Spray evaporation treatment method and system for desulfurization wastewater flue

A flue gas treatment system, spray evaporation technology, applied in the direction of gaseous effluent wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems that affect the safe operation of equipment, dust collector and flue corrosion, smoke Corrosion of the road wall surface and other problems, to increase the residence time, save energy and reduce corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

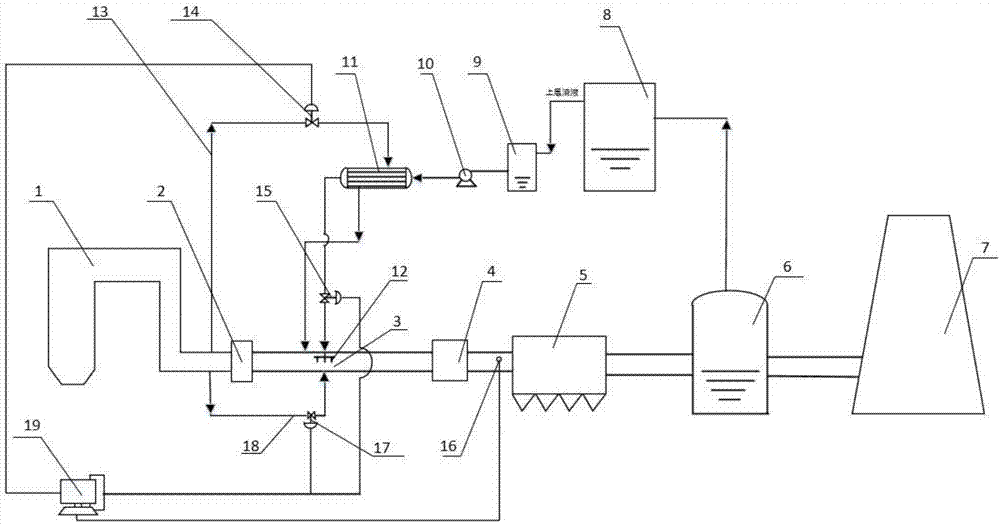

[0028] see figure 1 , a desulfurization wastewater flue spray evaporation treatment method and system of the present invention, including a flue gas treatment system, a desulfurization wastewater spray evaporation system, a bypass flue system, and an automatic control system.

[0029]After the flue gas generated by the flue gas generating device (1) in the flue gas treatment system passes through the air preheater (2) to recover waste heat, the atomized liquid droplets are evaporated in the flue (3) in front of the demister (4). The final water vapor and crystals flow forward with the flue gas, and the fog droplets and wet crystals mixed in the flue gas are removed by the mist eliminator (4), and the fine particles are removed in the dust collector (5) to form a clean flue gas. Then go through the desulfurization tower (6) to remove sulfu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com