Wafer processing method

a processing method and wafer technology, applied in the field of wafer processing methods, can solve the problems of faulty suction holding of the wafer, no chamfering of the sic wafer, damage to the device formed on the front side, etc., and achieve the effect of preventing the damage of the device and the faulty suction holding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

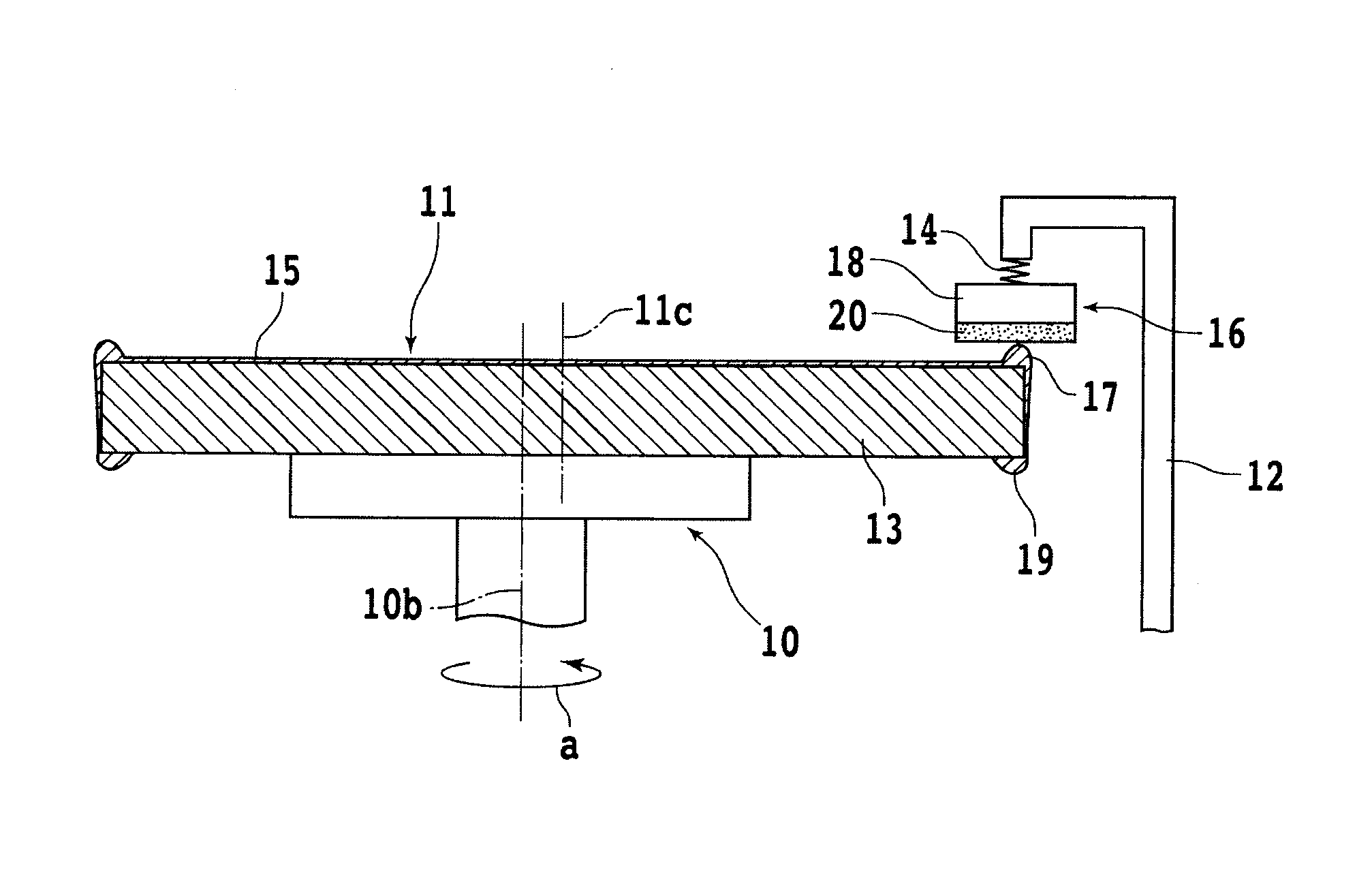

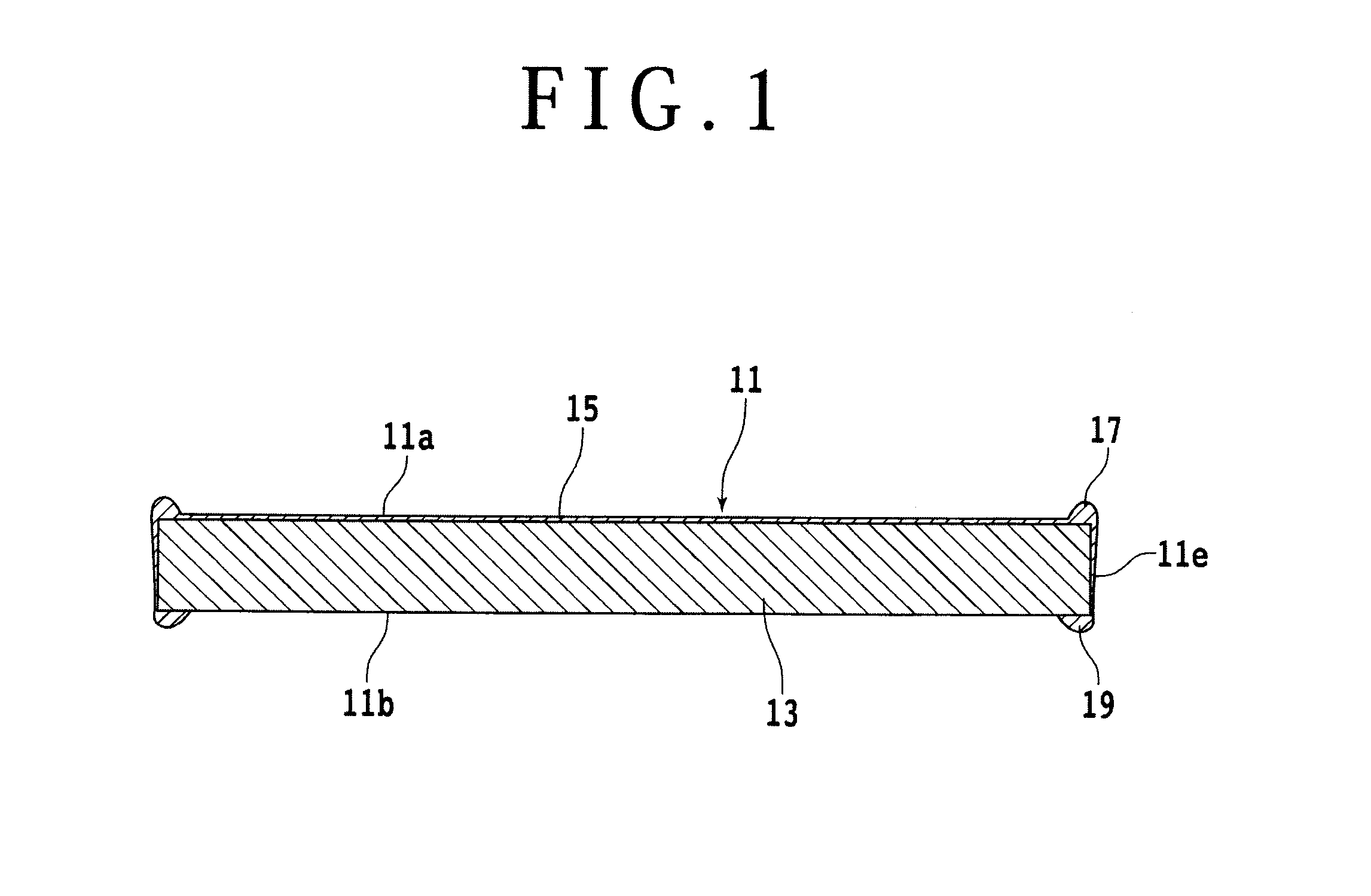

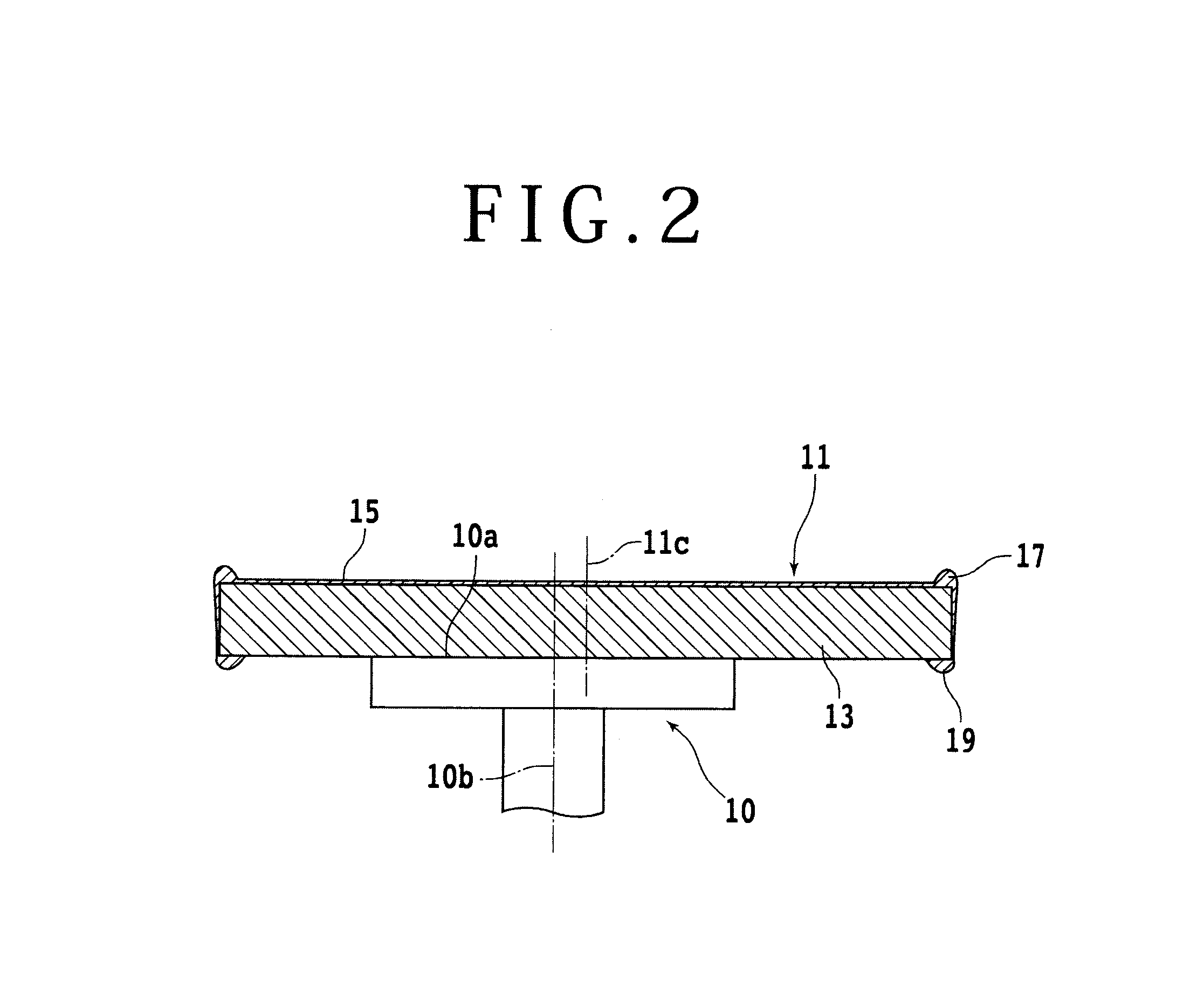

[0017]A preferred embodiment of the present invention will now be described in detail with reference to the drawings. Referring to FIG. 1, there is shown an SiC (silicon carbide) wafer 11. The SiC wafer 11 is composed of an SiC bulk wafer (SiC substrate) 13 and an epitaxial film 15 formed on the SiC bulk wafer 13 by epitaxial growth. That is, the epitaxial film 15 is formed as a single-crystal SiC thin film. Usually, the epitaxial film 15 of the SiC wafer 11 is formed by CVD (Chemical Vapor Deposition) or the like. The SiC wafer 11 has a front side 11a (upper surface), a back side 11b (lower surface), and a peripheral surface 11e substantially perpendicular to both the front side 11a and the back side 11b. That is, the peripheral surface 11e of the SiC wafer 11 is not formed with a chamfered portion.

[0018]In the case that the epitaxial film 15 is formed by epitaxial growth on such a wafer having no chamfered portion, e.g., the SiC wafer 11 as mentioned above, edge crowns (ridge port...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| semiconductor | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com