Bamboo cane drying device

A drying device and bamboo strip technology, which is applied in drying, drying machine, drying gas arrangement, etc., can solve the problems of unfavorable moso bamboo strip reprocessing, moso bamboo strip becoming brittle, and moso bamboo strip prone to mildew, so as to avoid Moisture condensation, avoid dry cracking, ensure stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

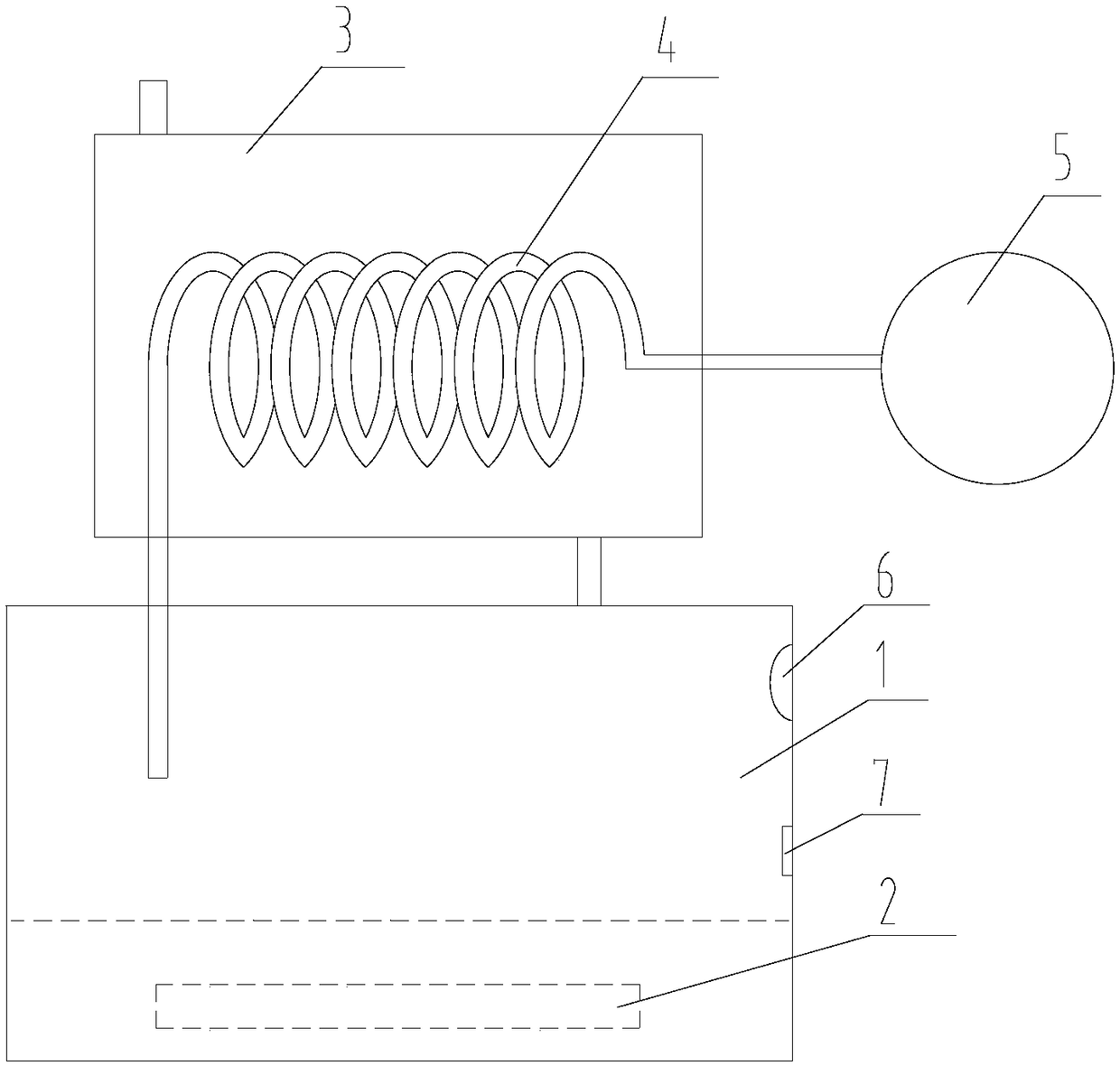

[0018] refer to figure 1 , a kind of bamboo stick drying device that the present invention proposes, oven 1, heater 2, preheating box 3, air supply pipe 4 and air pump 5.

[0019] The heater 2 is installed in the oven 1 , and the air supply pipe 4 is installed in the preheating box 3 . Both the inlet end and the outlet end of the air delivery pipe 4 stretch out from the preheating box 3 , and the inlet end of the air delivery pipe 4 is connected to the air pump 5 , and the outlet end of the air delivery pipe 4 is inserted into the oven 1 .

[0020] The preheating box 3 is provided with a steam inlet and an exhaust gas outlet, and the oven 1 is provided with a steam outlet, and the steam inlet and the steam outlet are connected. The bottom of the preheating box 3 is also provided with a water outlet.

[0021] When the bamboo stick drying device provided in this embodiment works, the bamboo sticks are first placed inside the oven 1, and then the heater 2 is turned on for heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com