Double-chamber fluidized bed sludge dryer

A sludge drying and fluidized bed technology, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve problems affecting the normal operation of fluidized bed dryers, and achieve the effect of ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

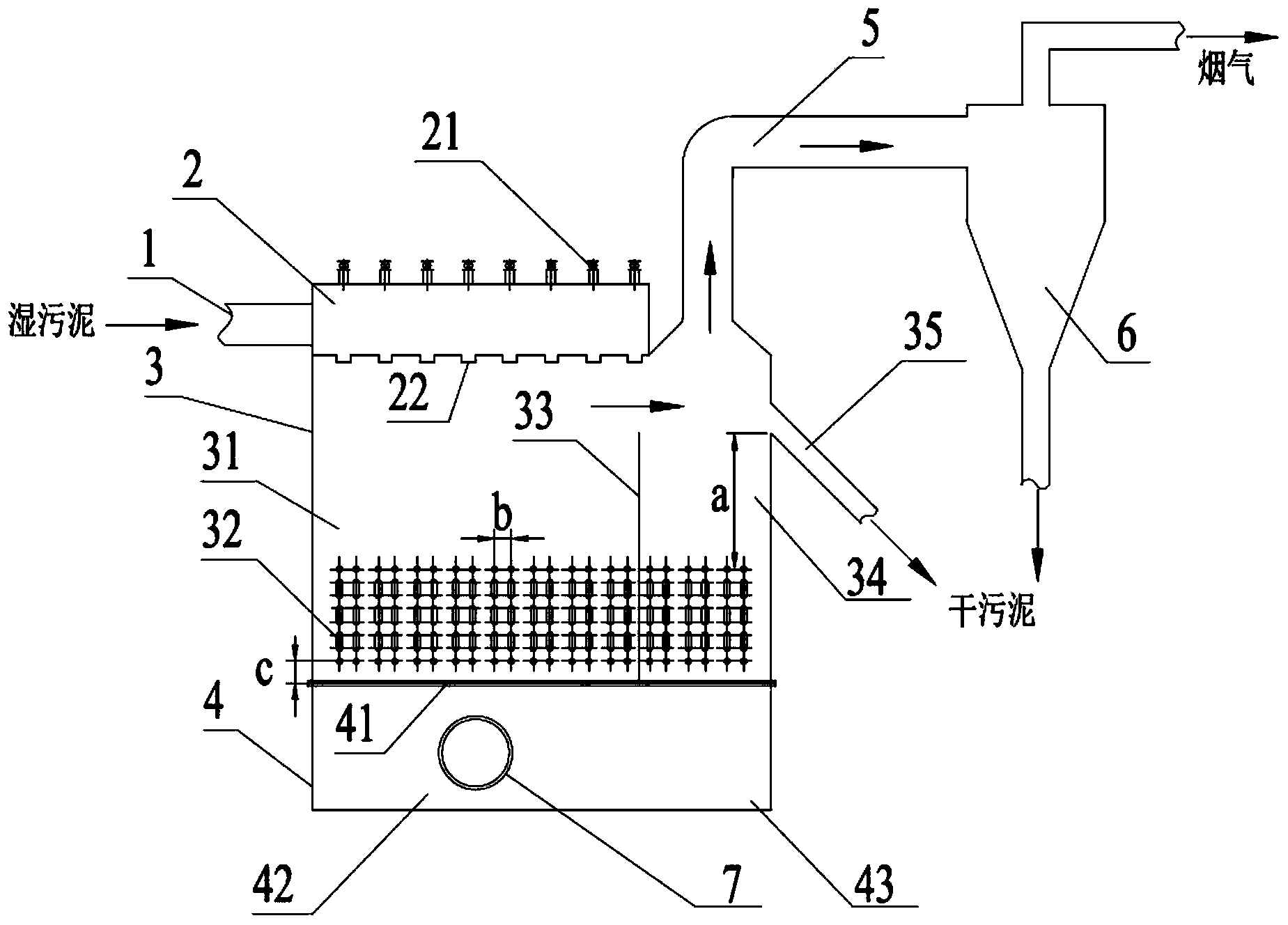

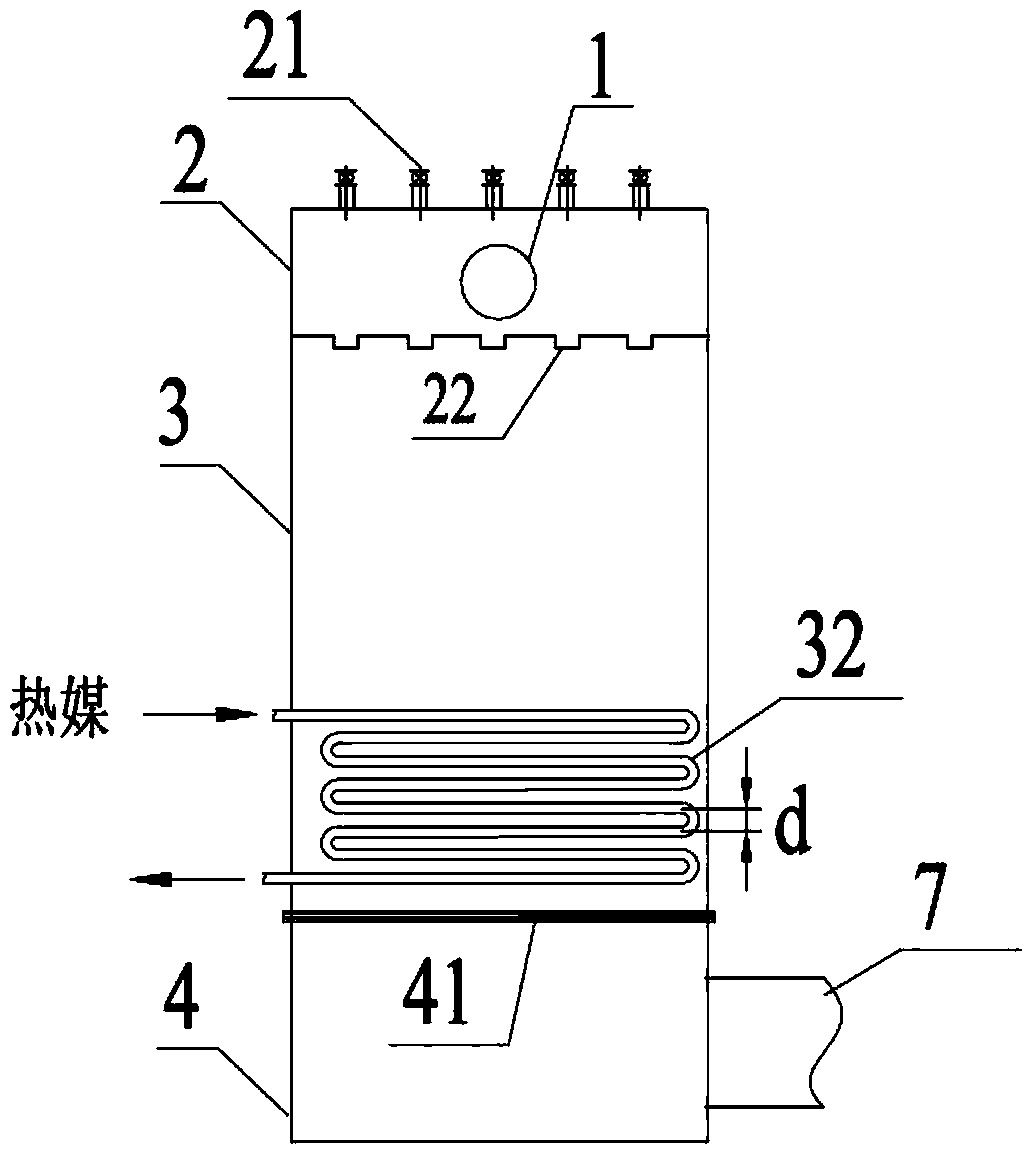

[0022] Embodiment 1: as figure 1 , figure 2 As shown, the double-chamber fluidized bed sludge dryer of the present invention is composed of a feed pipe 1, a distribution chamber 2, a drying chamber 3, an air chamber 4, an exhaust pipe 5, a cyclone separator 6, and an air inlet pipe 7. The distribution chamber 2 is arranged on the upper left side of the drying chamber 3, and the exhaust pipe 5 is arranged on the upper right side of the drying chamber 3; on the wall. The air chamber 4 is arranged directly below the drying chamber 3 , and the air chamber 4 is connected with the drying chamber 3 through an air distribution plate 41 . The cyclone separator 6 is arranged at the end of the exhaust pipe 5 , and the air inlet pipe 7 is connected to the air chamber 4 . Among them, several ball valves 21 are provided on the upper end surface of the distribution chamber 2, and one end of each ball valve 21 is connected to the distribution chamber 2, and several sludge nozzles 22 are p...

