Filter plate cleaning device for wastewater treatment and use method

A wastewater treatment and cleaning device technology, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of difficult disassembly, difficult cleaning, and affecting the filtering effect of the filter plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

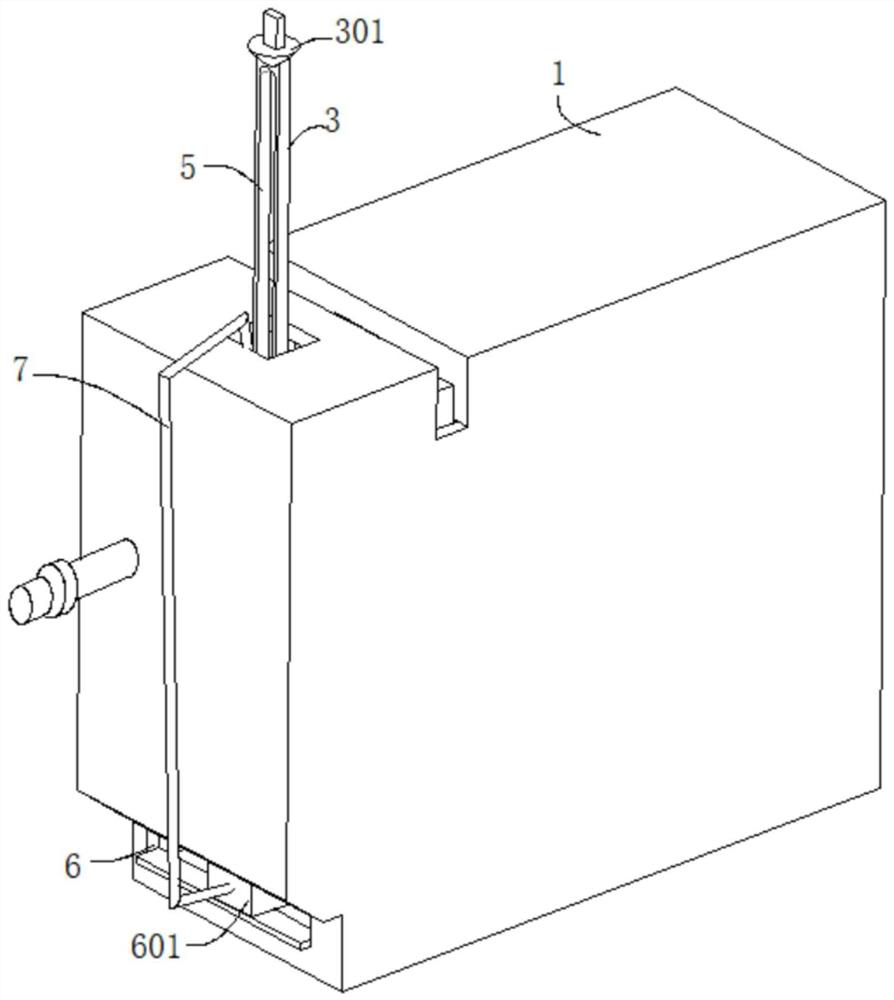

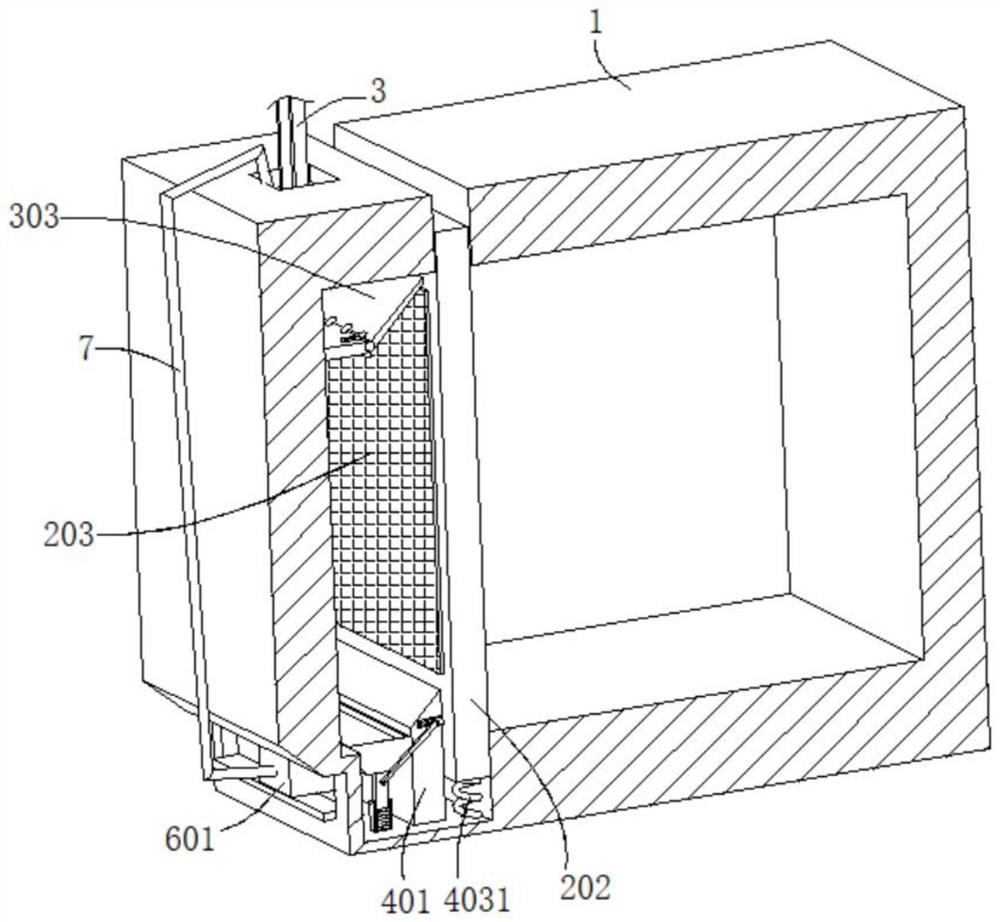

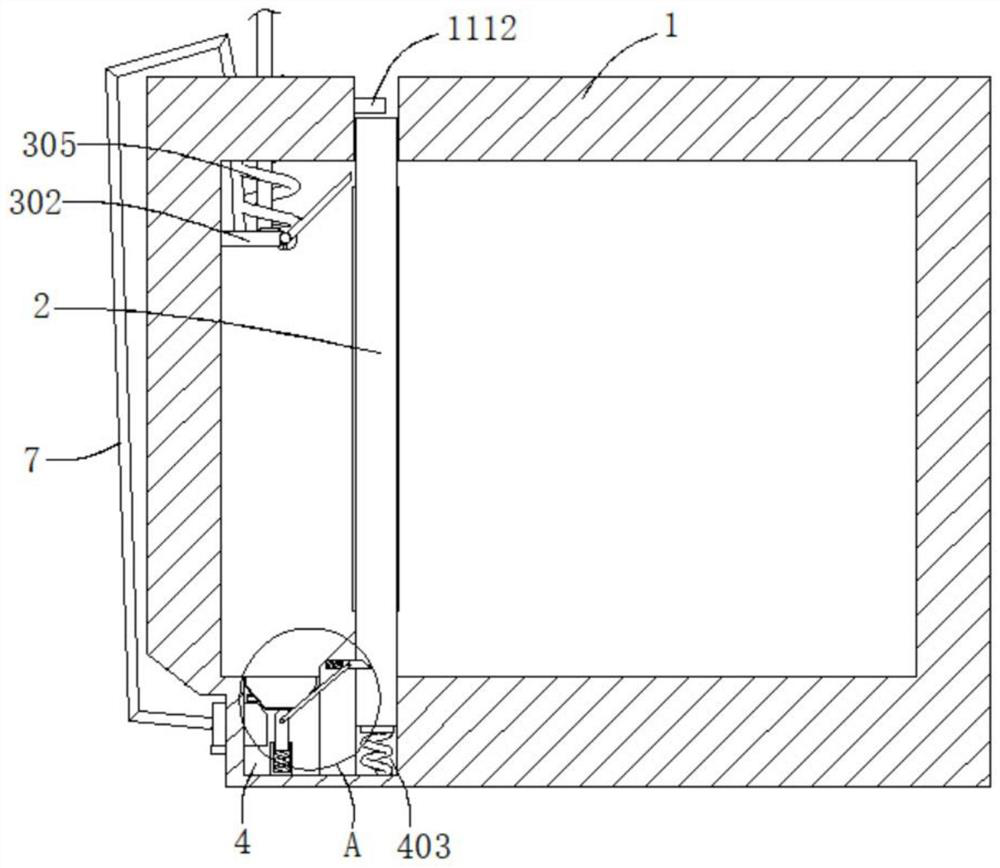

[0037] Reference figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Picture 8 , A filter plate cleaning device for waste water treatment, comprising a waste water treatment tank 1, a filter plate 2 is detachably connected to the waste water treatment tank 1, and a movable rod 3 is movably connected to the top of the waste water treatment tank 1, and a movable rod 3 The top is rotatably connected with a first bevel gear 301, the end of the moving rod 3 away from the first bevel gear 301 is connected with a moving plate 302, the moving plate 302 is slidably connected to the inner wall of the wastewater treatment tank 1, and the outer wall of the moving rod 3 is sleeved with first elastic Element 305, the first elastic element 305 is connected between the waste water treatment tank 1 and the moving plate 302, the outer wall of the moving plate 302 is connected with a scraper 303, the scraper 303 is movable against the outer wall of the filter plate 2, and the bottom of th...

Embodiment 2

[0040] Reference Figure 1-7 A filter plate cleaning device for wastewater treatment is basically the same as the first embodiment. Furthermore, the inner wall of the first cavity 402 is connected with a casing 4022, and the inner wall of the casing 4022 is connected with a second elastic element 