Patents

Literature

33results about How to "Normal load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

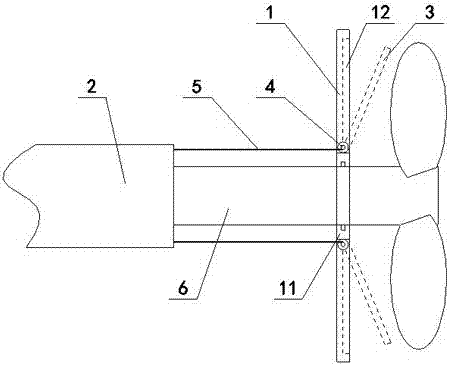

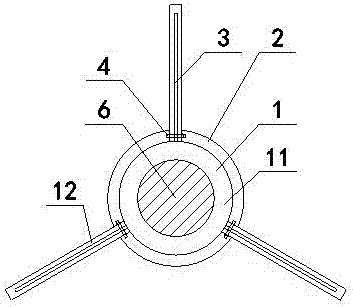

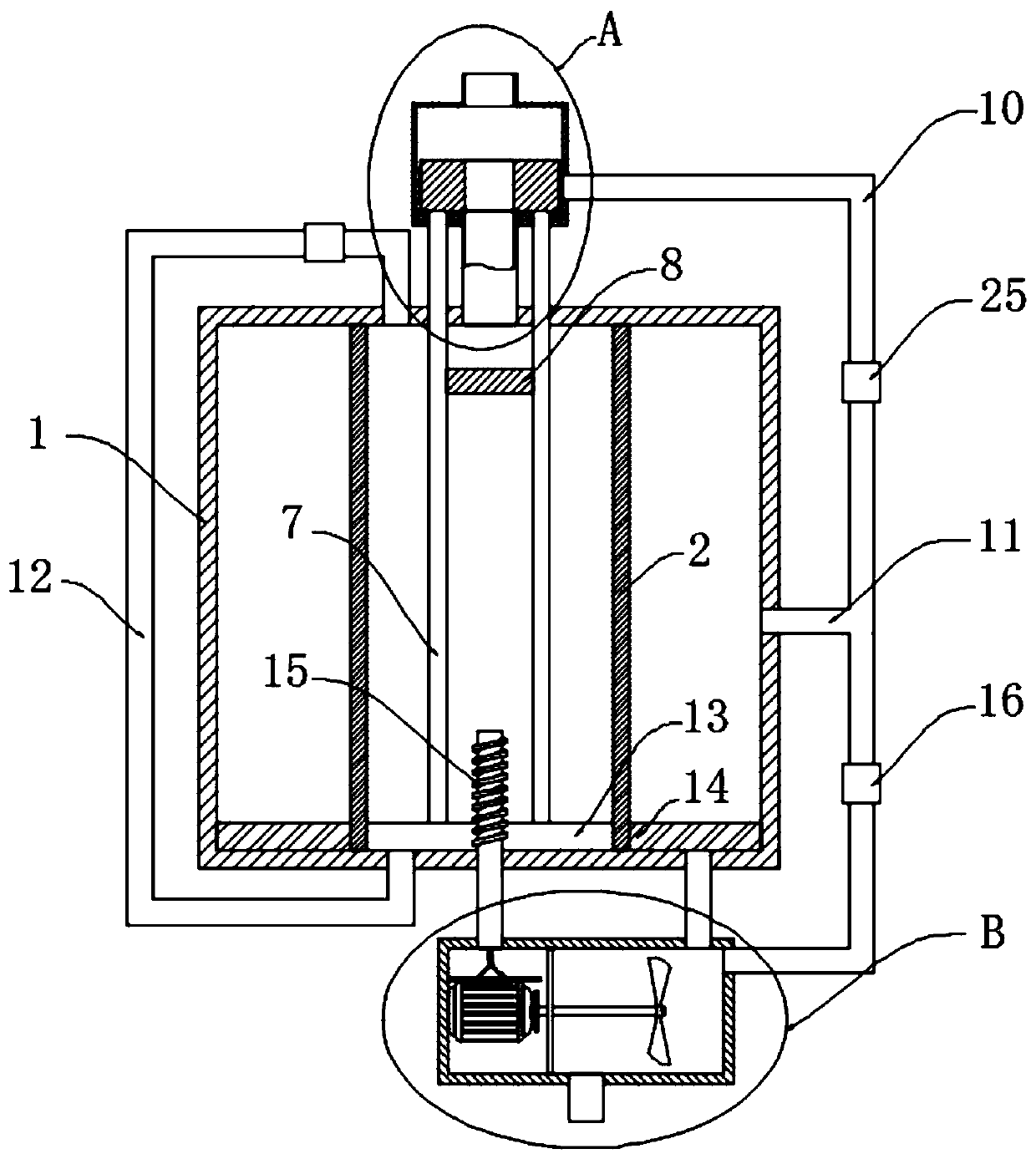

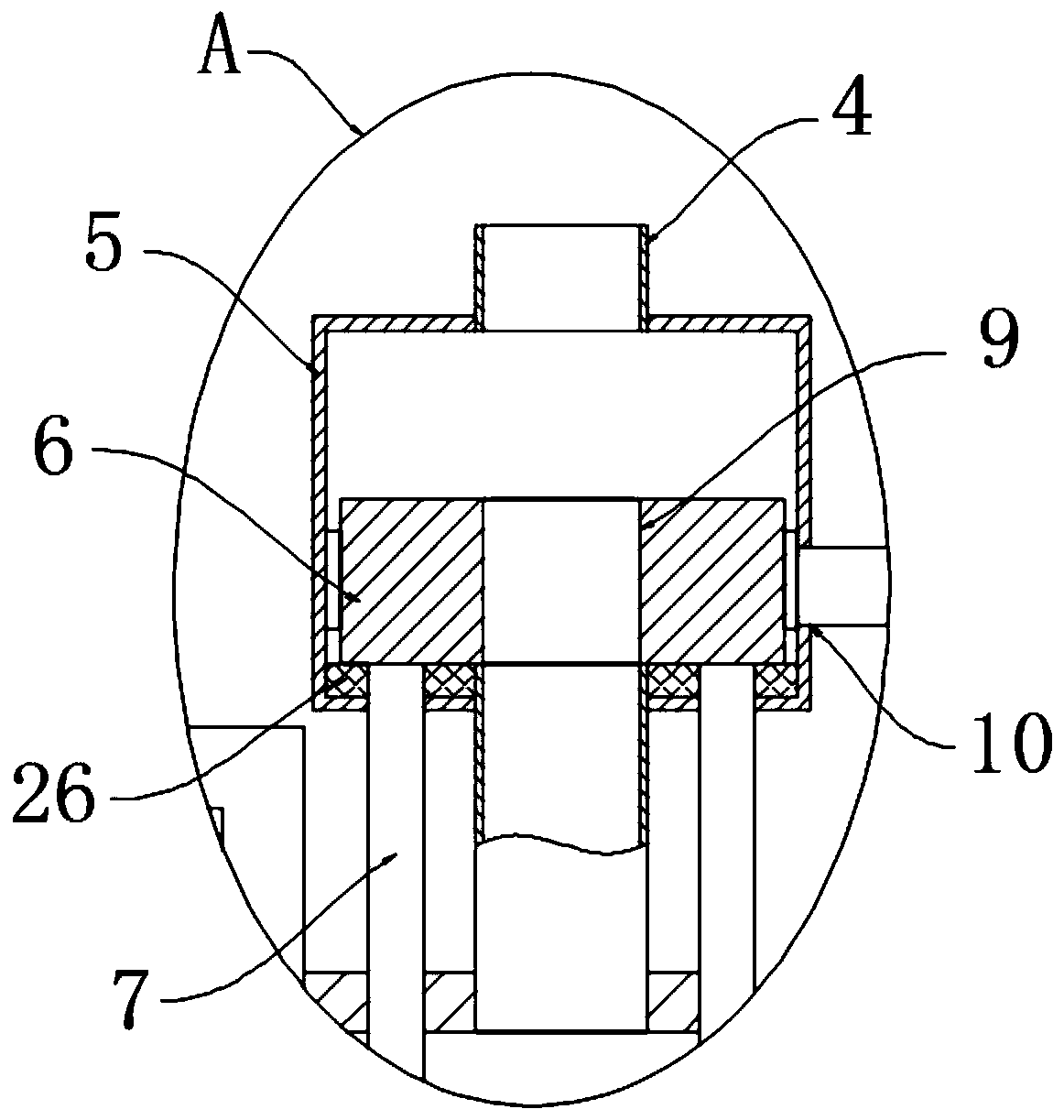

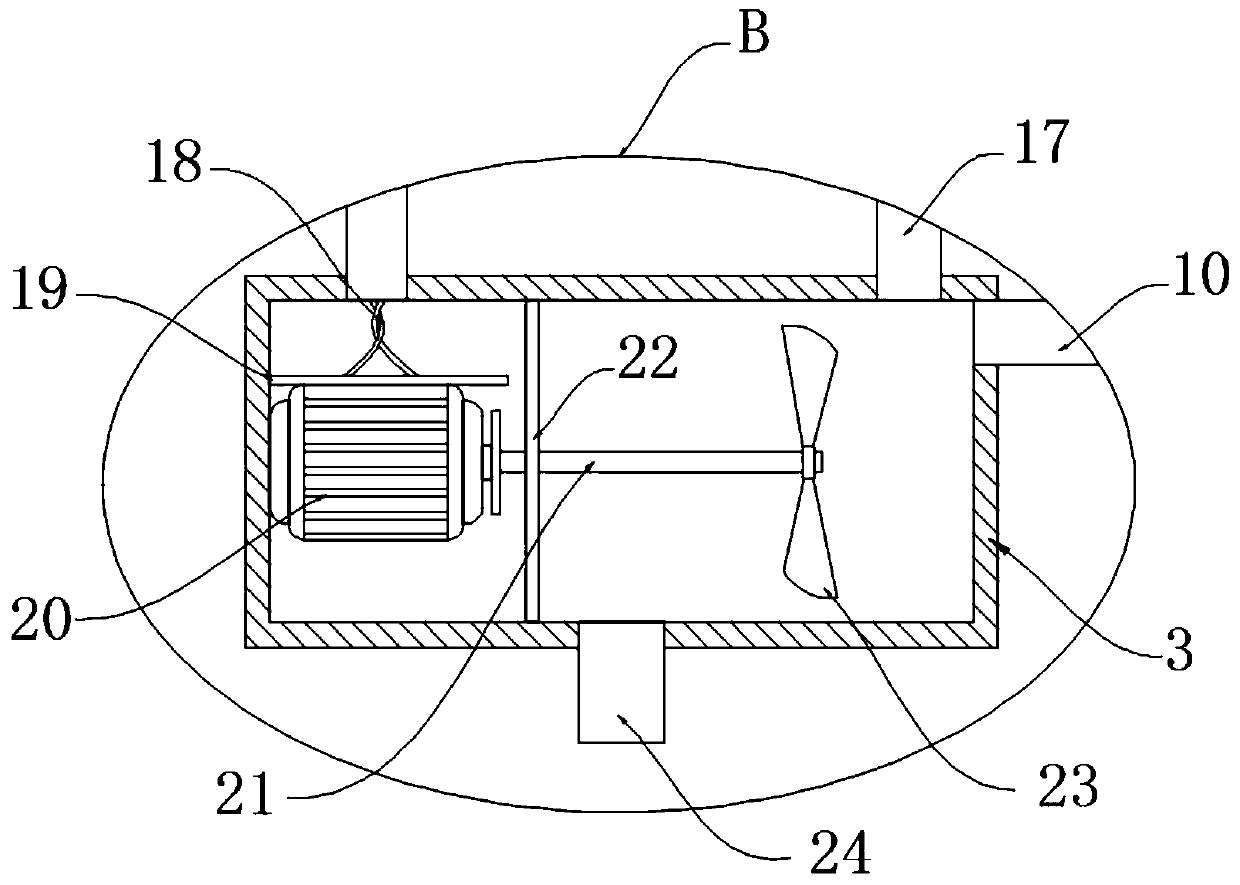

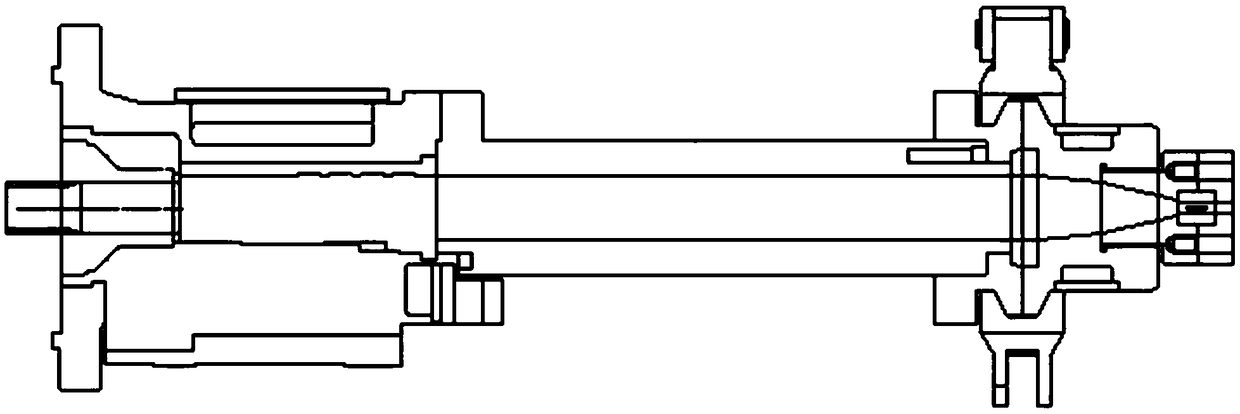

Immediate sewage disposal device of ship propeller thruster

The invention provides an immediate sewage disposal device of a ship propeller thruster and belongs to the technical field of ship engine protection. The technical problem to be solved is to provide the immediate sewage disposal device of the ship propeller thruster, wherein cleaning is conducted when a propeller is wound by water plants or fishing nets; the propeller is released; loads of the propeller are reduced; and normal work of the propeller is maintained. The adopted technical scheme is characterized in that a guide cylinder movably sleeves a rotation shaft of the propeller; a push-pull device is connected to one end of the guide cylinder located inside a ship body; at least three cutter bases are disposed on an installation ring of a current disk through circumferential radiation; the installation ring sleeves the rotation shaft of the propeller; a concave groove and a convex groove which are matched and used to prevent axial motion of the installation ring are disposed on contact faces of the rotation shaft and the installation ring; a cutter groove is formed in one side of each cutter base facing the propeller; a blade is in hinge connection in the cutter groove; a self-recovery spring is disposed on a cutter shaft of the blade; the cutter shaft is connected to one end of the guide cylinder by a pull rope; and the connection point between the pull rope and the cutter shaft is closest to the propeller when the blade is located inside the cutter groove.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

