Pixel structure, mask plate and display device

A pixel structure and display device technology, applied in vacuum evaporation plating, coating, electric solid devices, etc., can solve the problems of difficulty in ensuring sub-pixel aperture ratio, affecting product life, brightness, and difficulty in realizing high resolution, etc., to achieve Improve the effect of evaporation, prevent deformation, and reduce the difficulty of manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

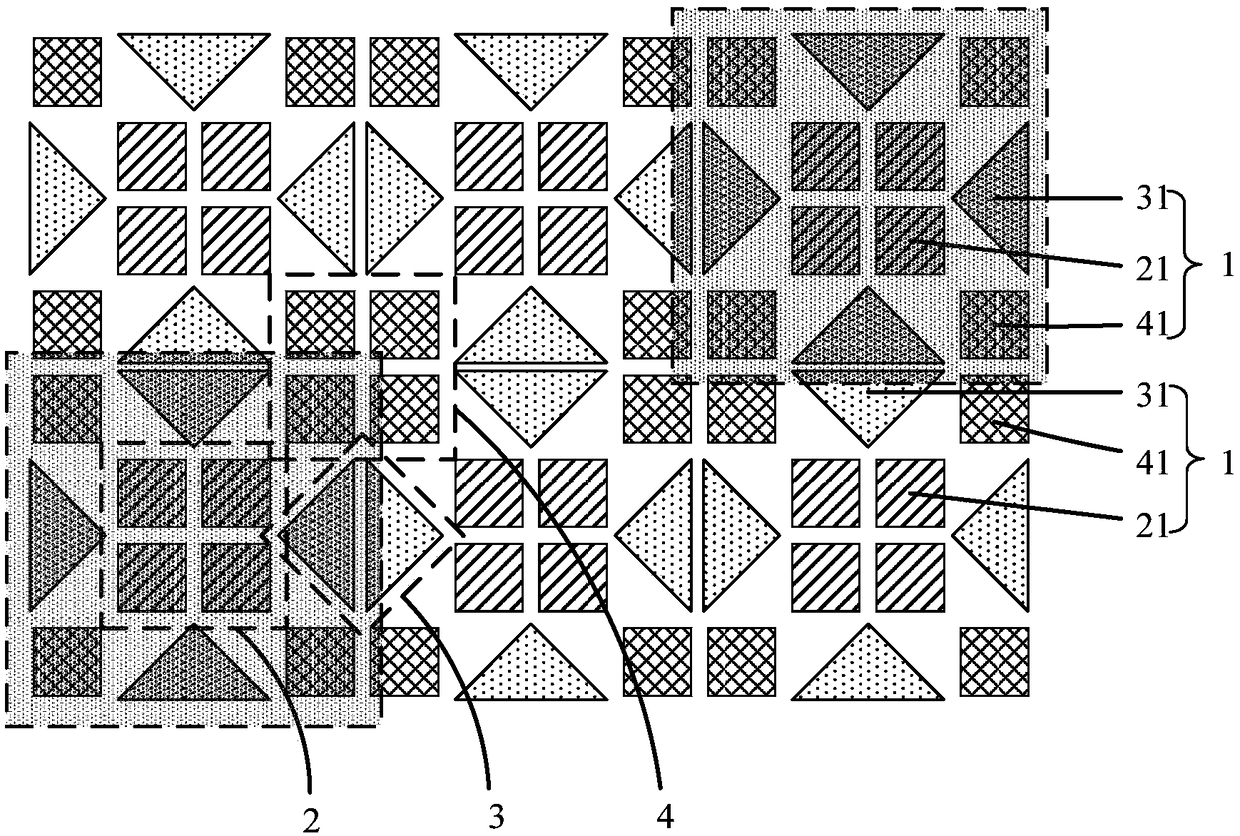

[0027] This embodiment provides a pixel structure, including: a plurality of repeating units arranged in an array (such as figure 1 shown in the shaded part), the outer contour of each repeating unit is a rectangle, which includes four first sub-pixels 21, four second sub-pixels 31 and four third sub-pixels 41, wherein the four first sub-pixels The pixels 21 are arranged in the center of the repeating unit in a 2×2 array, forming the first sub-pixel group 2; the four second sub-pixels 31 are respectively located on the four sides of the repeating unit; the four third sub-pixels 41 are respectively located on the four sides of the repeating unit. vertex angle; in any two adjacent repeating units, two adjacent second sub-pixels 31 form a second sub-pixel group 3, and the outer contour of the second sub-pixel group 3 is a polygon or a circle; any four are in the form of a polygon Among the four repeating units arranged in a 2×2 array, four adjacent third sub-pixels 41 form a thir...

