Patents

Literature

31results about How to "Instant cleanup" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

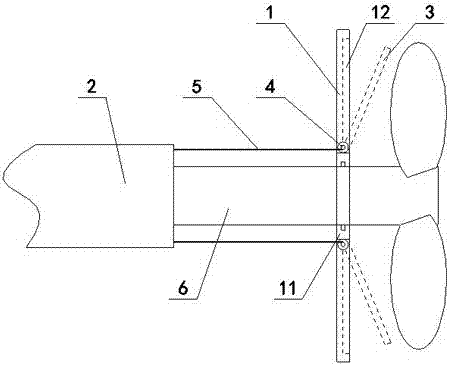

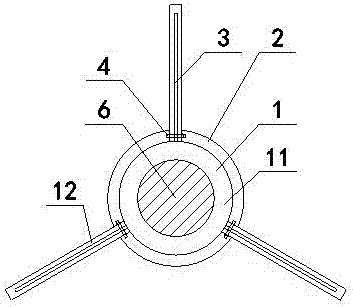

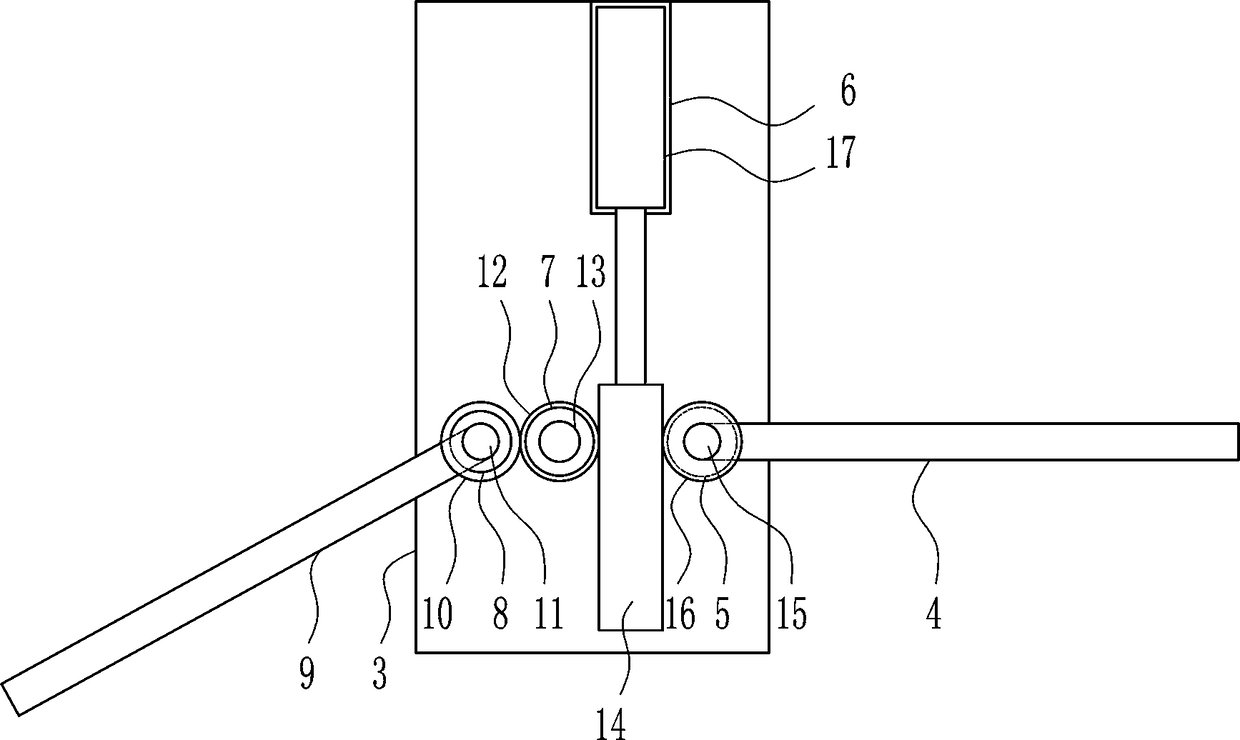

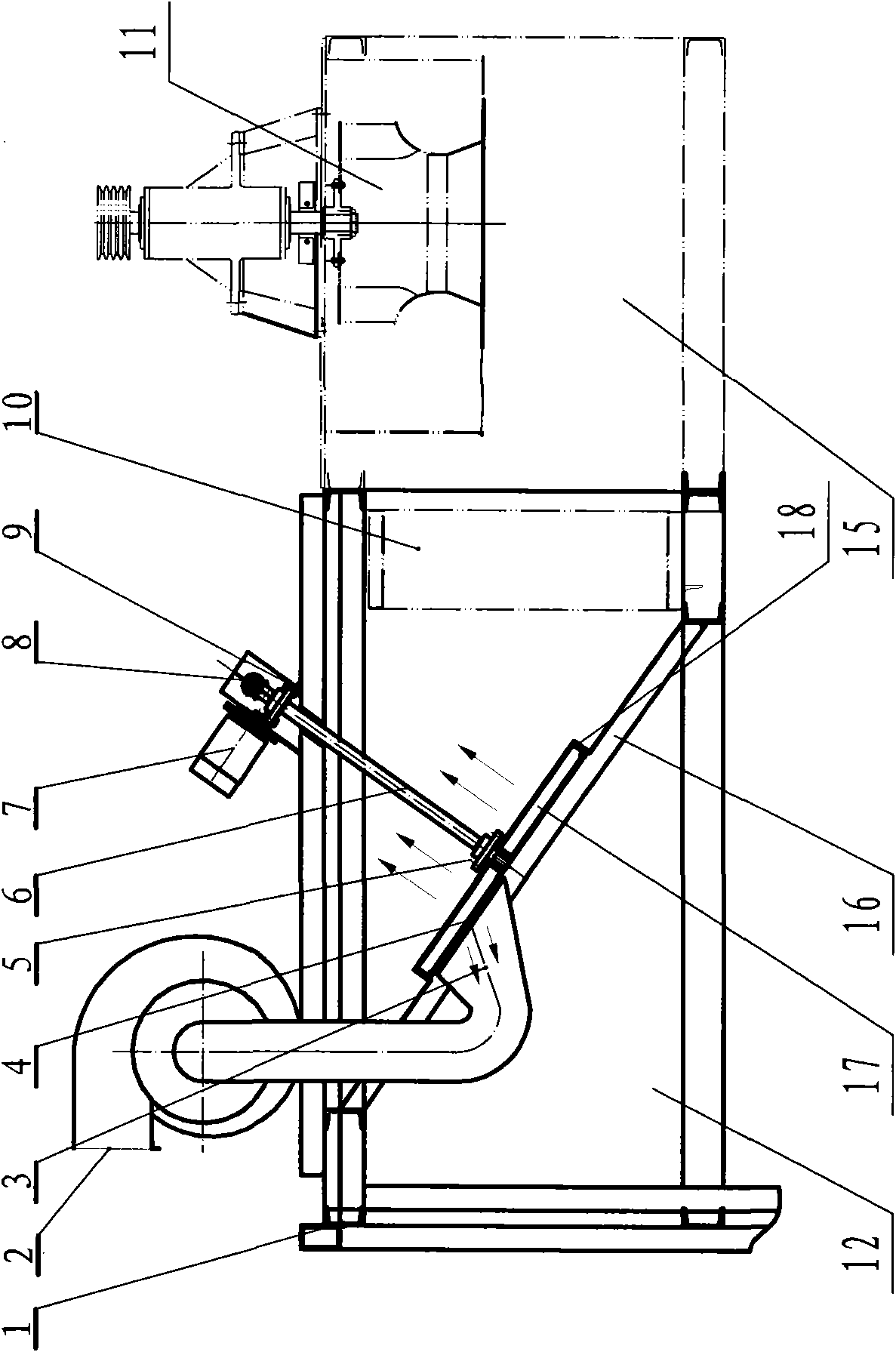

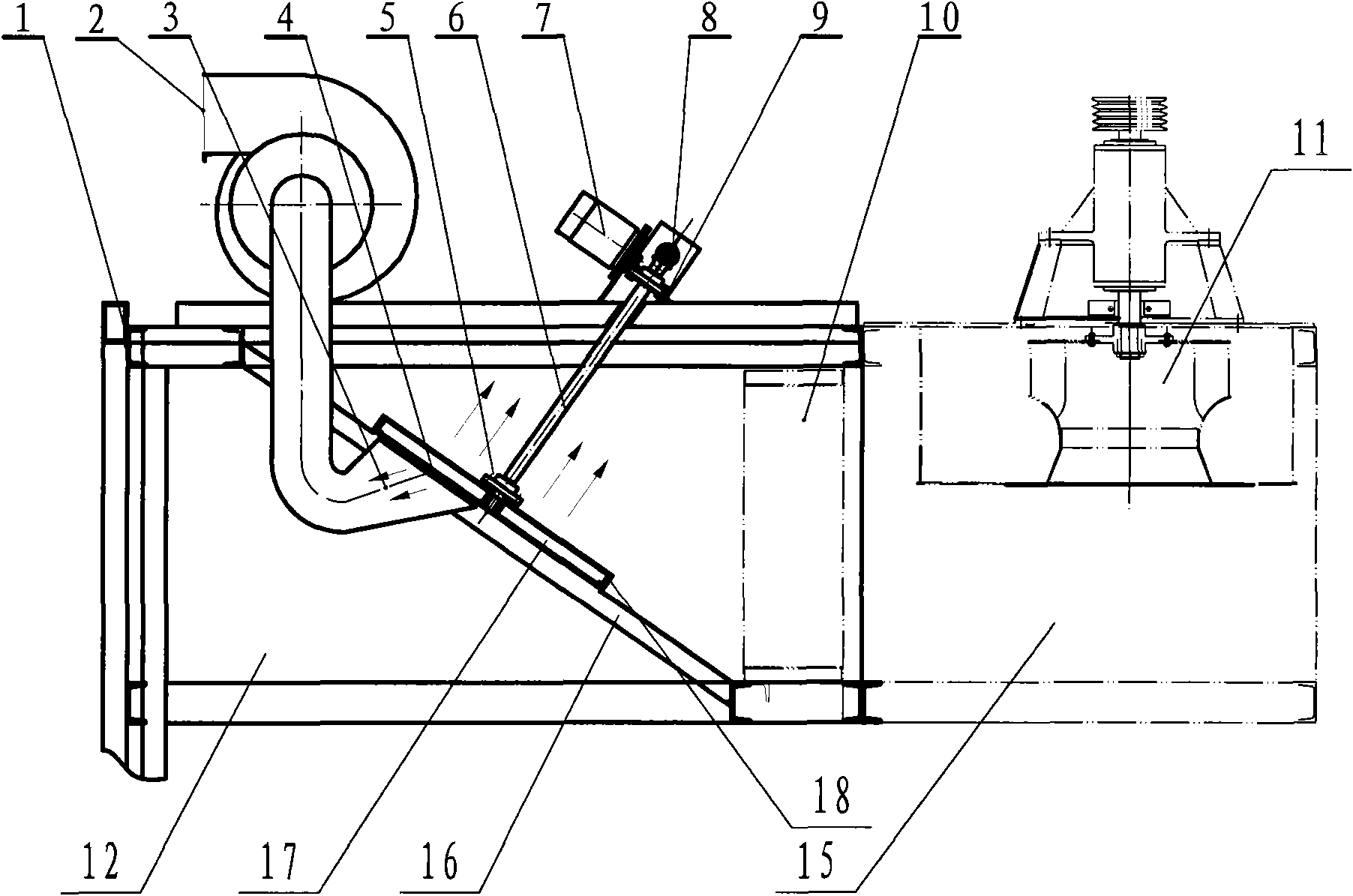

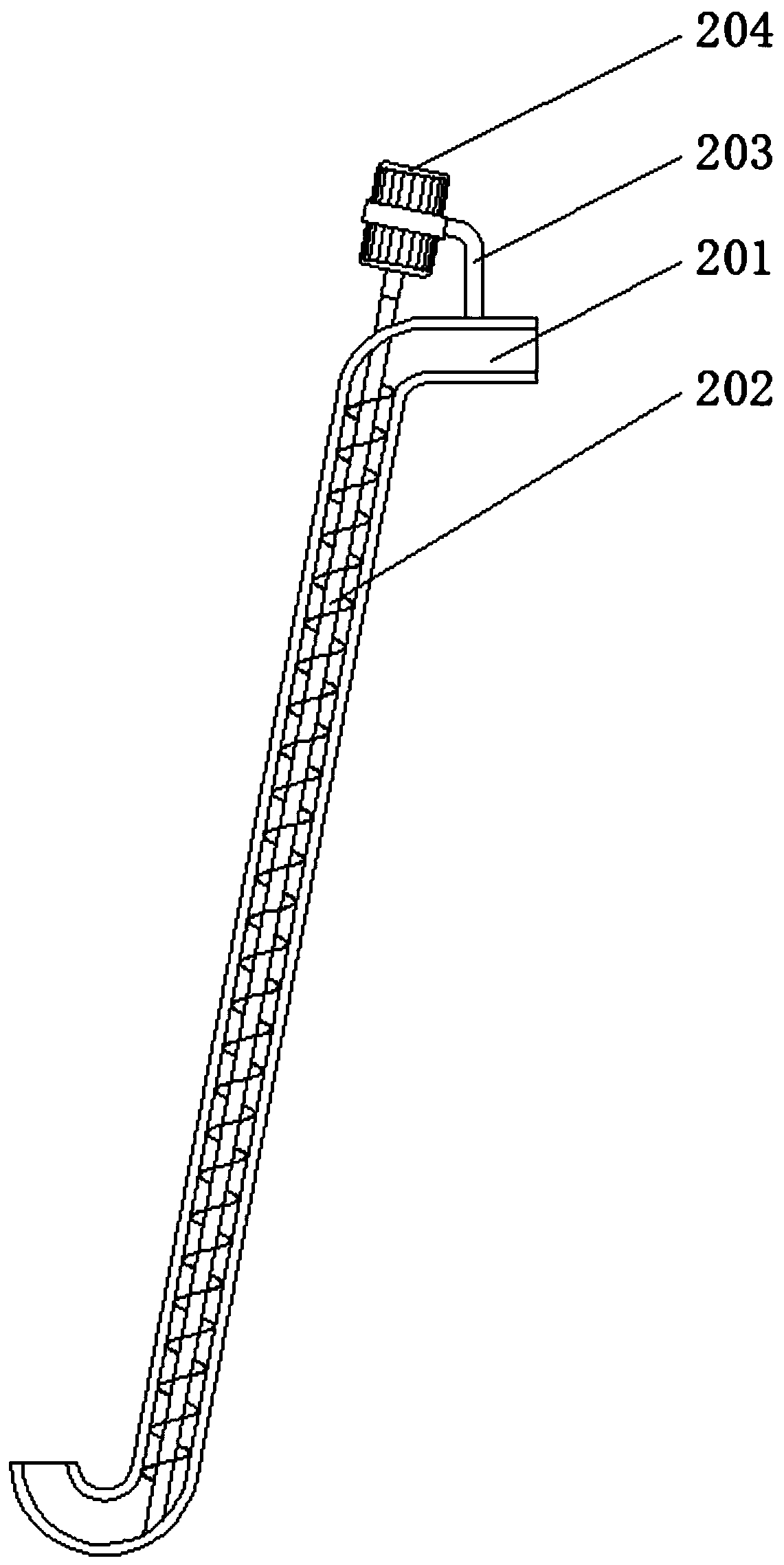

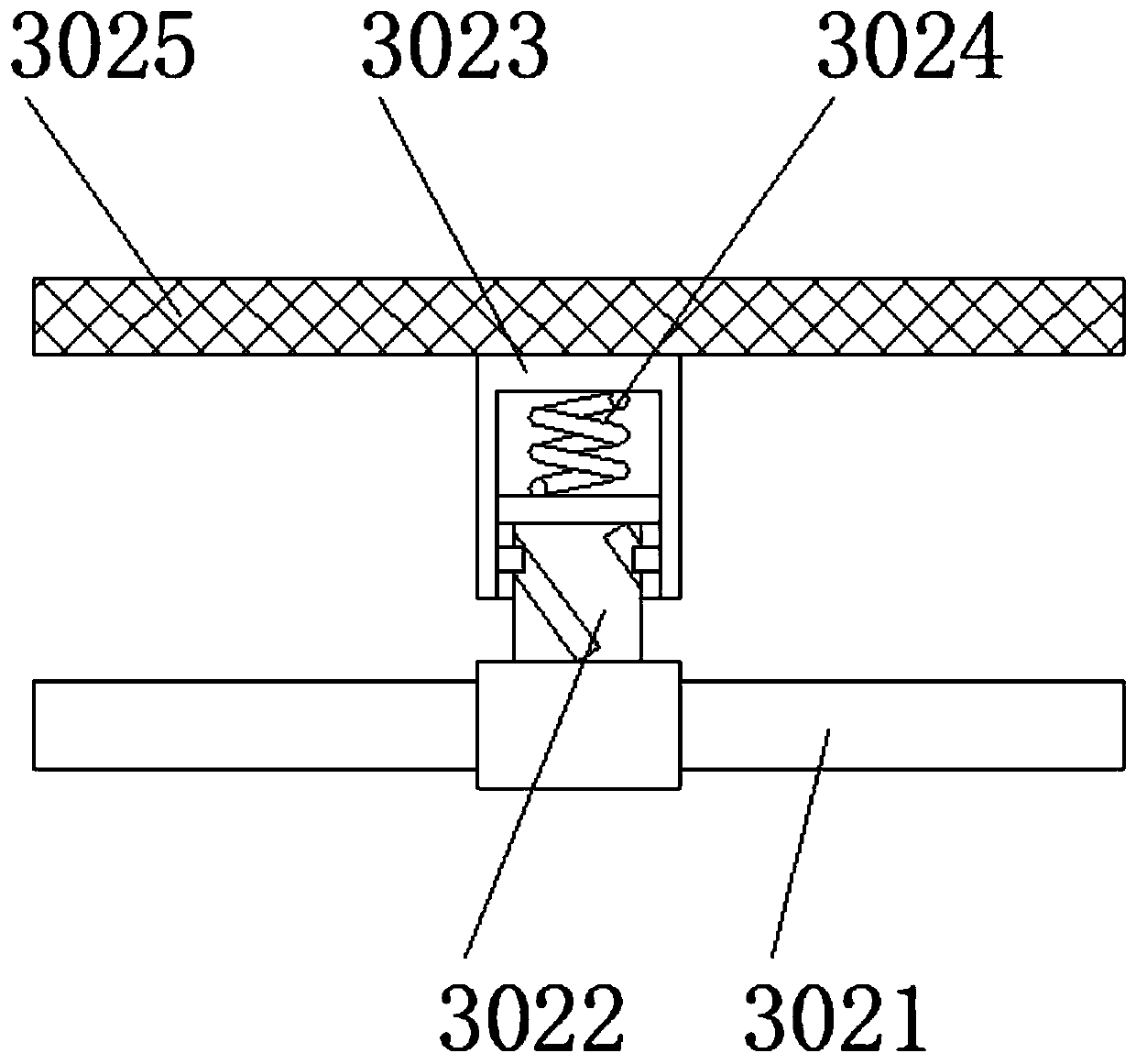

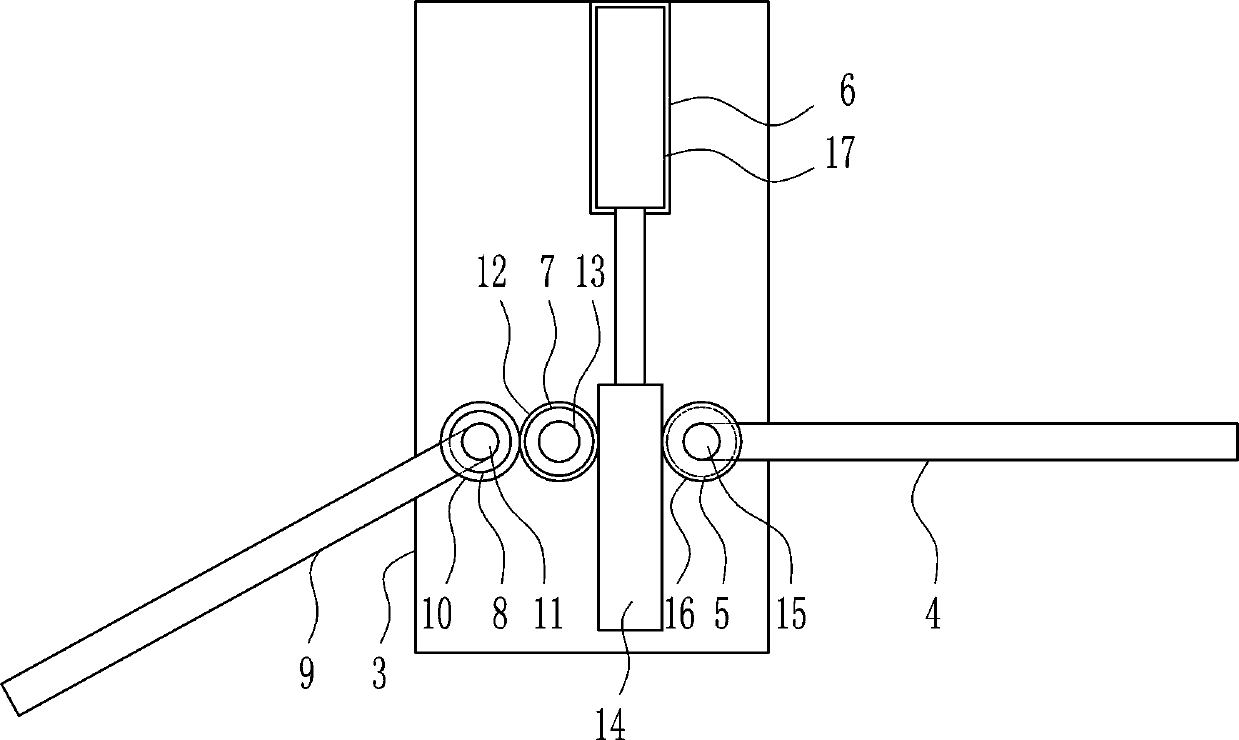

Immediate sewage disposal device of ship propeller thruster

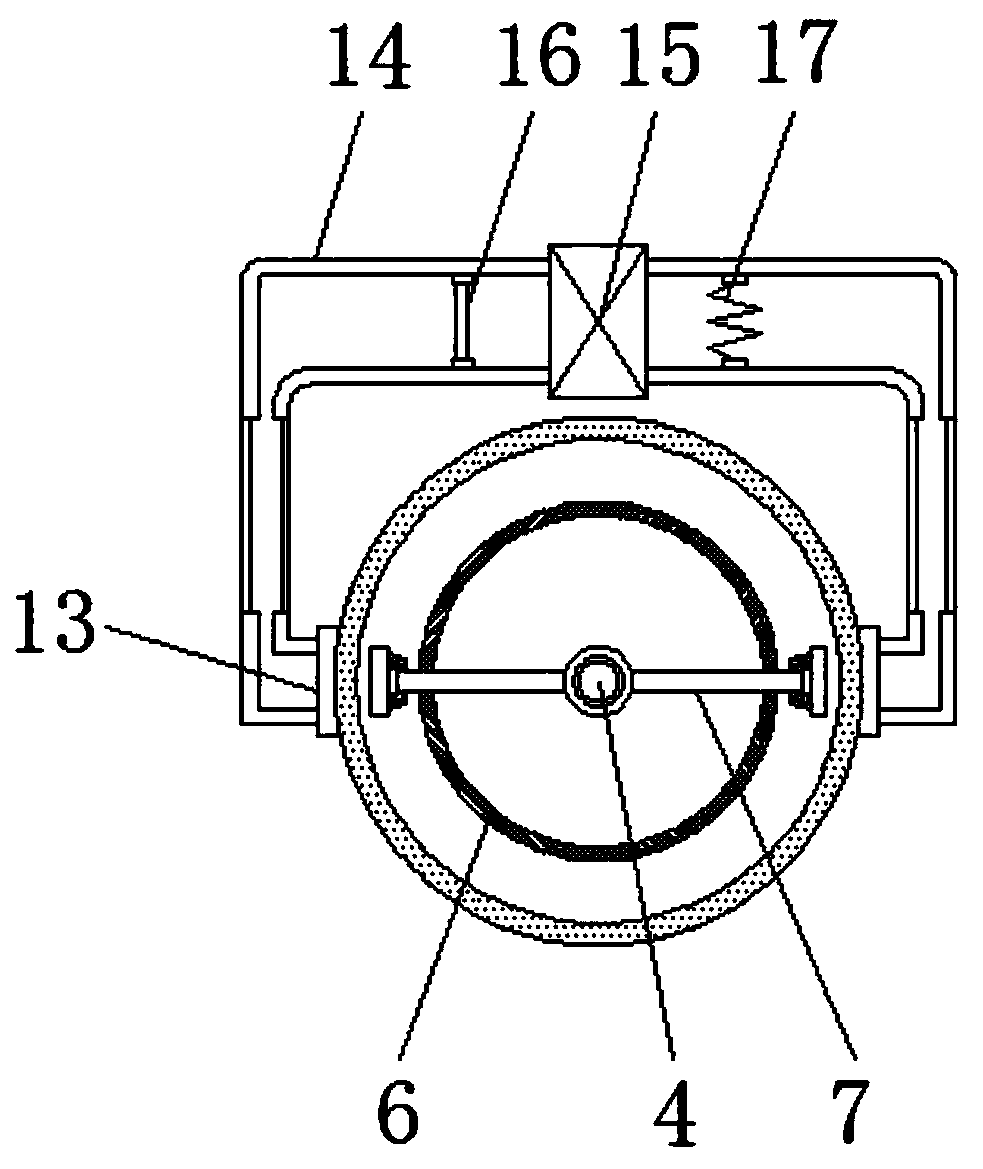

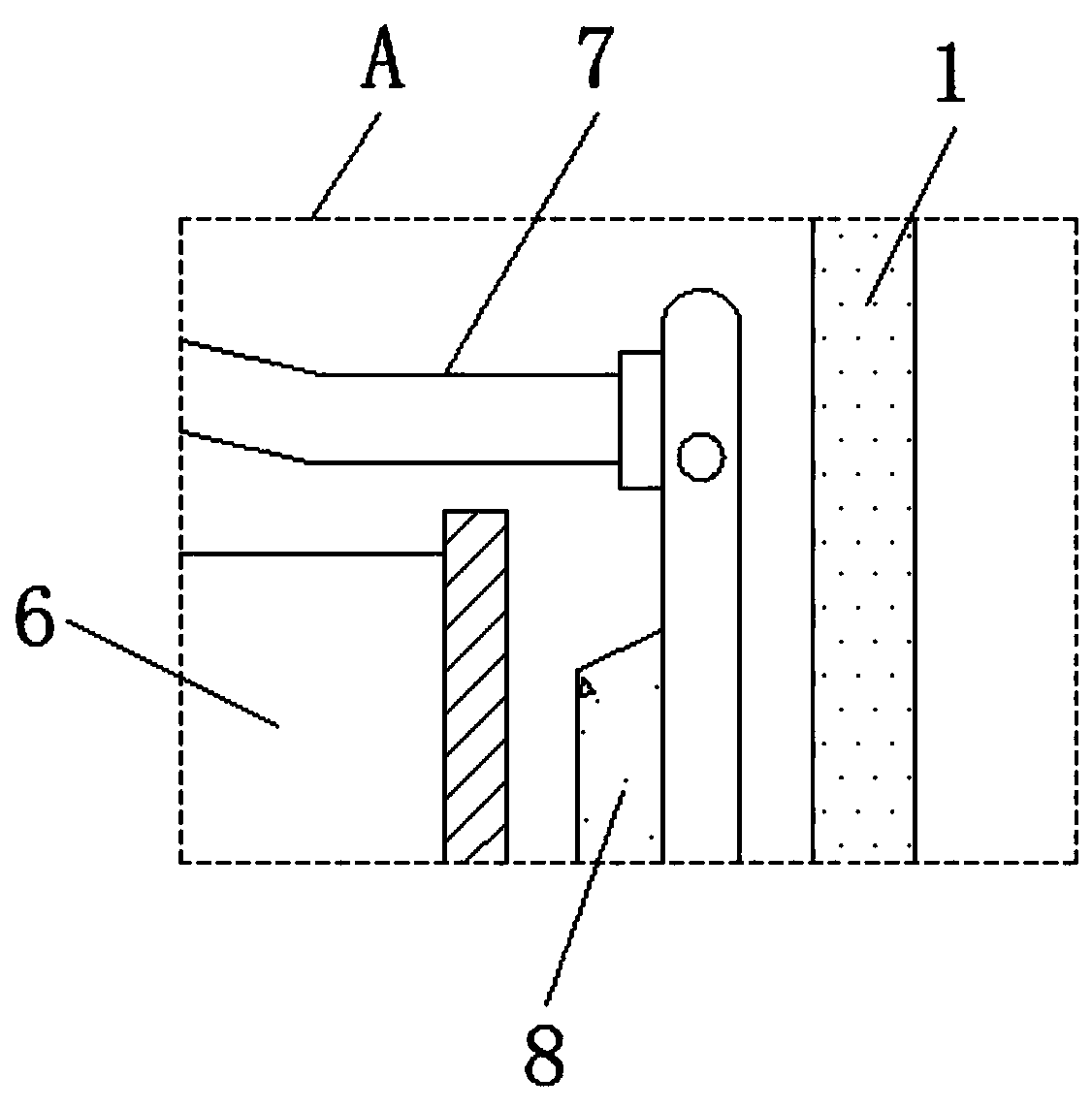

The invention provides an immediate sewage disposal device of a ship propeller thruster and belongs to the technical field of ship engine protection. The technical problem to be solved is to provide the immediate sewage disposal device of the ship propeller thruster, wherein cleaning is conducted when a propeller is wound by water plants or fishing nets; the propeller is released; loads of the propeller are reduced; and normal work of the propeller is maintained. The adopted technical scheme is characterized in that a guide cylinder movably sleeves a rotation shaft of the propeller; a push-pull device is connected to one end of the guide cylinder located inside a ship body; at least three cutter bases are disposed on an installation ring of a current disk through circumferential radiation; the installation ring sleeves the rotation shaft of the propeller; a concave groove and a convex groove which are matched and used to prevent axial motion of the installation ring are disposed on contact faces of the rotation shaft and the installation ring; a cutter groove is formed in one side of each cutter base facing the propeller; a blade is in hinge connection in the cutter groove; a self-recovery spring is disposed on a cutter shaft of the blade; the cutter shaft is connected to one end of the guide cylinder by a pull rope; and the connection point between the pull rope and the cutter shaft is closest to the propeller when the blade is located inside the cutter groove.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