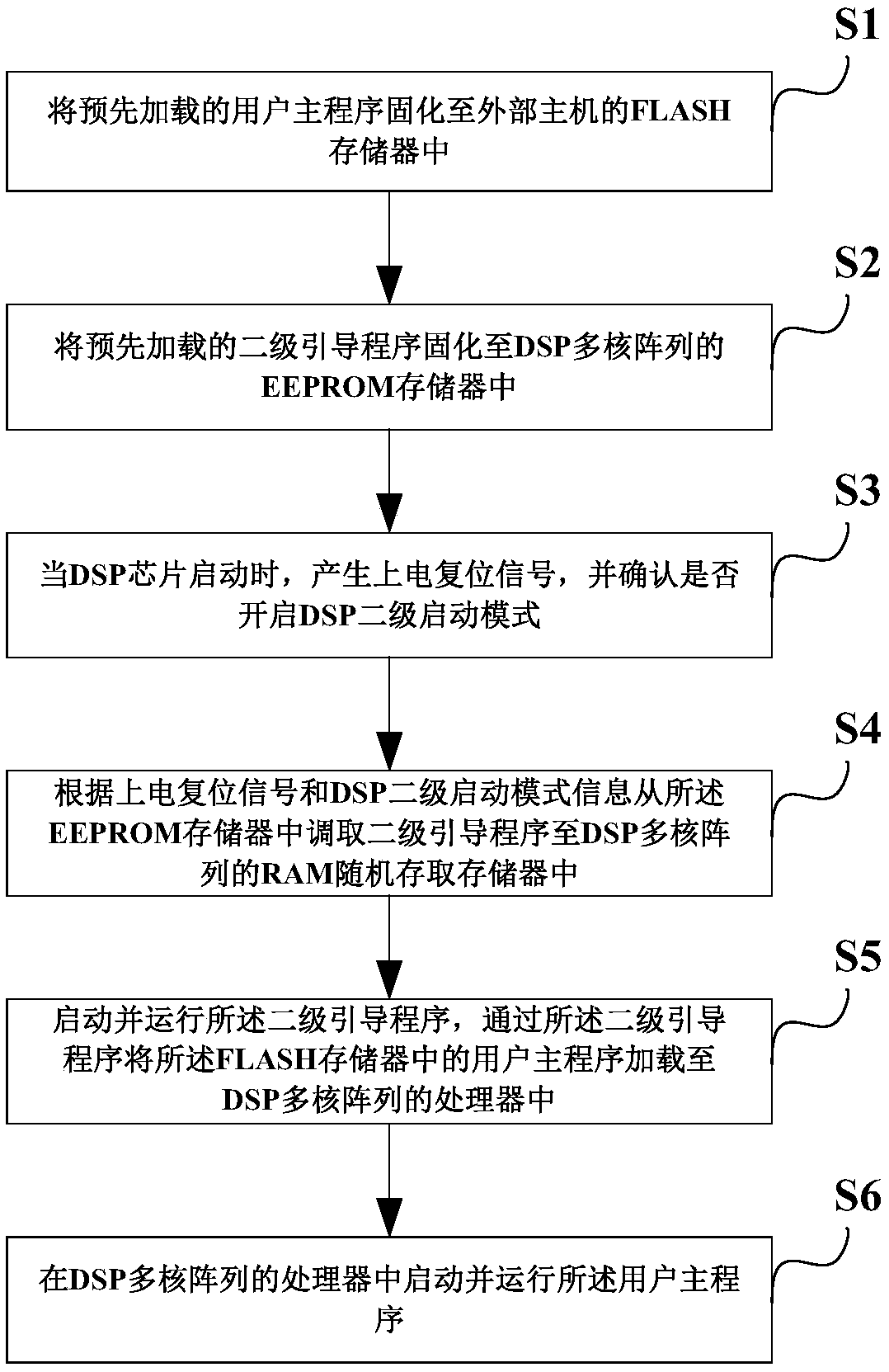

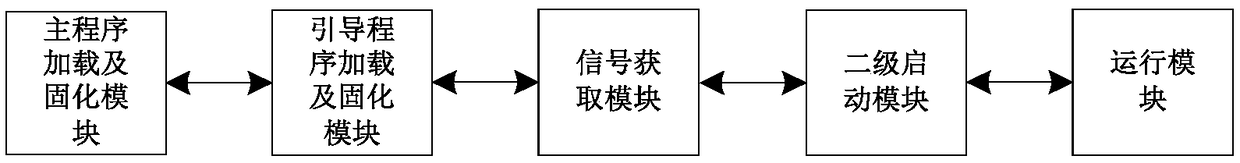

Secondary-starting method and device of DSP multi-core array

InactiveCN108762828AEasy accessImplement direct loadingBootstrappingProgram loading/initiatingPower-on resetElectricity

The invention provides a secondary-starting method and device of a DSP multi-core array. The method comprises: solidifying a pre-loaded user main-program into a FLASH memory of an external host; solidifying a pre-loaded secondary boot program into an EEPROM (Electrically Erasable Programmable read only memory) of the DSP multi-core array; when the DSP multi-core array is started, generating a power-on resetting signal, and confirming whether a DSP secondary-starting mode is started; retrieving the secondary boot program from the EEPROM to an RAM (Random Access Memory) of the DSP multi-core array according to the power-on resetting signal and DSP secondary-starting mode information, starting and running the secondary boot program, and loading the user main-program in the FLASH memory into processors of the DSP multi-core array through the secondary boot program; and starting and running the user main-program in the processors of the DSP multi-core array. According to the method, a secondary program loading and starting manner is adopted, and an effect that the DSP multi-core array directly loads the user main-program is realized without the need for relying on an external network and an external control device for realizing loading.

Owner:GUILIN CHANGHAI DEV

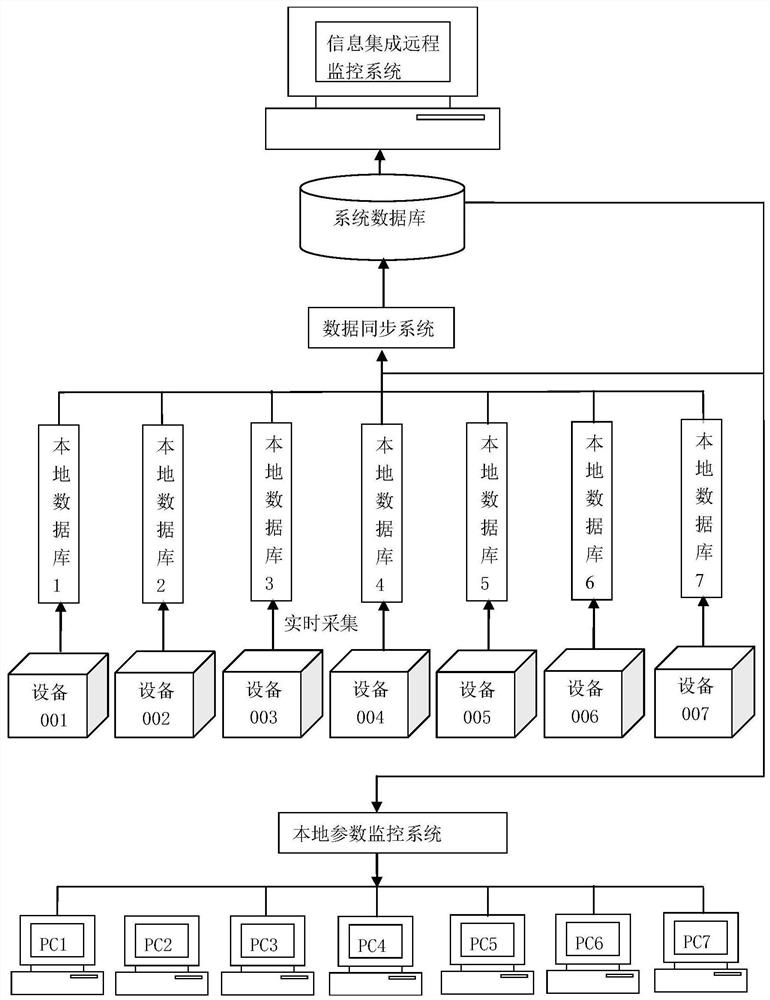

Intelligent remote parameter monitoring system for manned spacecraft manufacturing equipment production line

InactiveCN111624960AEasy to understandEasy for statistical analysisProgramme total factory controlData synchronizationData acquisition

The invention discloses an intelligent remote parameter monitoring system for a manned spacecraft manufacturing equipment production line. The intelligent remote parameter monitoring system comprisesa plurality of data acquisition systems, a plurality of local computers and a database server, wherein the plurality of data acquisition systems are correspondingly connected with the plurality of local computers, the plurality of local computers are connected with the database server, and each data acquisition system comprises a field controller, a camera, a card reader and a scanning gun; and each local computer is provided with an OPC client, a local database and a local parameter monitoring system. The database server is provided with a data synchronization system, a system database and aninformation integration remote monitoring system. According to the invention, local monitoring and remote monitoring of a plurality of equipment parameters are realized on a manned spacecraft manufacturing equipment production line. According to the invention, the production state and production data of each device can be remotely checked in real time by connecting with the Internet in a conference room large screen or an office terminal, and remote monitoring and management of field devices and task completion conditions are realized.

