Intelligent manufacturing printing equipment

A technology of printing equipment and intelligent manufacturing, which is applied in printing, printing machines, rotary printing machines, etc., can solve the problems of low drying efficiency of printing equipment and poor cleaning effect of equipment surface, so as to improve drying effect, uniformity, and The effect of the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

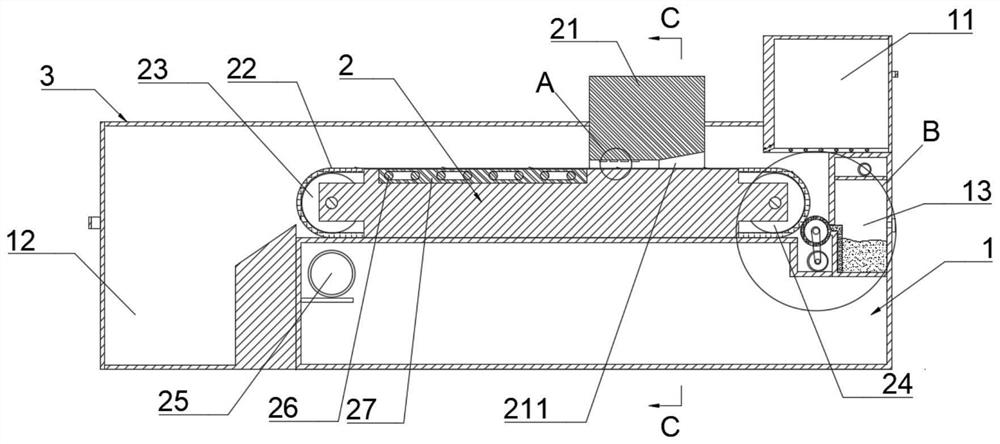

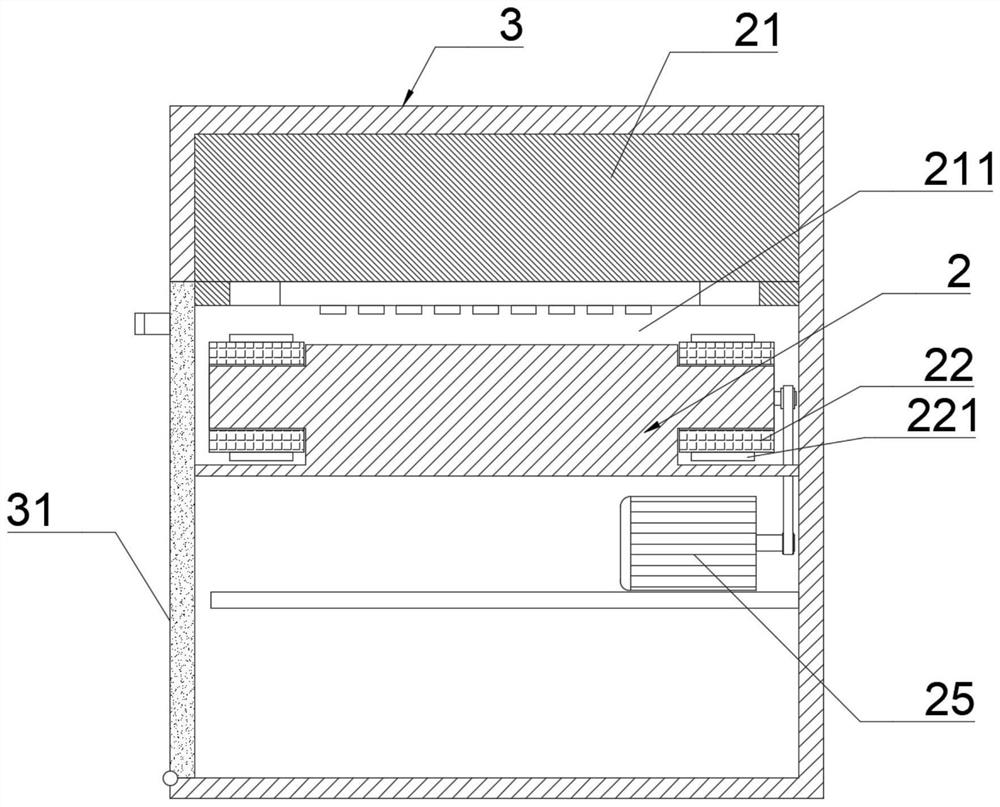

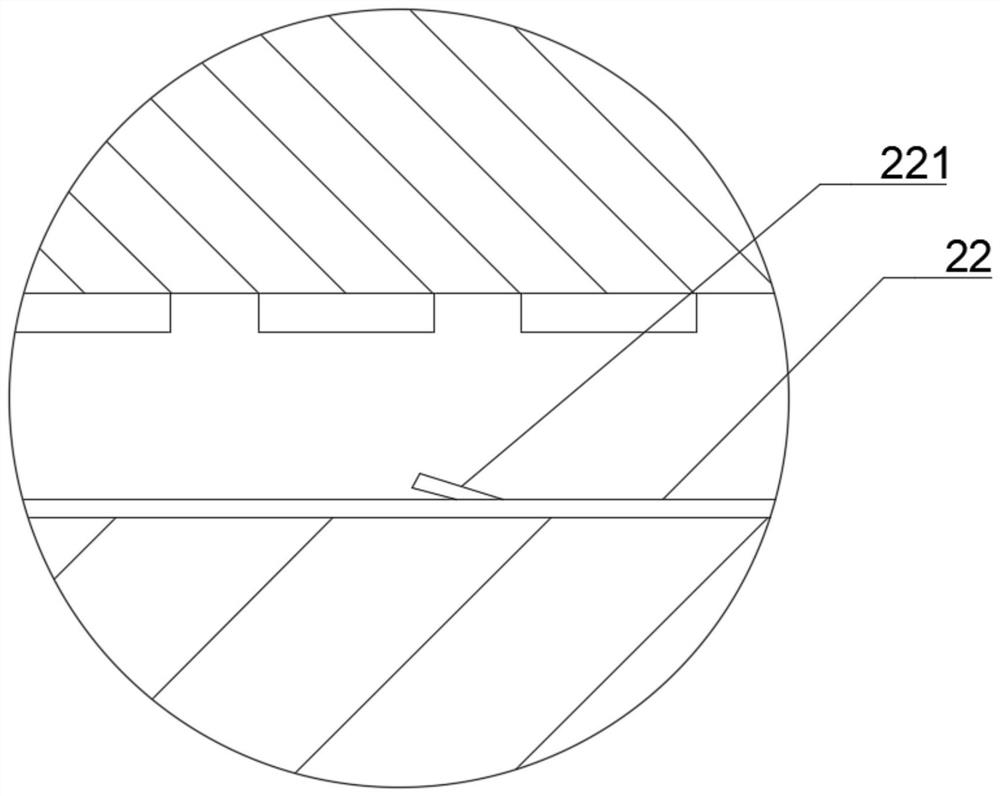

[0024] see figure 1 , an intelligently manufactured printing device, comprising a device main body 1, a discharge box 11 is welded on the upper end of the device main body 1, a transmission platform 2 is welded on the lower end of the discharge box 11, and a conveyor belt 22 is slidably connected to both sides of the transmission platform 2, The two ends of the conveyor belt 22 are interference-connected with a driving roller 23 and a driven roller 24, and the lower end of the driving roller 23 is equipped with a first motor 25 through a bolt, and the first motor 25 and the driving roller 23 are connected through a synchronous belt and a synchronous wheel. The upper end of the transmission platform 2 is equipped with a printing machine 21 through bolts, the transmission platform 2 is embedded with a heating wire 26, the side end of the equipment main body 1 is provided with a receiving box 12, and the front end of the transmission platform 2 is rotatably connected with a cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com