Embodiment 2

[0038] This embodiment provides a display device including any one of the pixel structures provided in Embodiment 1.

[0039]The display device can be any product or component with a display function such as a liquid crystal panel, an electronic paper, an OLED panel, a mobile phone, a tablet computer, a television, a monitor, a notebook computer, a digital photo frame, a navigator, and the like.

[0040] Preferably, the display device is an organic light-emitting diode (OLED; Organic Light-Emitting Diode;) display device. In the display device, since the pixel structure has a better evaporation process effect, the product yield of the display device is higher; moreover, since the mask opening for preparing the pixel structure is relatively large, the aperture ratio is improved, and the light emitting area is increased. Large, so as to improve the product brightness, lifespan and image quality definition of the organic light-emitting diode (OLED; Organic Light-Emitting Diode;) ...

Embodiment 3

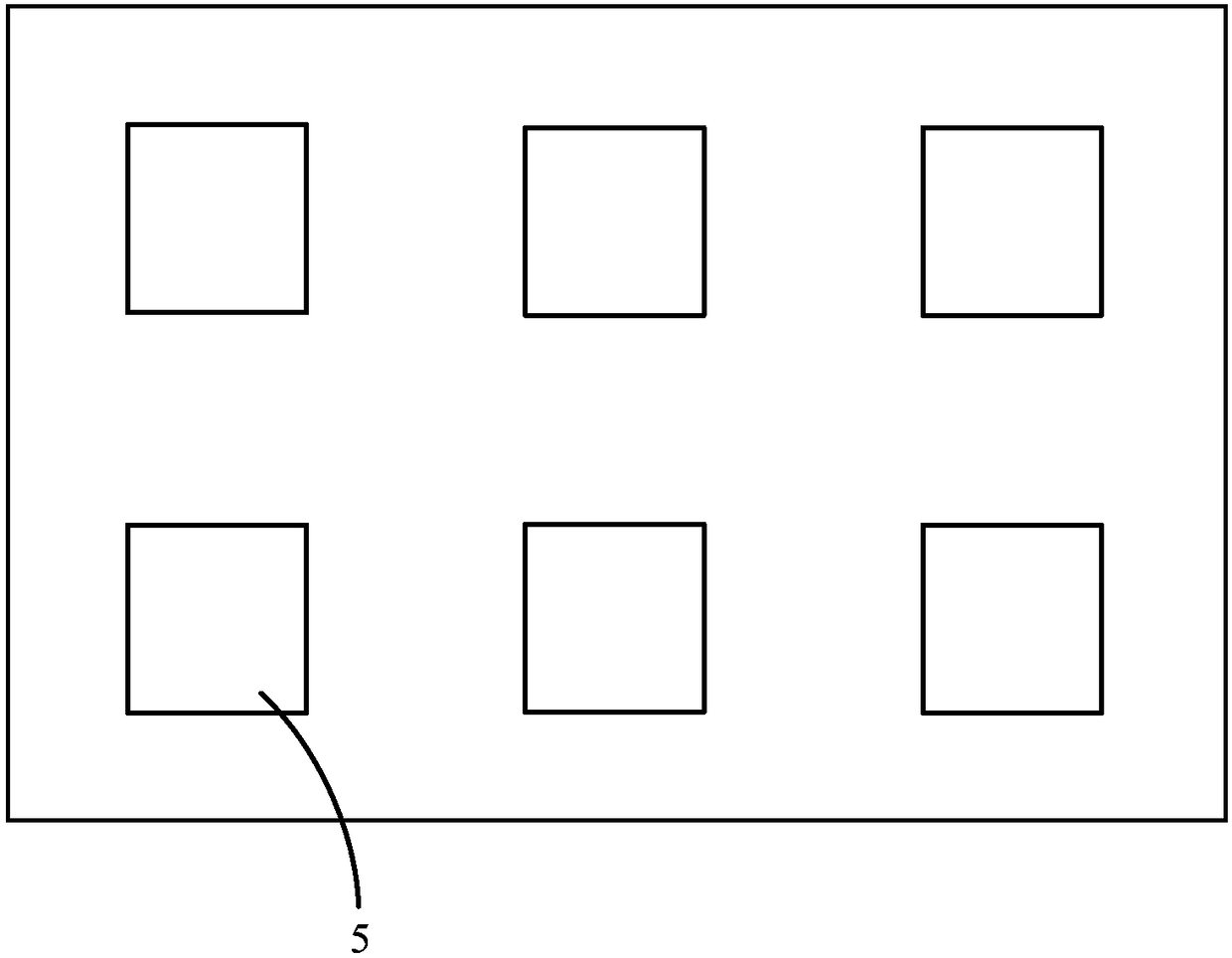