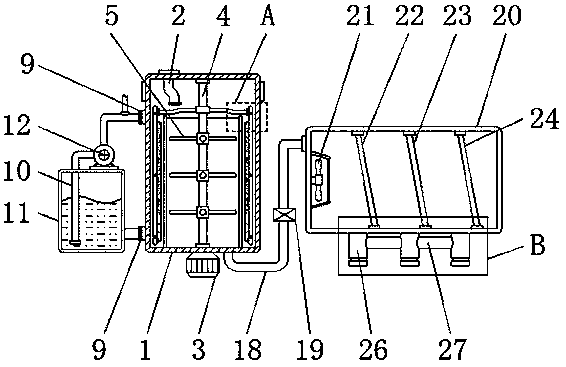

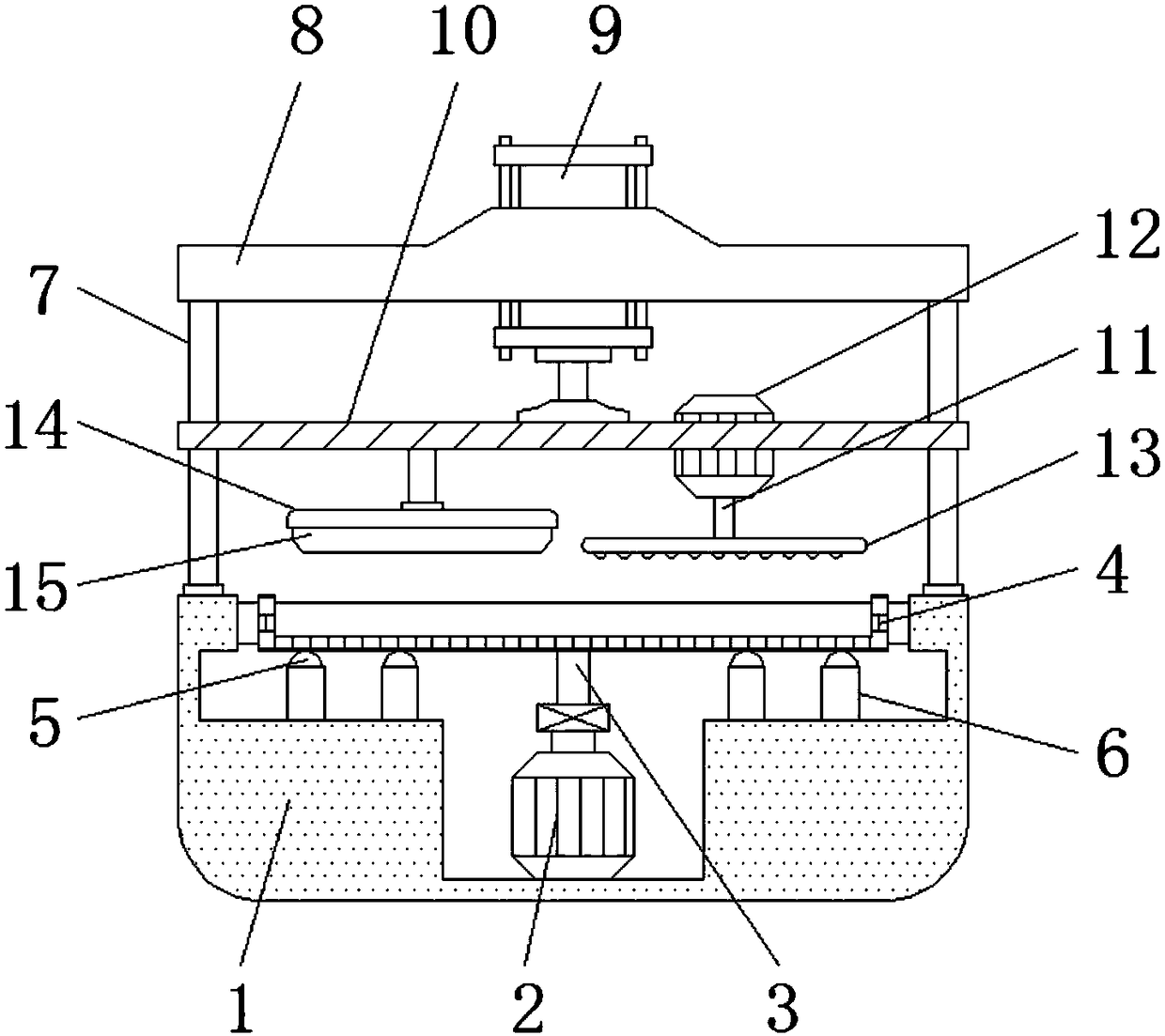

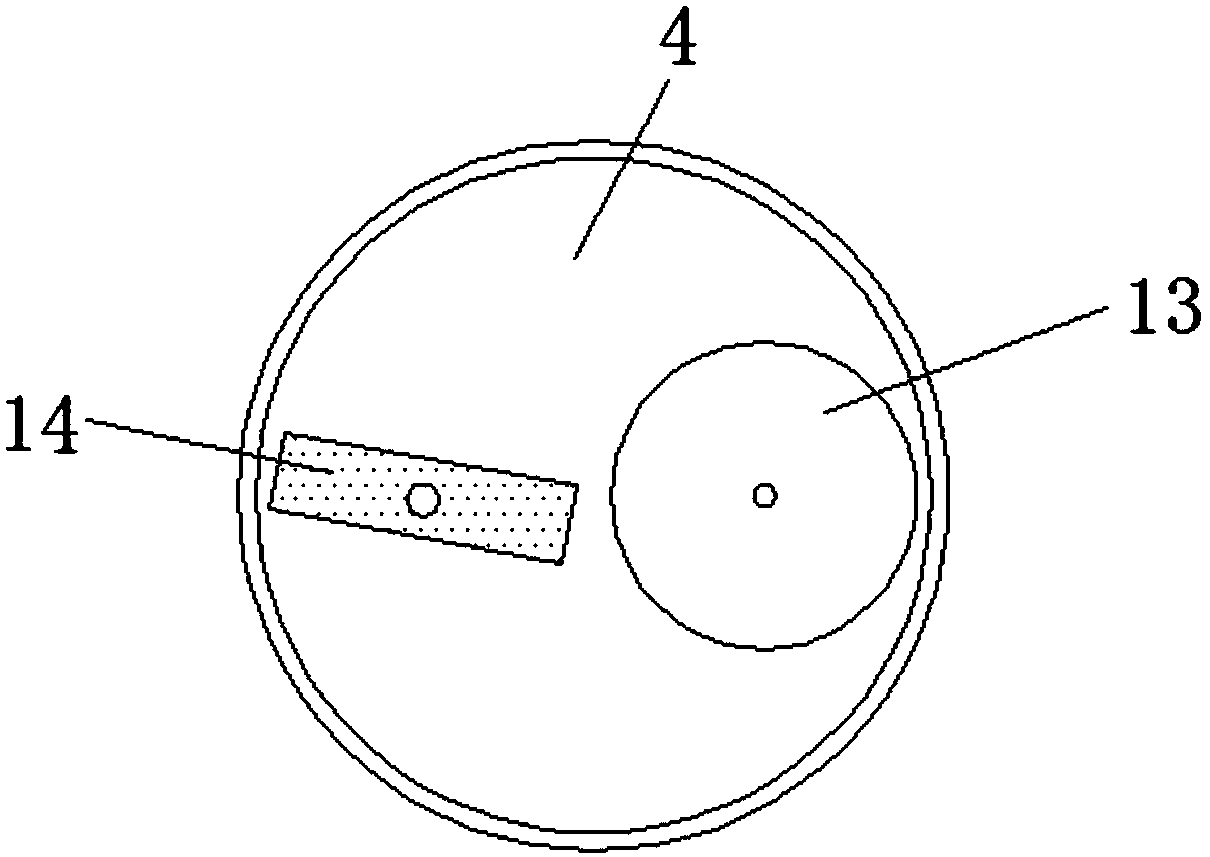

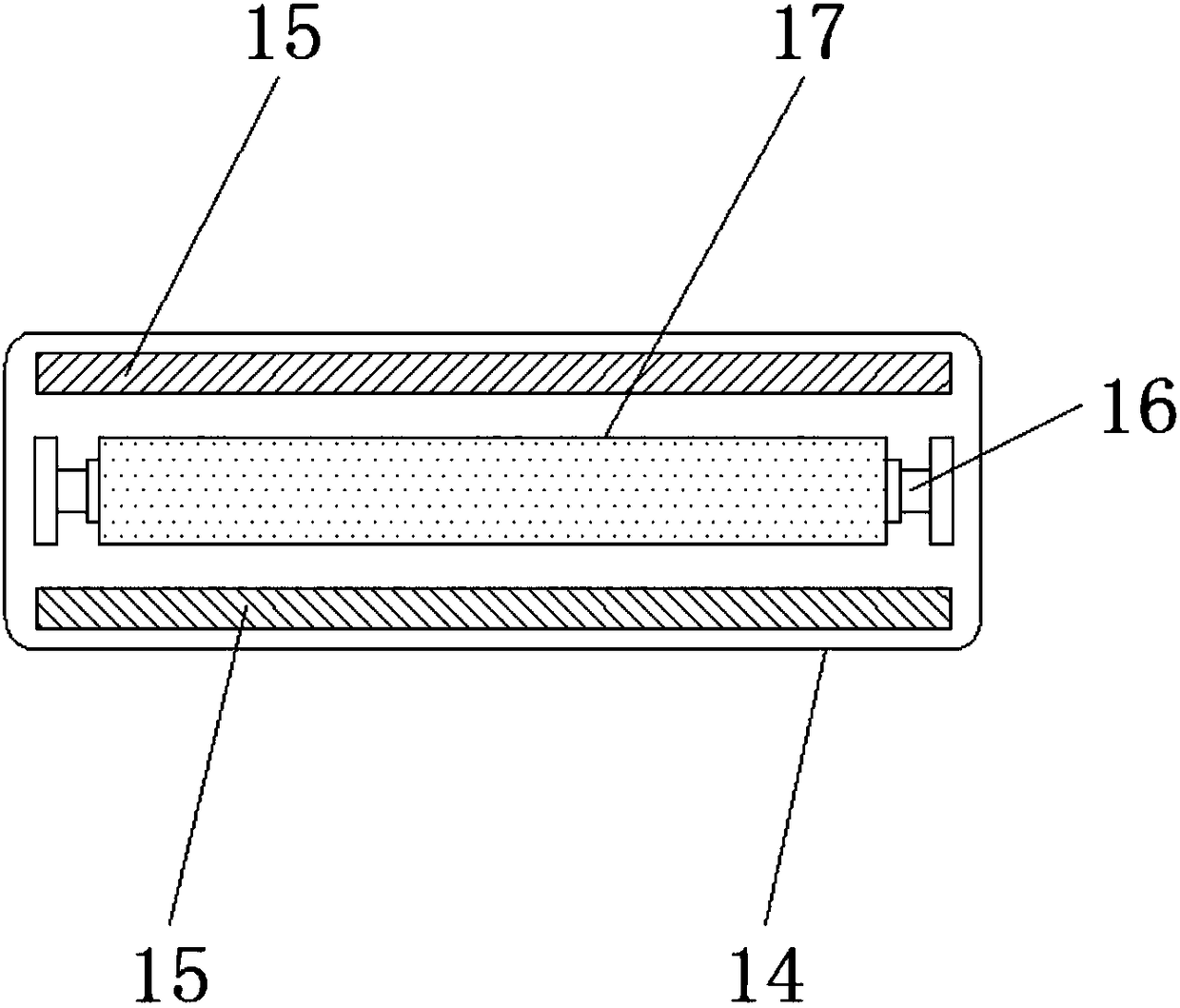

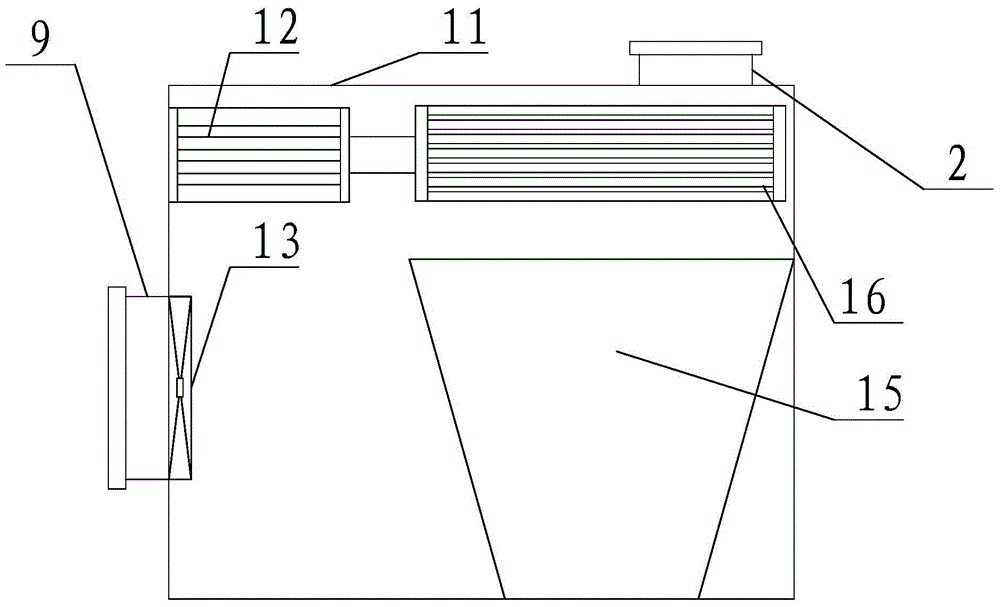

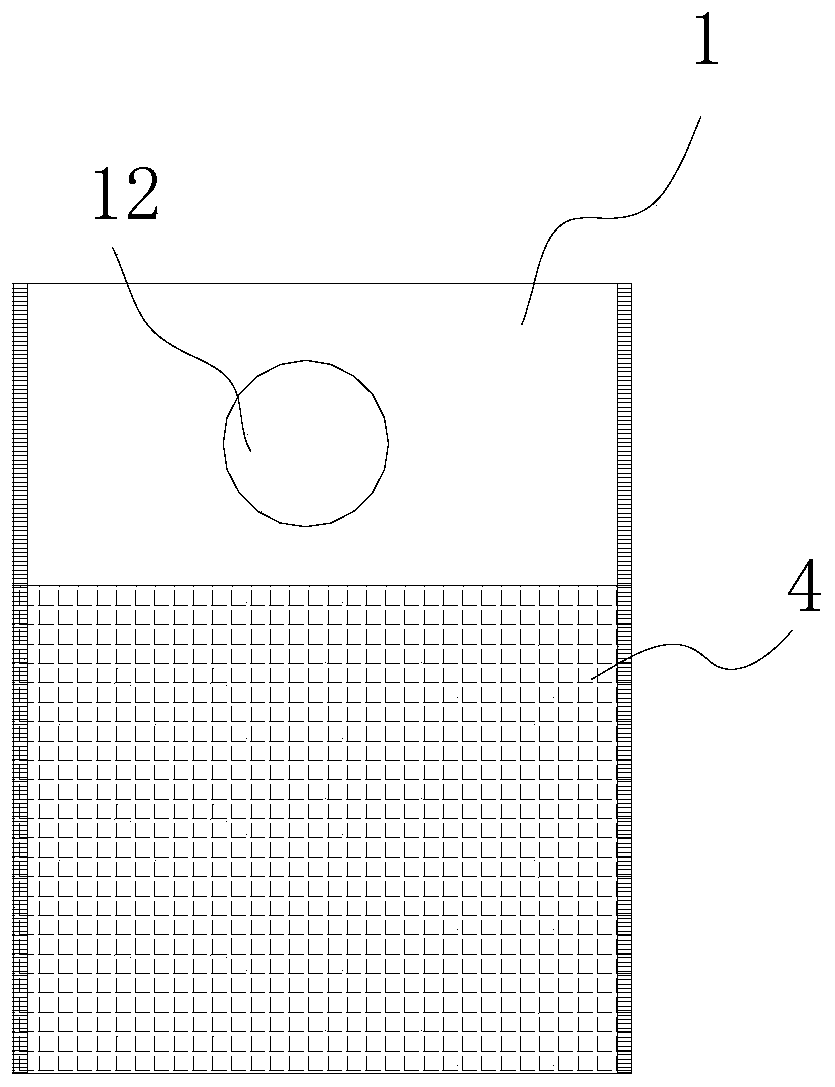

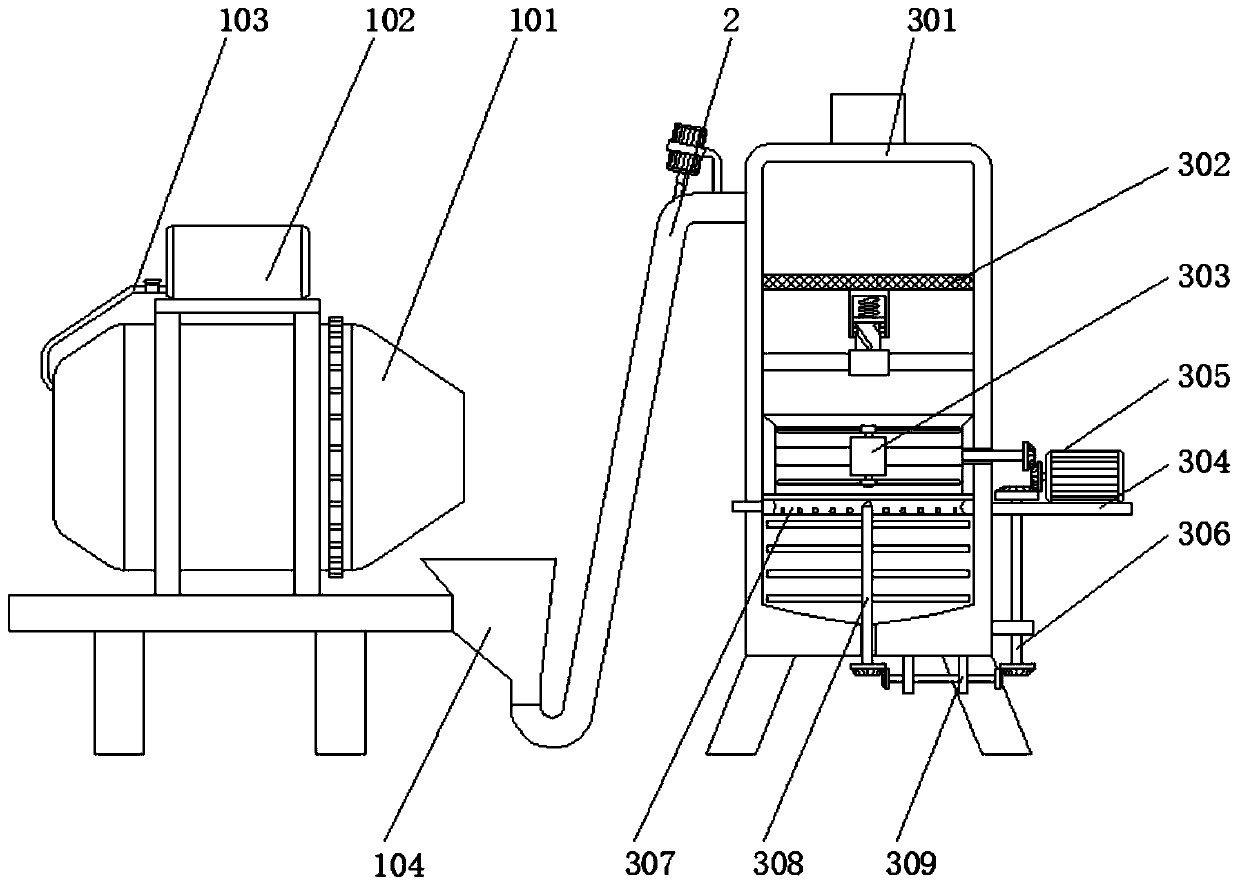

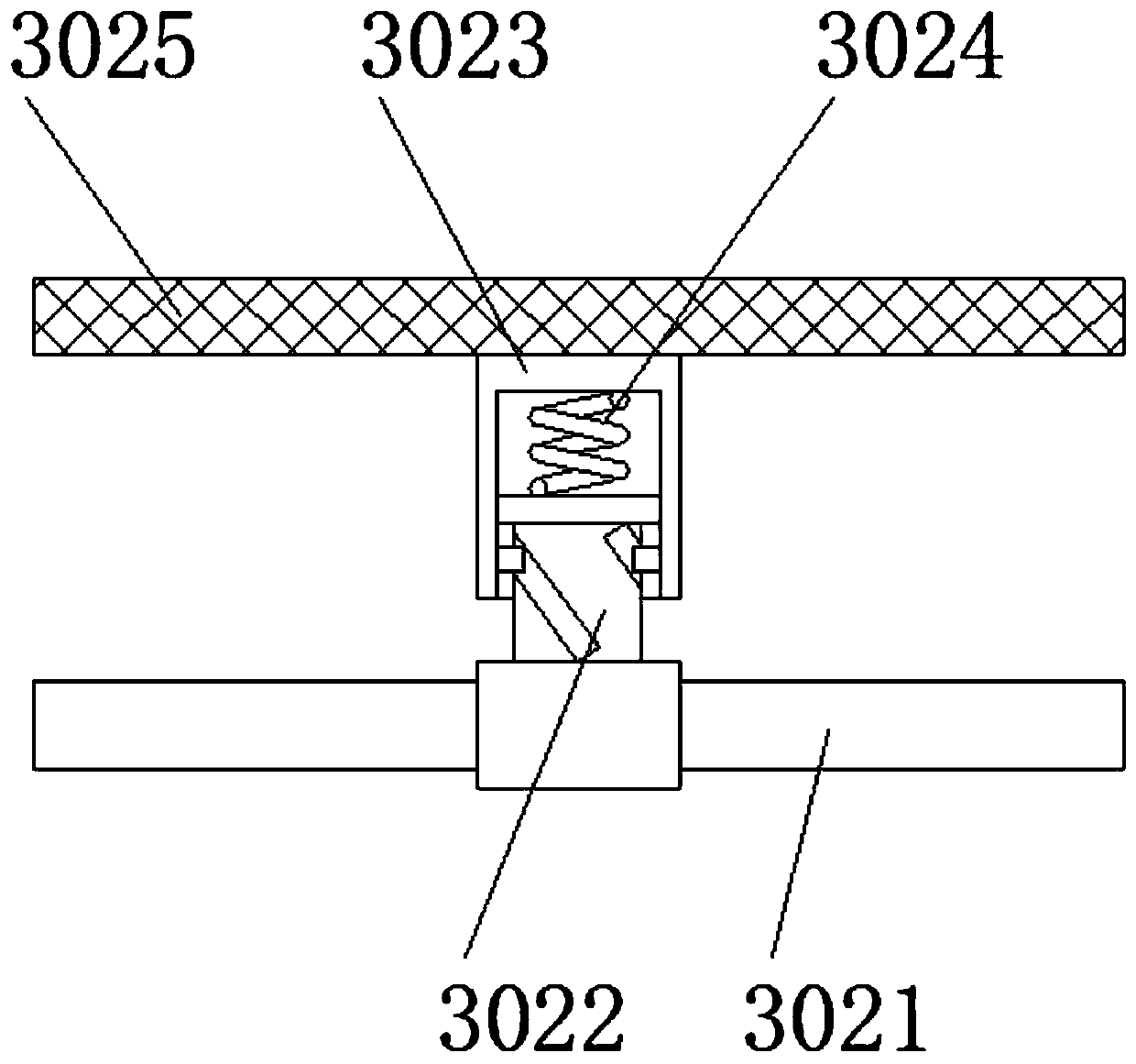

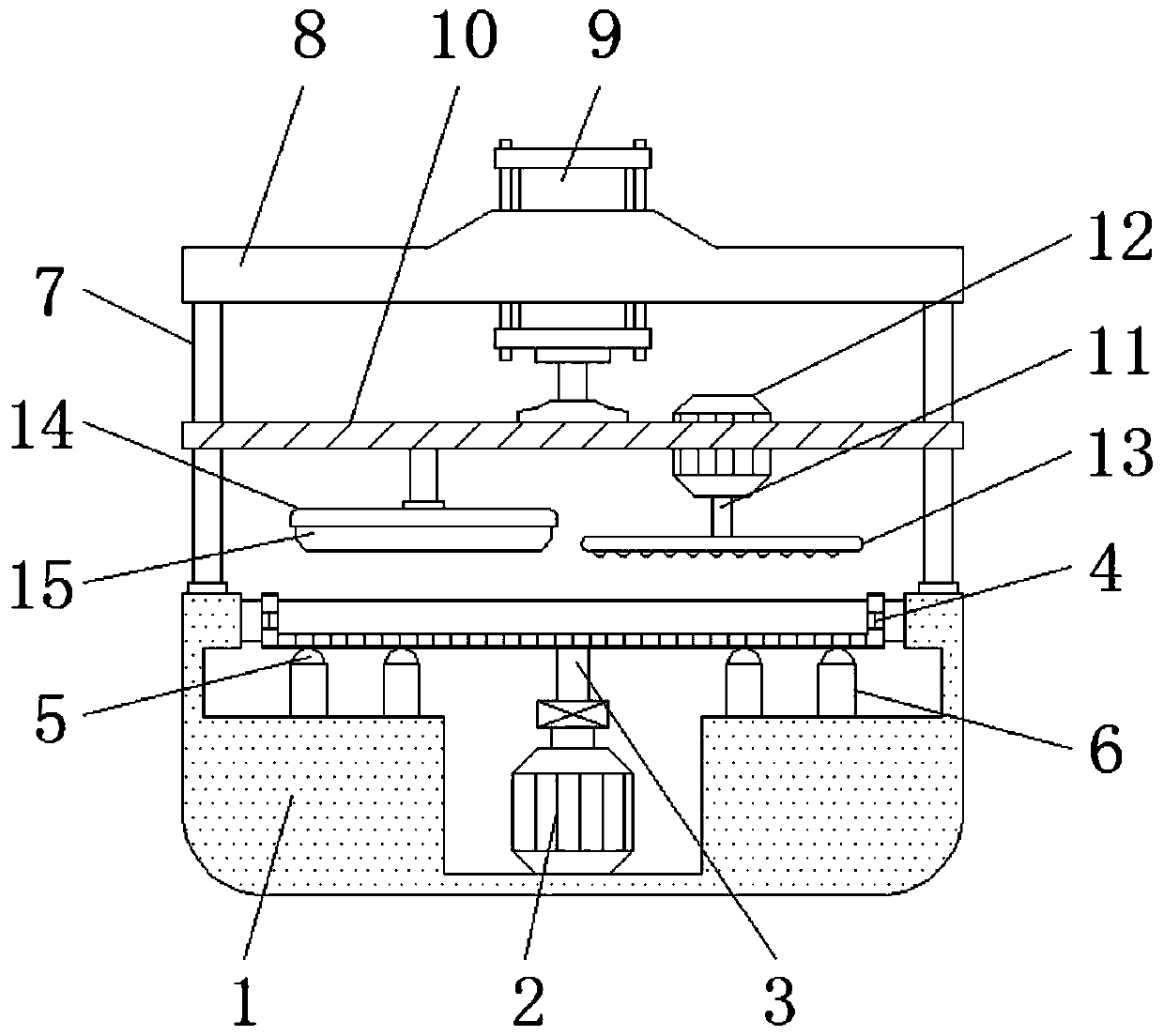

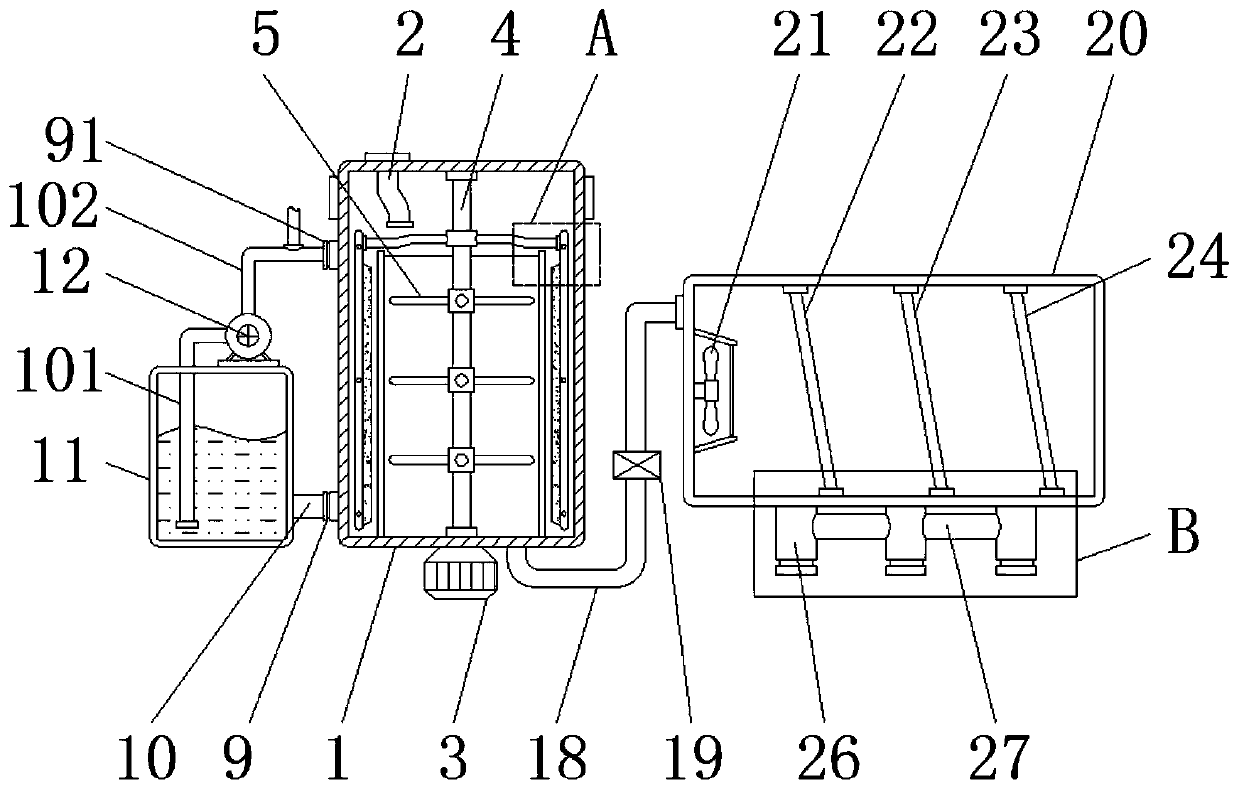

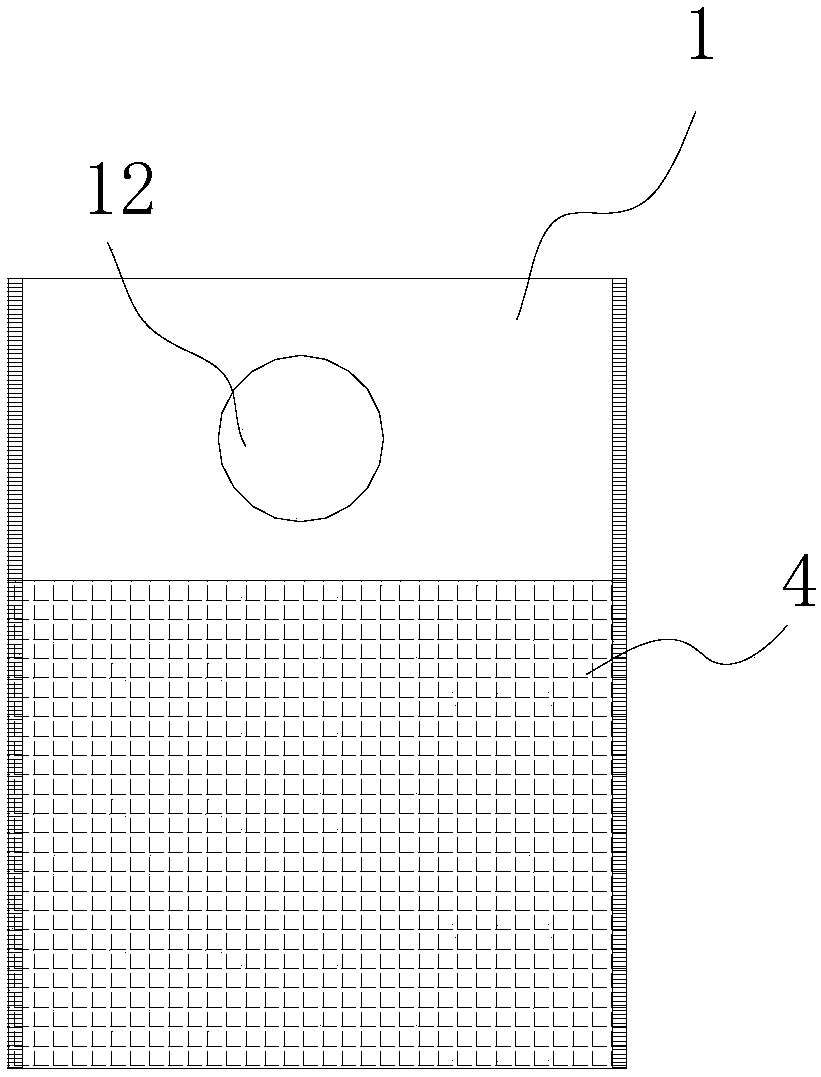

Cleaning device capable of quick screening for down feather processing

ActiveCN108166071AReasonable designMention efficiency and qualityWool fibre washing/scouringLiquid/gas/vapor removal by gas jetsEnvironmentally friendlyEngineering