Owner:BEIJING RES INST OF AUTOMATION FOR MACHINERY IND

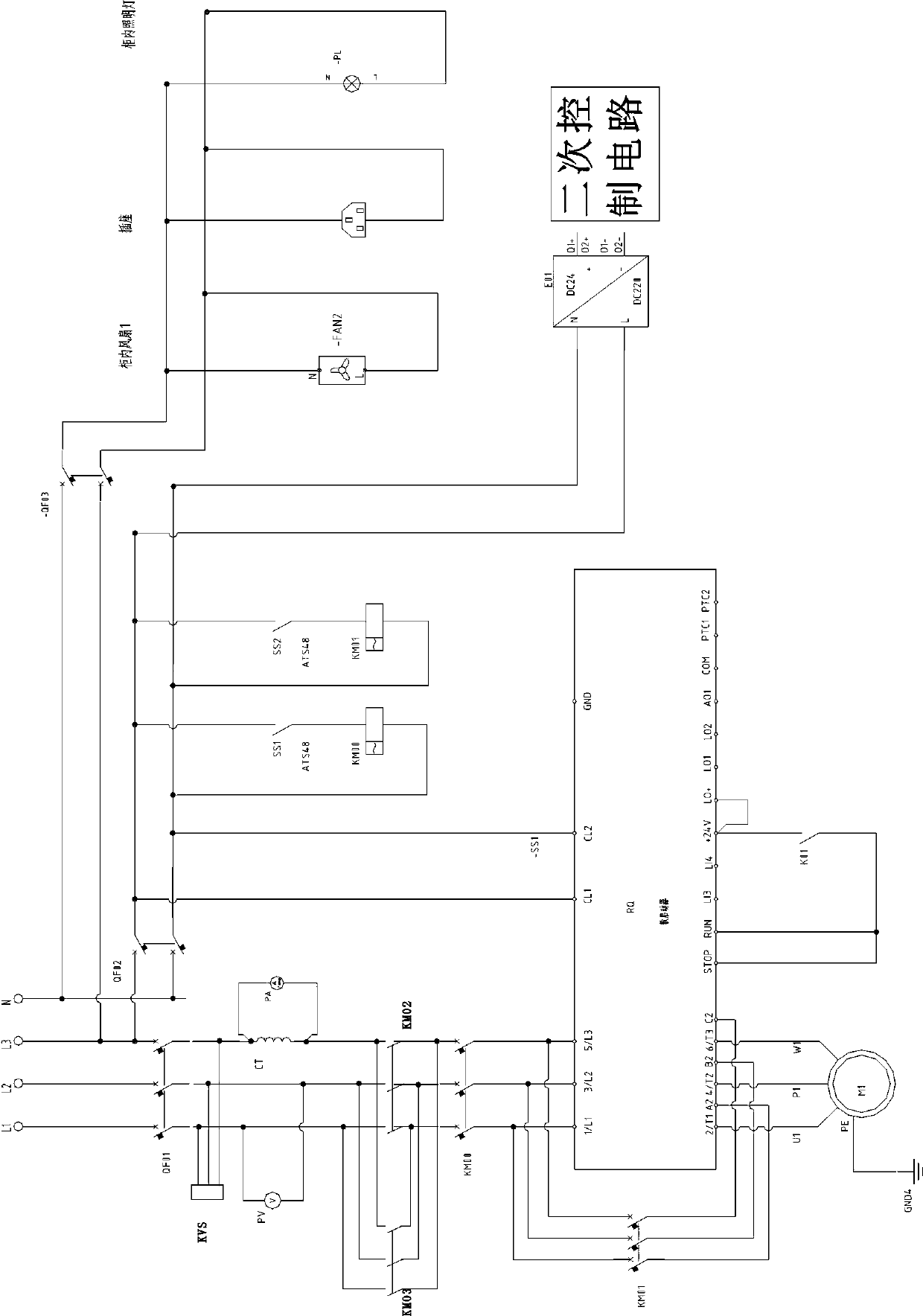

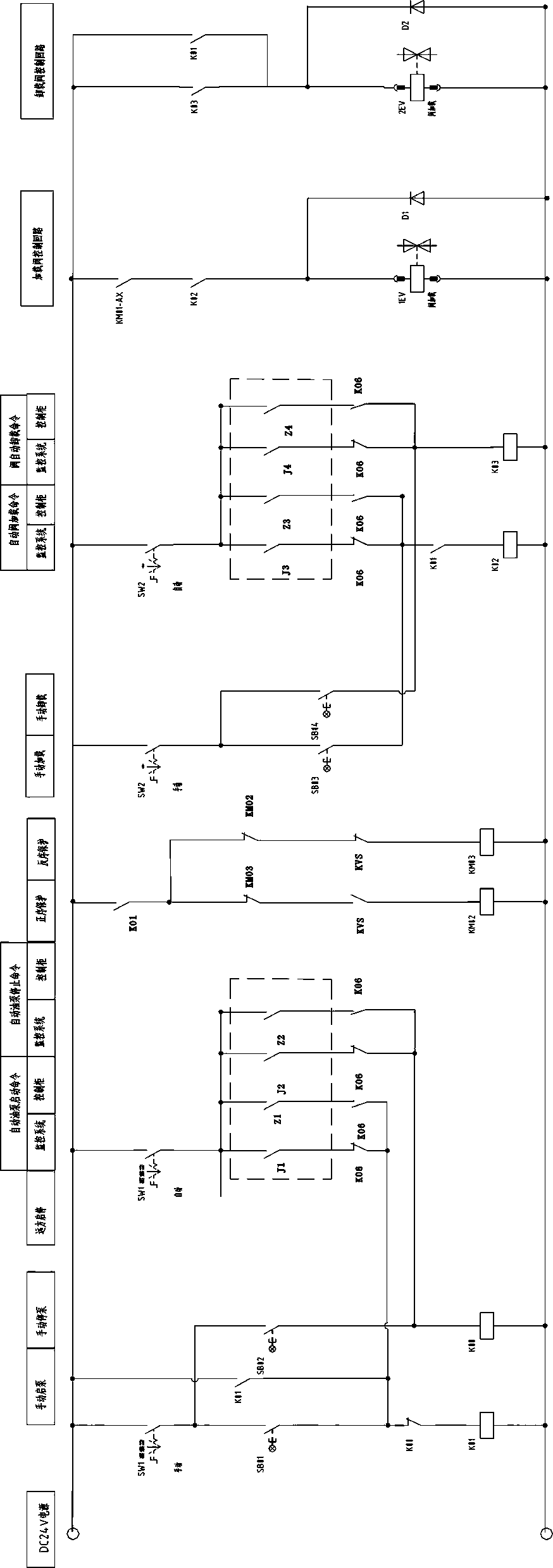

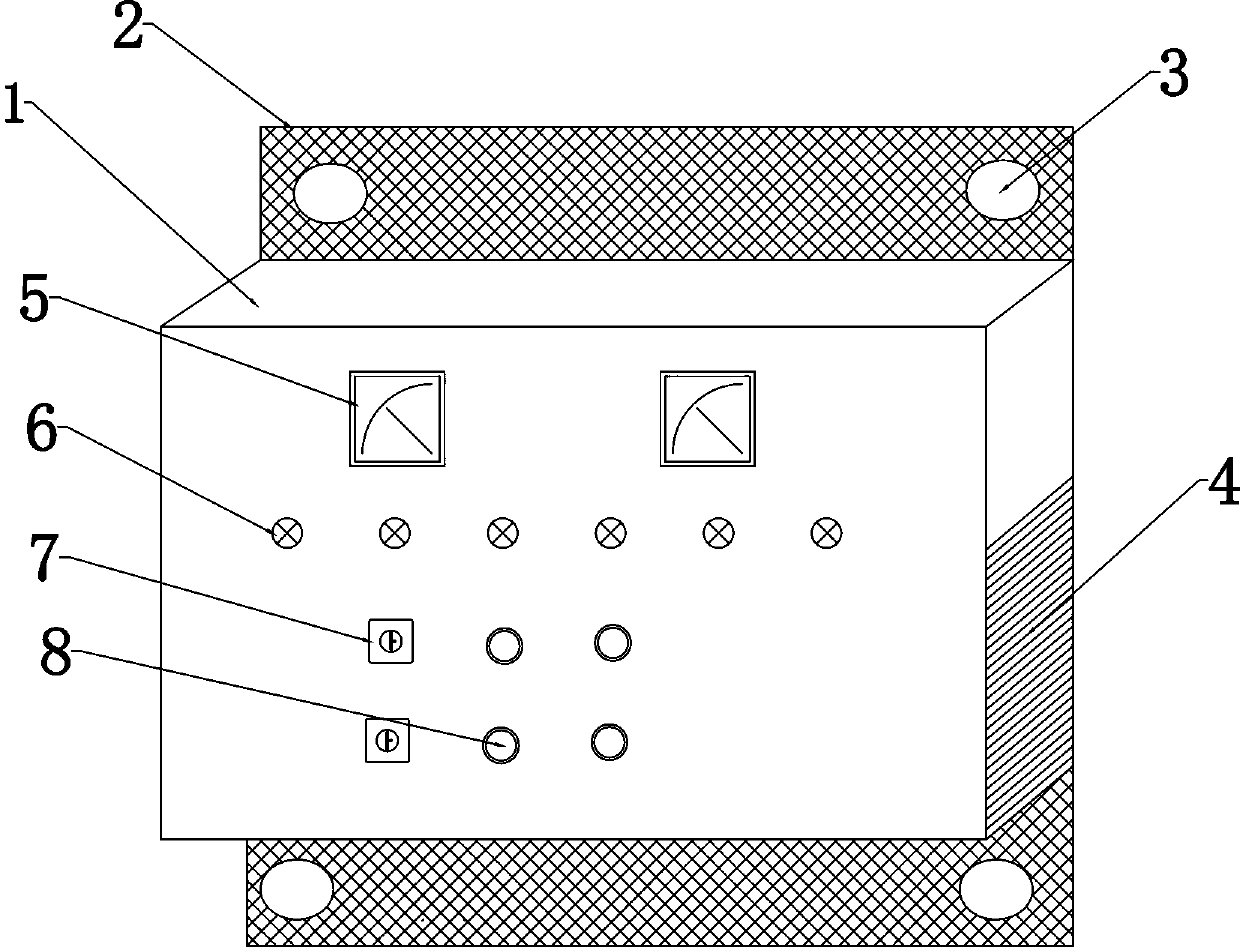

Electrical control device and method for pressure oil pump

PendingCN109751231AReduce shockReduce noisePump controlPositive-displacement liquid enginesControl mannerCircuit breaker

The invention relates to an electrical control device and method for a pressure oil pump. The electrical control device comprises a primary loop and a secondary loop. The primary loop comprises a circuit breaker QF01, a phase sequence protection device KVS, a positive sequence contactor KM02, a reverse sequence contactor KM03, a main contactor KM00, a bypass contactor KM01 and a soft starter RQ; and the secondary loop comprises a start button SB01, a stop button SB02, a loading button SB03, an unloading button SB04, a pump-starting relay K01, a pump-stopping relay K00, a loading relay K02, anunloading relay K03, a positive sequence contactor KM02, a reverse sequence contactor KM03, a loading valve 1EV, an unloading valve 2EV, a start-stop switching handle SW1, a loading-unloading switching handle SW2 and a control cabinet fault point relay K06. According to the electrical control device and method for the pressure oil pump, the control mode for the pressure oil pump of a speed regulator oil pressure device is technically optimized and studied so as to improve the operation reliability of the pressure oil pump.

Owner:CHINA YANGTZE POWER

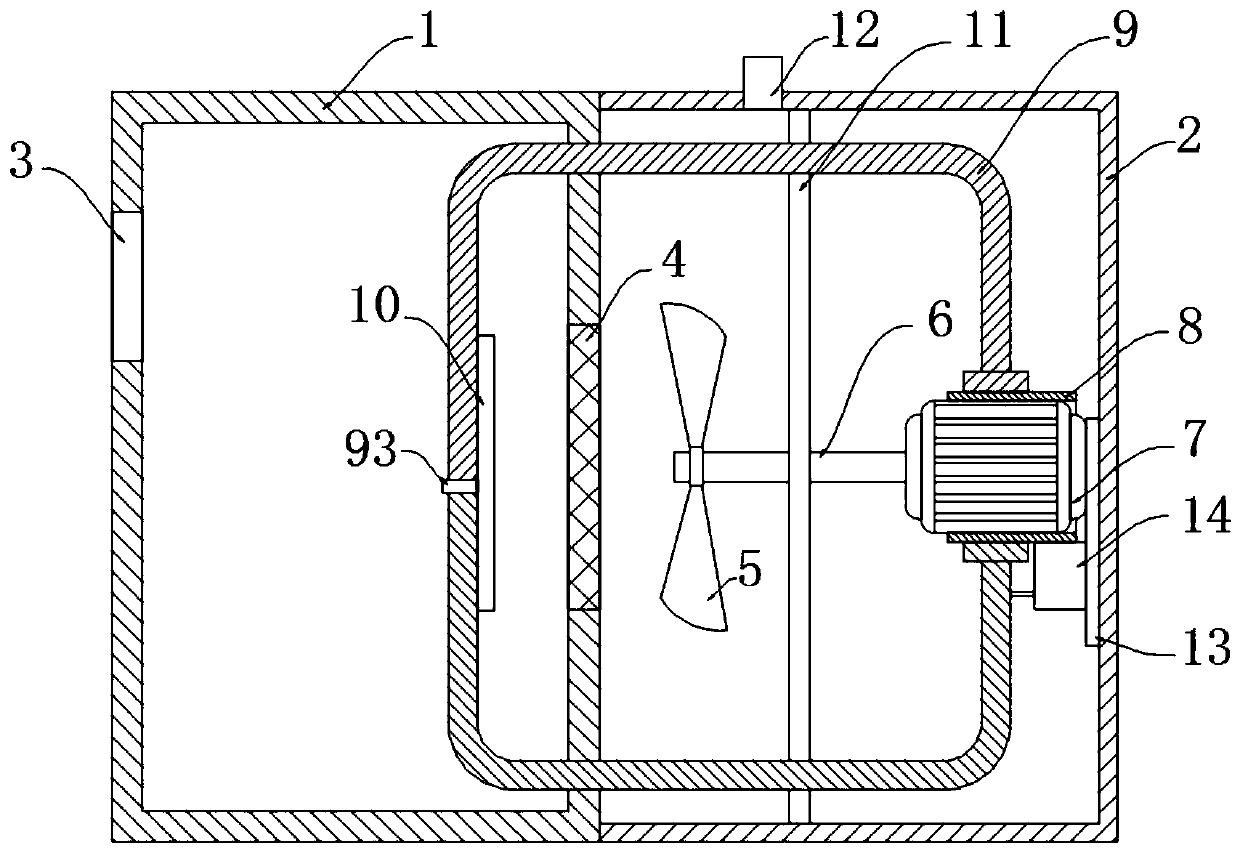

Filtering equipment of self-cleaning dust collector for spinning

InactiveCN110976466ANormal loadReduce loss along the wayGas treatmentDispersed particle filtrationTextile millSpinning

The invention discloses filtering equipment of a self-cleaning dust collector for spinning. The equipment comprises an ash collecting bottle, an annular filter screen is fixedly connected into the ashcollecting bottle; the geometric center line of the filter screen is aligned with the center line of the ash collecting bottle; an air chamber is arranged under the ash collecting bottle; the top ofthe ash collecting bottle is connected with a feeding pipe in a sealing manner; a sliding cavity sealed with the feeding pipe is formed in one section of the feeding pipe; a sliding block is connectedinto the sliding cavity in a sealed and sliding mode. A through hole of which the diameter is the same as that of the feeding pipe is formed in the center of the sliding block in a penetrating manner; the side wall of the sliding cavity is in sealed sliding connection with a first connecting pipe; and the tail end of the first connecting pipe is communicated with the air chamber. When meshes of the filter screen are blocked, backflushing is conducted through waste heat of a motor and changing of the gas flowing direction, so that the filter screen is automatically cleaned, on one hand, the situation that the working environment of a textile mill is affected due to reduction of the dust collection efficiency is avoided, and meanwhile electric energy waste and damage caused by idling of themotor are avoided.

