Cleaning device for garment production

A cleaning device and clothing technology, applied in the field of clothing production, can solve the problems of low cleaning efficiency, time interval, discontinuity, etc., and achieve the effects of cleaning cloth, improving decontamination ability, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

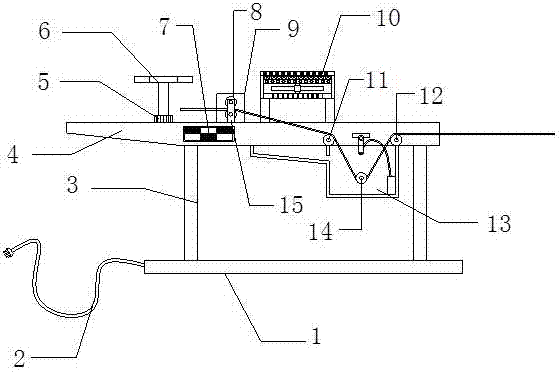

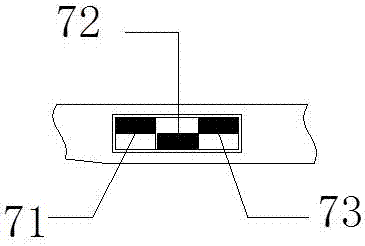

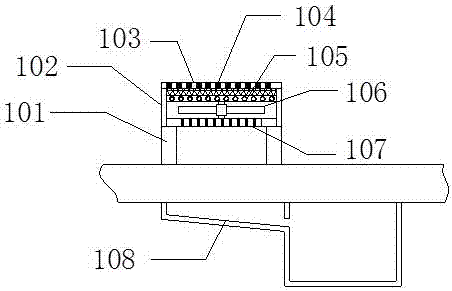

[0021] Specific implementation method: when carrying out clothing production, cloth should be cleaned first, now connect power plug 2 of the present invention to power supply, open motor control switch 71, drive motor 9 to convert electric energy into mechanical energy, drive motor 9 to drive combined pressing roller 8 rotates, and the combined pressure roller 8 rotates to drive the movement of the cloth at the same time. The cloth moves around the pressure roller 11, the pressure roller 2 12 and the pressure roller 3 14. When the cloth passes through the pressure roller 12 to the pressure roller 3 14 During the process, the cloth is cleaned in the water tank 131, and the water pump control switch 73 is turned on during the process of the cloth running from the third roller 14 to the first roller 11. Transfer to the combination nozzle 134, the combination nozzle 134 sprays clear water to the cloth to further decontaminate the cloth, thereby ensuring the cleanliness of the cloth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com