The invention discloses a cleaning device capable of quick screening for down feather processing. The cleaning device comprises a cleaning and drying tank, a separating cylinder, a cleaning strip, a collecting tank and a screening tank; a top end of the cleaning and drying tank is provided with an inlet pipe; the separating cylinder is installed inside the cleaning and drying tank; the cleaning strip is connected with the other end of a connecting rod; the collecting tank is connected with a water through hole in the cleaning and drying tank through a connecting pipe; the cleaning and drying tank is provided with a ventilating opening; filter holes are opened in a first filter board; a bottom end of the screening tank is provided with discharging pipes which are mutually connected throughshunt tubes ; an inner wall of the shunt tube is provided with a separator plate. According to the cleaning device capable of quick screening for down feather processing, down feather can be quickly cleaned and dried; the water resource after cleaning can be reused, which is more energy saving and environmentally friendly; at the same time, down feather can be quickly screened; the design is reasonable and the processing quality and efficiency of down feather can be greatly increased.

Owner:ZHANJIANG ZIJIN DOWN PROD

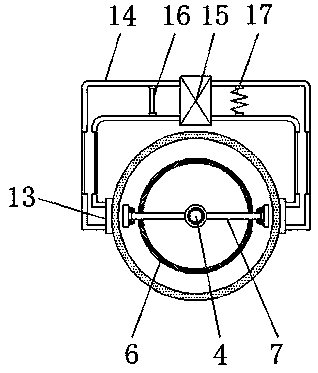

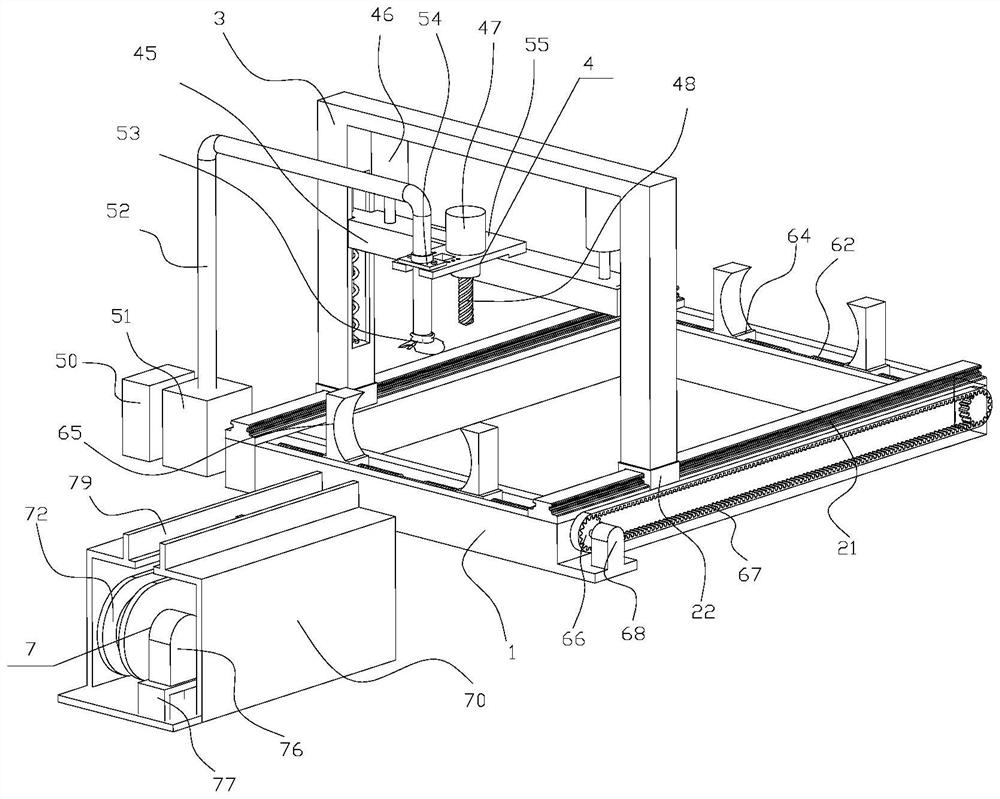

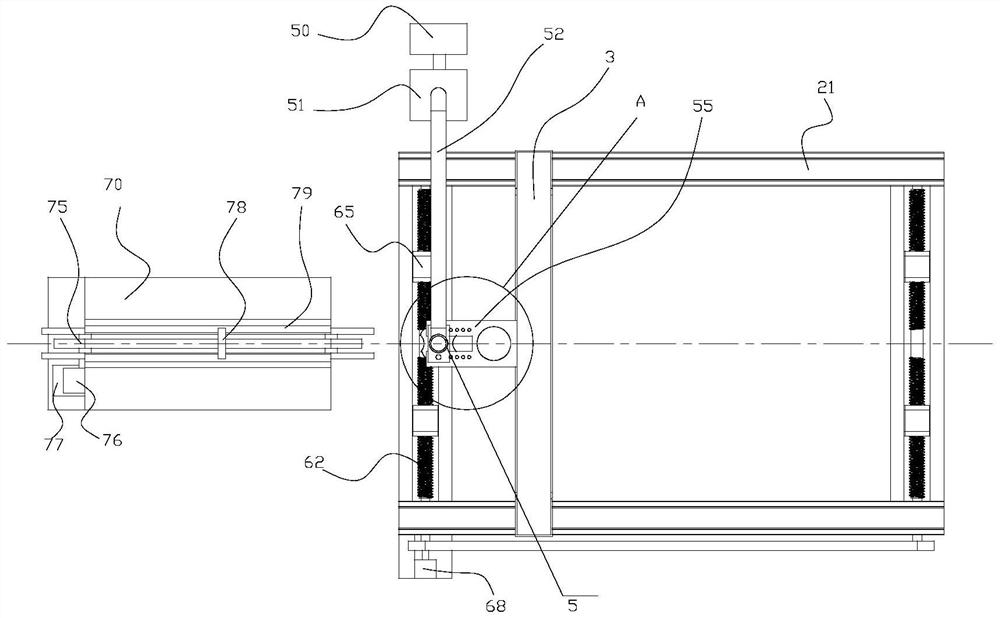

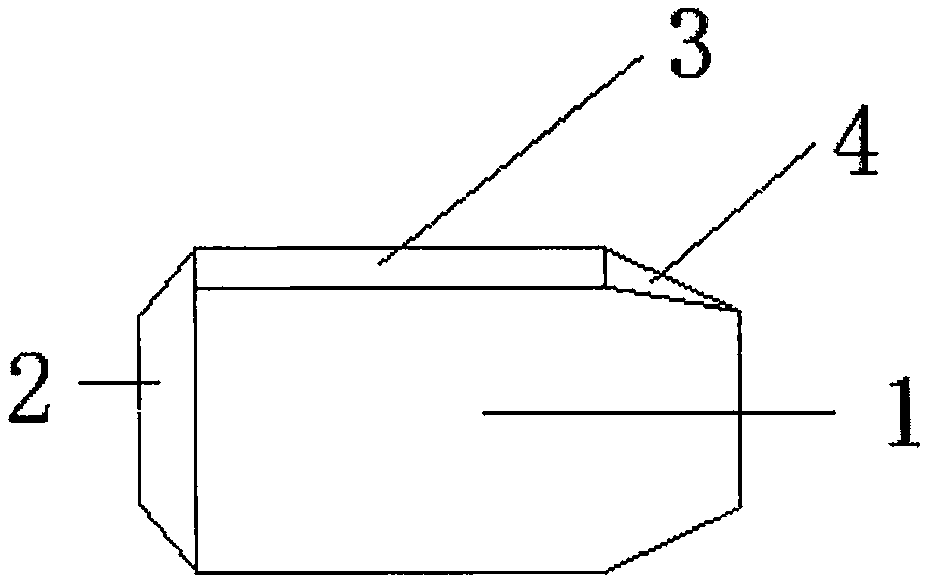

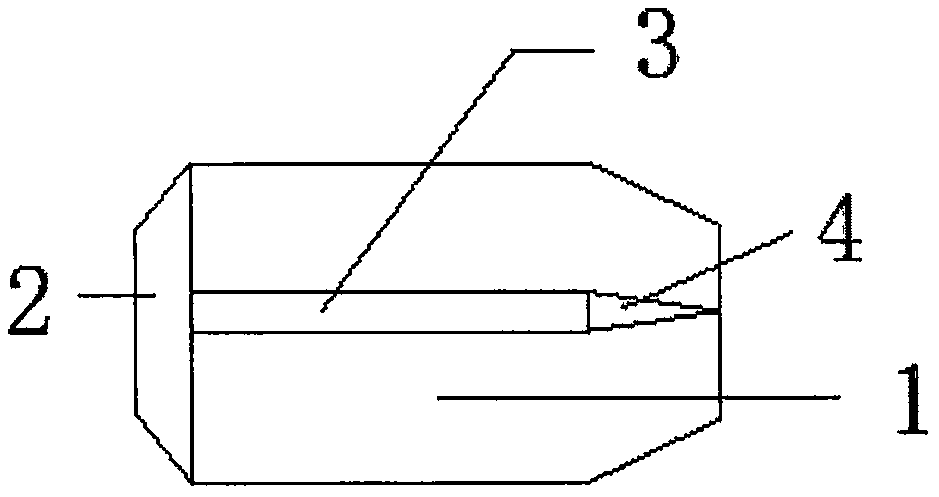

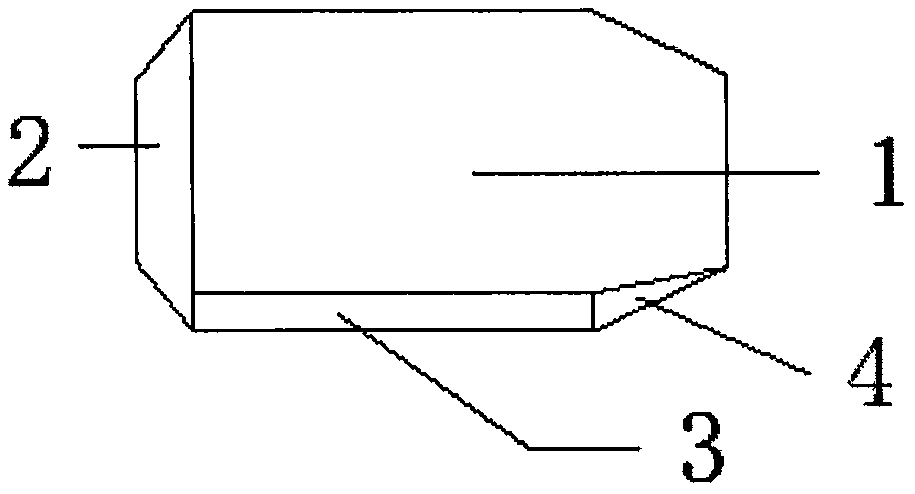

Metal panel grinding device capable of preventing looseness of materials

ActiveCN108544312APrevent looseningPolished evenlyGrinding carriagesGrinding work supportsProcess qualitySurface mounting

The invention discloses a metal panel grinding device capable of preventing looseness of materials. The metal panel grinding device capable of preventing looseness of materials comprises a device base, a ball, a regulating plate and a compaction plate, wherein a first motor is arranged on the inner side of the device base; the ball is located below a workpeice plate; the device base is connected to a device top seat through a supporting column, and a lifting device is mounted on the device top seat; the regulating plate and the lifting device are connected to each other, and the side edge of the regulating plate is mounted on the supporting column; a second motor is arranged on the regulating plate, and the second motor is connected to a grinding disc through a connecting shaft; the compaction plate is connected to the regulating plate, and a cleaning brush is mounted on the surface of the compaction plate. The metal panel grinding device capable of preventing looseness of materials can grind the surface of a panel uniformly, is more reasonable in structural design, can clean fragments left on the surface of the panel in the grinding process immediately, and meanwhile, can preventlooseness of the panel and is better in processing quality.

Owner:河南荣事德新型建材有限公司

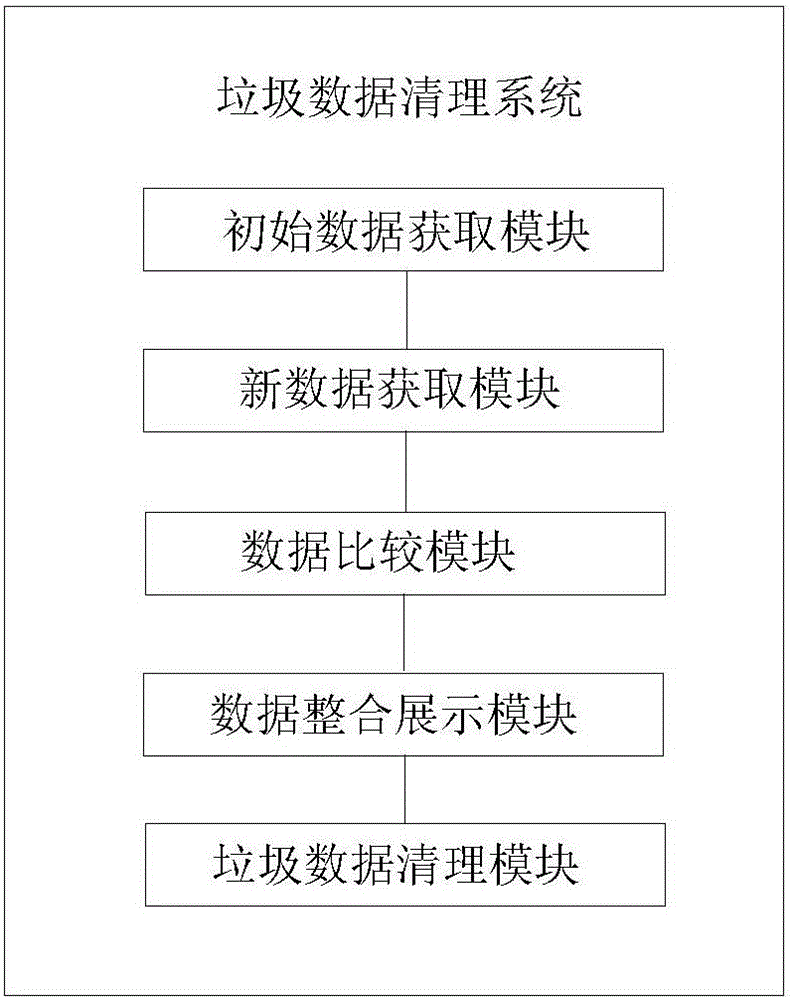

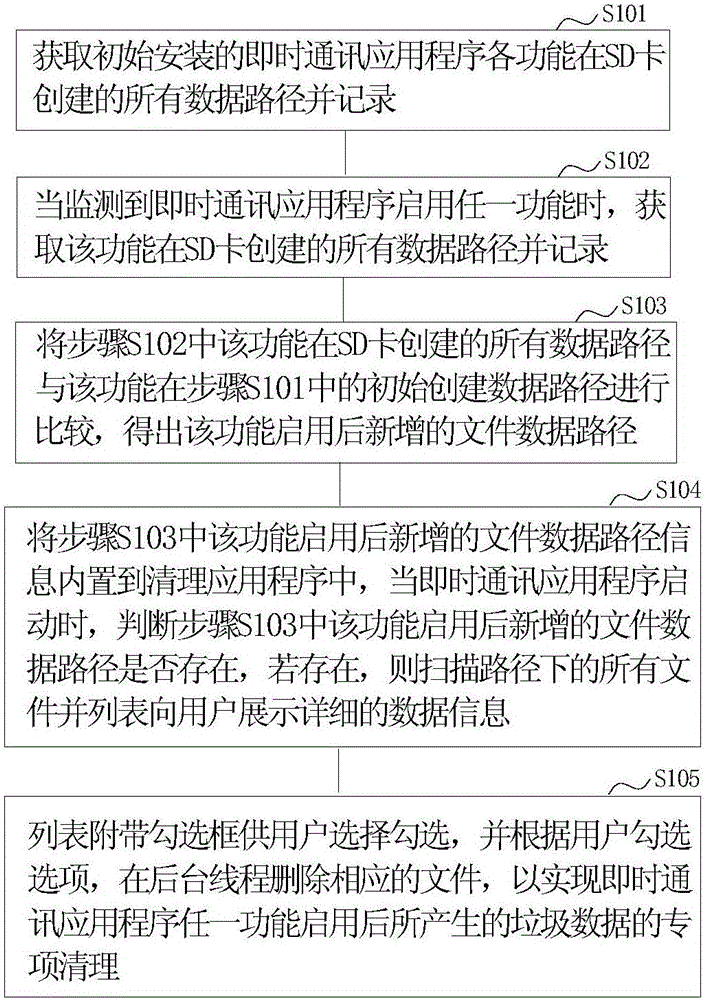

Junk data clearing method and system

InactiveCN105956132AInstant cleanupInput/output to record carriersSpecial data processing applicationsDatapathApplication software

The invention provides a junk data clearing method. The method comprises the steps of S1, obtaining and recording all data paths created in an SD card by each function of an initially installed instant messaging application; S2, when it is monitored that any function of the instant messaging application is enabled, obtaining and recording all data paths created in the SD card by the function; S3, comparing all the data paths created in the step S2 with the initially created data paths in the step S1 to obtain added file data paths; and S4, building the added file data paths in the step S3 into a clearing application, and when the instant messaging application is started, judging whether the added file data paths in the step S3 exist or not, and if the added file data paths exist, scanning all files in the paths, displaying the files to a user by listing, and deleting corresponding files in a background thread according to options checked by the user so as to realize clearing of junk data generated after any function of the instant messaging application is enabled. The invention furthermore provides a junk data clearing system.

Owner:GUANGZHOU GOMO SHIJI TECH CO LTD

Clean type cow driver for livestock

ActiveCN108184705AExpand the scope of evictionEasy to fixCleaning using toolsAnimal repellantsMilk cow'sEngineering

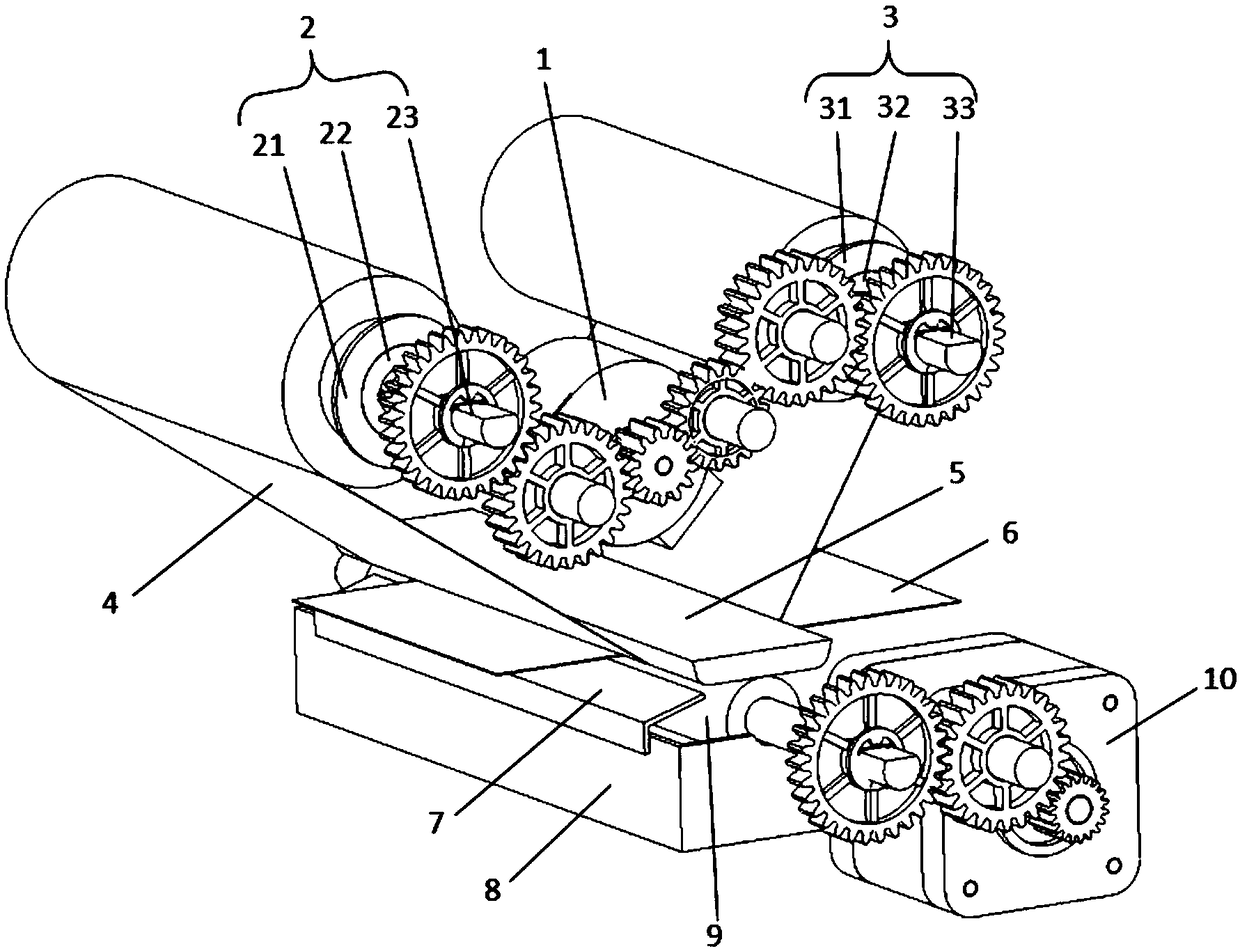

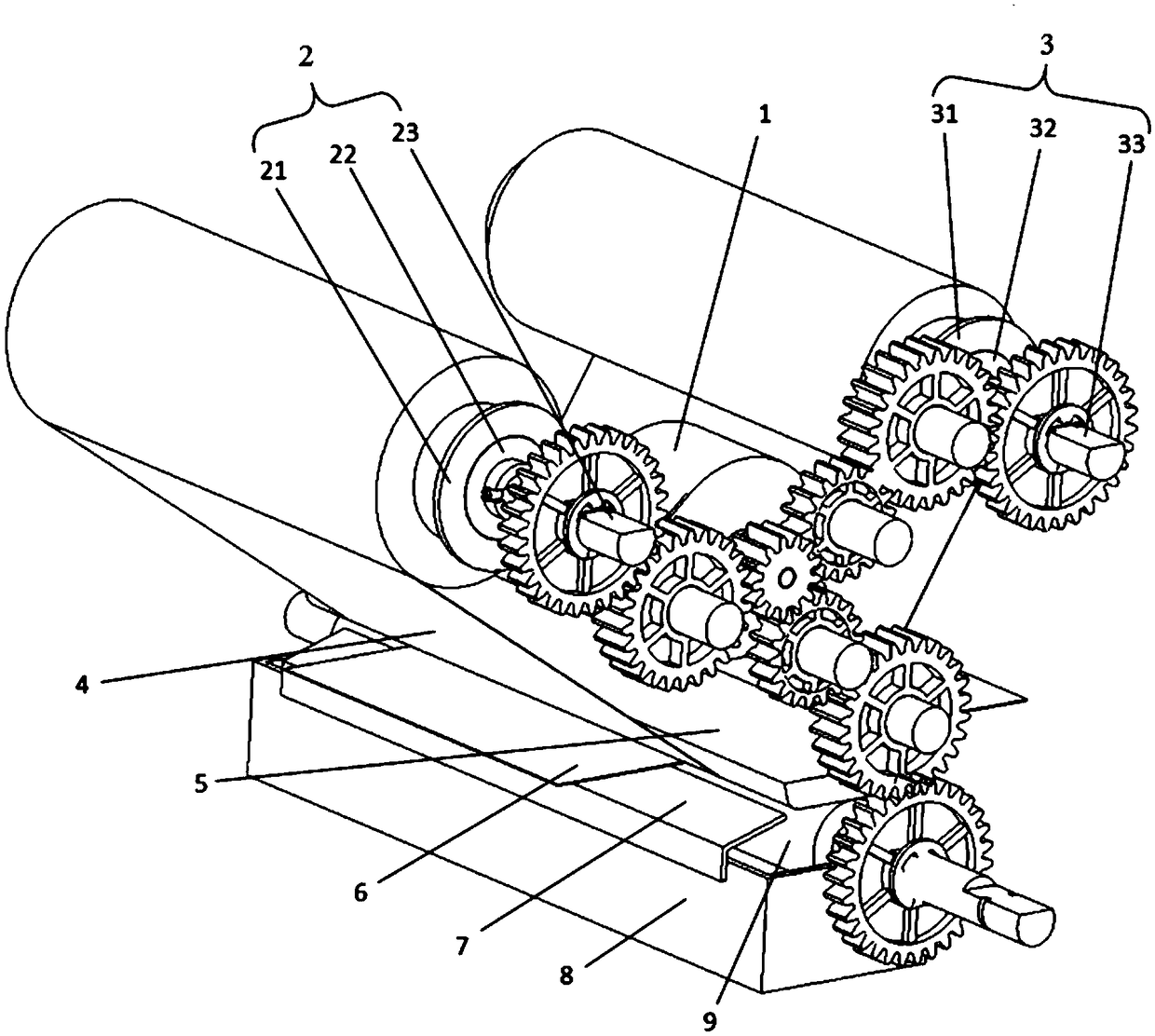

The invention relates to a driver, in particular to a clean type cow driver for livestock. In order to solve the technical problems, the clean type cow driver for livestock is provided. In order to solve the technical problems, the cow driver comprises universal wheels, a frame, a first driving strip, a right bearing pedestal, a support, a middle bearing pedestal, a left bearing pedestal, a seconddriving strip, a left gear, a left rotating shaft, a middle gear and the like. The universal wheels are installed at the bottom of the frame. The left bearing pedestal, the middle bearing pedestal and the right bearing pedestal are sequentially installed on the top of the frame from left to right and provided with the left rotating shaft, a middle rotating shaft and a right rotating shaft respectively. The effects of being convenient to use and capable of instantly cleaning the ground are achieved; the first driving strip and the second driving strip alternately swing forward and backward, cows in front are driven continuously, and farmers only need to push the cow driver instead of sparing large efforts to drive the cows.

