and each Each counterweight 18 is slidably connected with the slide rail 16, and the return spring 17 is positioned at the side close to the pin shaft. A scraper 19 is fixedly connected between the plurality of counterweights 18, and the lower end of the scraper 19 is connected to the rotating plate 5. sliding connection on the upper surface.

[0025] In this embodiment, when there are too many sundries on the upper end surface of the rotating plate 5 and the counterweight 18 slides to the low point in the corresponding slide rail 16 under its own gravity and stretches the return spring 17, then the two counterweights 18 Jointly drive the scraper 19 to clean up the debris on the upper end surface of the rotary p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com