Concentration apparatus for wet method phosphoric acid refinement

A concentration device and wet-process phosphoric acid technology, which is applied in the direction of phosphorus compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as difficult to achieve flash evaporation effect, difficulty in small liquid droplets, and inability to form continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1, forced circulation under negative pressure:

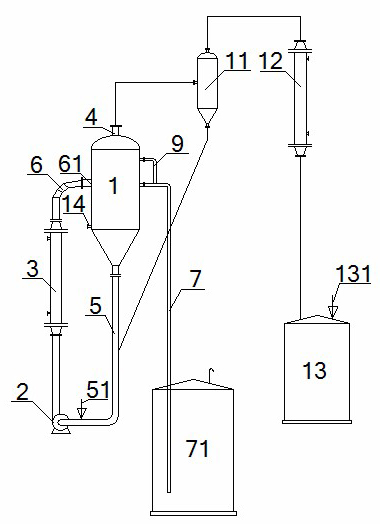

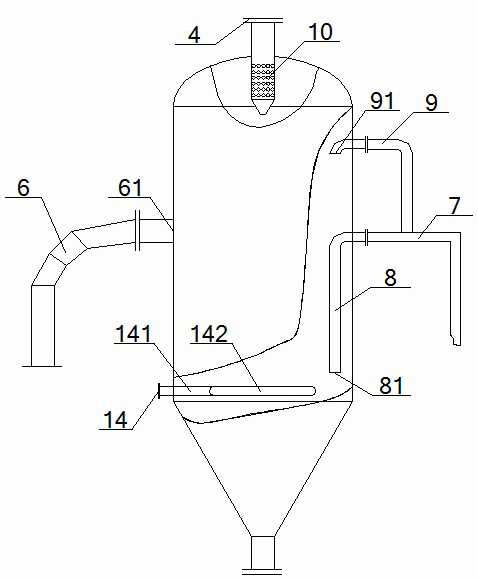

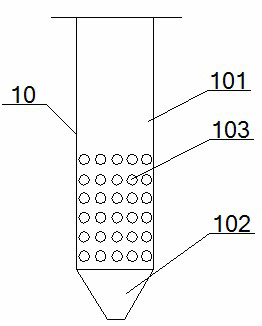

[0052] see figure 1 Connect the vacuum port 131 on the condensate tank 13 to the vacuum system and turn on the vacuum system. The concentrated feed liquid enters the forced circulation evaporation system through the feed port 51, and is sent to the heater 3 for heating through the forced circulation pump 2, and is heated to After a certain temperature, it enters the flash chamber 1, and the heated feed liquid releases secondary steam in the flash chamber 1, and the secondary steam passes through the defoaming pipe 10 to initially collect the liquid foam, and after the cyclone separator 11 removes the foam for the second time, Condensed in the condenser 12, the condensate flows into the condensate tank 13. If it is necessary to remove fluorine and chlorine, then open the steam pipe 14 to pass steam to the feed liquid in the flash chamber 1, which can promote the escape of fluorine and chlorine.

[0053] After the...

Embodiment 2

[0054] Embodiment 2, forced circulation under normal pressure situation:

[0055] see Figure 5 , the feed liquid that needs to be concentrated enters the forced circulation evaporation system through the feed port 51, and is sent to the heater 3 to be heated by the forced circulation pump 2. After being heated to a certain temperature, it enters the flash chamber 1, and the heated feed liquid is in the flash chamber 1. The secondary steam is released, and the secondary steam passes through the defoaming pipe 10 to initially collect the liquid foam, and after the cyclone separator 11 conducts secondary defoaming, it is condensed in the condenser 12 and flows into the condensate tank 13. If it is necessary to remove fluorine, chlorine or recover the extractant, the steam pipe 14 is opened to steam the feed liquid in the flash chamber 1, which can promote the escape of fluorine, chlorine and the extractant.

[0056] After the feed liquid is evaporated, the feed liquid that reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com