Owner:金寨县益农农业科技开发有限公司

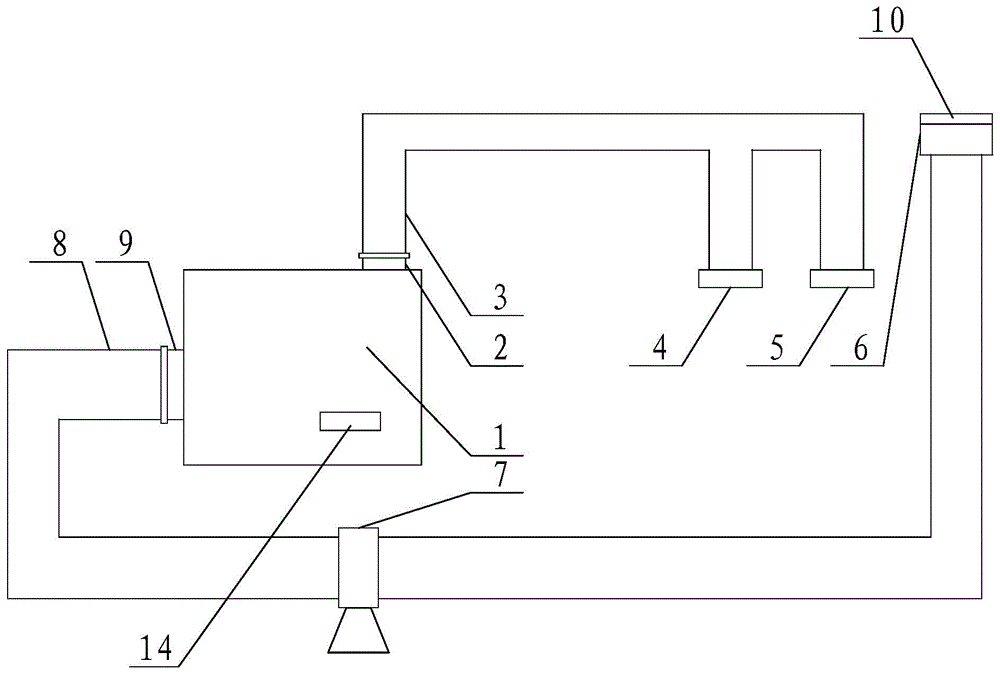

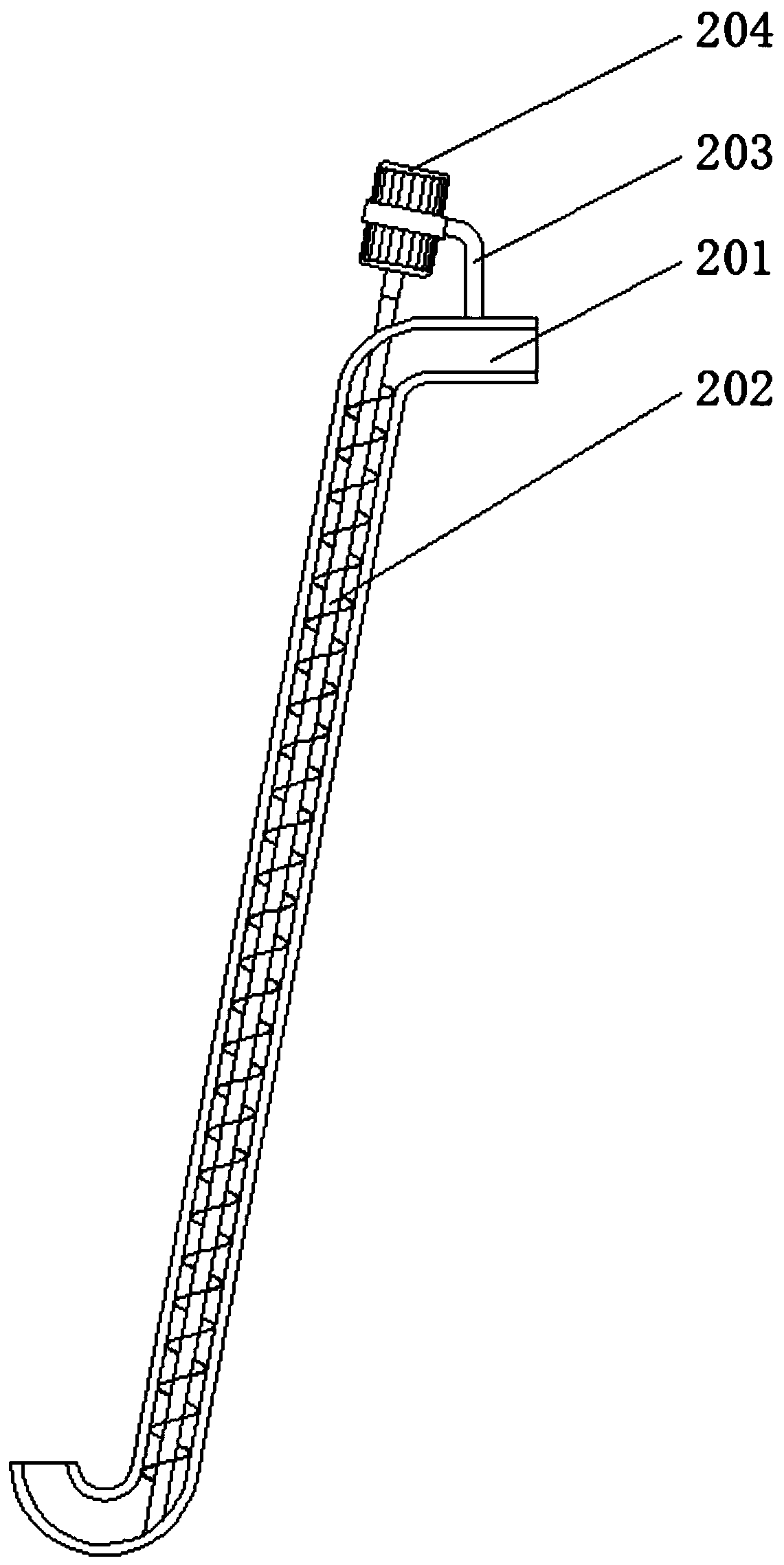

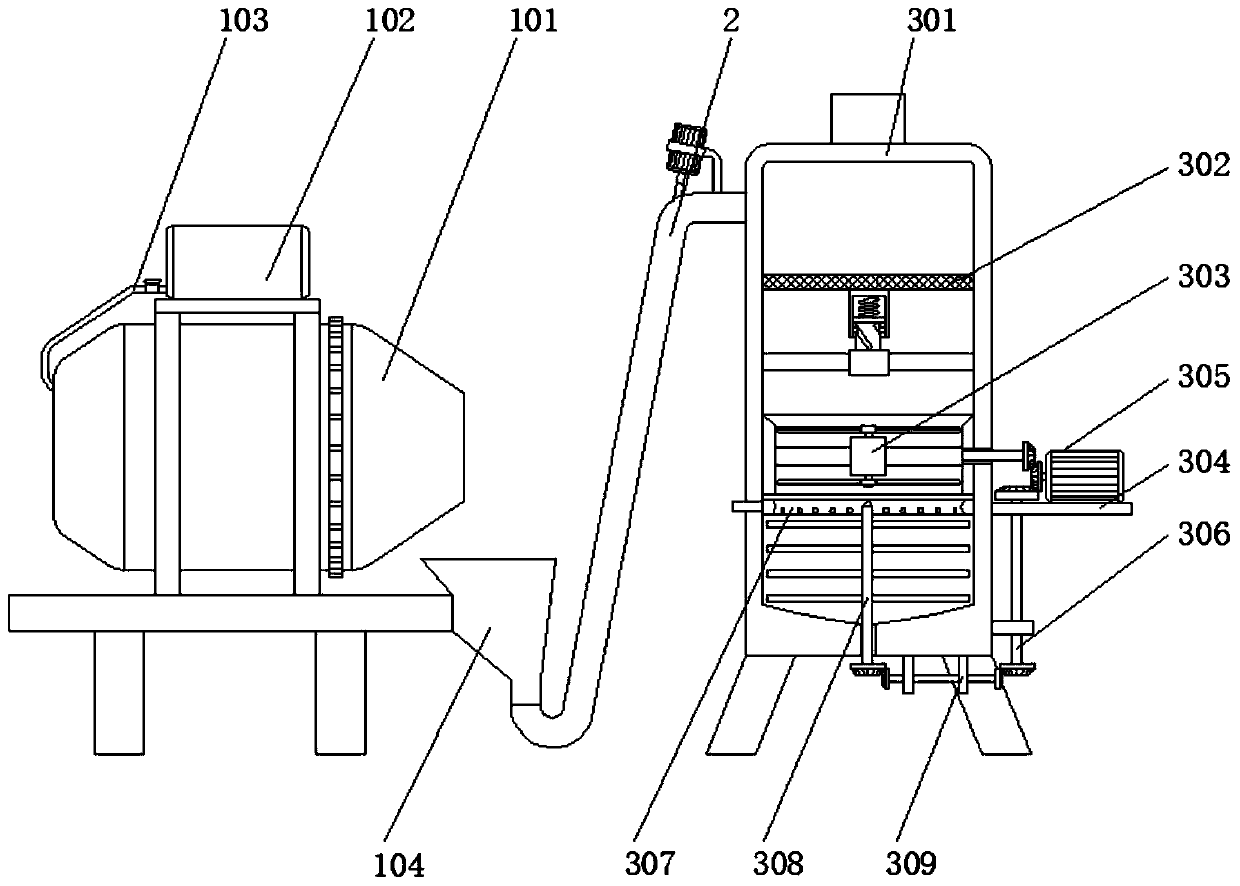

Dust removal exhaust system for Chinese medicinal herb processing workshop

InactiveCN104667642AQuick extractionInstant cleanupDispersed particle filtrationMedicinal herbExhaust pipe

The invention discloses a dust removal exhaust system for a Chinese medicinal herb processing workshop. The dust removal exhaust system comprises a dust remover, wherein the dust remover is provided with an air inlet and an air outlet; the air inlet is provided with an air inlet pipe, and the air outlet is provided with an air outlet pipe; the air inlet pipe is communicated with a first air suction pipeline and a second air suction pipeline of the Chinese medicinal herb processing workshop, and the air outlet pipe is provided with an air blower; one end, which is far away from the air outlet, of the air outlet pipe is provided with an exhaust pipe orifice; the dust remover comprises a shell; a filter screen is arranged in the shell on the air inlet, the filter screen is provided with a vibrator; and a detachable dust hopper is arranged on the inner wall of the shell below the filter screen. According to the dust removal exhaust system, air can be faster sucked in the workshop by arranging the two air suction pipelines, the air leaves dust through the filter screen of the dust remover to be purified, and the purified air is discharged through an air outlet pipeline.

Owner:XIAN ZHONGKEMAITE ELECTRONICS TECH EQUIP

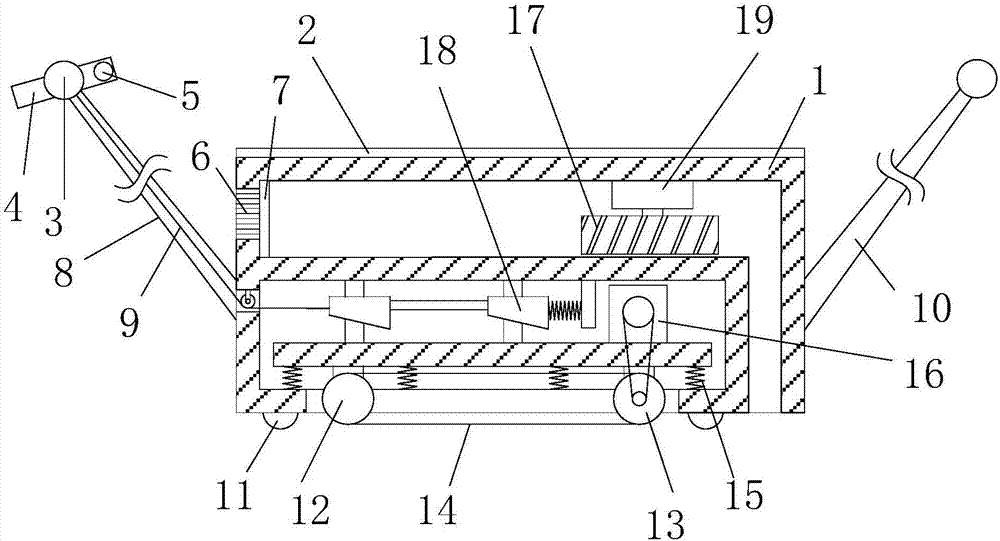

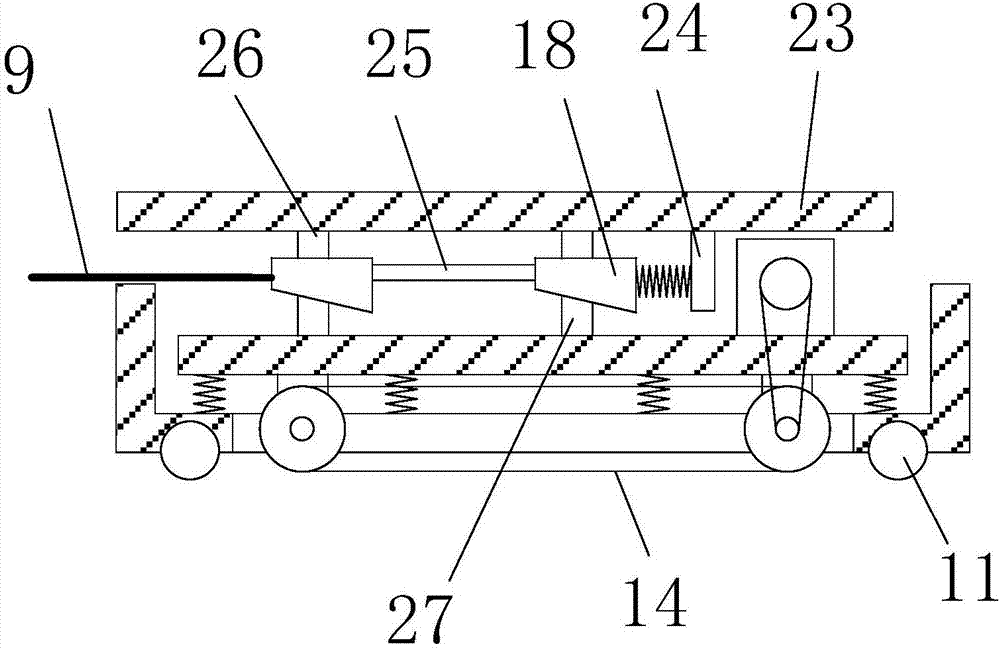

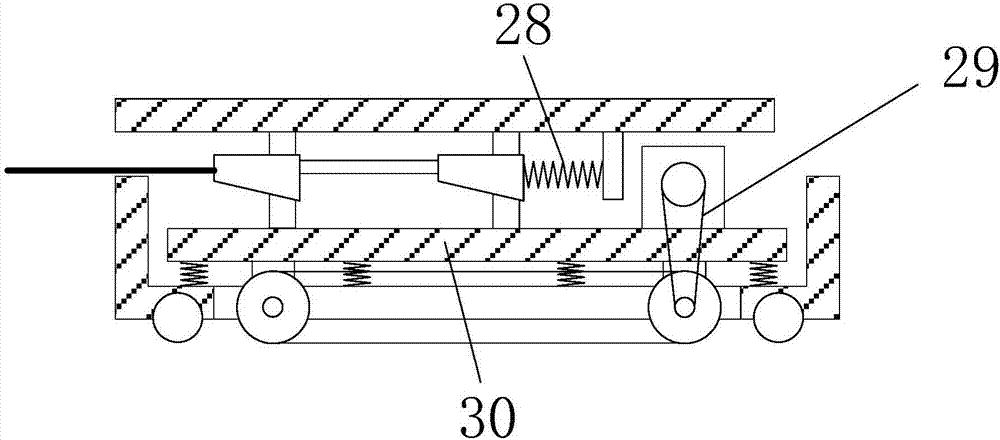

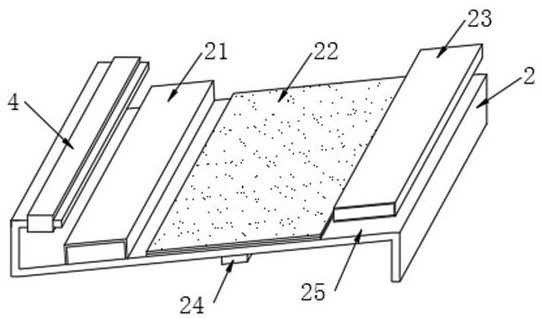

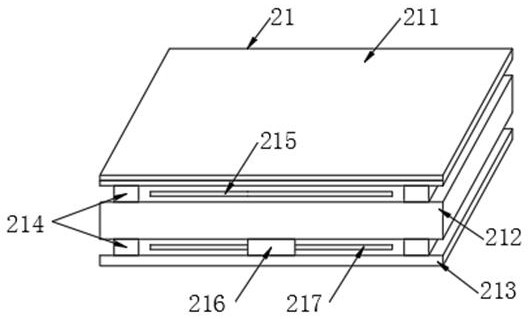

Solar battery charging based wood material surface treatment equipment of botanic garden scenic spots

ActiveCN107097111ALow proficiency requirementPolished evenlyBelt grinding machinesPlane surface grinding machinesEngineeringSolar battery

The invention discloses solar battery charging based wood material surface treatment equipment of botanic garden scenic spots. The solar battery charging based wood material surface treatment equipment comprises a main case, the interior of the main case is divided into a first cavity used for installing a grinding mechanism and a second cavity used for storing saw dust, a substrate connected to a bottom case through springs is arranged in the first cavity, rollers driven through a motor and an abrasive belt nested on the rollers are arranged on the substrate, a clamping device pushing the substrate to move vertically is arranged above the substrate, and the substrate moves vertically to enable the abrasive belt to contact or leave the ground; negative pressure used for absorbing sawdust produced by the grinding process is formed in the second cavity. The solar battery charging based wood material surface treatment equipment is suitable for grinding of outdoor wood floor materials, flatness is high, grinding depth is small, proficiency requirement for construction personnel is low, and time and effort are saved during grinding; charging in advance is combined with solar energy charging, and external power source is not needed during operation; sanitation and hygiene is achieved during construction.

Owner:山东借箭牛业发展有限公司

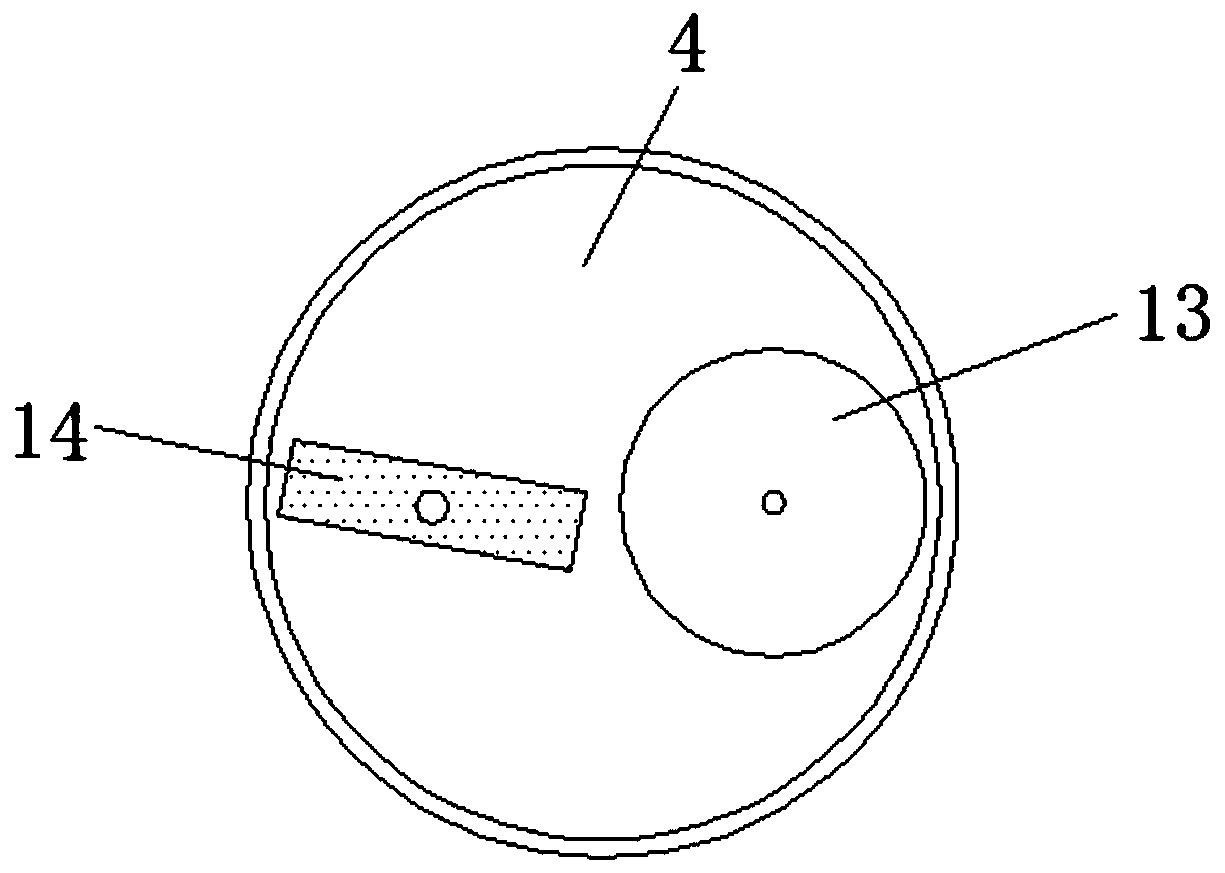

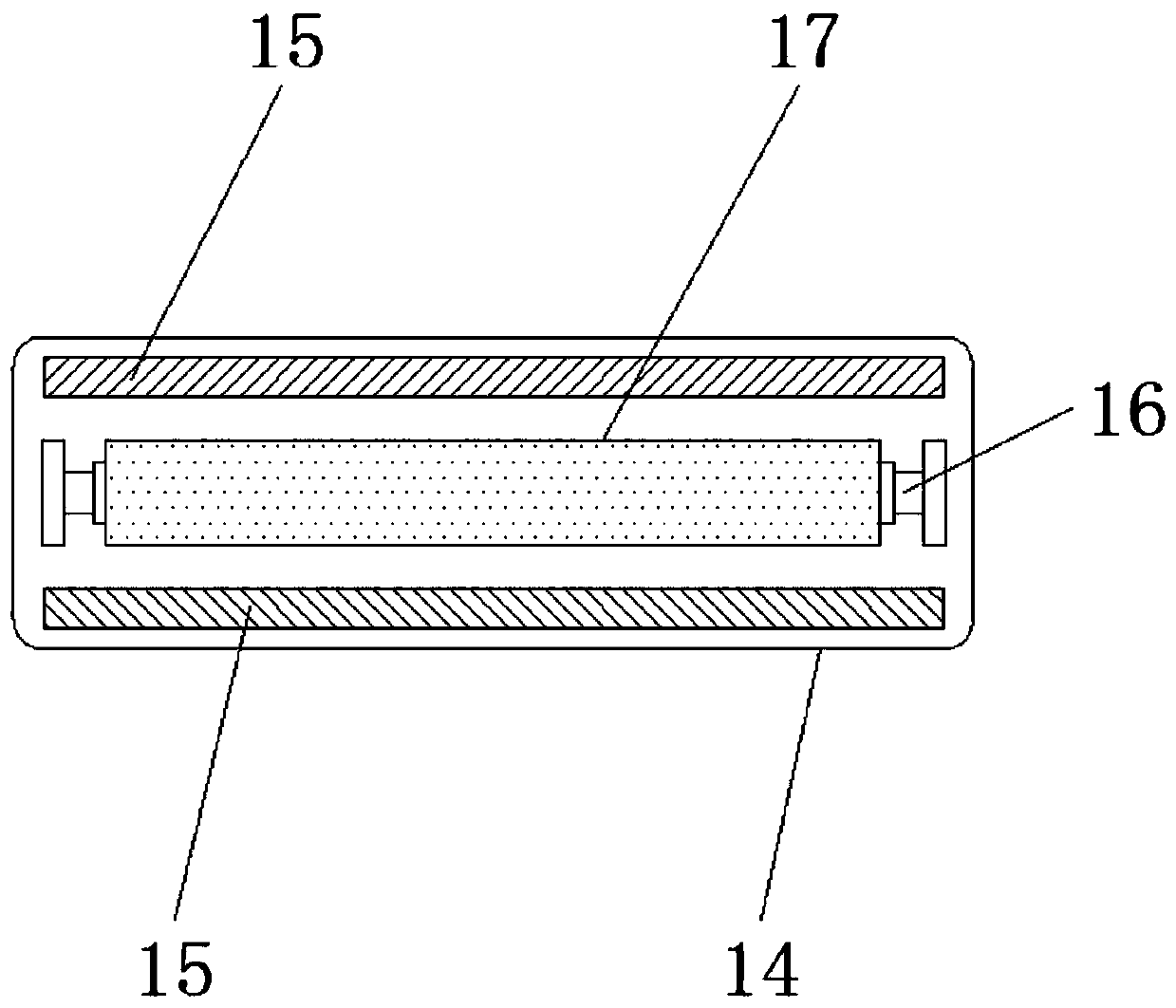

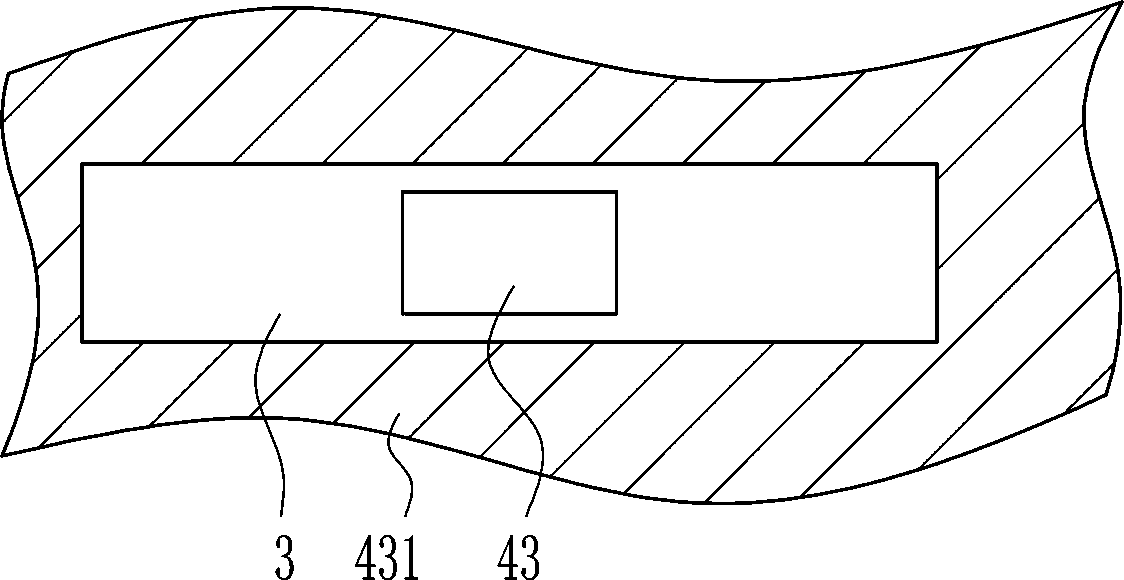

Automatic fur-absorbing device of open-width airflow soft drying machine

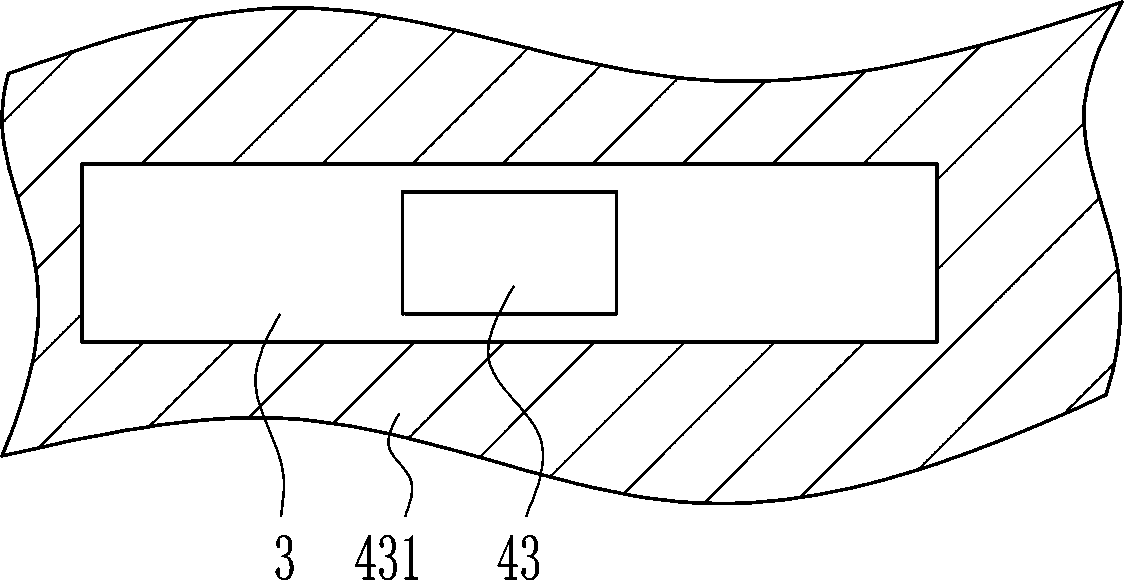

InactiveCN101837217AInstant cleanupDoes not impede air circulationDispersed particle filtrationDirt cleaningTextile manufacturingCircular disc

The invention relates to a textile manufacturing machine used for the continuous open-width drying and classification of woven fabrics and knitted fabrics, in particular to an automatic fur-absorbing device of an open-width airflow soft drying machine. The automatic fur-absorbing device of the open-width airflow soft drying machine is characterized in that an exhaust inlet is internally provided with a rotatable filter screen; an aspiration pipe fur-absorbing chew on a fur-absorbing fan is arranged at one side below the filter screen; and the fur-absorbing fan is fixed on a drying room framework. Since a narrow rectangle-shaped aspiration pipe fur-absorbing chew on the fur-absorbing fan is arranged below the rotatable filter screen, the fixed high-pressure fur-absorbing chew and the rotatable filter screen have relative movement, the device of the invention finishes cleaning the whole disc filter screen under the attractive force provided by a high-press dedusting fan, and can automatically finishes the whole process, thus saving manpower; and in addition, real-time cleaning is carried out on the surface of the filter screen, the airflow circulation in the drying room is not impeded, the drying efficiency is improved, and the air in the drying room is purified.

