Medium and energy internal recycle drying method and drying machine

A dryer and internal circulation technology, which is applied in local stirring dryers, dryers for static materials, dryers, etc., can solve the problems of difficult control of drying temperature, large power consumption for ventilation, and environmental pollution by exhaust gas. The effect of ventilation power consumption, soft drying process and good drying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

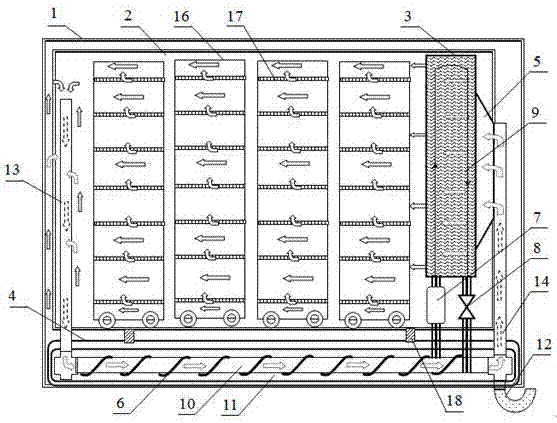

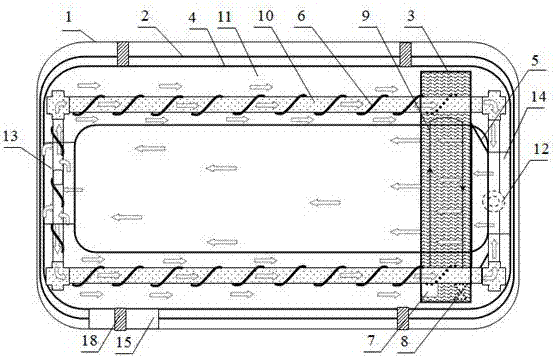

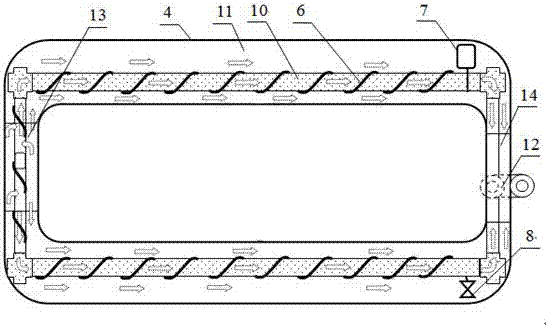

[0036] A medium, energy internal circulation dryer, such as Figure 1-5 As shown, it includes a dryer body 1, a drying chamber 2 and a circulation system, the drying chamber 2 and the circulation system are located inside the dryer body 1, and the circulation system communicates with the drying chamber 2;

[0037] The circulation system includes a fan 5, an evaporator 6, a compressor 7, an expansion valve 8, a condenser 9, a hot air inner flow channel 10, a hot air outer flow channel 11, a U-shaped water outlet pipe 12, a vertical hot air flow channel 13 and a cold air flow Road 14;

[0038] The condenser 9 is installed in the drying chamber 2, and the air outlet of the fan 5 is arranged opposite to the condenser 9, and is used to blow the heat released by the condenser 9 into the drying chamber 2, so as to realize heat circulation in the drying chamber 2;

[0039] The hot-air inner runner 10 is sleeved in the hot-air outer runner 11, the evaporator 6 is evenly distributed on...

Embodiment 2

[0046] A medium and energy internal circulation drying method, using the medium and energy internal circulation dryer described in Embodiment 1, the drying method comprises the following steps:

[0047] A. Put the tray 17 with the material on the loading vehicle 16, and after loading the loading vehicle 16 into the drying chamber 2 from the door 15, close the door 15;

[0048] B. Turn on the heat pump unit 3 and the fan 5, the working medium in the heat pump unit 3 is sucked into the compressor 7 from the evaporator 6 under the action of the compressor 7, and is compressed into a liquid in the condenser 9, and the temperature rises rapidly to generate heat; Then, the working medium enters the evaporator 6 through the expansion valve 8, absorbs heat and cools down the hot air inner flow channel 10 and the hot air outer flow channel 11;

[0049] C. The fan 5 blows cold air into the drying chamber 2 through the condenser 9, and the condenser 9 heats the cold air into hot air; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com