Owner:李乔

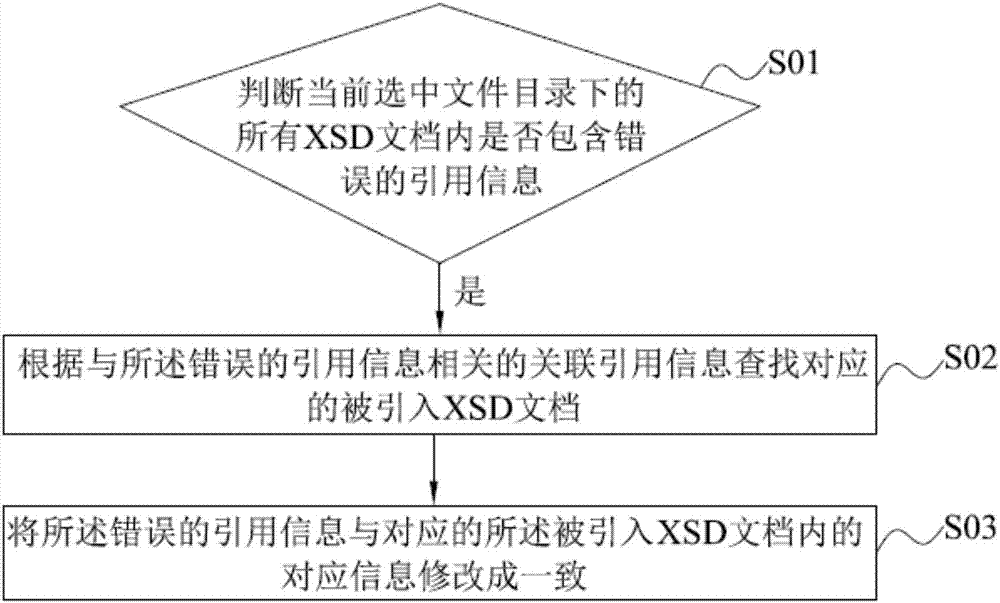

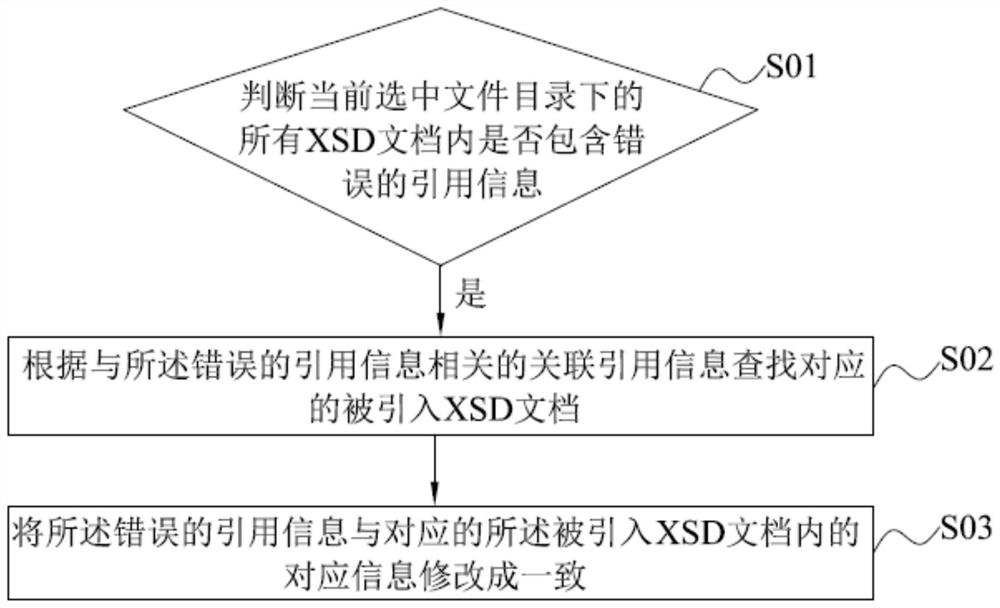

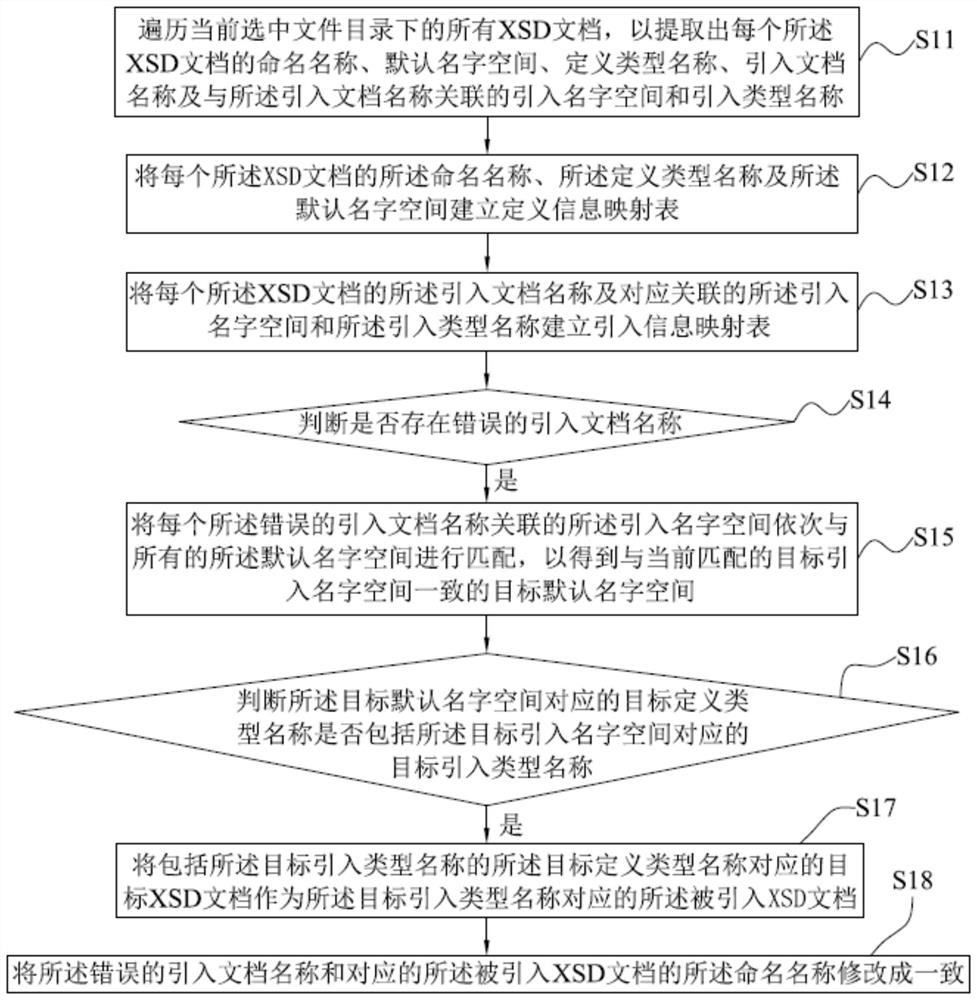

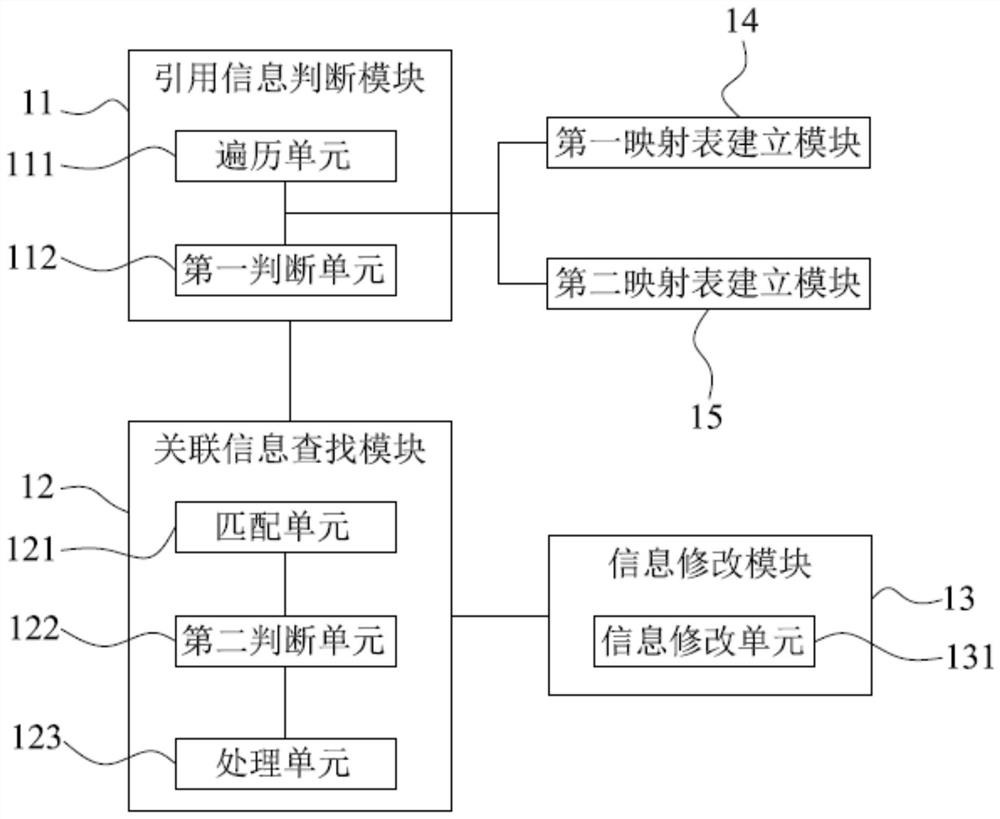

Document restoration method and system, readable storage medium and computer equipment

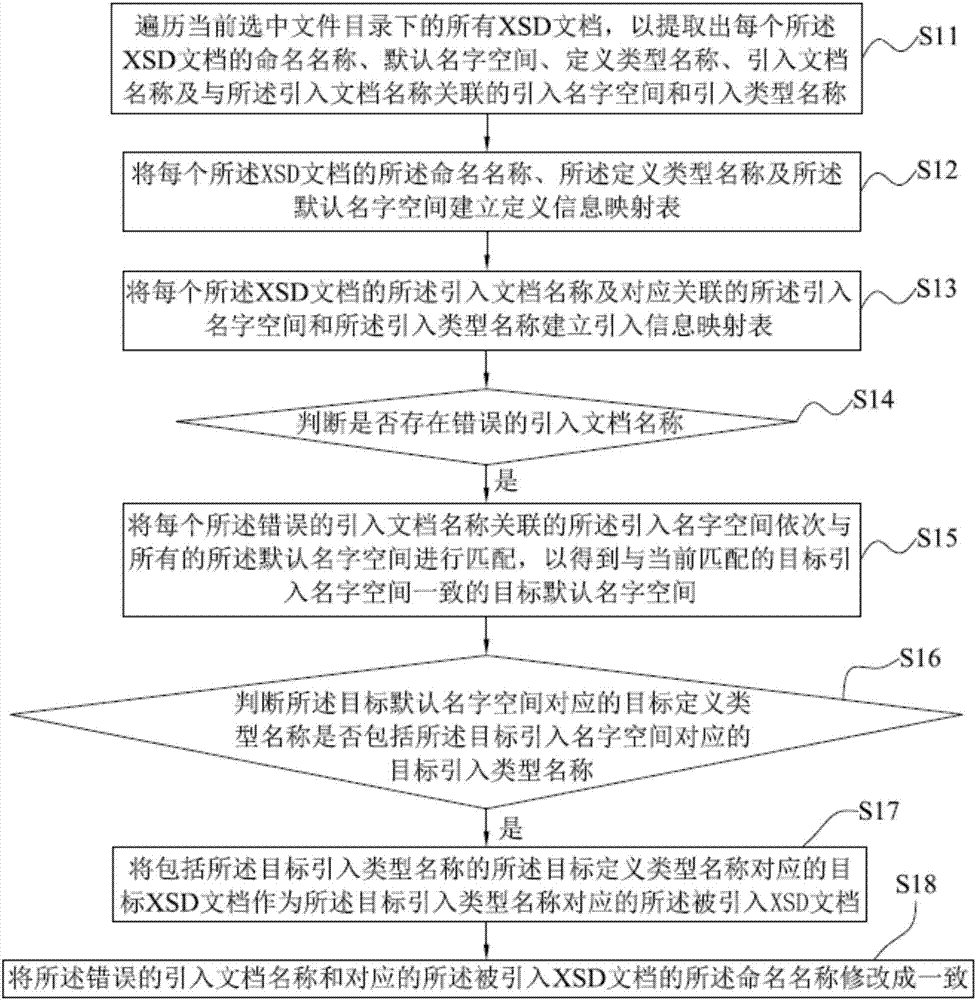

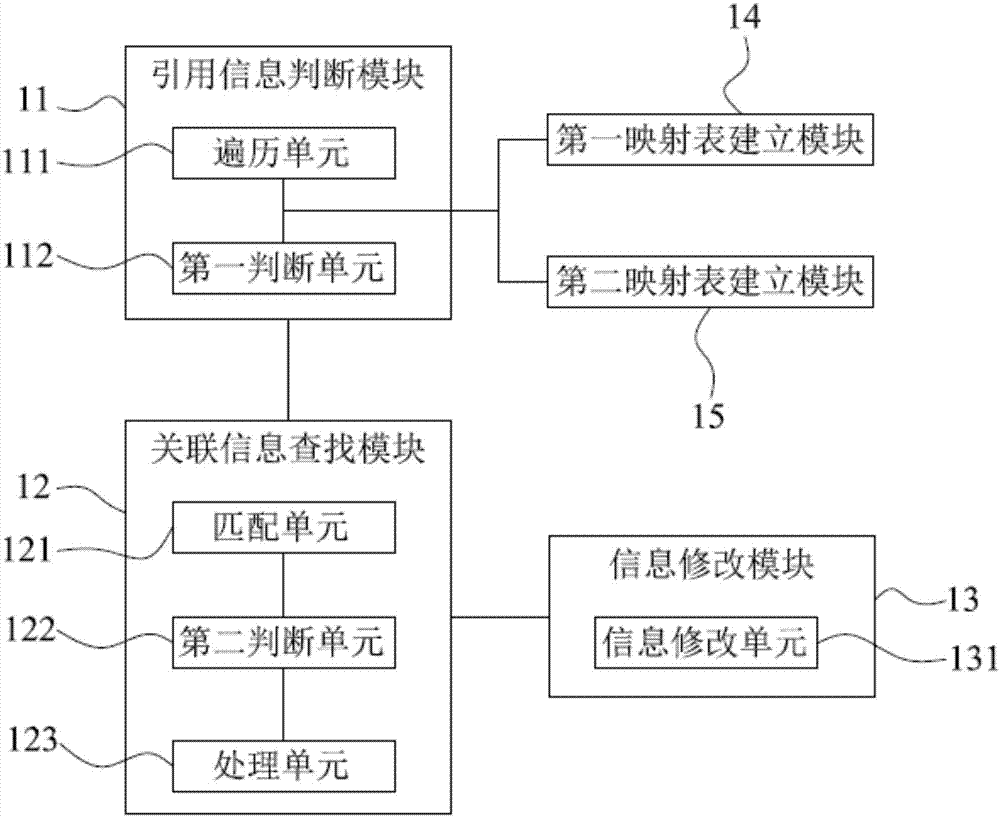

ActiveCN107479910ANormal loadImplement modificationSemi-structured data indexingProgram loading/initiatingRestoration methodInformation finding

The invention provides a document restoration method and system, a readable storage medium and computer equipment. The method comprises the steps that whether all the XSD documents in a current selected file directory contain wrong reference information or not is judged; if yes, the corresponding imported XSD documents are searched for according to the associated reference information related to the wring reference information; the wrong reference information is modified to be consistent with the corresponding information in the imported XSD documents. According to the document restoration method, the wrong imported information in XSD files can be repaired.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD +1