Owner:王正群

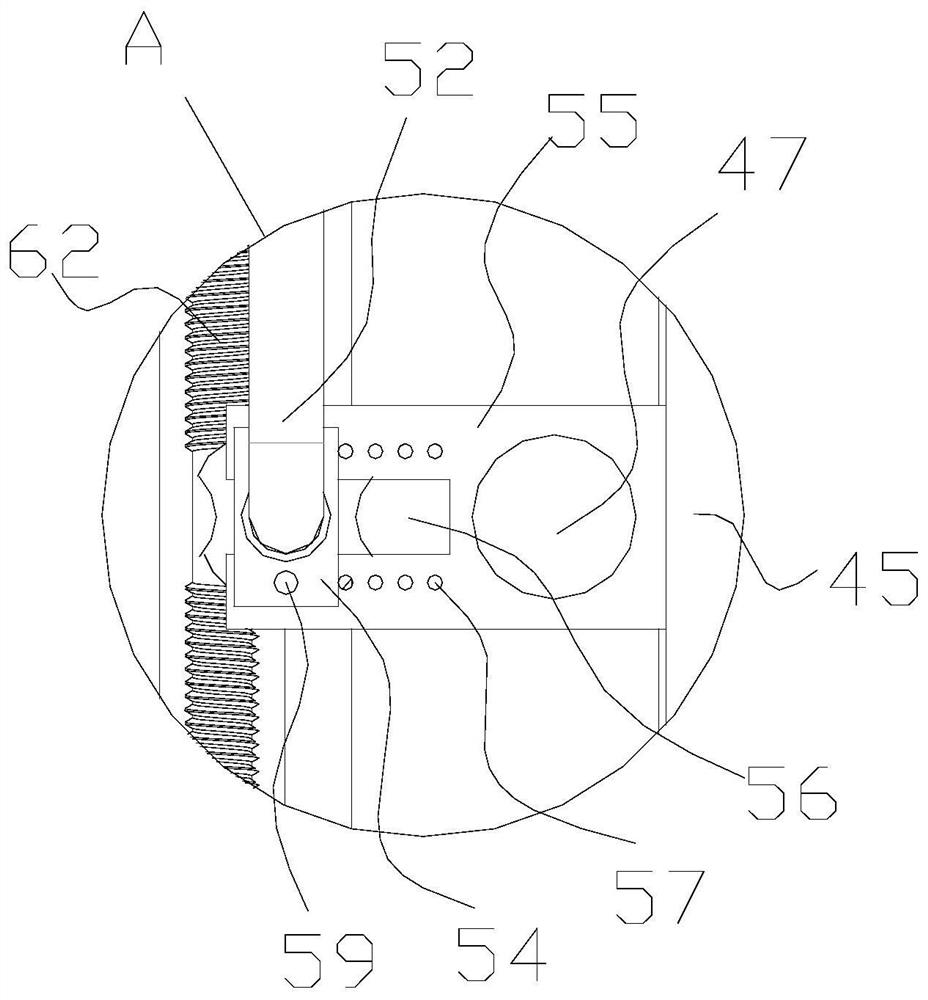

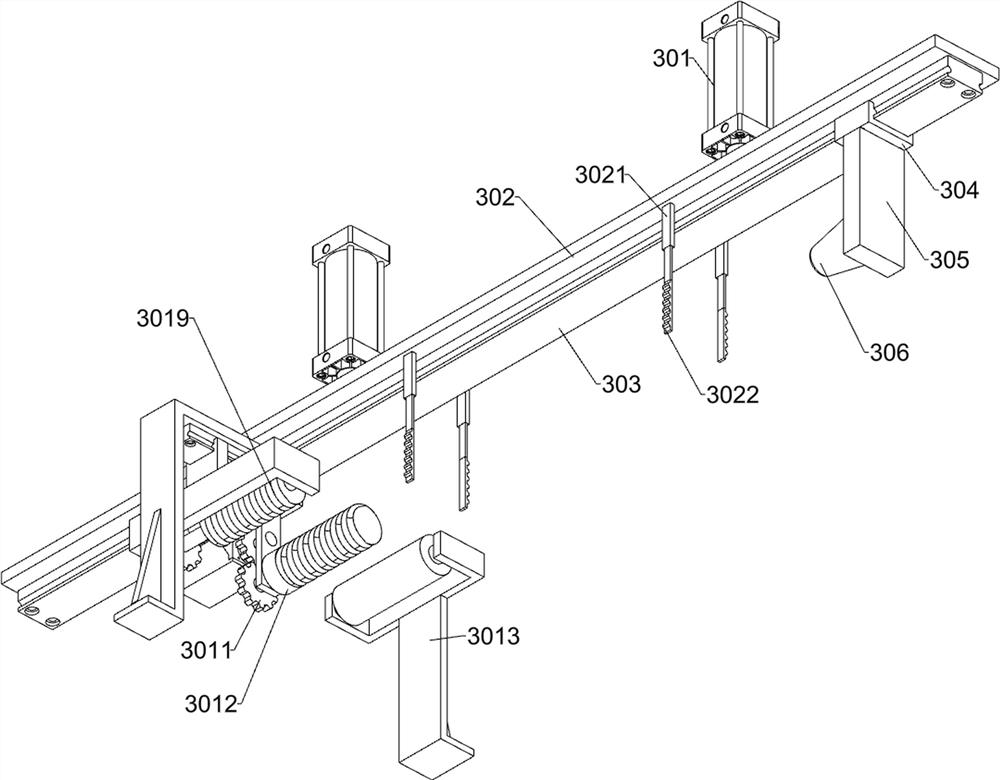

PE pipe drilling equipment

InactiveCN111890463ARealize automatic feedingInstant cleanupMetal working apparatusMechanicsDrill hole

The invention discloses PE pipe drilling equipment. The equipment comprises a base, a sliding rail, a first sliding block, a vertical frame, a drilling assembly arranged on the inner side of the vertical frame, a chip removing assembly arranged on one side of the drilling assembly, a clamping assembly arranged on the base, and a feeding assembly arranged on the feeding side of the clamping assembly. The equipment is characterized in that the chip removing assembly comprises a suction cup connected to the other end of a pipeline, a limit plate fixedly arranged on the pipeline in a sleeving mode, a first support frame arranged below the limit plate, a through hole formed in the first support frame, a plurality of first limit holes equidistantly and symmetrically formed in both sides of the through hole, and second limit holes symmetrically formed in both sides of the limit plate. According to the equipment, through the arrangement of the suction cup, immediate removing of sweeps at the drilling positions of PE pipes is achieved, subsequent centralized processing is avoided, processing procedures are simplified, and economic waste is avoided; and through the arrangement of the feedingassembly, automatic feeding of the PE pipes is achieved, and the processing efficiency is improved.

Owner:林典松

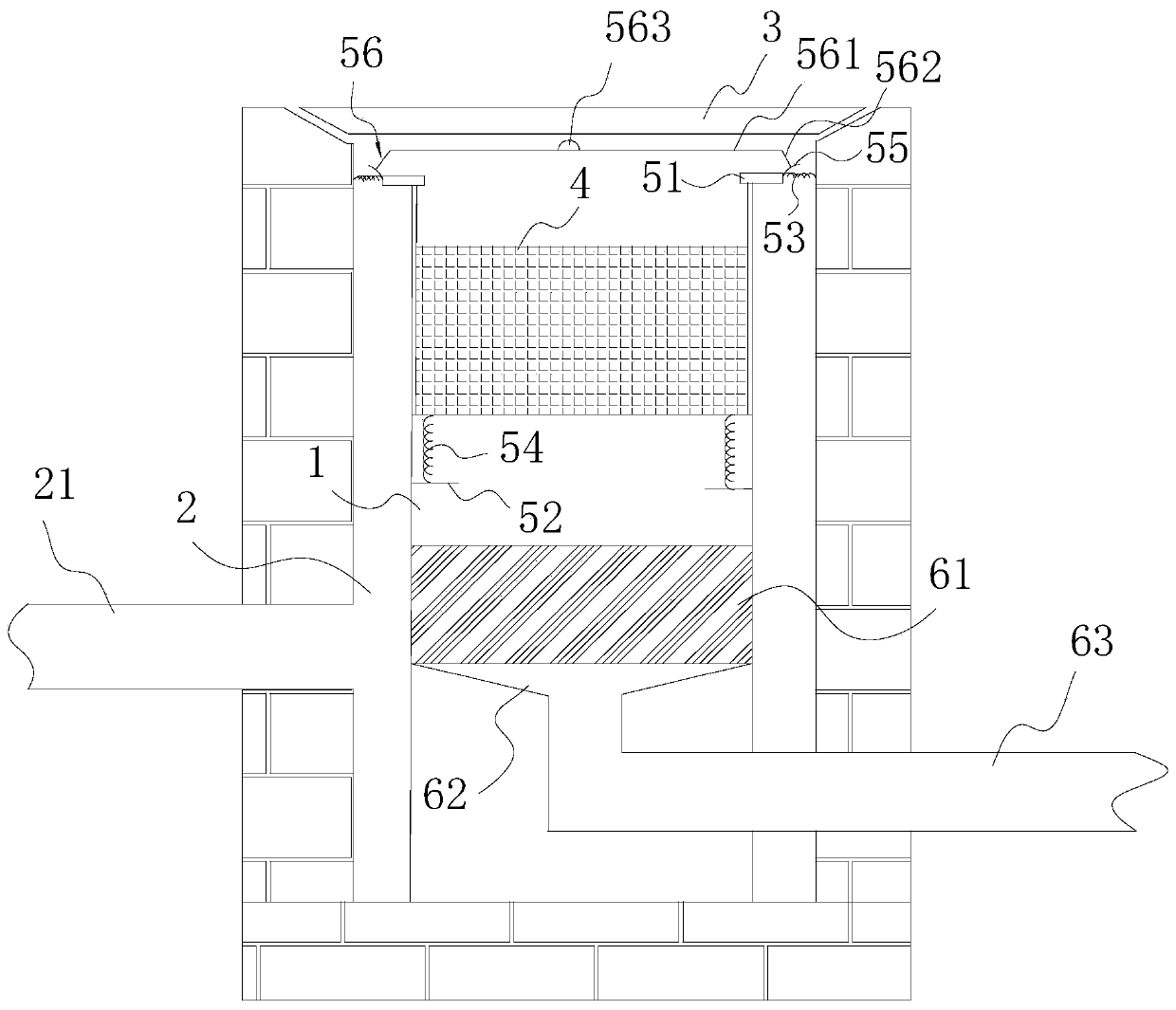

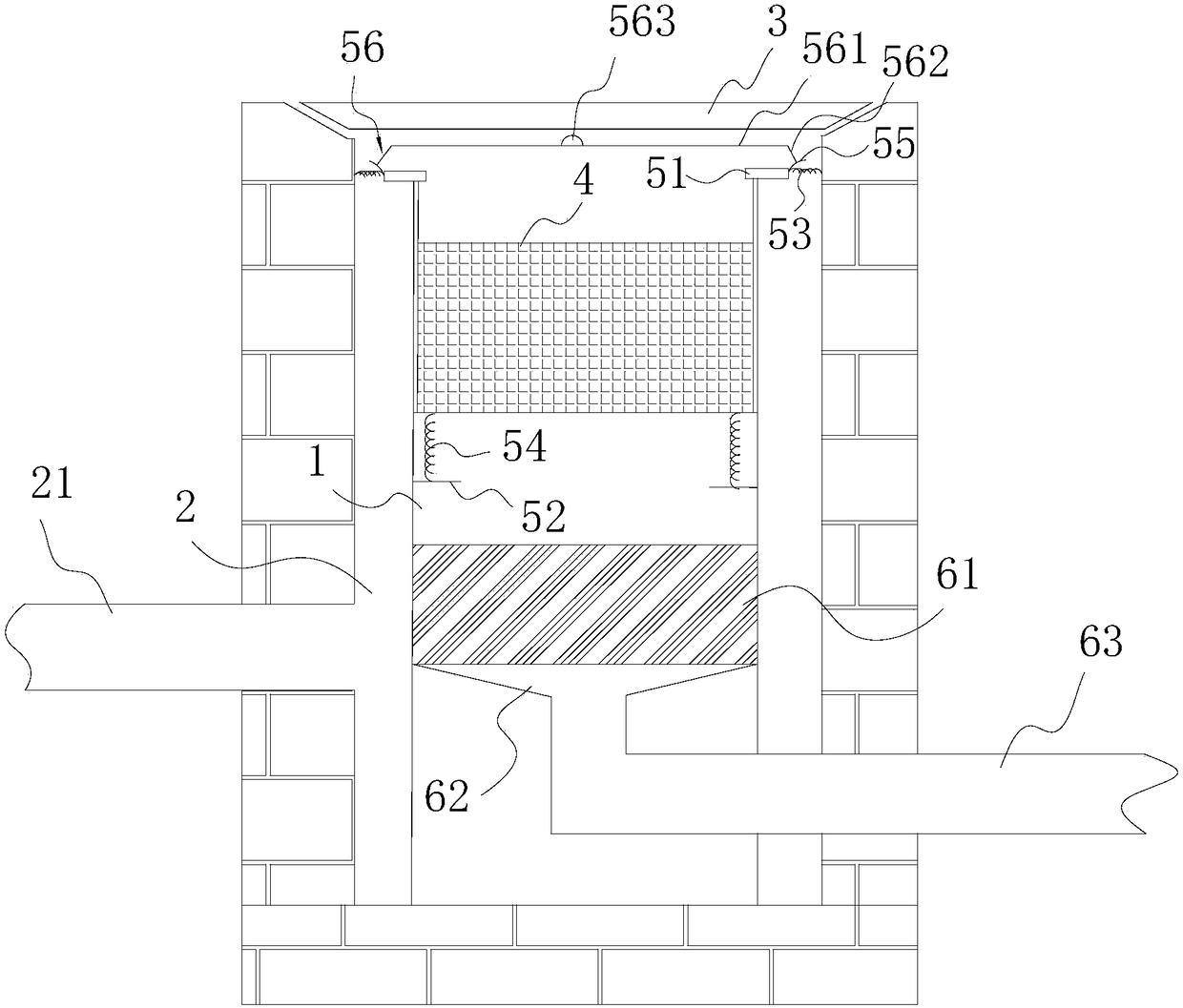

Sewage interception spout for easy cleaning

ActiveCN108222227BEasy to intercept sewage treatmentAchieve recyclingFatty/oily/floating substances removal devicesSewerage structuresRainwater tankWater resources

Owner:ANHUI UNIV OF SCI & TECH

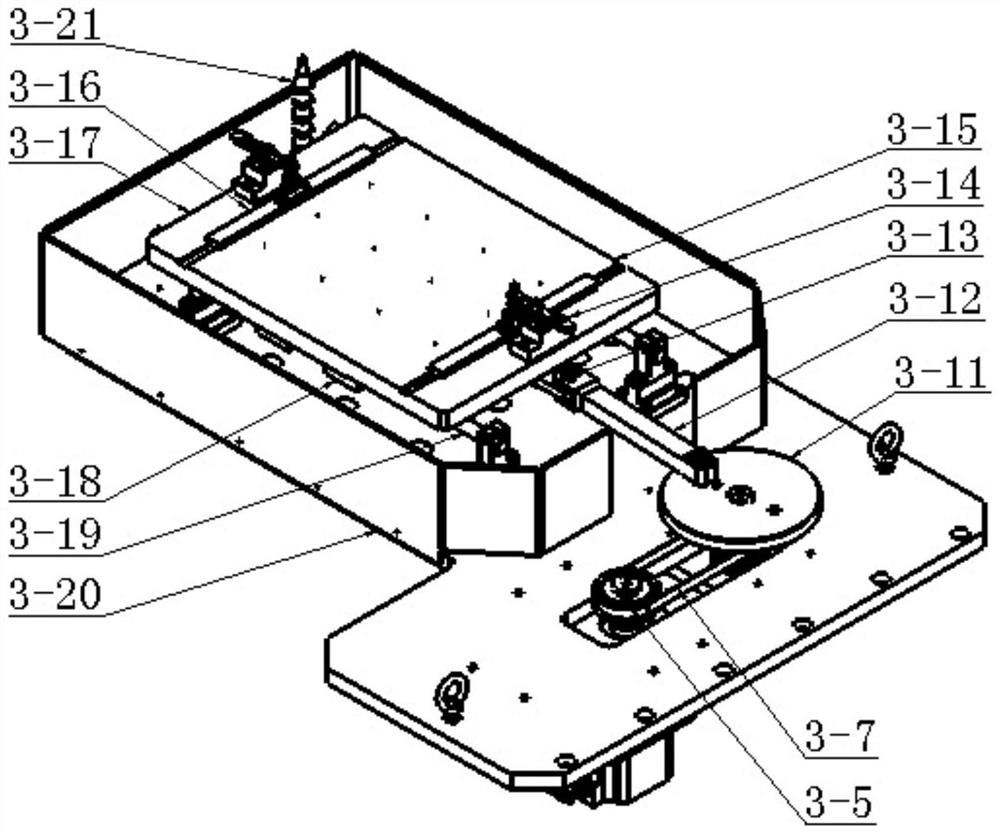

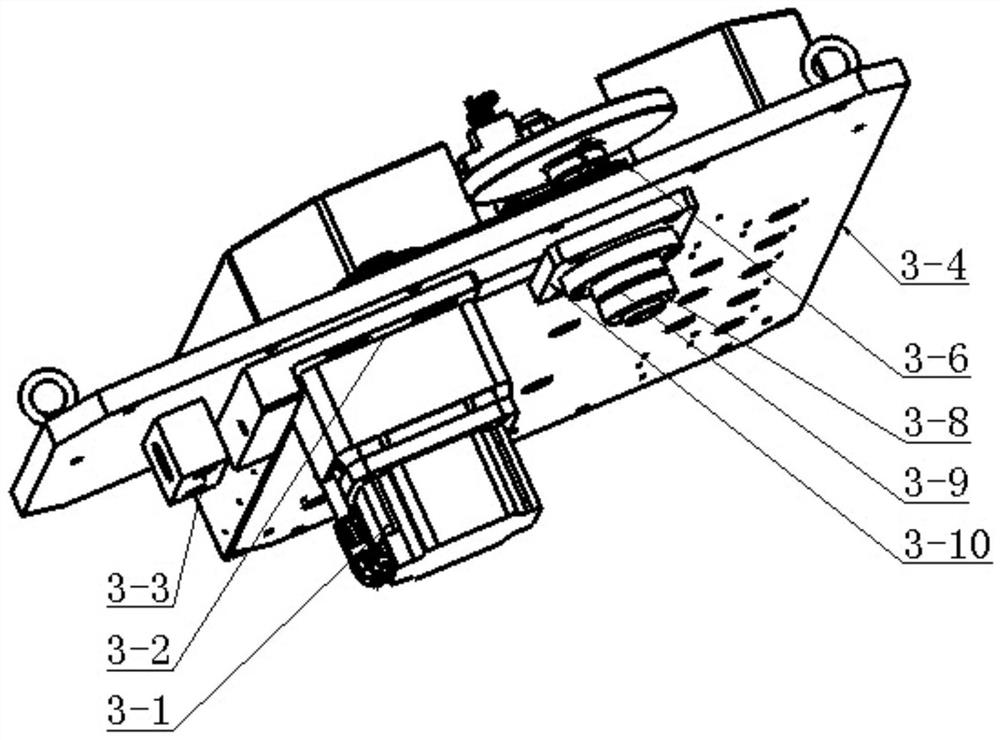

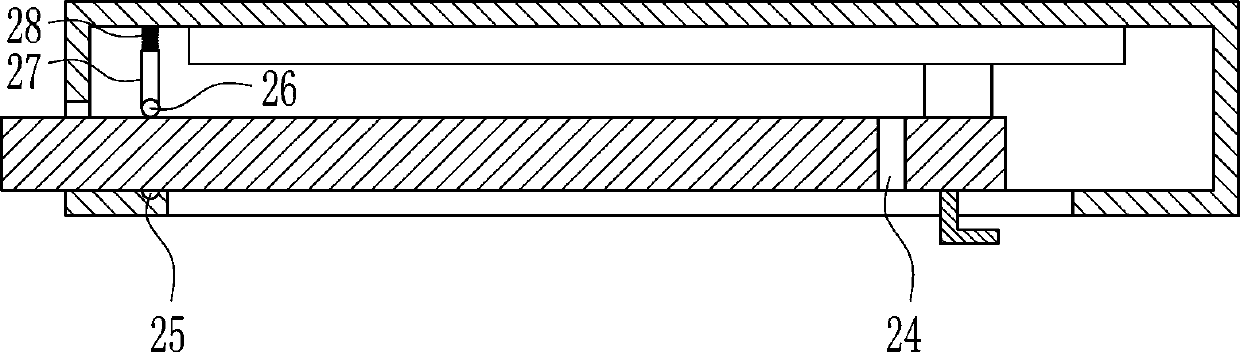

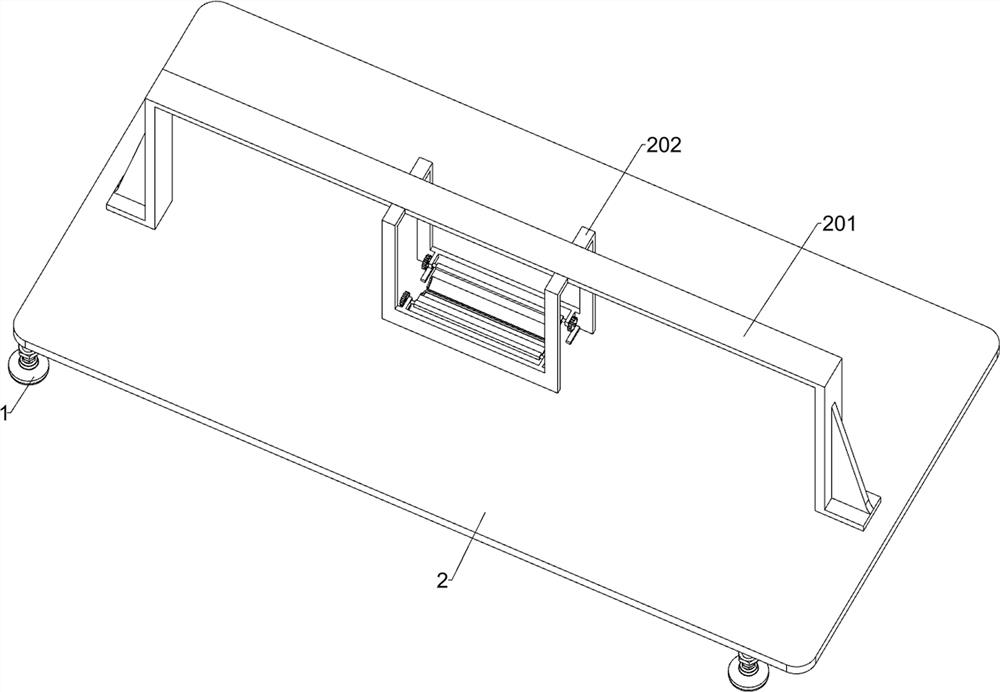

Polishing mechanism

InactiveCN111922866AImprove consistencyPrecise amount of sandingGrinding wheel securing apparatusGrinding carriagesReciprocating motionElectric machinery

The invention discloses a polishing mechanism, and aims to solve the technical problems in the prior art that the manual polishing efficiency is low, the polishing period is long, the polishing amountof each time is difficult to ensure, and the polishing cost of a robot is high. According to the polishing mechanism, a motor is arranged below a polishing bottom plate, a turntable is driven to rotate through the motor, and the turntable is hinged to an abrasive paper fixing plate through a polishing connecting rod; therefore, one end of the polishing connecting rod rotates around the edge of the turntable, the other end of the polishing connecting rod pulls the abrasive paper fixing plate to reciprocate, a workpiece is fixed above the abrasive paper fixing plate when the polishing mechanismis used, the motor is turned on, then the workpiece can be polished by abrasive paper on the abrasive paper fixing plate, the accurate polishing amount can be obtained by controlling the frequency ofthe motor, and the consistency of the workpiece polishing is high; and due to the fact that the polishing connecting rod rotates around the edge of the turntable, in order to make the movement of theabrasive paper fixing plate more stable, guide rods for guiding the movement of the abrasive paper fixing plate are also arranged on the polishing bottom plate so as to further improve the stabilityof the polishing mechanism.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

A garbage incineration device for garbage disposal

ActiveCN109681882BSolve the situation of incomplete combustionWell mixedFuel feeding arrangementsRotary stirring mixersProcess engineeringMetal debris

The invention discloses a garbage incineration device for garbage treatment, relates to the technical field of garbage treatment, and specifically includes a stirring device, a conveying device and a burning device. A combustion device is fixedly installed on the side, and the stirring device includes a mixer, and a storage box is fixedly installed in the middle of the top of the mixer, a drainage pipe is fixedly installed on one side of the bottom of the storage box, and a funnel is fixedly installed on one side of the bottom of the mixer. The garbage incineration device used for garbage treatment can make the garbage burn more fully during incineration, and the combustion accelerant is mixed inside the garbage, which can effectively avoid metal debris that cannot be completely burned when the garbage is mixed with metal debris. The rotation of the mixer can uniformly mix the garbage and the combustion accelerant, which solves the problem that the existing garbage incineration device does not completely burn the garbage.

Owner:潘晓丹

Dry-type hospitalization cage excrement treatment and recycling system

PendingCN112450091AFast evaporationInhibition of reproductionSludge treatment by thermal conditioningMeasurement devicesBiotechnologyFeces

The invention belongs to the technical field of pet medical treatment, and particularly relates to a dry hospitalization cage excrement treatment and recycling system which comprises two hospitalization cages. A top cover is fixedly installed at the top ends of the hospitalization cages, cage doors are hinged to the left sides of the hospitalization cages, and a bearing tray is clamped and fixed to the middle positions of the two hospitalization cages. An exhaust sterilization assembly is additionally arranged on the bearing tray and composed of a draught fan and an ozone machine, the draughtfan is used for quickly drying excrement and urine on a slope, bacteria are prevented from breeding, heat is taken away and odor is quickly removed, and a urine adsorption strip is additionally arranged at the other end of the bearing tray and used for adsorbing urine. The urine adsorption strip takes honeycomb activated carbon sponge as a probiotic propagation culture bed and contains probiotic strains and nutrient powder, when sewage containing urine slides into a fermentation strip along the inclined plane, the nutrition powder at the top is dissolved and fused with a lower bacteria bed, and warm air at the bottom heats the fermentation strip to activate propagation of probiotics, so that the purposes of deodorization and environmental protection are achieved.

Owner:四川云知萌医疗科技有限公司

Heat transfer printer with carbon belt erasing and carbon deposit clearing functions,

PendingCN109177515AInstant cleanupGuaranteed to erase the ribbon effectInking apparatusEngineeringCarbon deposit

The invention discloses a heat transfer printer with carbon belt erasing and carbon deposit clearing functions. The heat transfer printer with the carbon belt erasing and carbon deposit clearing functions comprises a carbon belt supporting roller I and a carbon belt supporting roller II, wherein the carbon belt supporting roller I is arranged above a printing head, is used for winding a printed finished carbon belt in a printing process and releasing the carbon belt to be erased in a carbon belt erasing process, and the carbon belt supporting roller II is used for releasing the carbon belt tobe printed and winding the carbon belt erased in the printing process of the carbon belt erasing; and a rubber roller is used for receiving the coating separated from the carbon belt and driving printing paper and the carbon belt to move, and one side of the rubber roller is provided with a carbon scraping piece for scraping a carbon deposit layer on the rotating rubber roller to a carbon receiving box. The printing process and the carbon belt erasing process can compatible with a set of printing head and rubber roller, so that an independent external carbon belt erasing device is saved; the carbon deposit can be cleared in real time, and then the effect of erasing the carbon belt, the printing quality and the speed stability are continuously guaranteed.

Owner:CASHWAY FINTECH CO LTD

Waterproof strip welding equipment capable of preventing protruding burrs

PendingCN114799921AAchieve weldingSoftening effectShearing machinesOther manufacturing equipments/toolsStructural engineeringMechanical engineering

The invention relates to the field of waterproof strips, in particular to waterproof strip welding equipment capable of preventing protruding burrs. The technical problems that when a waterproof strip is cut manually through a cutter, deviation can happen, the end of the waterproof strip is uneven, it cannot be guaranteed that the exposed parts of the two waterproof strips are the same when the waterproof strip is manually pushed, and the two waterproof strips can locally protrude after welding are solved. According to the technical scheme, the waterproof strip welding equipment capable of preventing the protruding burrs comprises a first mounting plate, a welding unit and the like; the front portion of the upper side of the first mounting plate is connected with a welding unit. Welding of the waterproof strips is achieved, the ends of the waterproof strips are flattened through longitudinal cutting of the cutter, meanwhile, the exposed parts of the two waterproof strips are the same through the limiting effect of the cutter, the phenomenon that after welding, the welding position locally protrudes is avoided, in addition, a heating softening tool is cleaned in real time, and the working efficiency is improved. And the phenomenon that subsequent softening of the waterproof strips is seriously affected due to accumulation of the adhered waterproof strips is avoided.

