Compressed air dryer

A compressed air and dryer technology, applied in gas treatment, chemical instruments and methods, membrane technology, etc., can solve problems such as prone to equipment failure, increased perforation, poor anti-interference, etc., to achieve improved water exchange efficiency and no easy loss Parts and effects of heat exchange efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

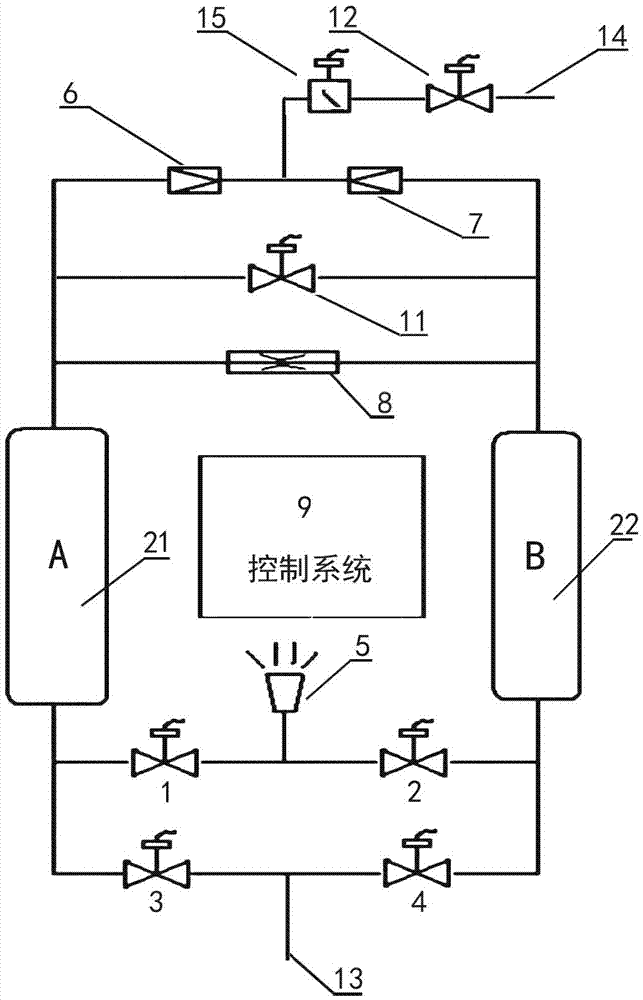

[0022] figure 1 It is a three-dimensional schematic diagram of a compressed air dryer, including two adsorption tanks A and B filled with adsorbents arranged in parallel, and the lower parts of the adsorption tanks A and B are connected in parallel through two intake valves and two dehumidification valves , the air inlet is set between the two intake valves 3 and 4, and the muffler is set between the two dehumidification valves 1 and 2; The check valves opposite to the output end are connected, and the outlet valve is connected between the two check valves 6 and 7, and the outlet valve is connected to the moisture detector; the control system is connected with the inlet valve, the dehumidification valve, the pilot valve, the outlet valve and The moisture detector is electrically connected.

[0023] The adsorbent is activated alumina particles, adsorption tank A and adsorption tank B are made of steel, various connecting pipes are made of PPR material, and various valves are m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com