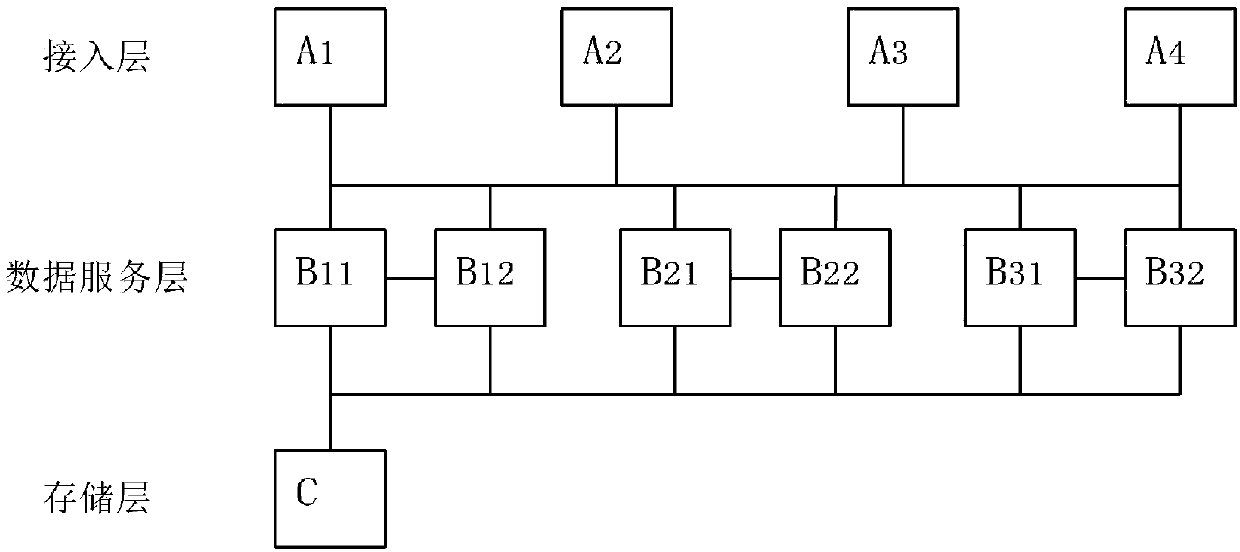

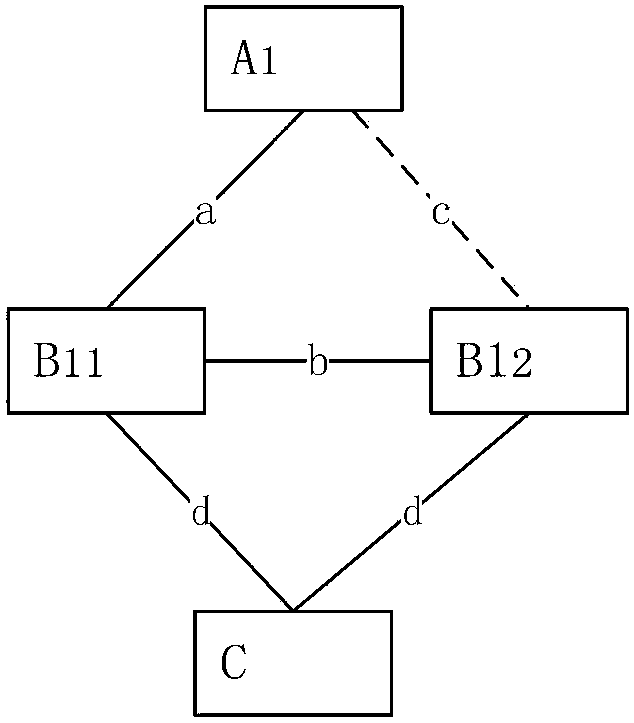

A DHCP service cluster and a construction method

InactiveCN109842666AImprove availabilityGuaranteed reliabilityTransmissionHigh availabilityData access layer

The invention provides a DHCP (Dynamic Host Configuration Protocol) service cluster and a construction method. The method is characterized in that a flat access layer is established, an access load ofthe access layer is shared, a DHCP request of a bearing device and access modules are not mutually influenced and independent, any one data service module is abnormal, and the operation of other dataservice modules is not influenced; The data service layer guarantees reliability and consistency of data and guarantees uniqueness of IP address distribution; The data service layer consists of a plurality of groups of data service module groups, each group is mutually used as a master and a standby, and each group bears distribution and lease management of partial IP address pools; The storage layer ensures the safety of IP address pool configuration, IP address state and lease data, and after the data service is abnormal, the IP address pool configuration, the IP address state and the IP address lease data can be normally and quickly loaded; According to the DHCP cluster mode, the DHCP service with high capacity, high flux and high availability can be realized.