Owner:陈滴生

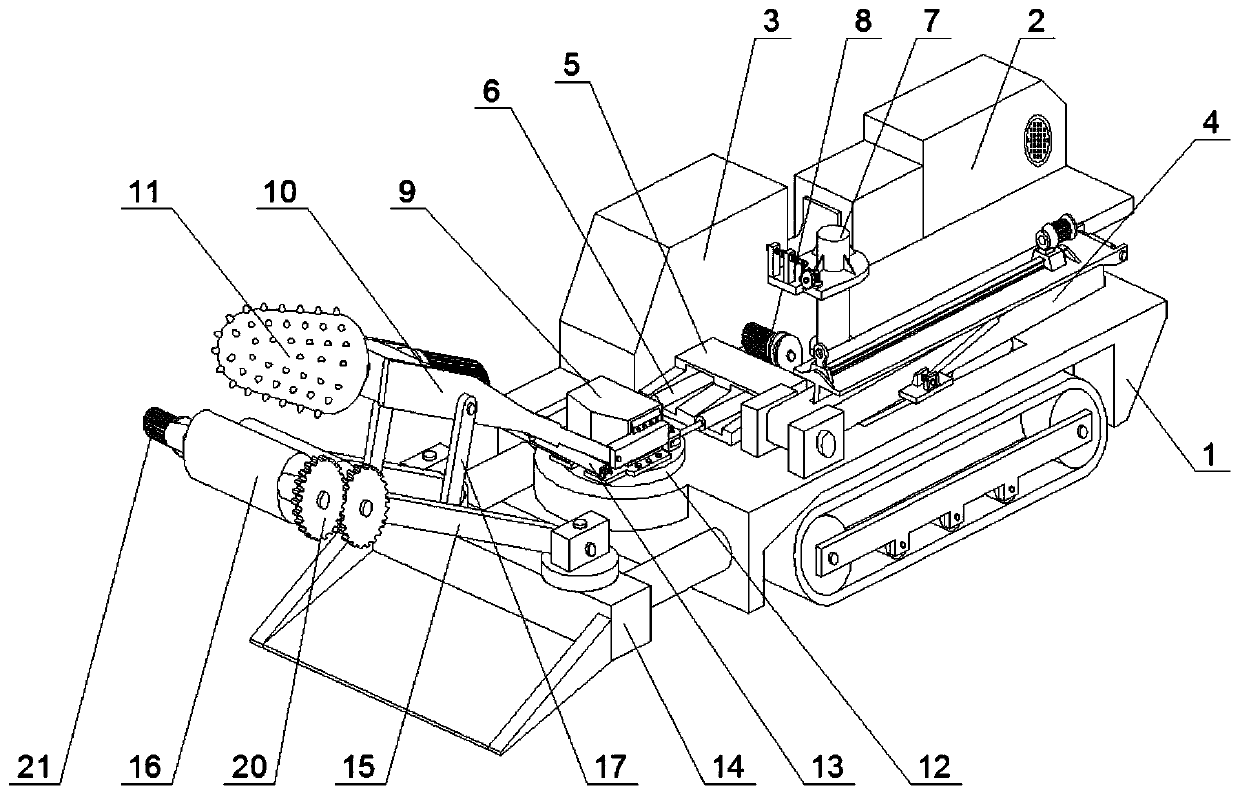

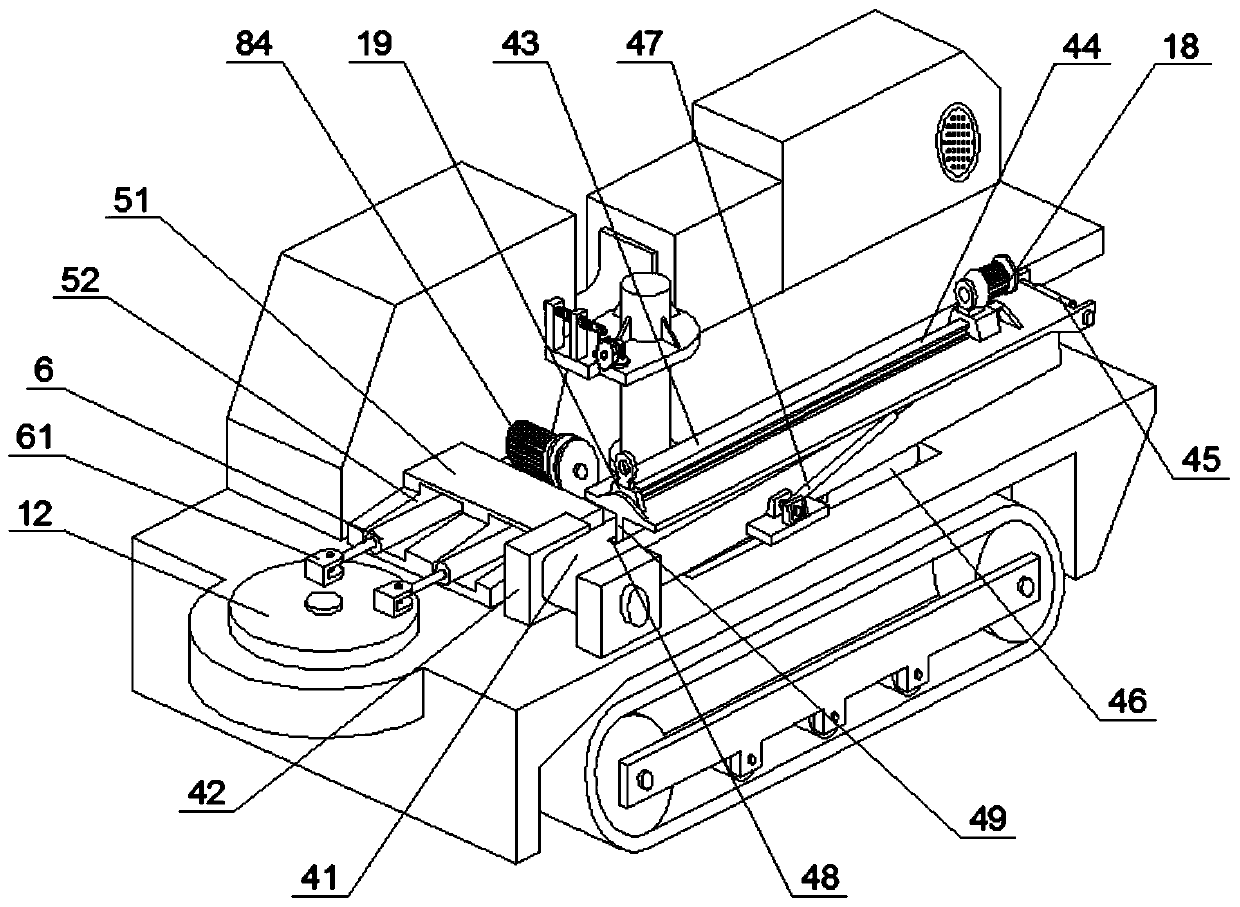

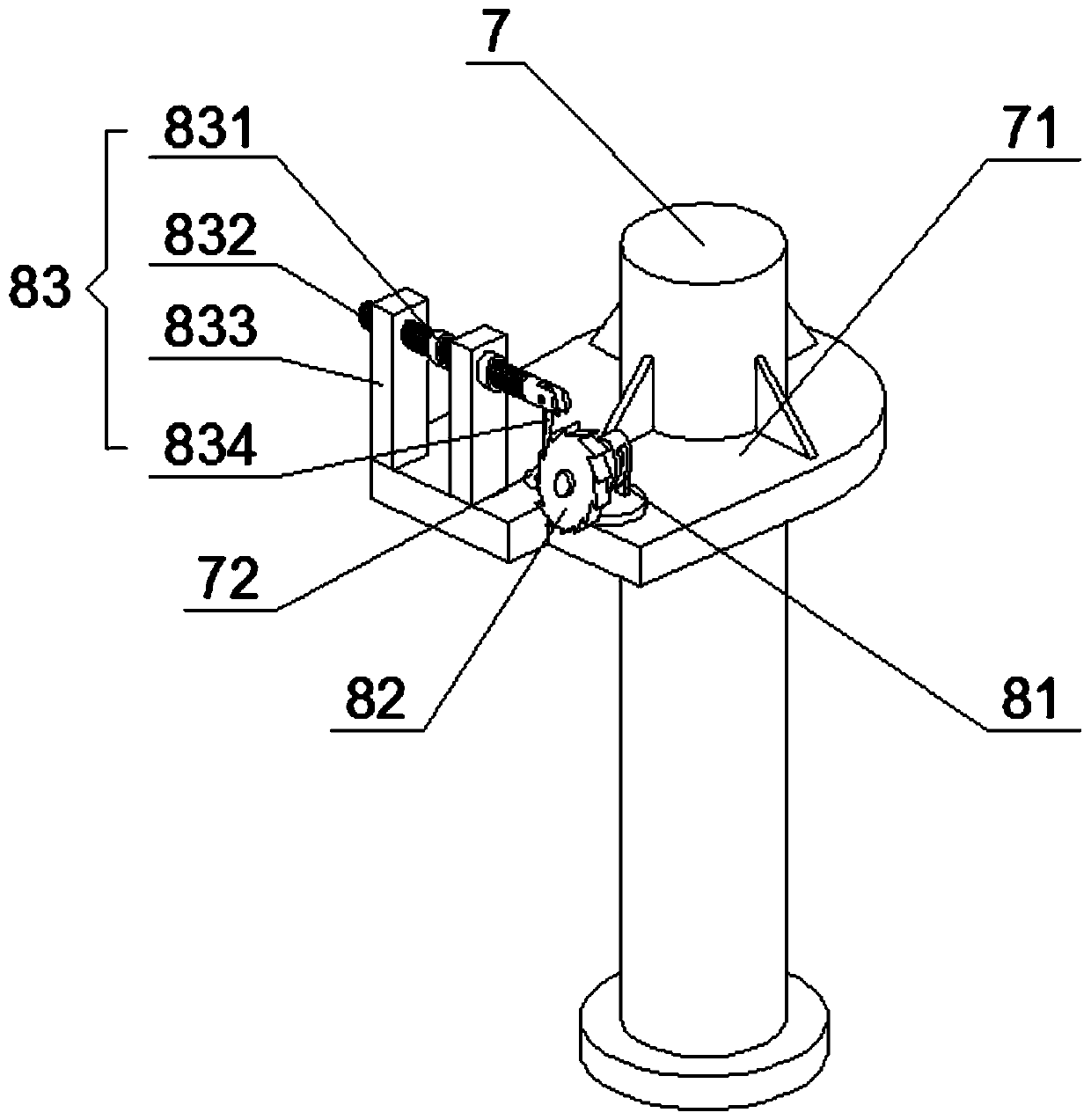

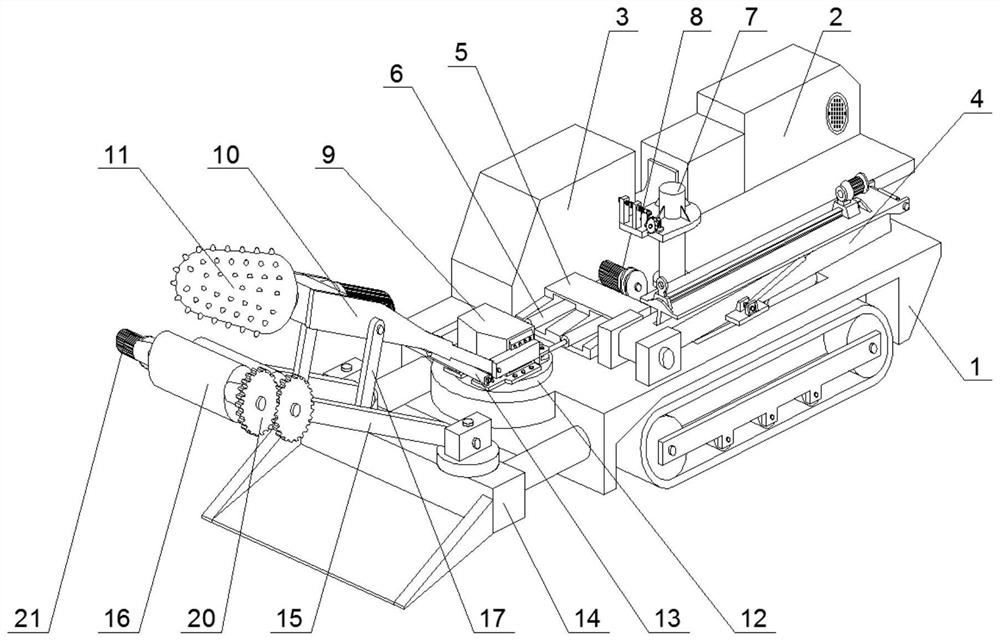

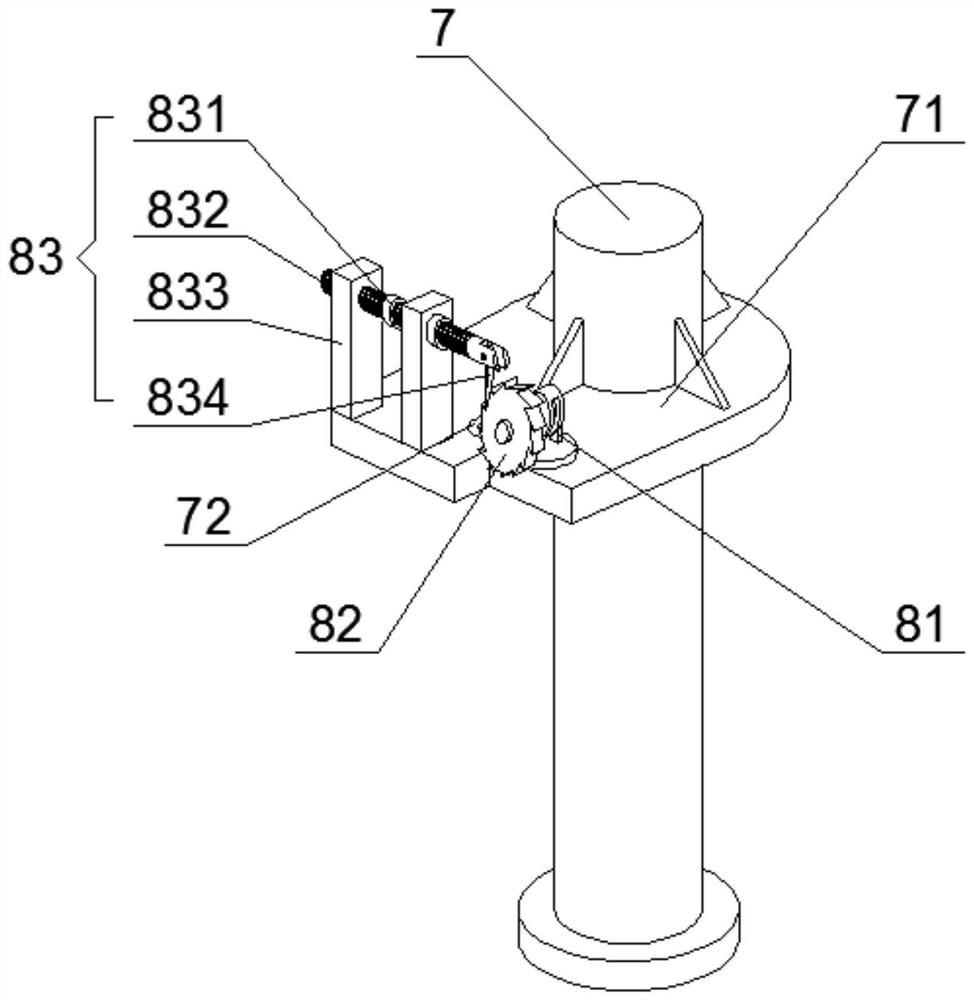

Multifunctional mining equipment for plaster stone

ActiveCN110374590AImprove mining progressGuaranteed stabilityDerricks/mastsDriving meansSlagEngineering

The invention discloses multifunctional mining equipment for plaster stone. The multifunctional mining equipment comprises a walking part, a power assembly and a control assembly, wherein the power assembly and the control assembly are arranged on the walking part; a mining part is arranged at the front end of the walking part; a work drilling mechanism used for hole drilling is arranged on the walking part; the mining part comprises a tunneling mechanism and a slag crushing mechanism; the tunneling mechanism comprises a tunneling support frame, a tunneling head arranged on the tunneling support frame and a tunneling motor used for providing power for the tunneling head; the slag crushing mechanism comprises a slag crushing support frame and two groups of crushing rollers arranged on the slag crushing support frame; a bucket is arranged on the front side wall of the walking part; one end of the slag crushing support frame is hinged onto the bucket; and at least one connecting arm is hinged between the middle parts of the slag crushing support frame and the tunneling support frame. The multifunctional mining equipment has the advantages that on the basis of tunneling functions of atraditional tunneling machine, hole drilling and timely crushing functions are added, so that the mining operation on rock stratums with different cross sections and hardness can be realized; and themineral product yield is ensured.

Owner:康定龙源穗城石膏有限责任公司

A grinding device for sheet metal that can prevent loosening of materials

ActiveCN108544312BPrevent looseningPolished evenlyGrinding carriagesGrinding work supportsStructural engineeringBrush

The invention discloses a metal panel grinding device capable of preventing looseness of materials. The metal panel grinding device capable of preventing looseness of materials comprises a device base, a ball, a regulating plate and a compaction plate, wherein a first motor is arranged on the inner side of the device base; the ball is located below a workpeice plate; the device base is connected to a device top seat through a supporting column, and a lifting device is mounted on the device top seat; the regulating plate and the lifting device are connected to each other, and the side edge of the regulating plate is mounted on the supporting column; a second motor is arranged on the regulating plate, and the second motor is connected to a grinding disc through a connecting shaft; the compaction plate is connected to the regulating plate, and a cleaning brush is mounted on the surface of the compaction plate. The metal panel grinding device capable of preventing looseness of materials can grind the surface of a panel uniformly, is more reasonable in structural design, can clean fragments left on the surface of the panel in the grinding process immediately, and meanwhile, can preventlooseness of the panel and is better in processing quality.

Owner:河南荣事德新型建材有限公司

Waste incineration device for waste disposal

InactiveCN109737416ASolve the situation of incomplete combustionWell mixedIncinerator apparatusCombustionLitter

The invention discloses a waste incineration device for waste disposal, and relates to the technical field of waste disposal. The waste incineration device specifically comprises a stirring device, aconveying device and a combustion device, the conveying device is fixedly mounted at the bottom of one side of the stirring device, the combustion device is fixedly mounted on one side of the top of the conveying device, the stirring device comprises a stirring machine, a storage box is fixedly mounted in the middle of the top end of the stirring machine, a draining pipe is fixedly mounted on oneside of the bottom of the storage box, and a funnel is fixedly mounted on one side of the bottom of the stirring machine. The waste incineration device for the waste disposal can make the waste be burned more thoroughly during the incineration, an incineration supporting agent is mixed in the waste, the fact that the metal debris cannot be completely burned when the waste is mixed with the metal debris can be effectively avoided, the waste and the incineration supporting agent can be mixed evenly through the rotation of the stirring machine, and the problem that the waste is not burned completely by using an existing waste incineration device is solved.

Owner:陈卫

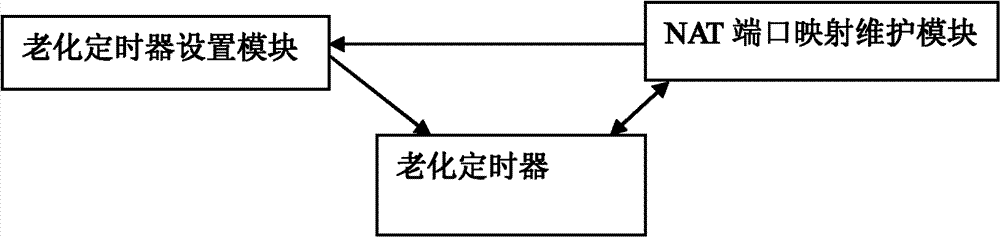

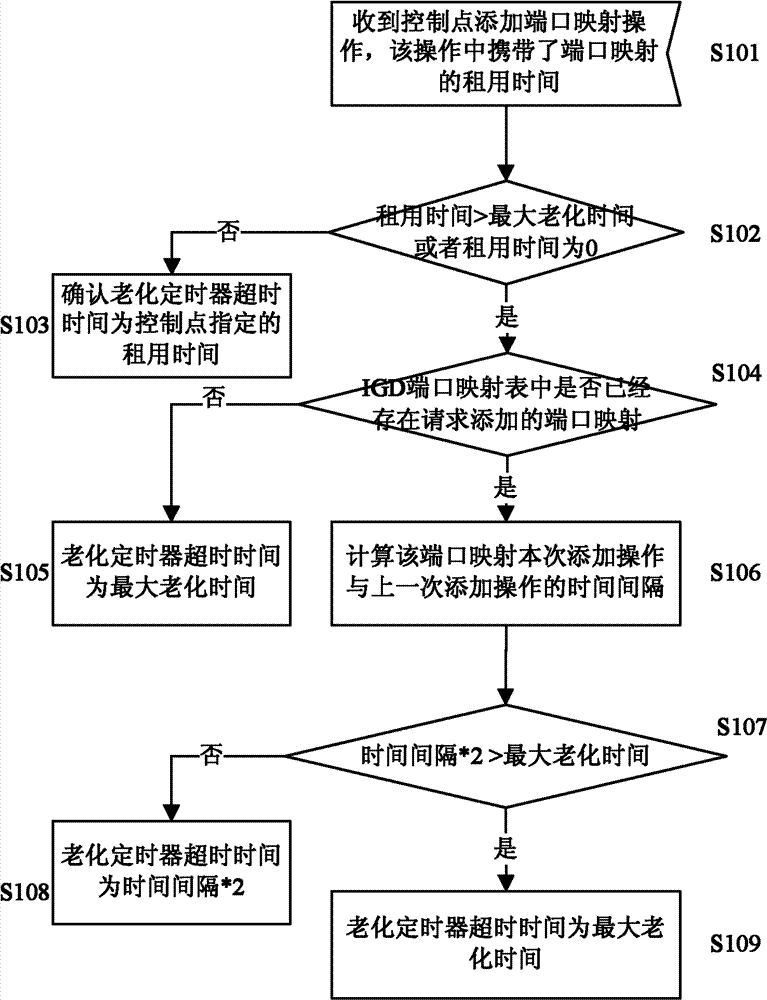

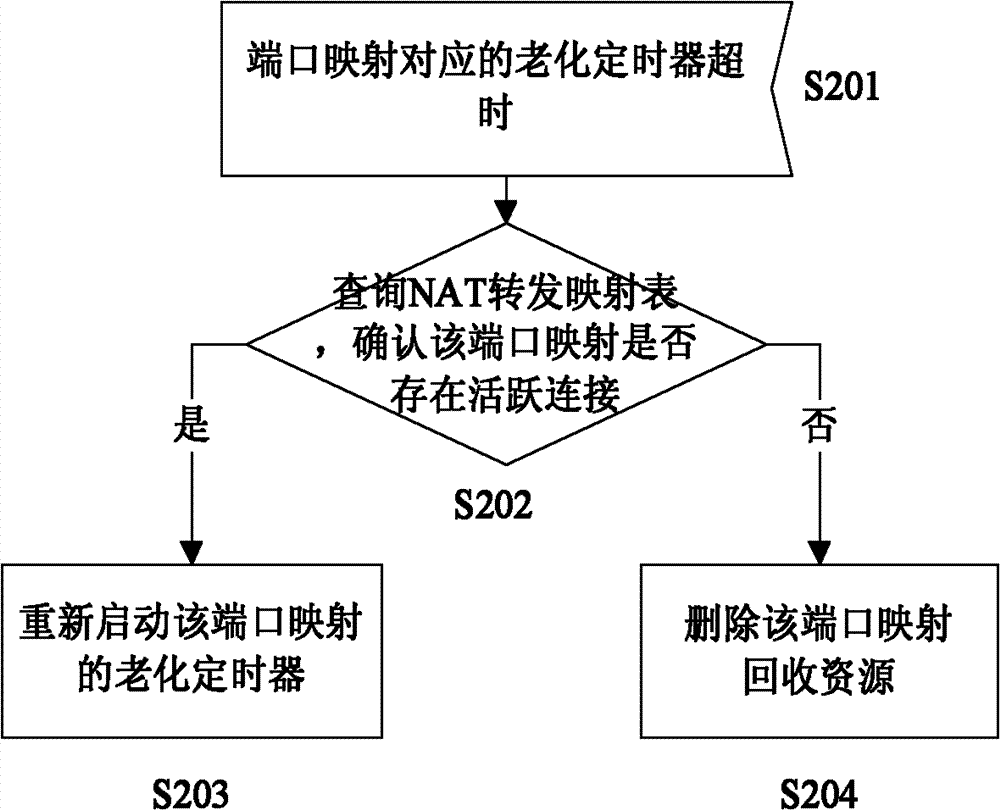

UPnP (Universal Plug-n-Play) gateway equipment NAT (Network Address Translation) port mapping maintenance method and equipment thereof

ActiveCN101860575BGood network service experienceAutomate cleaningNetwork connectionsTime rangeNetwork address translation

The invention provides a UPnP (Universal Plug-n-Play) gateway equipment NAT (Network Address Translation) port mapping maintenance method and gateway equipment for realizing the method, and the gateway equipment can immediately delete ossified port mapping. The UPnP gateway equipment NAT port mapping maintenance method comprises the steps of: starting an ageing timer aiming at an NAT port after receiving the NAT port mapping addition operation by the gateway equipment, and setting the timeout time of the ageing timer; and when the ageing timer is time-out, deleting the NAT port mapping. Through configuring the ageing timer for the NAT port mapping, ossified port mapping can be aged overtime within a proper time range, thereby achieving the aims of automatically deleting the ossified port mapping by the gateway equipment and recycling resources on the premise of not restarting the gateway equipment or manually interfering by a user.