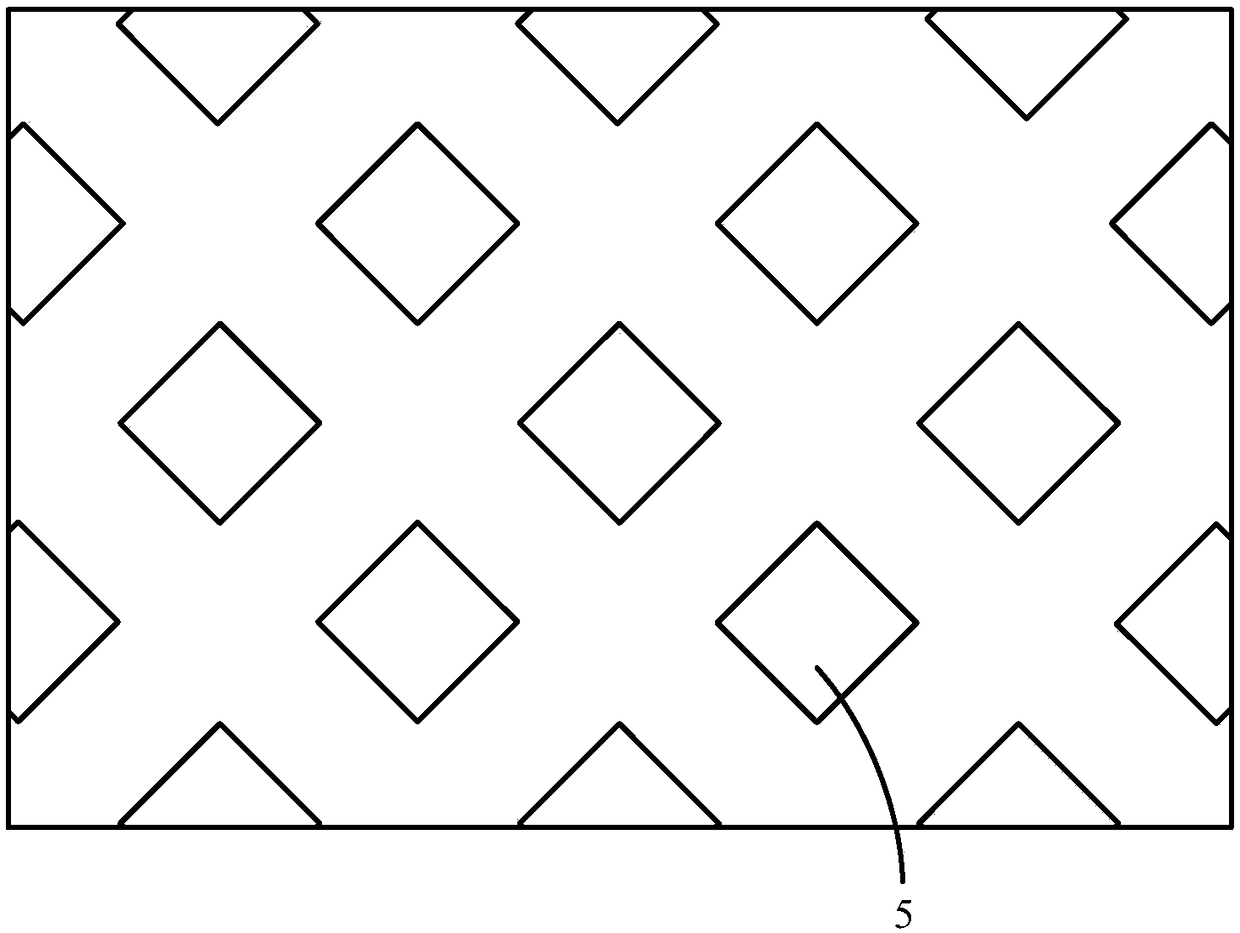

[0042] like Figure 2 to Figure 4 As shown, this embodiment provides a mask for preparing any one of the pixel structures provided in Embodiment 1.

[0043] The mask plate includes: a substrate, and a mask opening 5 on the substrate corresponding to the outline of the sub-pixel group.

[0044] Compared with the mask plate in the prior art, the mask opening 5 in the mask plate provided in this embodiment corresponds to the sub-pixel group in the pixel structure provided in Embodiment 1, that is, the mask in this embodiment The opening 5 corresponds to four sub-pixels of the same color. Specifically, the first sub-pixel group, the second sub-pixel group and the third sub-pixel group can be respectively prepared by using three kinds of masks with different openings, for example, using figure 2 The mask plate shown is used to prepare the first sub-pixel group, using image 3 The mask plate shown is used to prepare the second sub-pixel group, using Figure 4 The mask plate sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com