Owner:GUANGDONG ESHORE TECH

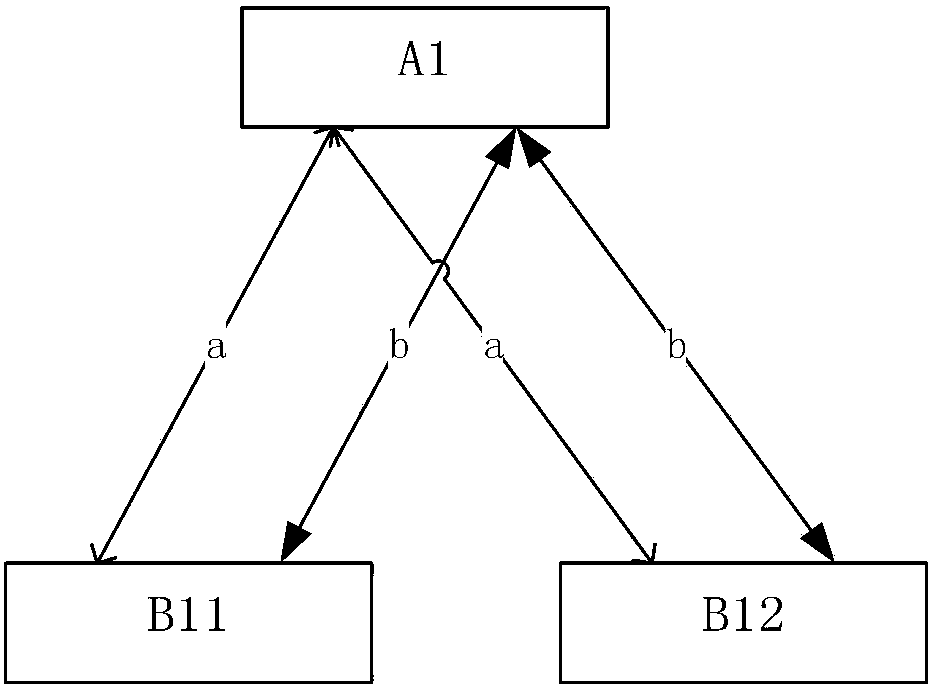

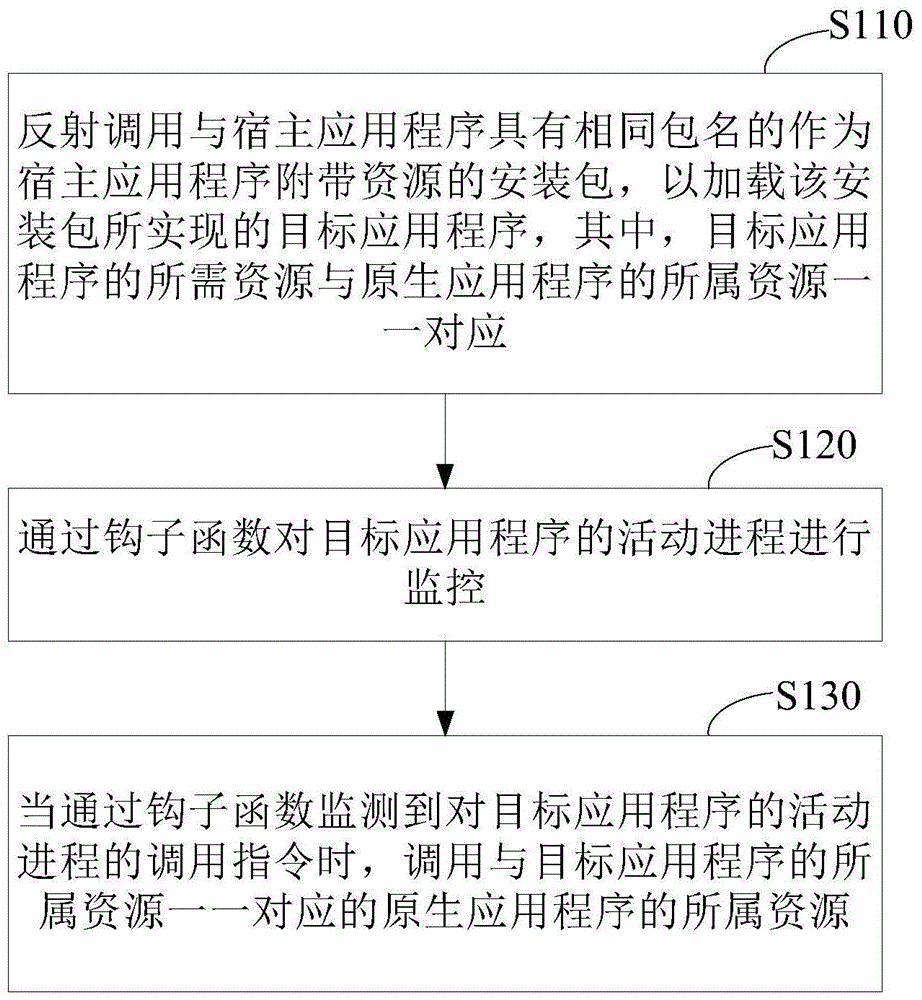

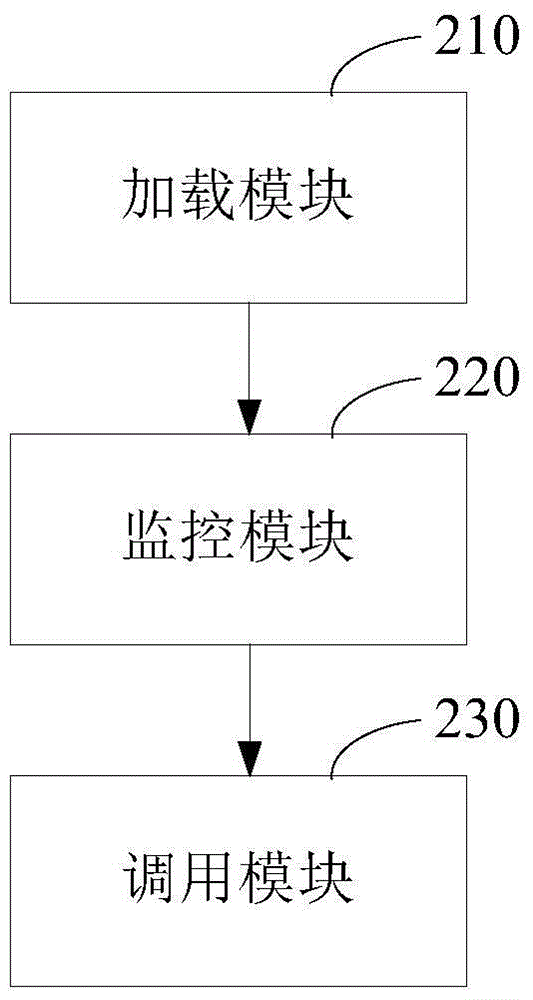

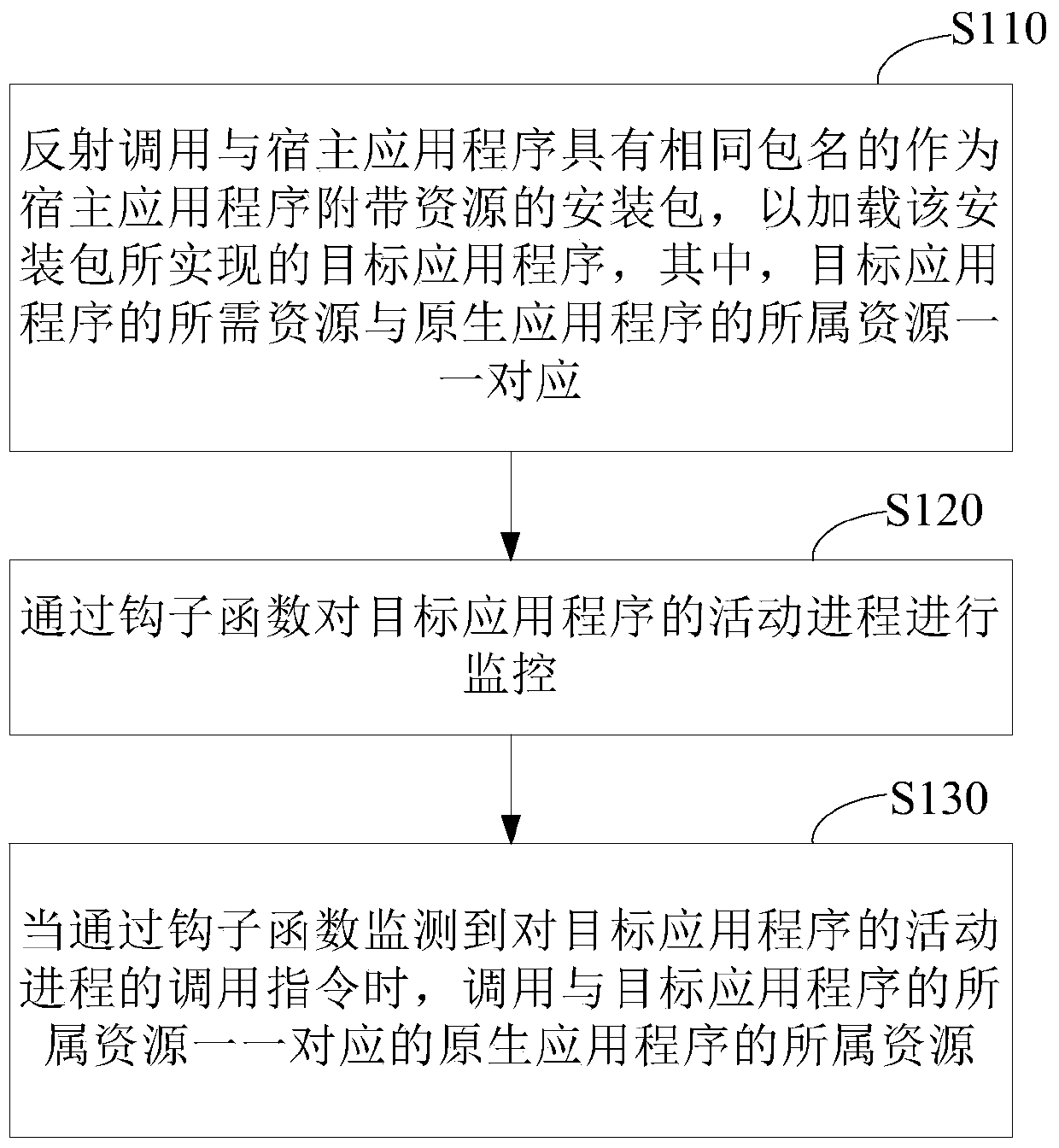

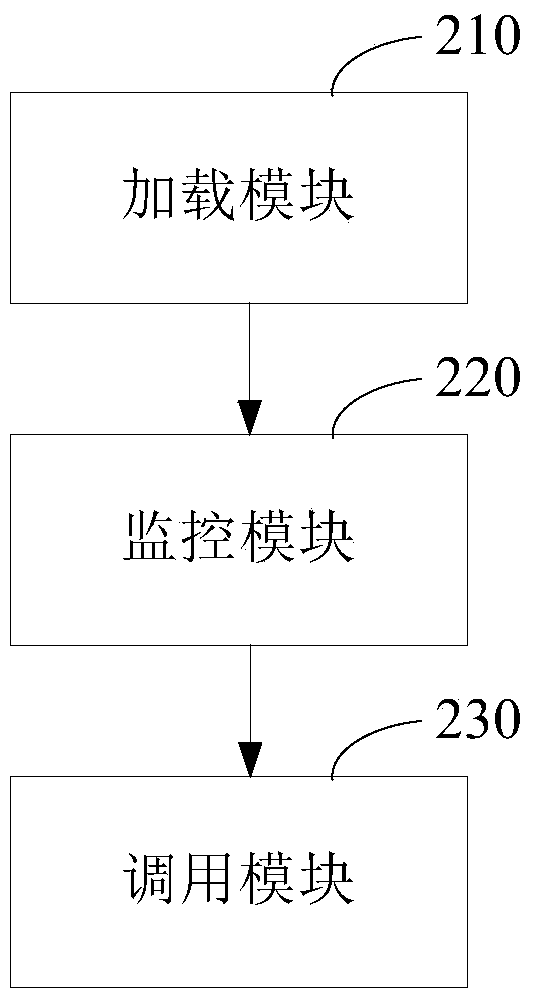

Method and device for running control of application programs

ActiveCN105975333AImprove operational efficiencyReduce error rateProgram initiation/switchingPlatform integrity maintainanceApplication softwareOperating system

The invention provides a method for running control of application programs. The method comprises the steps that an installation package which has the same package name with a host application program and is taken as an attached resource of the host application program is reflected and called, and a target application program implemented by the installation package is loaded, wherein resources required by the target application program have a one-to-one correspondence relationship with resources required by a native application program; a hook function is used to monitor activity processes of the target application program; and when the hook function monitors a calling instruction towards the activity processes of the target application program, the resources which are required by the native application program and have a one-to-one correspondence relationship with the resources required by the target application program can be called. The invention also provides a device for the running control of the application programs. By execution of the relevant resources of the target application program, an execution result which is completely the same with an execution result obtained by execution of the relevant resources of the native application program can be obtained; and the target application program is operated in a sandbox which is established by the host application program, so that installation and running activities are not sensed by a system.

Owner:BEIJING QIHOO TECH CO LTD

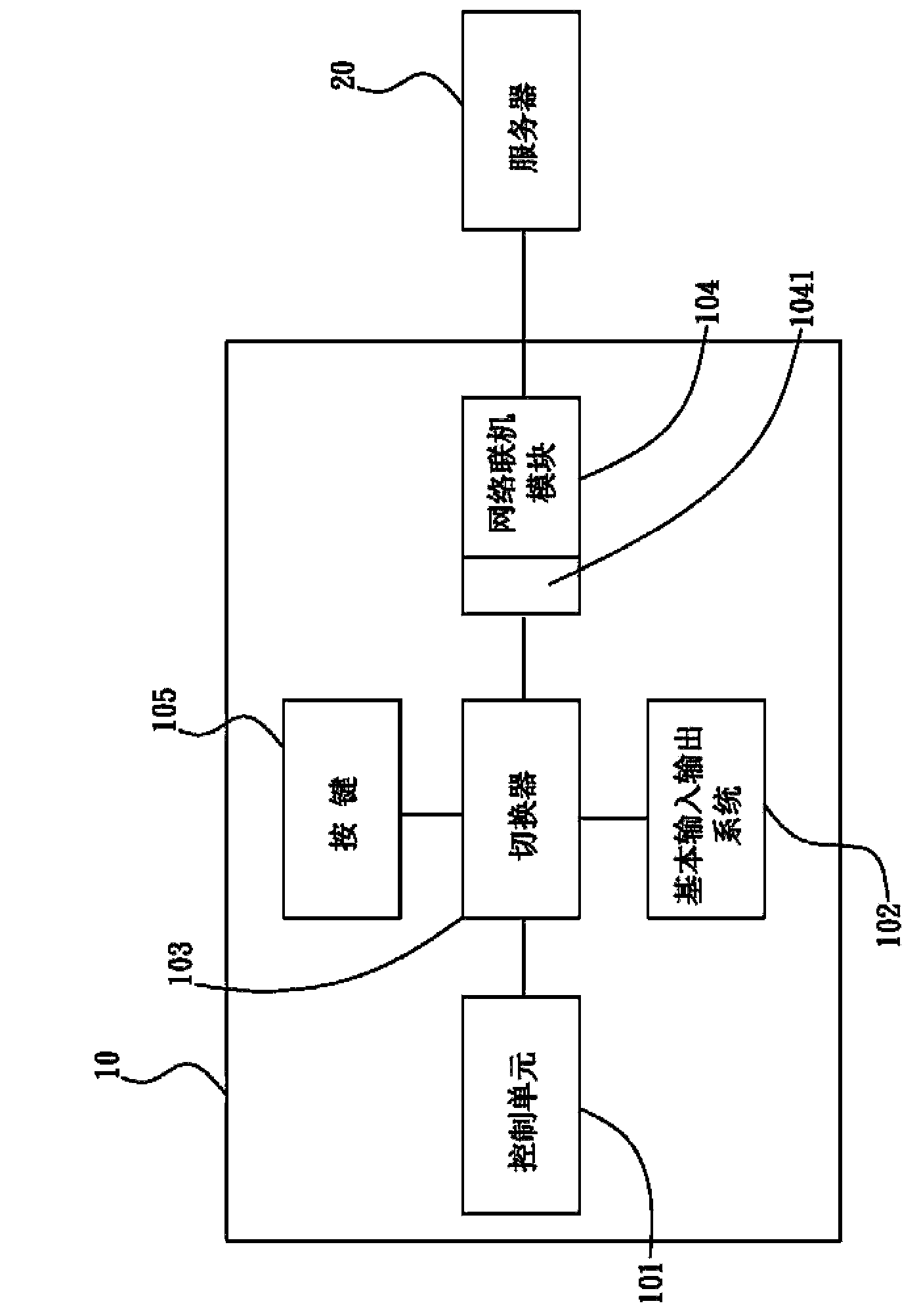

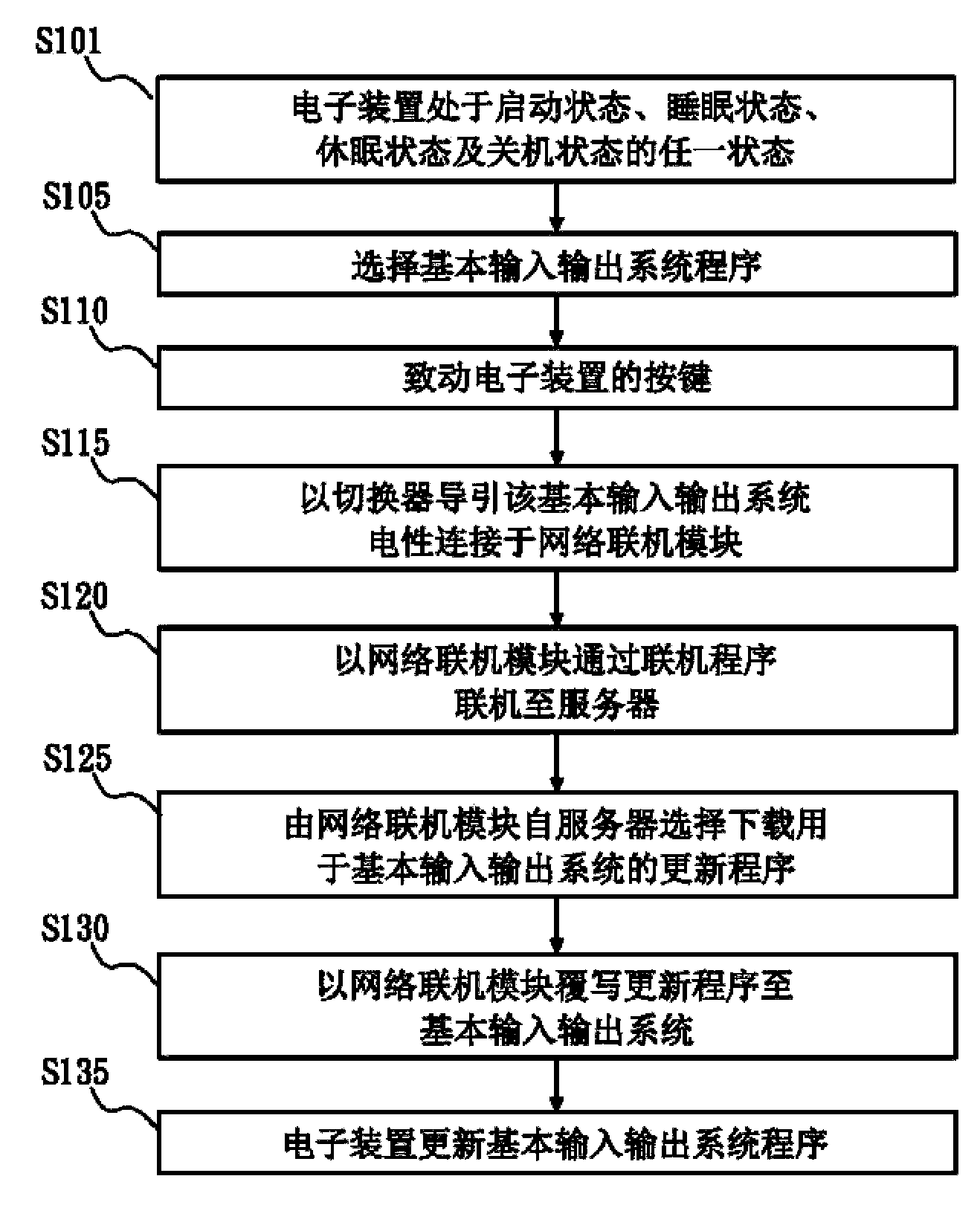

Electronic device having updatable bios and bios updating method thereof

ActiveCN103902329AGuaranteed normal operationNormal loadProgram loading/initiatingSelective content distributionNetwork connectionBIOS

An electronic device (10) having updatable BIOS (102) is used to perform a BIOS updating method. The electronic device (10) electrically connects to a server (20), in which update data is stored. The electronic device (10) includes a Basic Input / Output System (BIOS (102)), a network connection module (104) and a switch (103). A BIOS program is stored in the BIOS (102), and a connecting program is stored in the network connection module (104) for connecting to the server (20). When the electronic device (10) is updating, the BIOS (102) switches to electrically connect to the network connection module (104) via the switch (103), and the network connection module (104) connects to the server (20) by executing the connecting program, downloads the update data applying to the BIOS (102), and overwrites the update data to the BIOS (102) to update the BIOS program.

Owner:GIGA BYTE TECH CO LTD

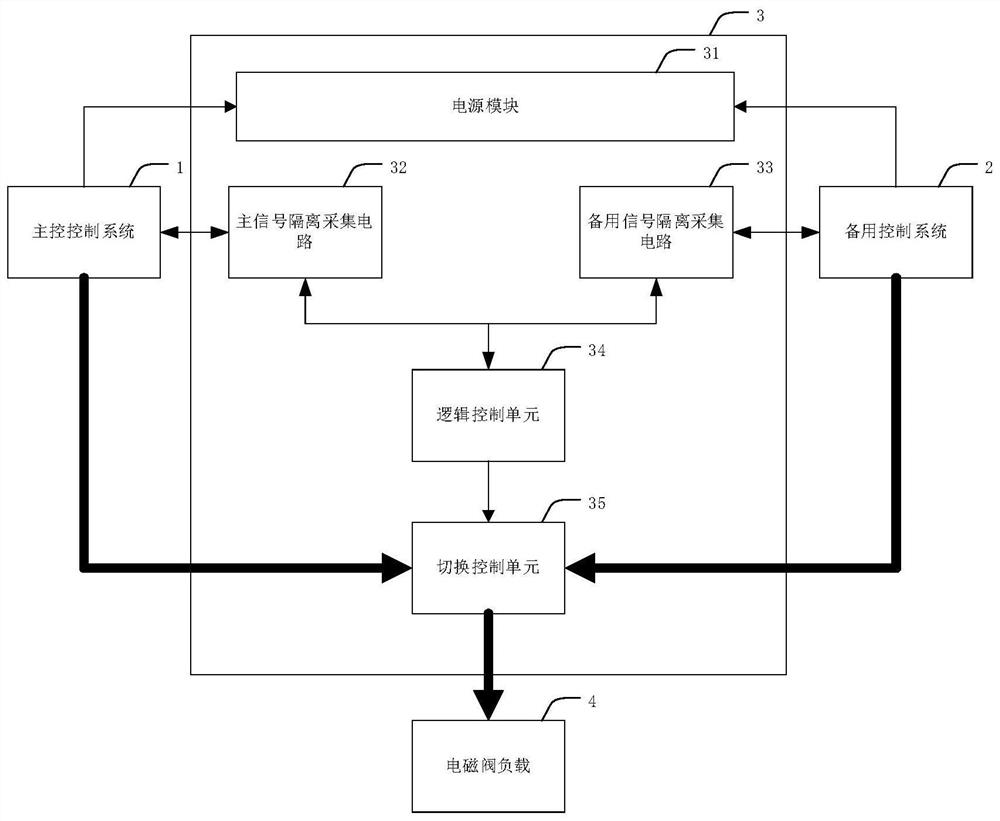

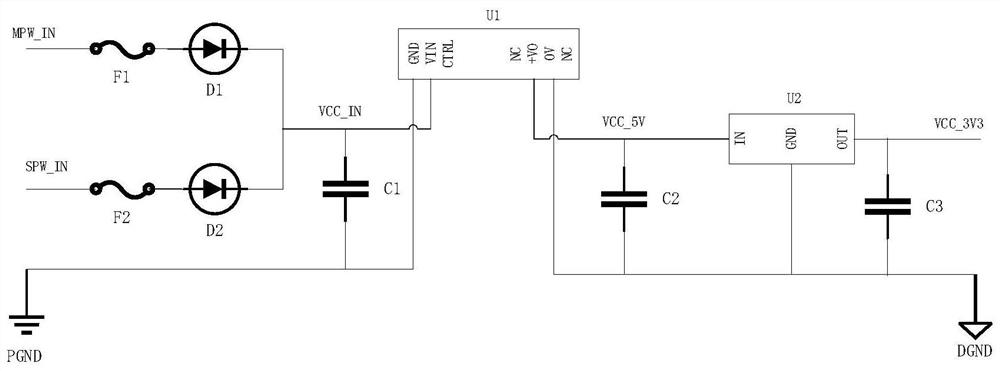

Redundancy switching device and control method thereof

The invention discloses a redundancy switching device and a control method thereof, which are mainly suitable for automatic switching control of a control system on load control of a marine diesel engine in a dual-control system mode. And the redundancy switching device receives a heartbeat control instruction and a control request instruction of the control system, carries out judgment accordingto an instruction signal of the control system, finally determines the ownership of the control right of the load, and switches the load to the control system with the control right for control through the switching of a switching control unit.