Owner:MAIPU COMM TECH CO LTD

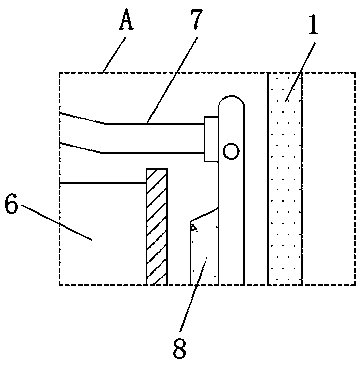

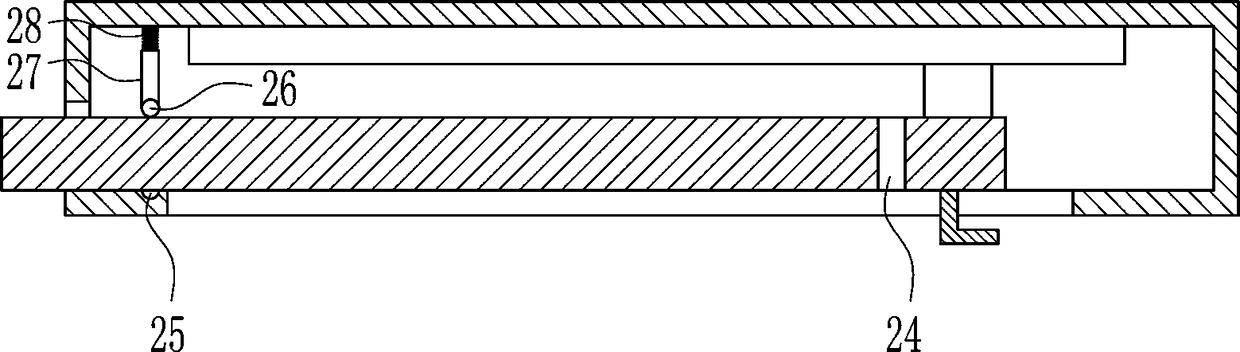

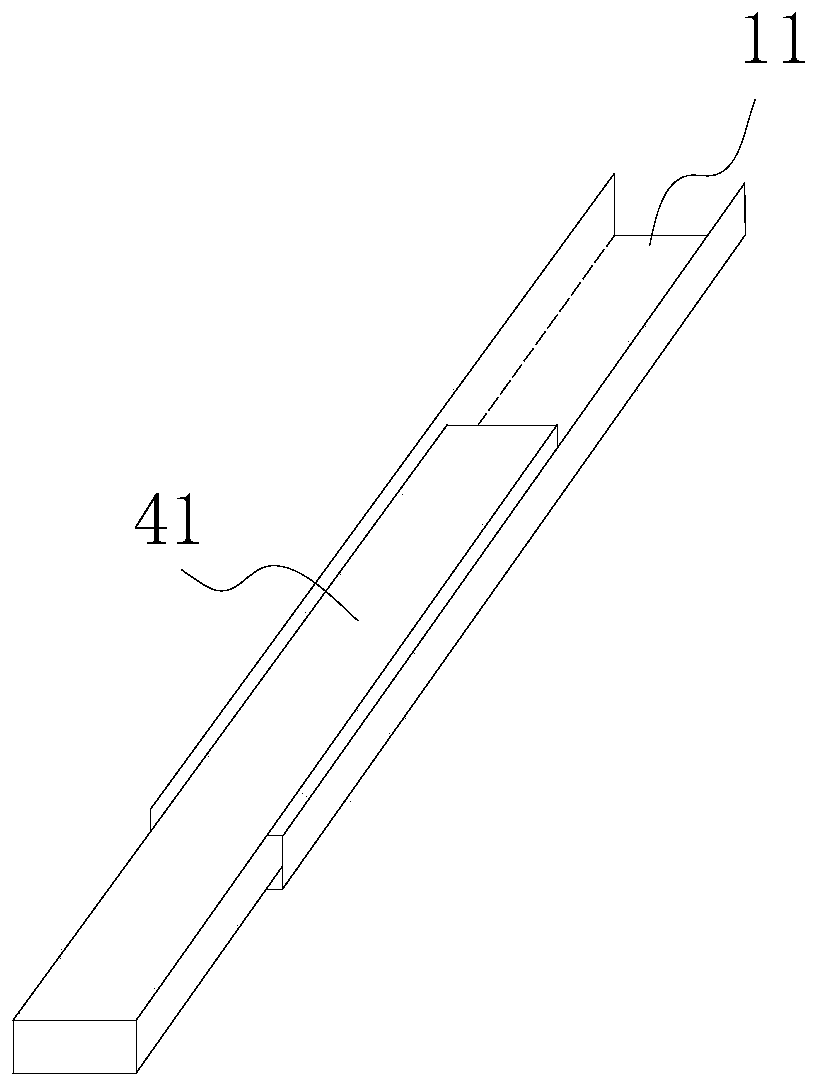

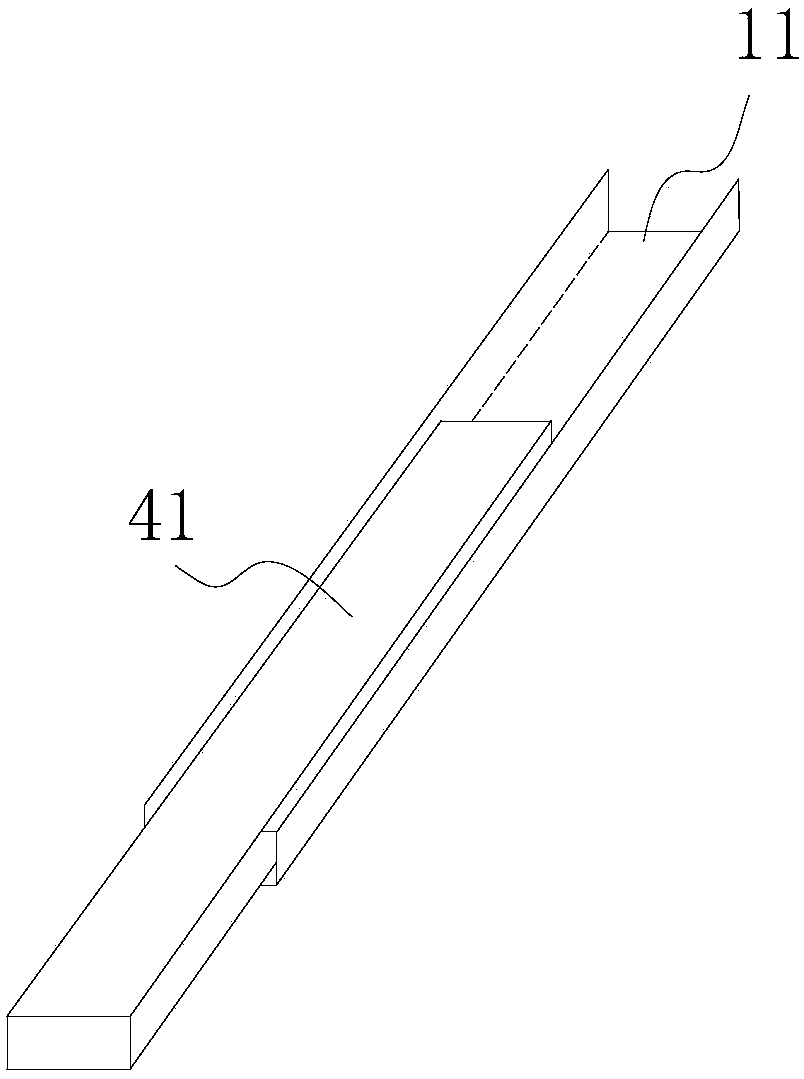

Small windscreen wiper of automobile reflector

The invention relates to a small windscreen wiper of an automobile reflector and relates to the technical field of automobiles. The small windscreen wiper of the automobile reflector comprises the reflector, a sliding guide rail, a rigid windscreen wiper body and a flexible windscreen wiper body. The small windscreen wiper is characterized in that the sliding guide rail is arranged at one edge of the outer side of the reflector, and the rigid windscreen wiper body is arranged at the upper end of the reflector; the flexible windscreen wiper body is arranged at one end of the rigid windscreen wiper body; and the other end of the rigid windscreen wiper body is connected with the sliding guide rail. The small windscreen wiper has the advantages that the structure is simple, safety and convenience are achieved, and a function that the automobile reflector is cleaned immediately is achieved.