Embodiment 2

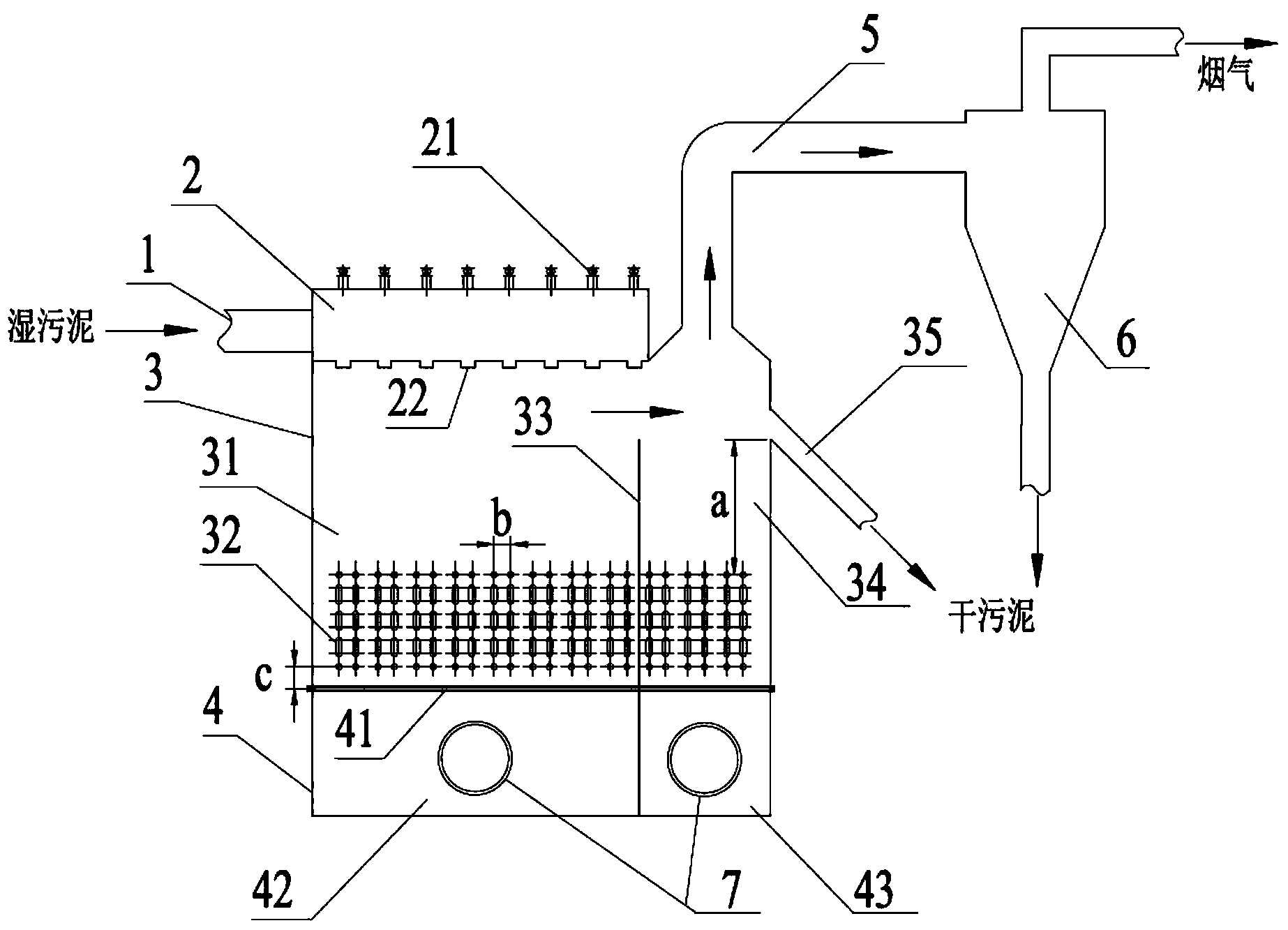

[0025] Embodiment 2: as image 3 As shown, the difference with Embodiment 1 is only: 1. The partition plate 33 divides the drying chamber 3 into a first sub-drying chamber 31 and a second sub-drying chamber 34 with a ratio of 3:1. In the first sub-drying chamber 31 Arrange 75% of the total heat exchanger area; 2. The air chamber 4 is also divided into the first sub-air chamber 41 and the second sub-air chamber 42 with a left-right ratio of 3:1 through the partition, and the two sub-air chambers are respectively connected through the air inlet pipe The independent air source of the wrist is set up to further control the ratio of the air intake of the two sub-drying chambers, and the first sub-drying chamber 31 is controlled to enter 75% of the total air volume to improve the drying efficiency; The fluidized bed drying chamber has the same structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com