Owner:CHONGQING HONGJIANG MACHINERY

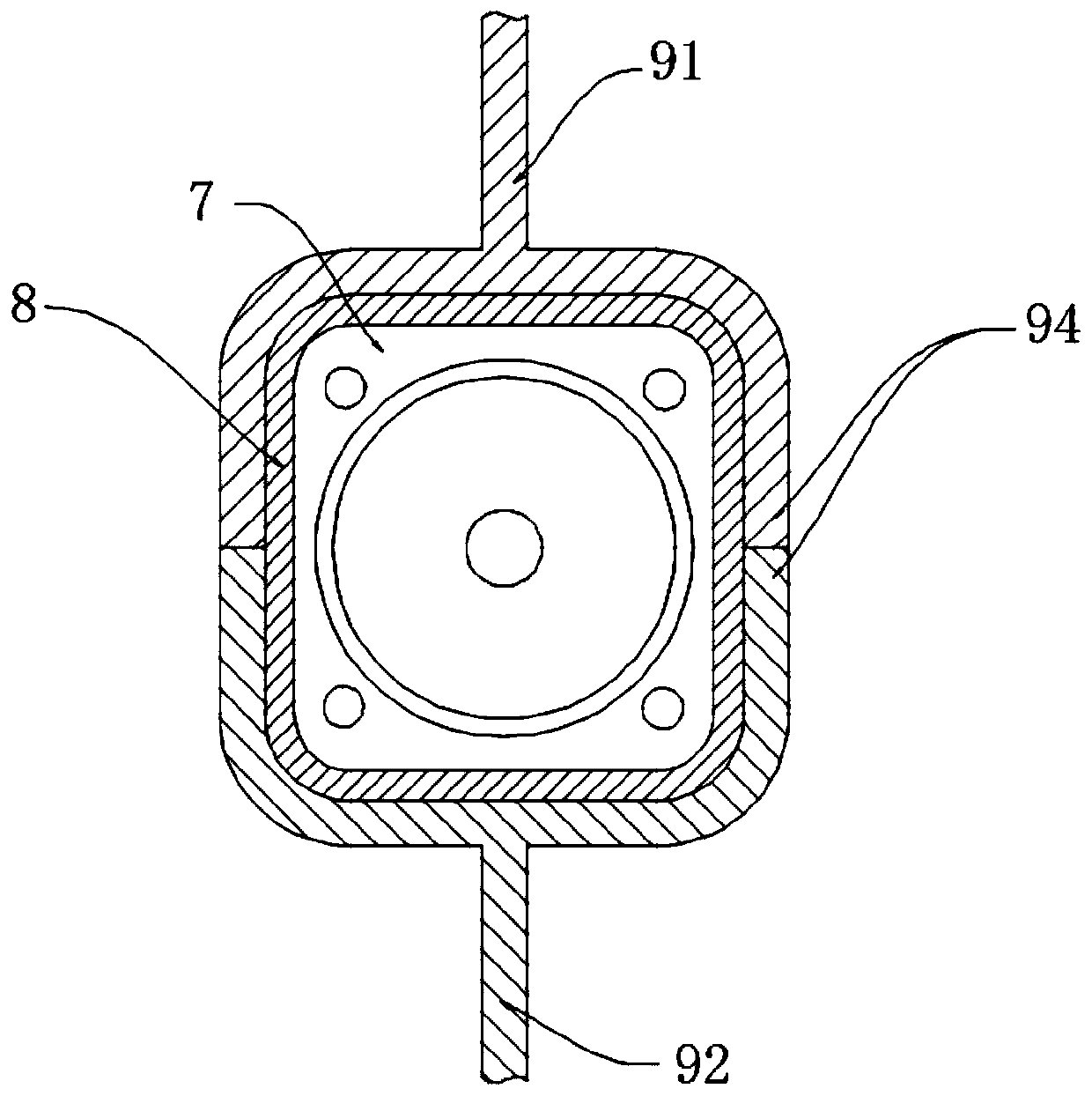

Filter screen anti-blocking device for dust collection equipment for textile

ActiveCN110947256ANormal loadNormal dust filtering operationDispersed particle filtrationTransportation and packagingElectrical conductorElectric machine

The invention discloses a filter screen anti-blocking device for dust collection equipment for textile. The filter screen anti-blocking device comprises a dust collecting box, a feeding port is formedin one side of the dust collecting box, a filter screen is arranged on the other side of the dust collecting box, an air chamber is fixedly connected to the side, close to the filter screen, of the dust collecting box, a baffle is connected into the air chamber in a sealed mode, and an impeller is arranged in the air chamber; and a rotation center of the impeller is fixedly connected with a rotating shaft, the rotating shaft penetrates through the baffle and is fixedly connected with a motor, and the motor is connected with a conductive structure. According to the invention, when the mesh ofthe filter screen is blocked, thermoelectricity is formed through the temperature difference generated by the residual heat of the motor, so that an electric plate close to one side of the filter screen is electrified, and dust in the filter screen is sucked under the action of electrostatic adsorption; and on the other hand, under the condition that the internal energy of the motor is larger, thevoltage at both ends of the motor is reduced through a thermistor, and a current is applied to a conductor ring, so that the temperature of the motor is lowered by the principle of temperature difference refrigeration, and the motor is prevented from being burnt out.

Owner:夏邑恒天永安新织造有限公司

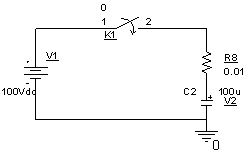

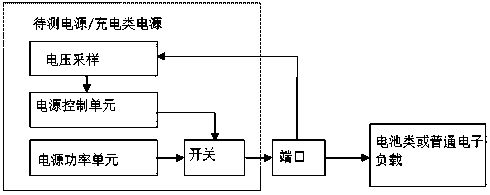

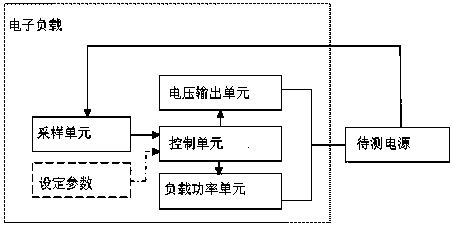

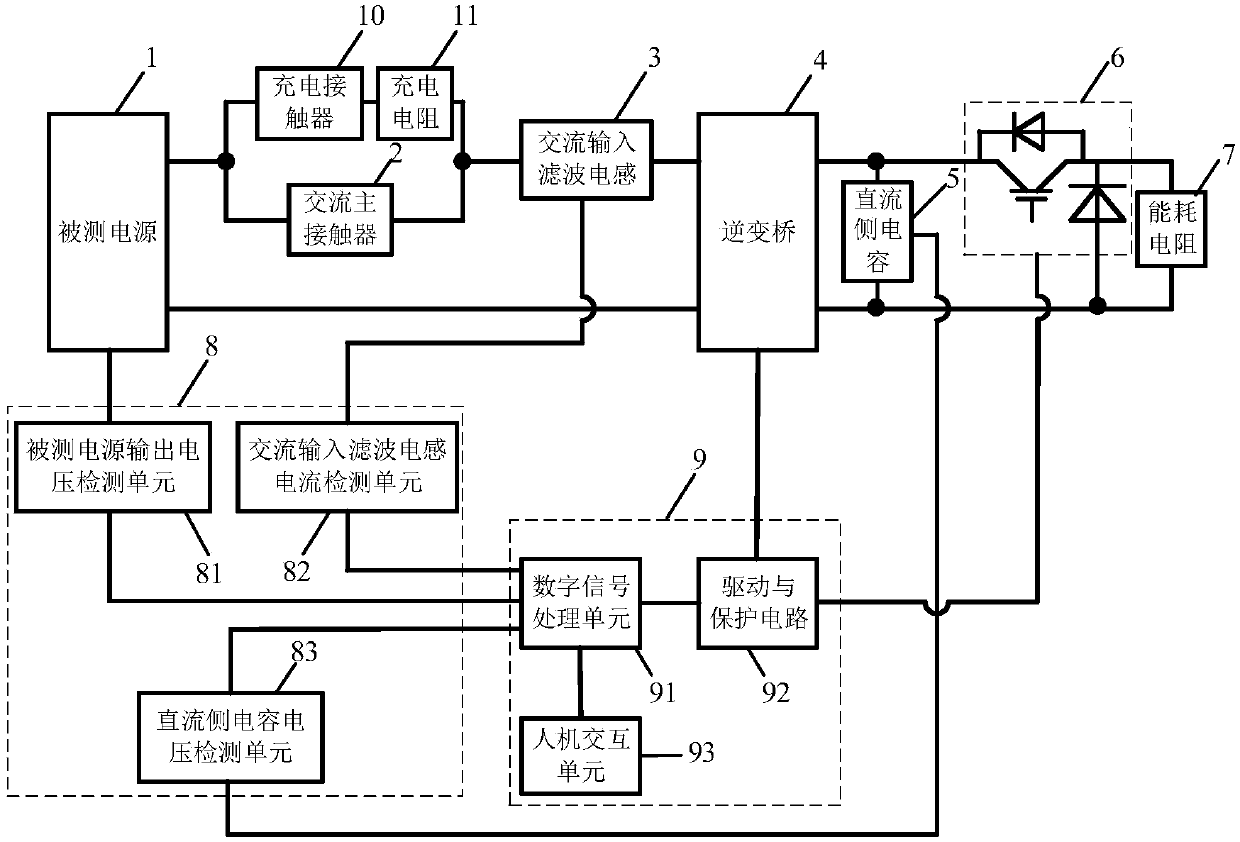

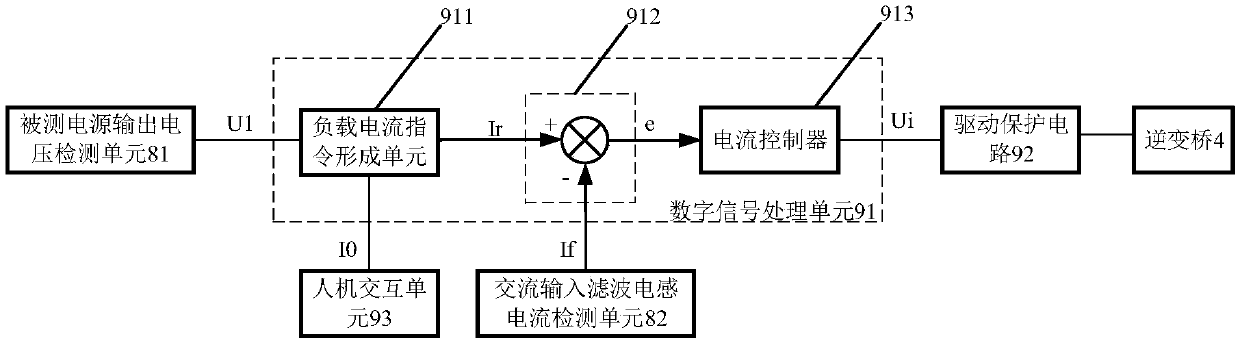

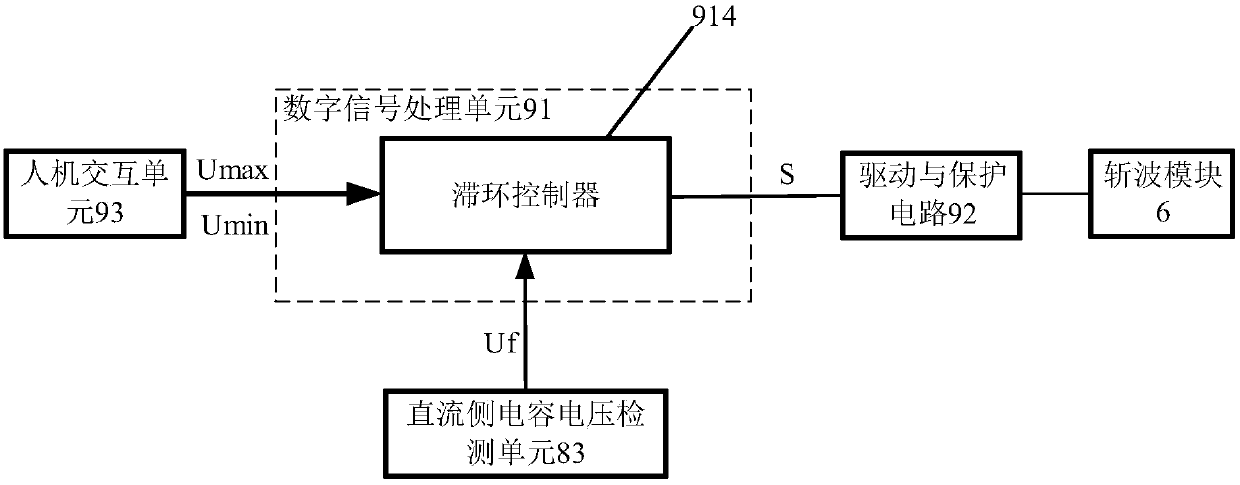

Programmed type electronic load device capable of generating voltage output and testing method

PendingCN108508379AEliminate instantaneous high currentNormal loadBase element modificationsPower supply testingCapacitancePower unit

The invention provides a programmed type electronic load device capable of generating voltage output and a testing method. The device comprises a load power unit, a control unit and a voltage output unit, the control unit control the voltage output unit according to independent voltage setting to output voltage to a load port so as to trigger a connected power source to be tested to turn on the output load power unit for performing load pulling; or the control unit controls the voltage output unit according to voltage of a sampled object to be tested to output the matched voltage at the outputend of the object to be tested to the load port, and connection between an electronic load and the object to be tested is opened so as to avoid current generated by the voltage difference of two equipment ports; the phenomenon that instant large current caused by a port capacitor and then self-protection and component loss of the power source to be tested are caused is eliminated; meanwhile, setvoltage is output through set parameters, the battery voltage is simulated, and the power source to be tested outputs energy to an electronic load device for performing normal load pulling.