Owner:CHANGSHU NANJING NORMAL UNIV DEV RES INST

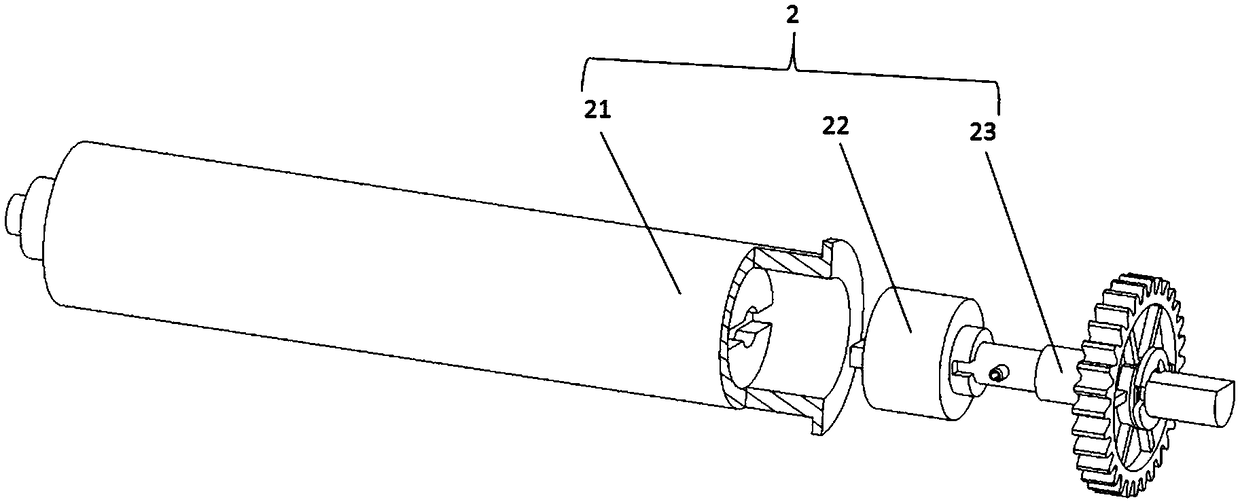

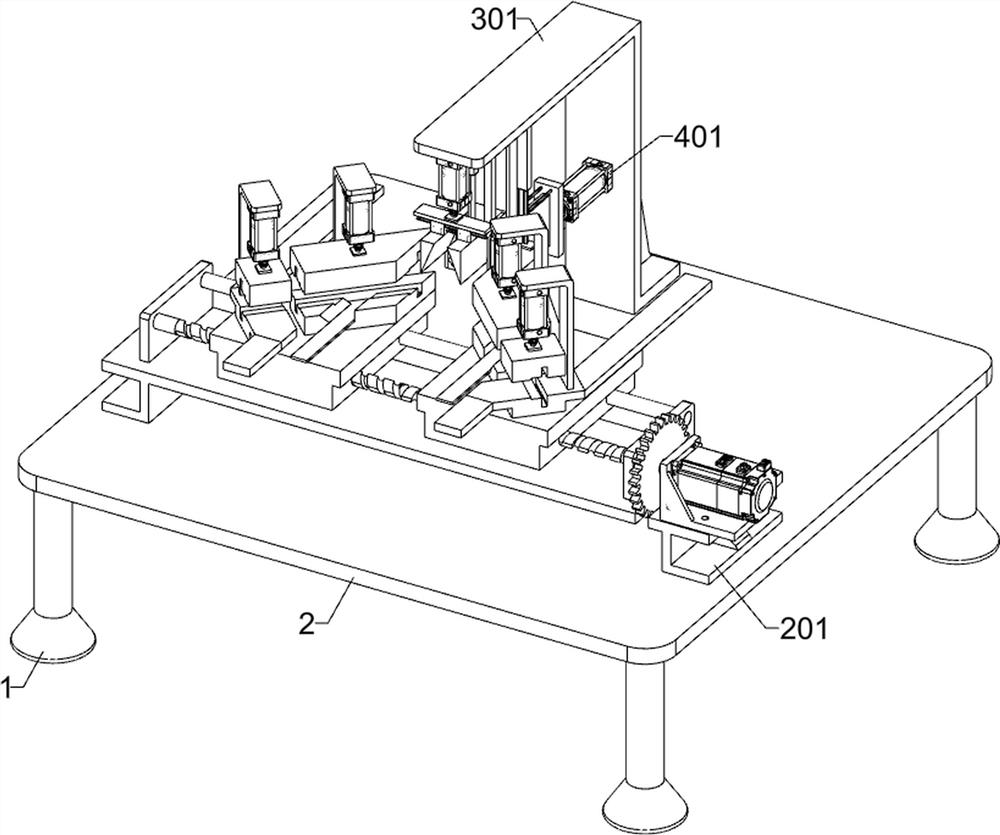

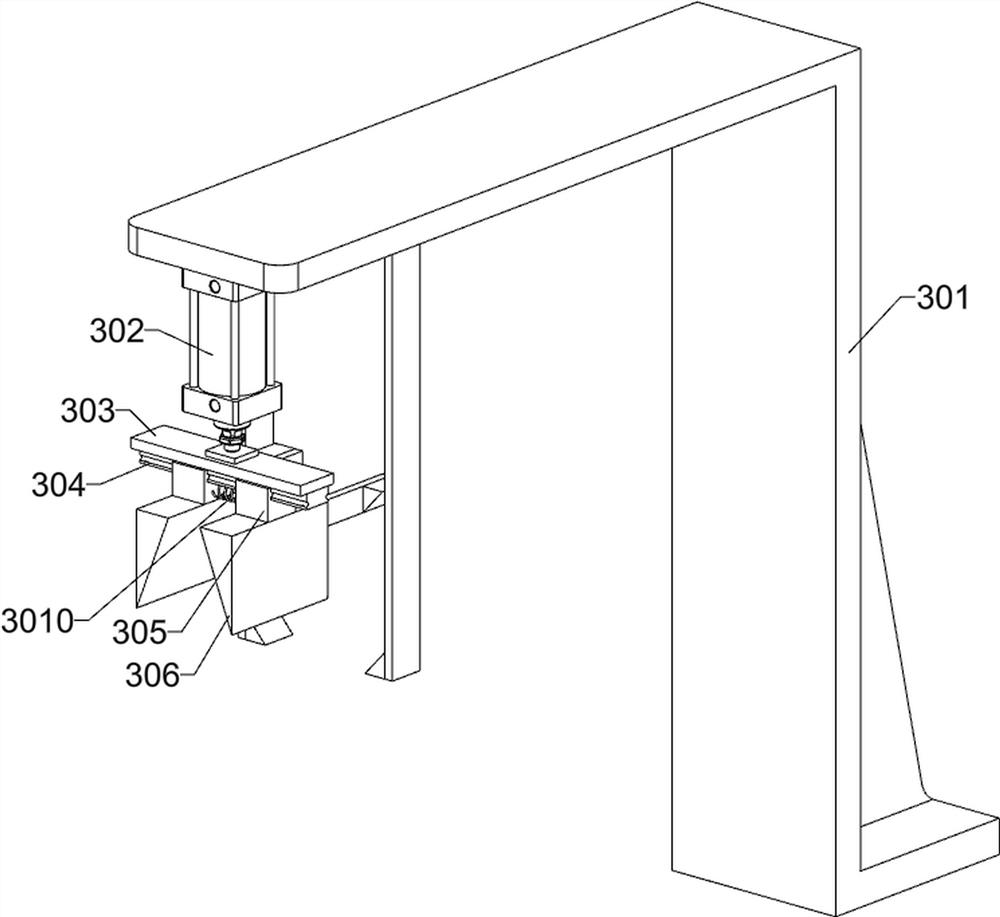

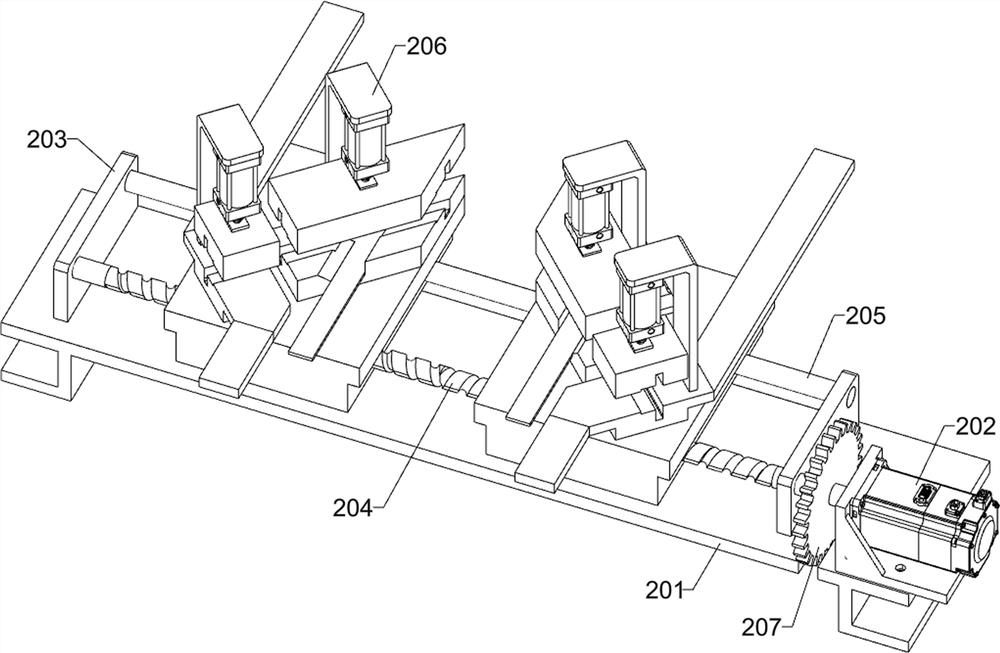

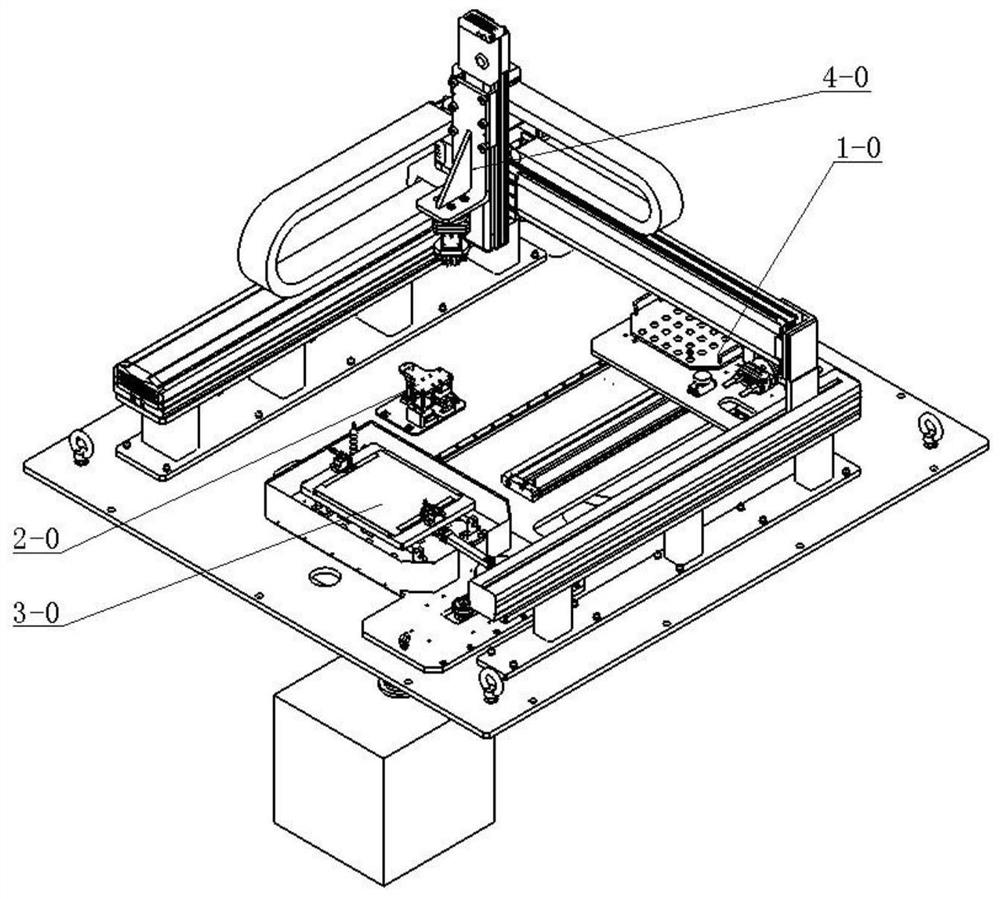

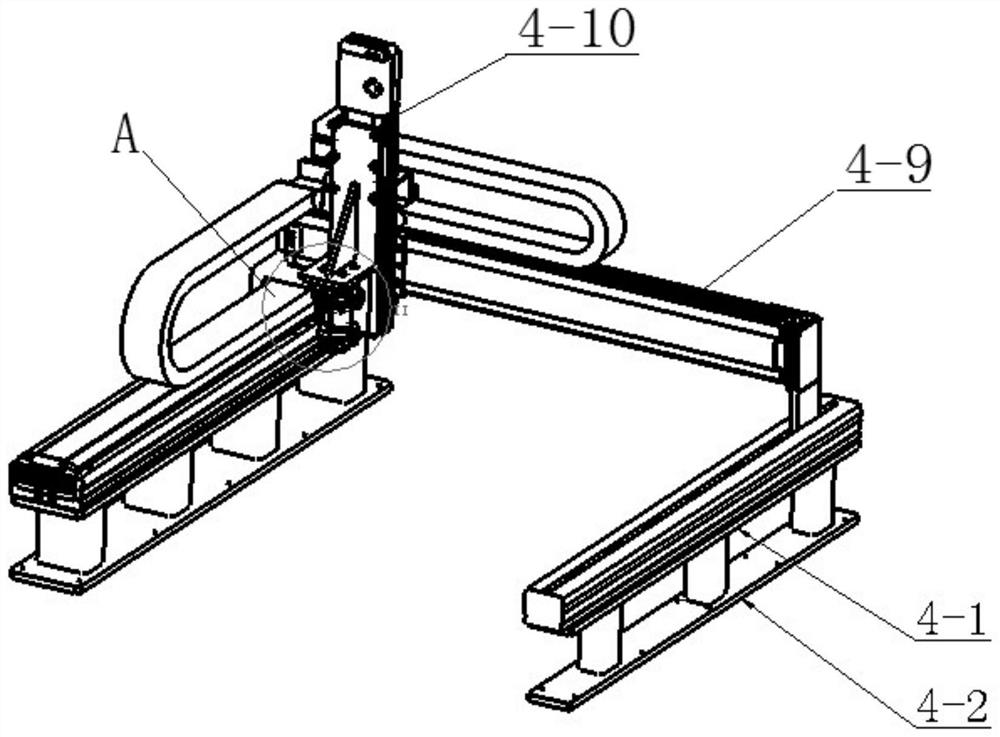

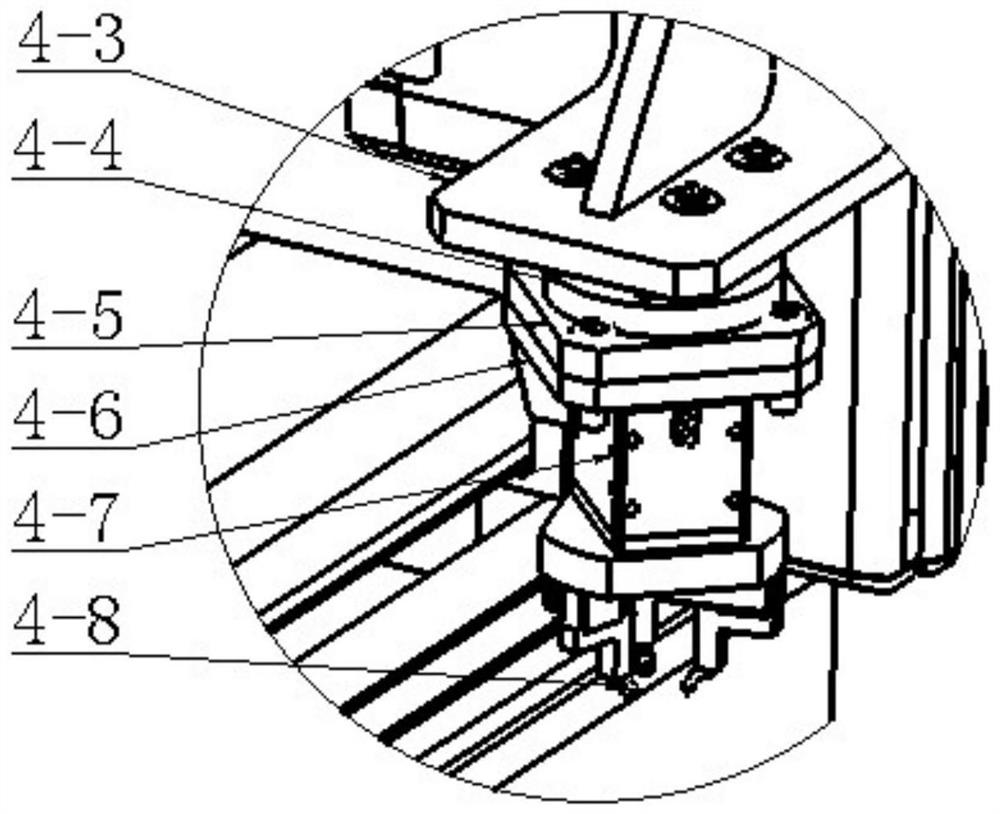

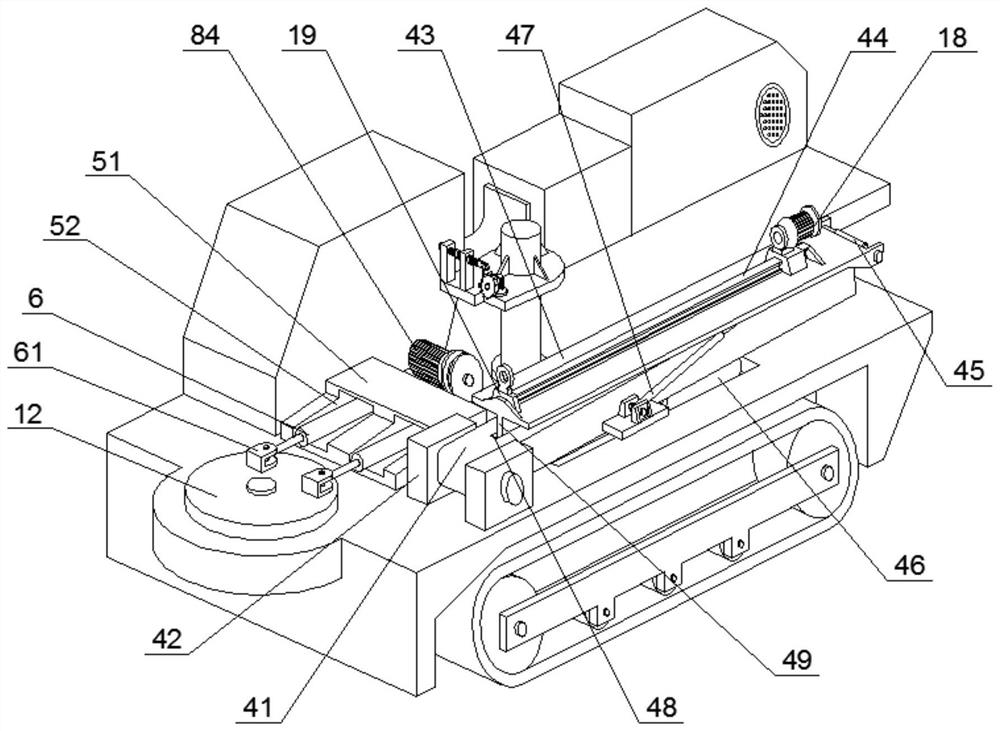

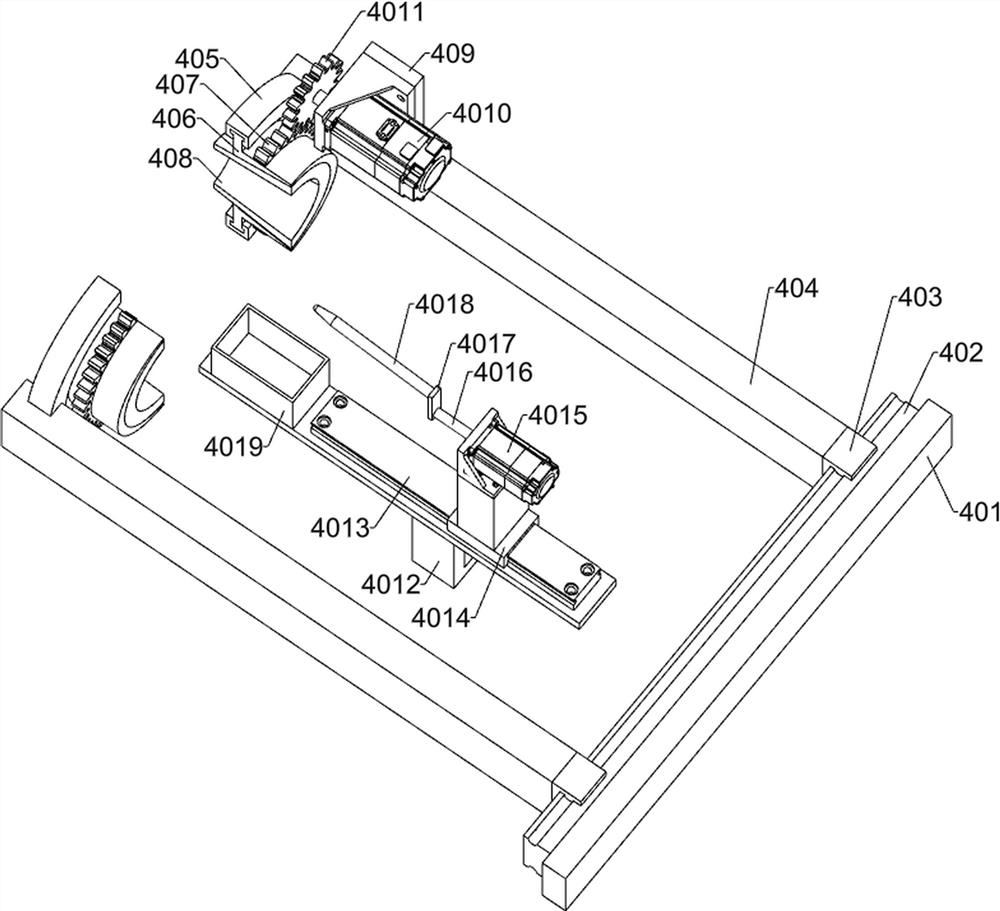

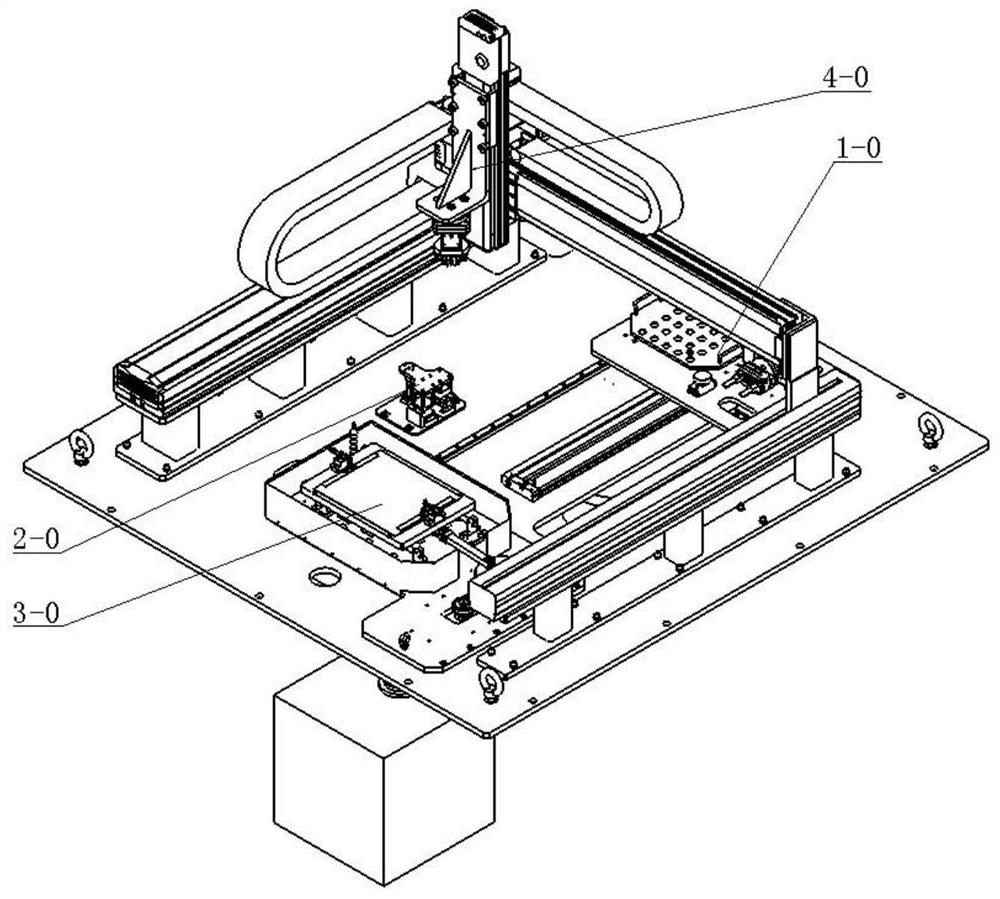

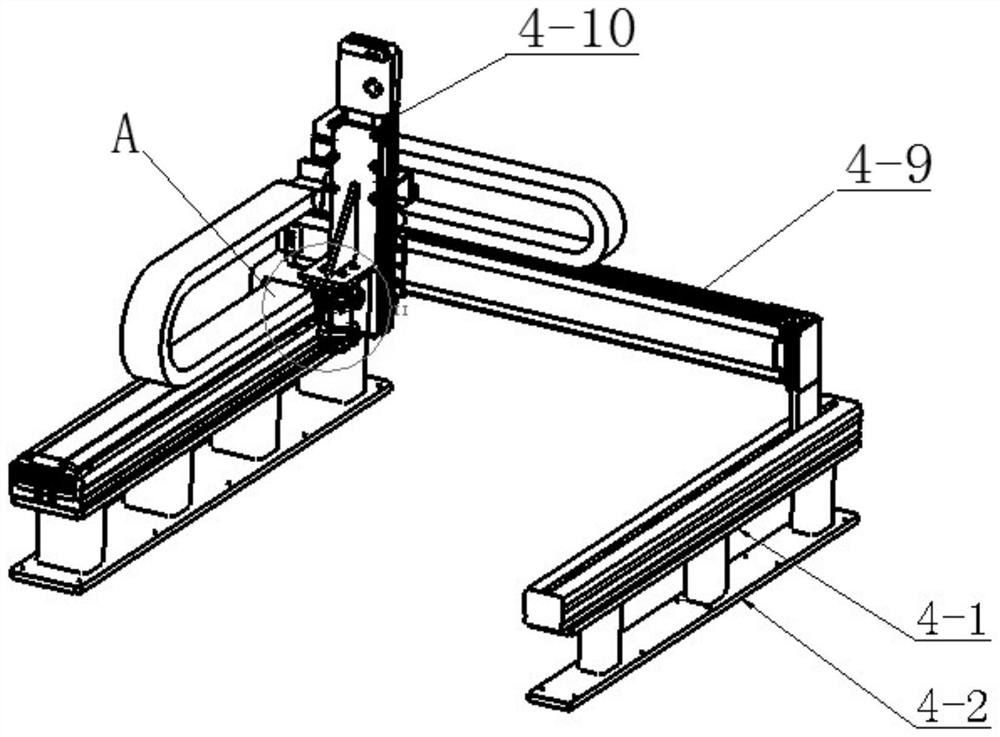

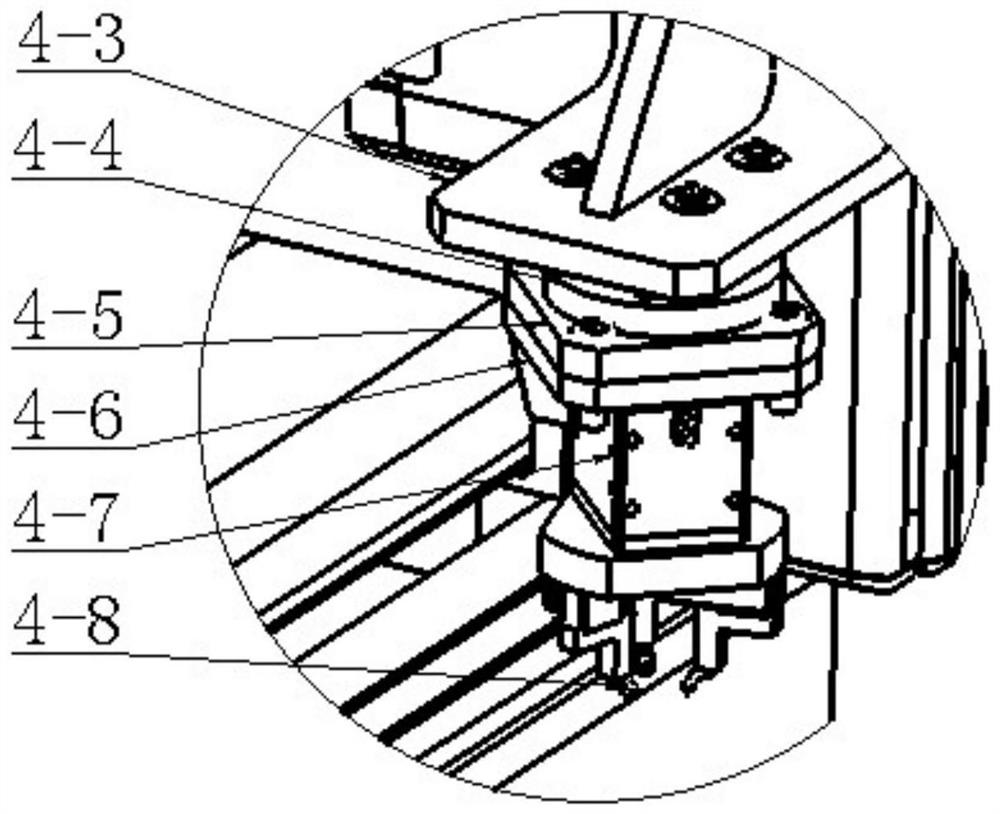

A grinding detection system and method for ceramic screws

ActiveCN111922842BReasonable arrangementImprove consistencyGrinding carriagesMeasurement devicesProcess engineeringProcessing cost

The invention discloses a grinding detection system and method for ceramic screws, aiming to solve the problem of low production efficiency caused by manual manual operation of ceramic screw grinding in the prior art, and it is difficult to ensure the grinding amount each time and realize the realization of ceramic screws. For the technical problem of high-precision alignment during screw testing, the present invention enables the entire grinding system to have both grinding, testing, flipping and three-degree-of-freedom transfer and grabbing processes through a reasonable combination of a three-axis robot, a grinding mechanism, a detection mechanism and a flipping mechanism. , From feeding to final inspection and classification, no manual participation is required in the middle, and the mechanized procedure makes the final qualified ceramic screw products with high consistency, high yield and high precision. The whole process lasts for a short period of time, and the arrangement of each mechanism is reasonable, which effectively saves time and processing costs. The grinding method of the present invention is efficient and orderly, the whole process does not need manual participation, the continuous period is short, and the consistency of the polished qualified products is high.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

Clean cow driver for animal husbandry

ActiveCN108184705BInstant cleanupEasy to useCleaning using toolsAnimal repellantsAnimal scienceCrop livestock

The present invention relates to a driving device, in particular to a clean cow driving device for animal husbandry. The technical problem to be solved by the present invention is to provide a clean cow drive for animal husbandry. In order to solve the above technical problems, the present invention provides such a clean type cow driver for animal husbandry, including a universal wheel, a frame, a first driving bar, a right bearing seat, a support, a middle bearing seat, a left bearing seat, a third Two drive bars, left gear, left rotating shaft, middle gear, etc.; a universal wheel is installed at the bottom of the frame, and a left bearing seat, a middle bearing seat and a right bearing seat are installed on the top of the frame from left to right. The left rotating shaft, the middle rotating shaft and the right rotating shaft are respectively installed on the right bearing seat. The invention is easy to use and can clean the ground immediately. The first driving bar and the second driving bar alternately swing back and forth to continuously drive away the cows in front. The breeding personnel only need to push the device without spending a lot of effort to drive them away.

Owner:金寨县益农农业科技开发有限公司

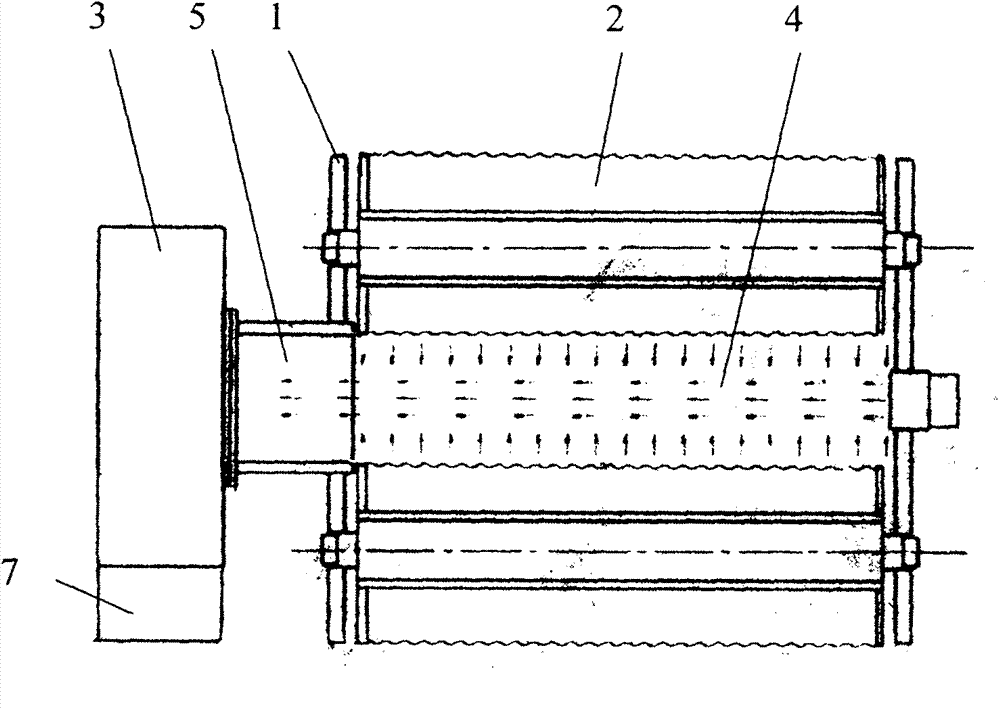

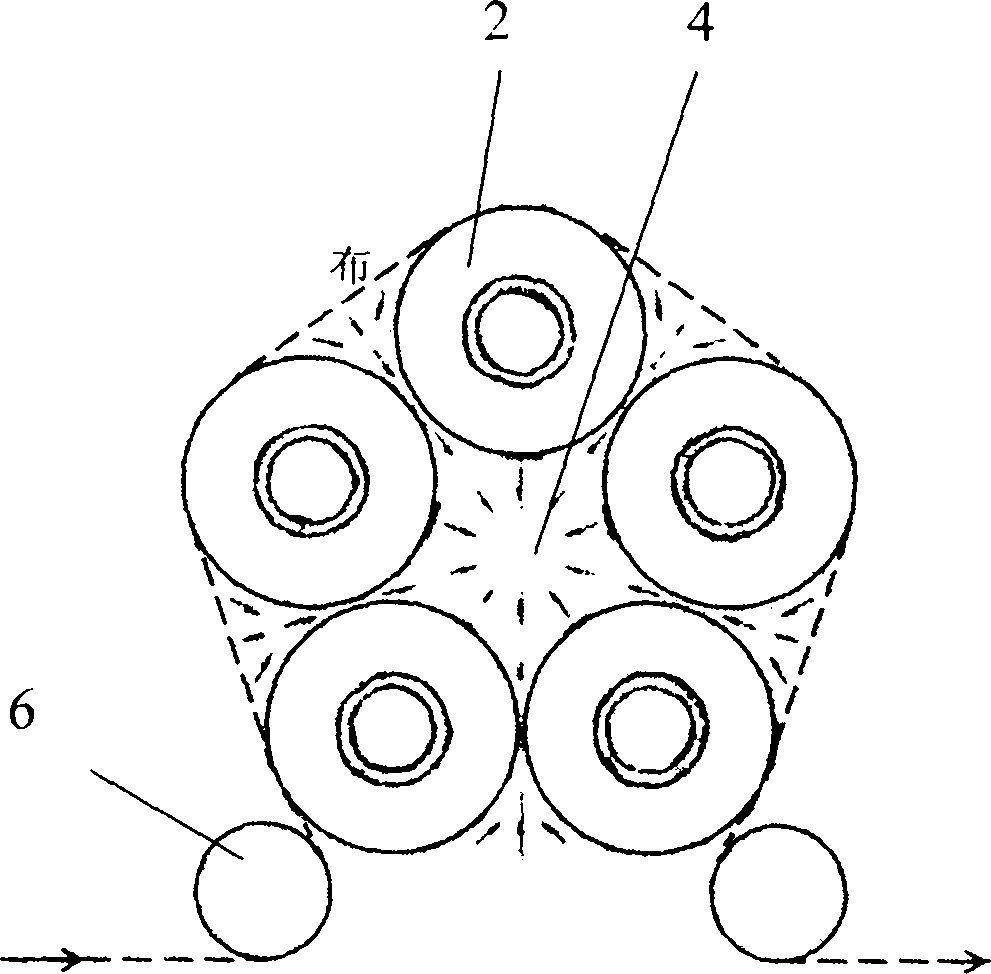

Central dust collection device of sanding machine

The invention discloses a dust collection device, and particularly relates to a central dust collection device of a sanding machine. The central dust collection device comprises support drums, hairbrush rollers and a fan, wherein multiple hairbrush rollers forming a circle are arranged between two support drums; each hairbrush roller can autorotate clockwise or anticlockwise; multiple hairbrush rollers define a central inner cavity; the support drums are arranged on the two sides of the central inner cavity; an air channel is formed in the support drum on the left side and connected with the fan; the support drum on the right side is in a sealed state so that the central inner cavity forms a closed space; two cloth guide rollers are arranged below the hairbrush rollers; a dust collection box is arranged below the fan; five hairbrush rollers are provided. Since the central inner cavity defined by the hairbrushes is a closed space, the sealing property is good; since the fan has enough dust collection power, the dust collection effect is good, and the hairbrush rollers can be cleaned in time.

Owner:GUANGDONG RUITUO ENVIRONMENTAL PROTECTION MACHINERY

A cleaning device for down processing that can be quickly screened

ActiveCN108166071BQuick screeningMention qualityWool fibre washing/scouringLiquid/gas/vapor removal by gas jetsWater resourcesEngineering

The invention discloses a cleaning device capable of quick screening for down feather processing. The cleaning device comprises a cleaning and drying tank, a separating cylinder, a cleaning strip, a collecting tank and a screening tank; a top end of the cleaning and drying tank is provided with an inlet pipe; the separating cylinder is installed inside the cleaning and drying tank; the cleaning strip is connected with the other end of a connecting rod; the collecting tank is connected with a water through hole in the cleaning and drying tank through a connecting pipe; the cleaning and drying tank is provided with a ventilating opening; filter holes are opened in a first filter board; a bottom end of the screening tank is provided with discharging pipes which are mutually connected throughshunt tubes ; an inner wall of the shunt tube is provided with a separator plate. According to the cleaning device capable of quick screening for down feather processing, down feather can be quickly cleaned and dried; the water resource after cleaning can be reused, which is more energy saving and environmentally friendly; at the same time, down feather can be quickly screened; the design is reasonable and the processing quality and efficiency of down feather can be greatly increased.

Owner:ZHANJIANG ZIJIN DOWN PROD

Multifunctional mining equipment for gypsum rock

ActiveCN110374590BImprove mining progressGuaranteed stabilityDerricks/mastsDriving meansSlagElectric machinery

The invention discloses multifunctional mining equipment for plaster stone. The multifunctional mining equipment comprises a walking part, a power assembly and a control assembly, wherein the power assembly and the control assembly are arranged on the walking part; a mining part is arranged at the front end of the walking part; a work drilling mechanism used for hole drilling is arranged on the walking part; the mining part comprises a tunneling mechanism and a slag crushing mechanism; the tunneling mechanism comprises a tunneling support frame, a tunneling head arranged on the tunneling support frame and a tunneling motor used for providing power for the tunneling head; the slag crushing mechanism comprises a slag crushing support frame and two groups of crushing rollers arranged on the slag crushing support frame; a bucket is arranged on the front side wall of the walking part; one end of the slag crushing support frame is hinged onto the bucket; and at least one connecting arm is hinged between the middle parts of the slag crushing support frame and the tunneling support frame. The multifunctional mining equipment has the advantages that on the basis of tunneling functions of atraditional tunneling machine, hole drilling and timely crushing functions are added, so that the mining operation on rock stratums with different cross sections and hardness can be realized; and themineral product yield is ensured.

Owner:康定龙源穗城石膏有限责任公司

Alloy shell part anodizing equipment with high sealing performance

PendingCN114481259AImprove the sealing effectAvoid sealing effectSurface reaction electrolytic coatingPolytetrafluoroethyleneAnodizing

The invention relates to the field of alloys, in particular to alloy shell part anodizing equipment with high sealing performance. The technical problems that after a polytetrafluoroethylene tape is manually wound, a gap still exists between the polytetrafluoroethylene tape and the threaded surface of a tool, the polytetrafluoroethylene tape is not completely sunken into a threaded groove, when the polytetrafluoroethylene tape is rotationally inserted into a shell part, a threaded structure in the shell part can cause damage to the polytetrafluoroethylene tape, and therefore the sealing effect is reduced are solved. According to the technical scheme, the alloy shell part anodizing equipment with the high sealing performance comprises a first mounting plate, a supporting unit and the like; a supporting unit is connected to the middle of the upper side of the first mounting plate. The anodizing treatment on the outer surface of the shell part is realized, the first screw rod and the conical rubber plug are inserted into the shell part to seal the shell part, then the shell part is immersed into corrosive liquid to be anodized, and a polytetrafluoroethylene tape is tightly wound on the outer surface of the first screw rod before insertion, so that the sealing effect is enhanced.

Owner:唐光怀

Polishing and detecting system and method for ceramic screws

ActiveCN111922842AReasonable arrangementImprove consistencyGrinding carriagesMeasurement devicesPolishingProcessing cost

The invention discloses a polishing and detecting system and method for ceramic screws, and aims to solve the technical problems that in the prior art, manual operation is adopted to polish the ceramic screw, so that the production efficiency is low, the polishing amount at each time is difficult to ensure, and high-precision alignment during ceramic screw testing is difficult to achieve. Throughreasonable combination of a three-axis robot, a polishing mechanism, a detecting mechanism and a turnover mechanism, the whole polishing system has the polishing, detecting, turnover and three-degree-of-freedom displacement grabbing process, manual participation is not needed from feeding, final detection, classification and collocation, and a mechanical program enables final qualified ceramic screw products to be high in consistency, yield and precision. The whole process is short in lasting period and reasonable in position arrangement of each mechanism, so that the time cost and the processing cost are effectively saved. The polishing method is efficient and orderly, manual participation is not needed in the whole process, the continuous period is short, and the consistency of the polished qualified products is high.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

Easy-to-clean sewage-intercepting rainwater inlet

ActiveCN108222227AEasy to intercept sewage treatmentAchieve recyclingFatty/oily/floating substances removal devicesSewerage structuresWater resourcesRainwater tank

The invention discloses an easy-to-clean sewage-intercepting rainwater inlet which mainly comprises a rainwater tank, an overflow box arranged outside the rainwater tank and a rainwater strainer arranged on the rainwater tank. A sewage-intercepting basket is arranged on the upper portion of the rainwater tank and is in sliding fit with side walls of the rainwater tank, and the sewage-interceptingbasket is provided with an automatic sewage-intercepting tank ejecting device; a rainwater filtering device is arranged on the lower portion of the rainwater tank. By the arrangement, the rainwater inlet is subjected to sewage intercepting conveniently, rainwater can be recycled, treated and utilized in a timesaving and laborsaving manner, maintenance load of the rainwater inlet is greatly reduced, working efficiency is improved, and meanwhile, water resources are greatly saved.

Owner:ANHUI UNIV OF SCI & TECH

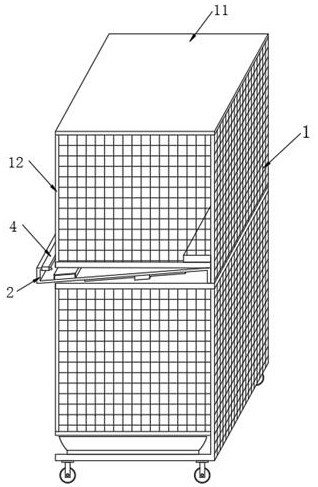

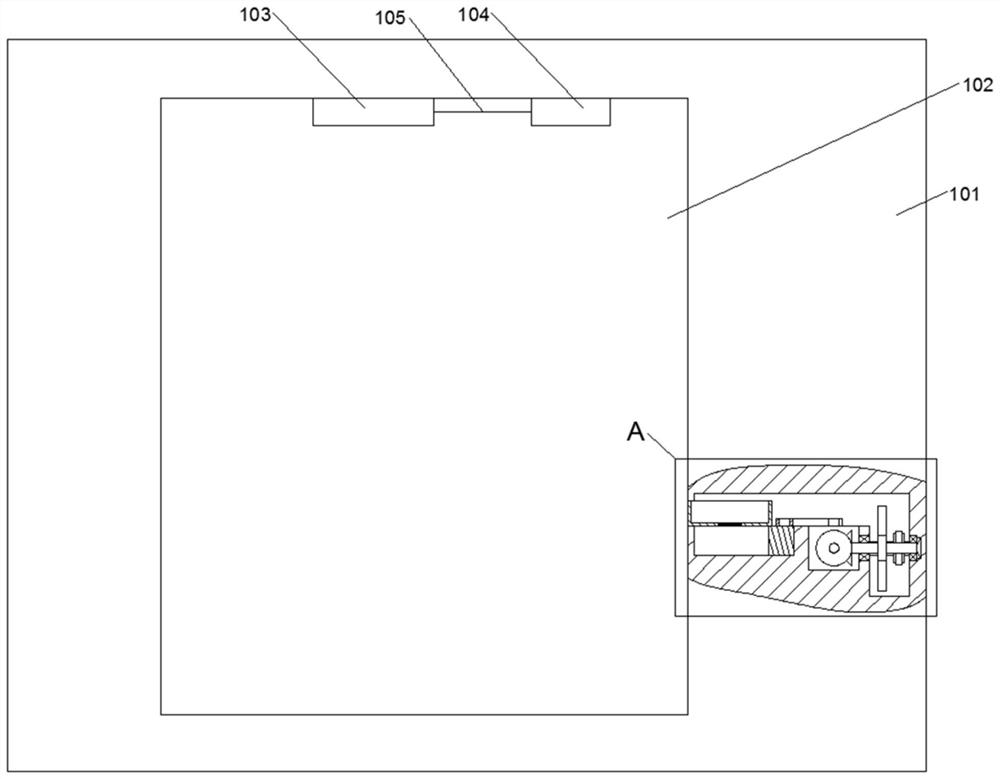

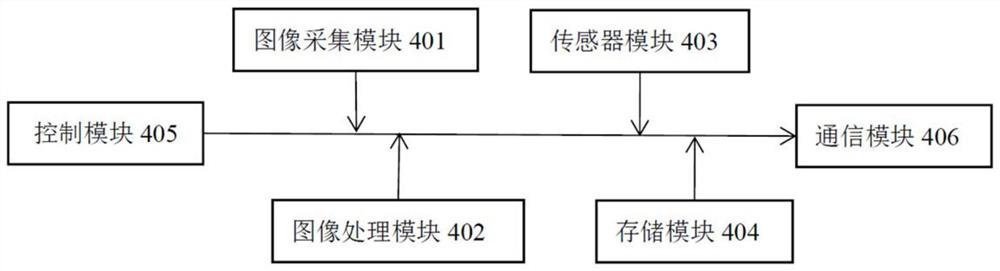

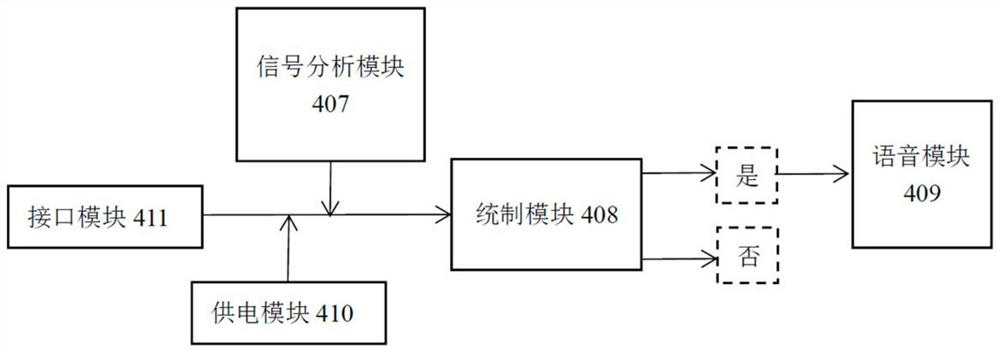

A device for detecting and cleaning pet waste in elevators

ActiveCN111392556BAchieve the purpose of remindingInstant cleanupElevatorsBuilding liftsComputer hardwareCompanion animal

The invention discloses a device for detecting and cleaning pet excrement in an elevator, which includes an elevator, electric wires, a detection module, an analysis module and a cleaning device. An elevator car is arranged in the elevator, and the cleaning device is arranged in the elevator car On the side, the detection module and the analysis module are set in the elevator, the analysis module is provided with a voice module, the wires communicate and supply power for the detection module and the analysis module, and the detection module transmits the acquired data to the According to the above analysis module analysis, the voice module prompts the pet owner. The device of the present invention is convenient to use, safe and environmentally friendly. The device with a simple structure provides cleaning tools for pet owners in time, and realizes the purpose of immediate treatment of pet excrement, and has obvious progress and practicability.

Owner:虏克电梯有限公司

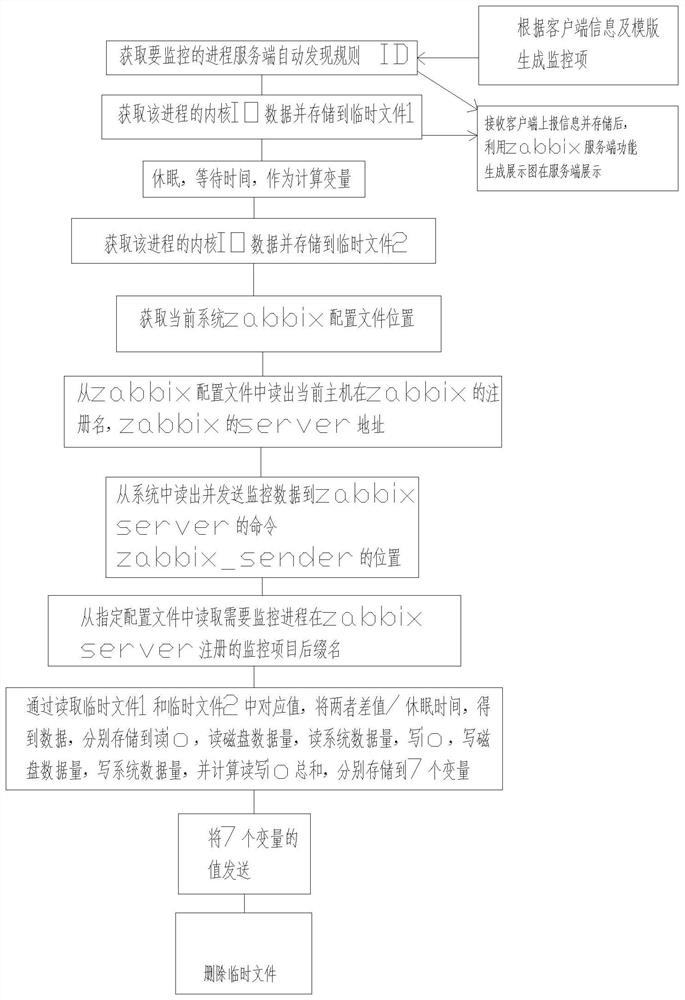

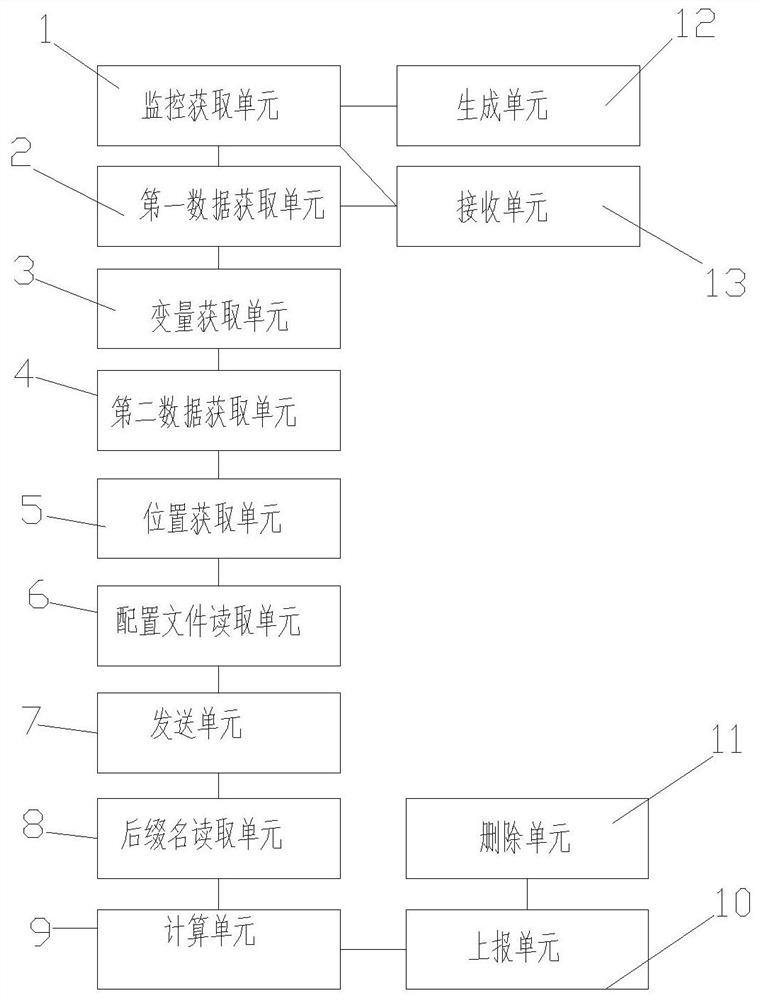

Disk IO processing method and system

InactiveCN112965658AInstant cleanupAvoid high load situationsInput/output to record carriersComputer hardwareEngineering

The invention discloses a disk IO processing method and system, and the system comprises a client module and a server module which can clean the space of a disk, thereby reducing the unnecessary overhead. According to the disk IO processing method and system, the disk space can be cleaned in time, and the situation that the load of a server is very high due to the fact that disk IO is exhausted when multiple sets of mongodb are used is avoided.

Owner:许亮

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com