Method and equipment for mounting part

A technology of installation device and installation method, which is applied in the direction of electrical components, electrical components, etc., can solve the problems of narrowing and restriction of nozzle opening area, and achieve the effect of avoiding waste and preventing defective circuit substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

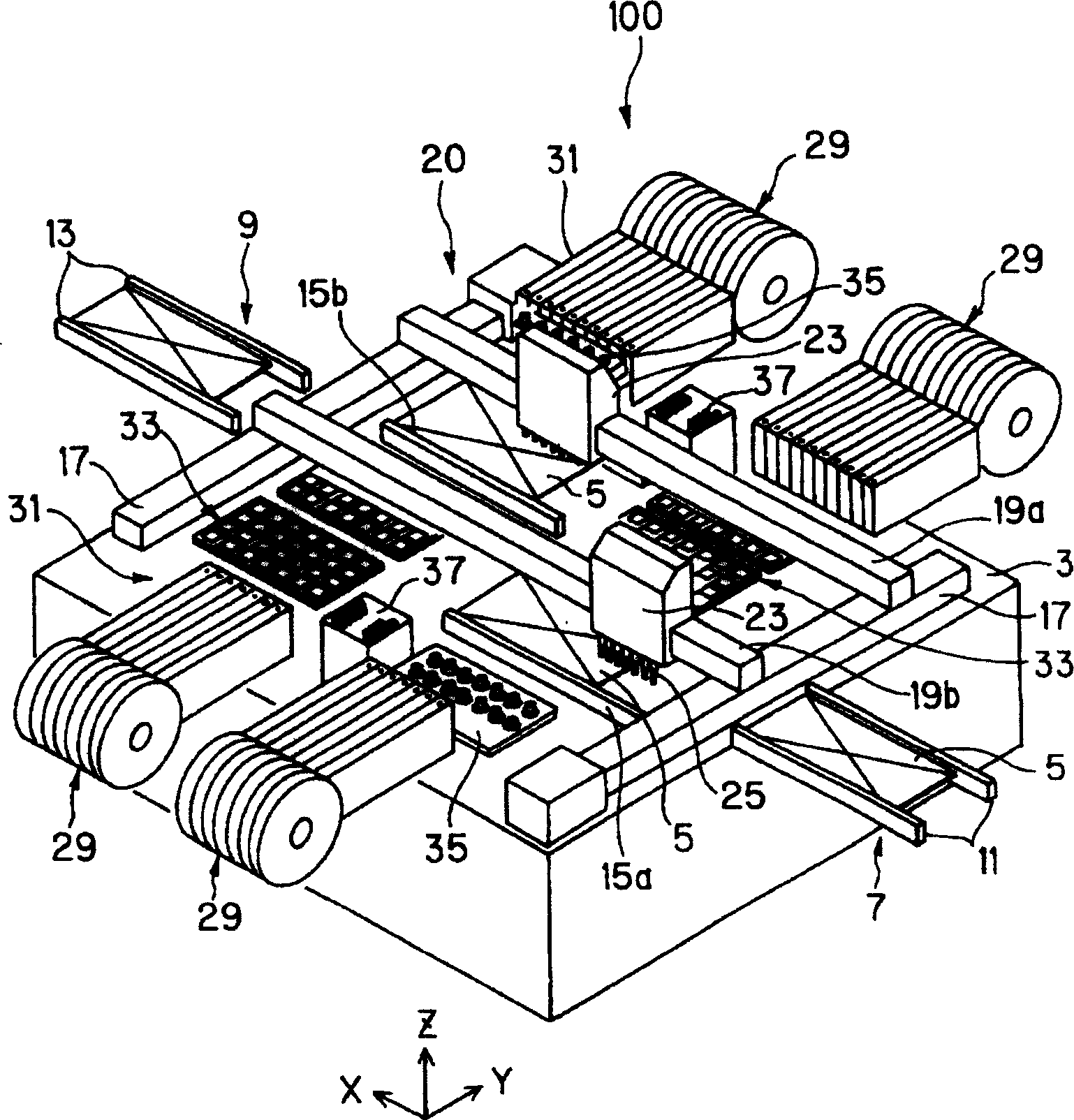

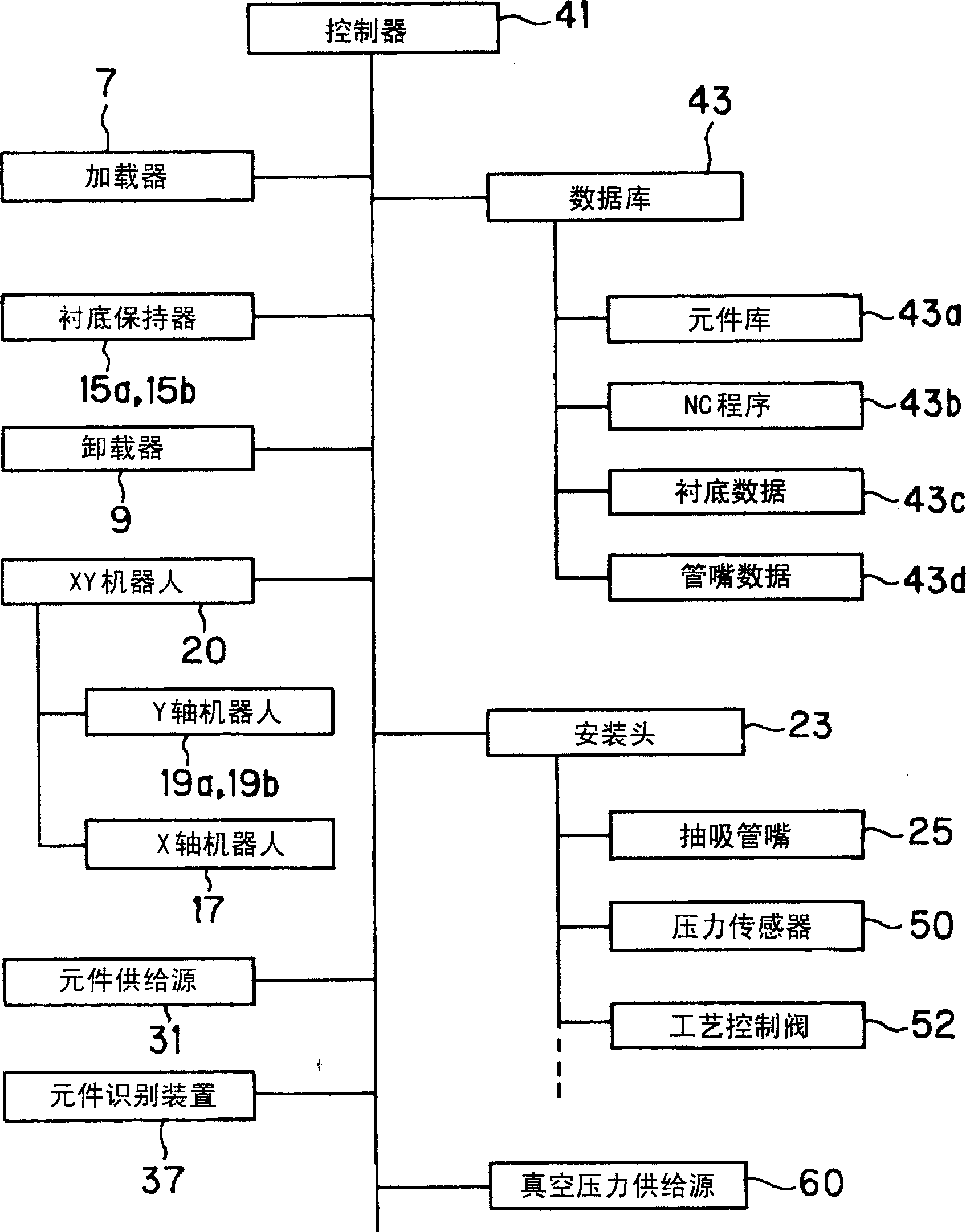

[0063] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings. A first embodiment of the invention relates to a method and apparatus for mounting components with a process or means for detecting missing components through a nozzle. figure 1 An overall view of the component mounting device according to the present invention is shown. now refer to figure 1 , the component mounting apparatus 100 has a loader 7 for loading the circuit substrate 5 into the component mounting apparatus 100 , the loader 7 is located on the right-hand side of the base 3 in the X direction. Opposite to the loader 7 on the left-hand side in the X direction, the component mounting apparatus 100 has an unloader 9 for unloading a circuit substrate from the component mounting apparatus 100 . The loader 7 and the unloader 9 respectively have a pair of guide rails 11 and 13 arranged for conveying the circuit substrate 5 .

[0064] A first substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com