4023. The end of the two elastic elements 4023 away from the bottom wall of the casing 4022 is connected with a guide rod 4024. The top of the guide rod 4024 is connected to the bottom of the receiving tray 4021. The outer wall of the guide rod 4024 is connected to a swing rod 9 which is away from the guide rod 4024. An insert block 10 is rotatably connected to one end of the fixed block 401 and the outer wall of the filter plate 2 are respectively excavated with a second groove 4011 and a slot 201 that match the insert block 10, and between the insert block 10 and the second groove 4011 A third elastic element 4012 is connected, a fourth elastic element 4031 is connected to the inner w...

Embodiment 3

[0043] Reference Figure 1-8 , A filter plate cleaning device for wastewater treatment, basically the same as the first embodiment, and further is that the moving plate 302 and the scraper 303 are connected by a hinge, the outer wall of the hinge is sleeved with a torsion spring 304, two of the torsion spring 304 The ends are respectively connected to the outer walls of the moving plate 302 and the scraper 303; the scraper 303 is connected to the outer wall of the moving plate 302 through the torsion spring 304, which is beneficial for the scraper 303 to always be with the filter screen during the downward movement of the moving plate 302. The outer walls of the plate 2 are opposed to each other to improve the cleaning effect and cleaning efficiency of the scraper 303.

[0044] The invention also discloses a method for using a filter plate cleaning device for wastewater treatment, which includes the following steps:

[0045] S1: The waste water after mixing with the reagent enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com