Owner:ILD ELECTRONICS CO LTD

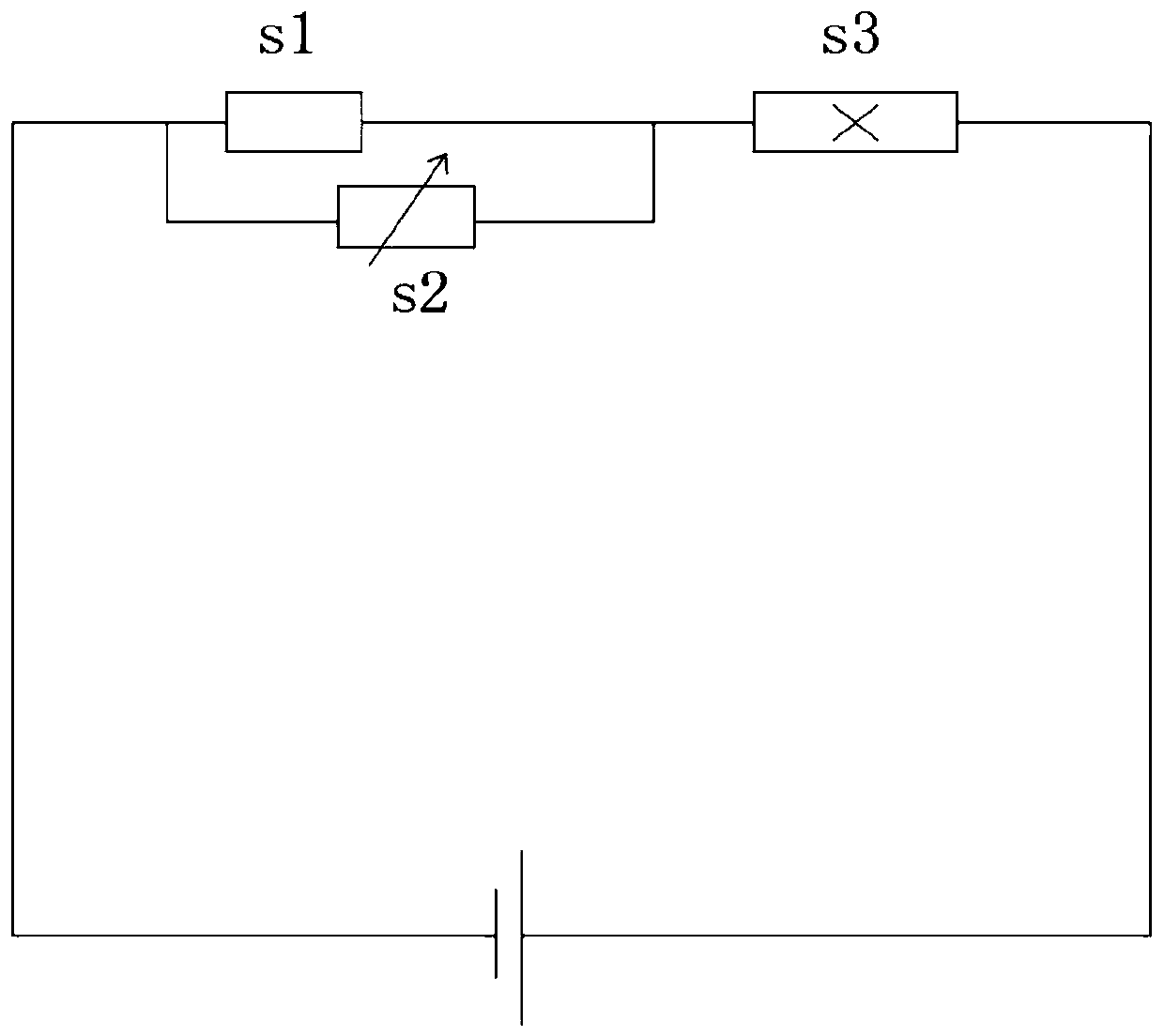

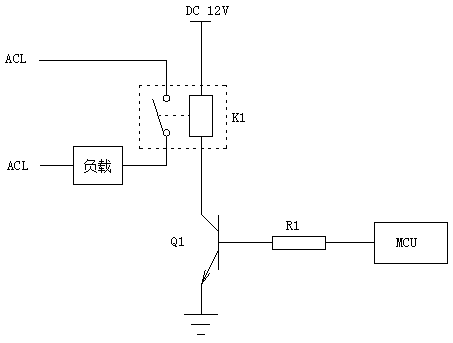

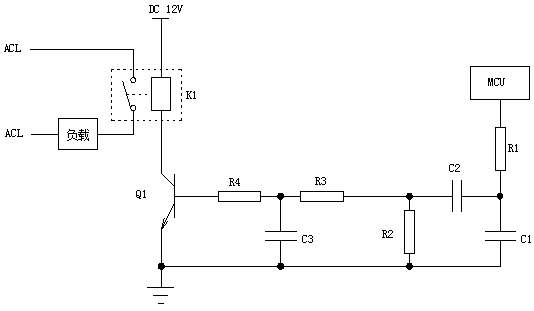

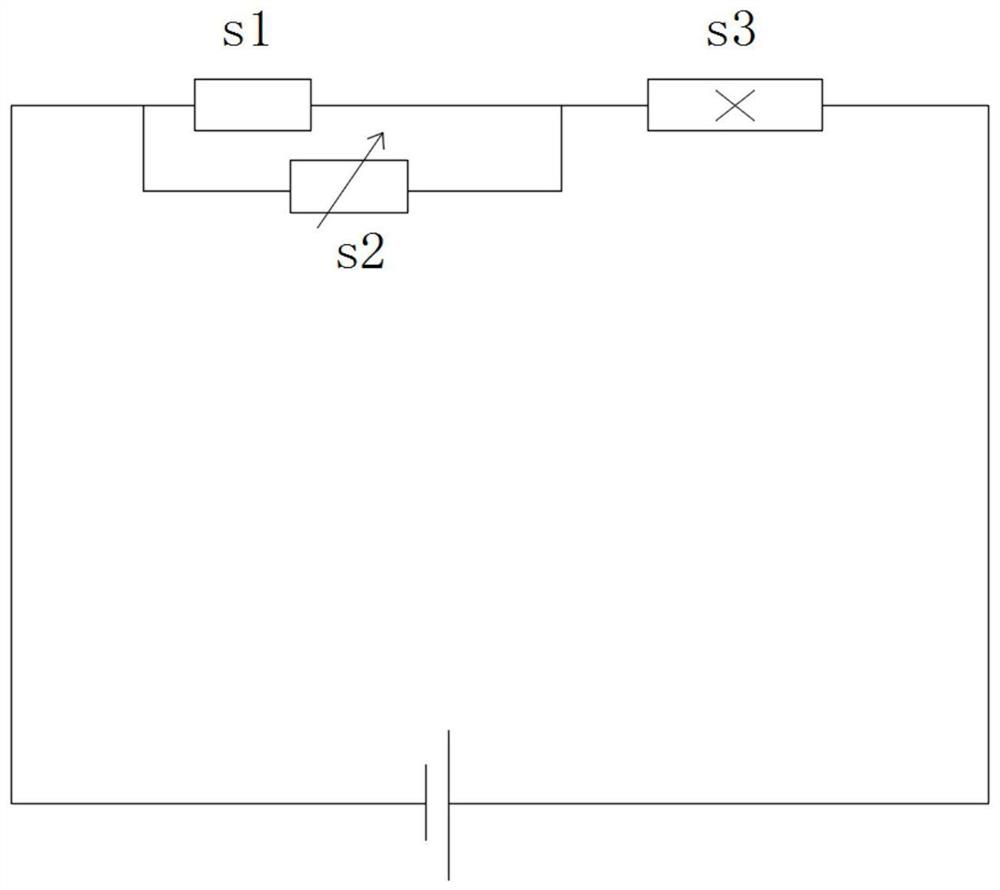

Load control circuit and its control method

ActiveCN105867225BGuaranteed to stop workingGuaranteed loadProgramme controlComputer controlControl signalBand-pass filter

The invention relates to a load control circuit and a control method thereof. The load control circuit comprises a low-pass filter, a high-pass filter, a driving circuit, an electronic switch and a relay circuit, wherein the low-pass filter, the high-pass filter, the driving circuit, the electronic switch and the relay circuit are successively connected. The low-pass filter is connected with the high-pass filter, thereby forming a band pass filter. The critical frequency of the low-pass filter is omega1, and the critical frequency of the high-pass filter is omega2, wherein omega1>omega2. The low-pass filter is used for connecting with the control signal output end of a controller. The band pass filter is used for performing gating processing on a control signal which is output from the control signal output end of the controller. The driving circuit is used for switching on and switching off the electronic switch according to the control signal after gating process and furthermore controlling the operation state of the relay circuit. The relay circuit is used for connecting and disconnecting a load and a power supply. The load control circuit and the control method thereof can settle a problem of easy accident caused by interference to the controller.

Owner:GUANGZHOU LIANTE ELECTRONICS TECH CO LTD

Application program operation control method and device

ActiveCN105975333BImprove operational efficiencyReduce error rateProgram initiation/switchingPlatform integrity maintainanceApplication softwareOperating system

The invention provides a method for running control of application programs. The method comprises the steps that an installation package which has the same package name with a host application program and is taken as an attached resource of the host application program is reflected and called, and a target application program implemented by the installation package is loaded, wherein resources required by the target application program have a one-to-one correspondence relationship with resources required by a native application program; a hook function is used to monitor activity processes of the target application program; and when the hook function monitors a calling instruction towards the activity processes of the target application program, the resources which are required by the native application program and have a one-to-one correspondence relationship with the resources required by the target application program can be called. The invention also provides a device for the running control of the application programs. By execution of the relevant resources of the target application program, an execution result which is completely the same with an execution result obtained by execution of the relevant resources of the native application program can be obtained; and the target application program is operated in a sandbox which is established by the host application program, so that installation and running activities are not sensed by a system.

Owner:BEIJING QIHOO TECH CO LTD

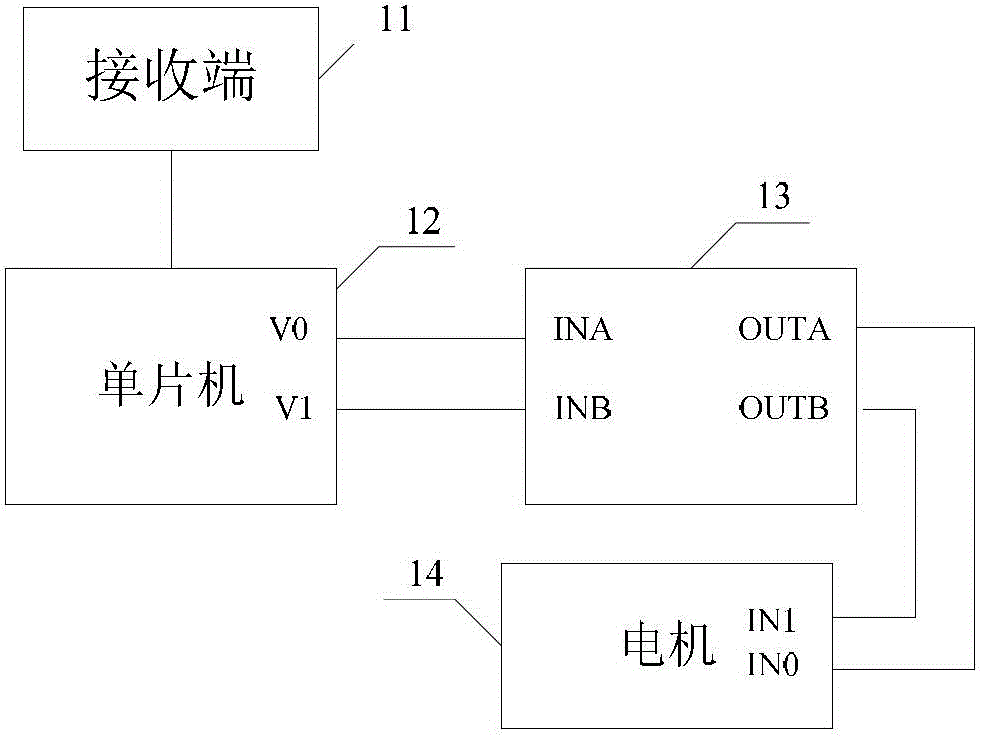

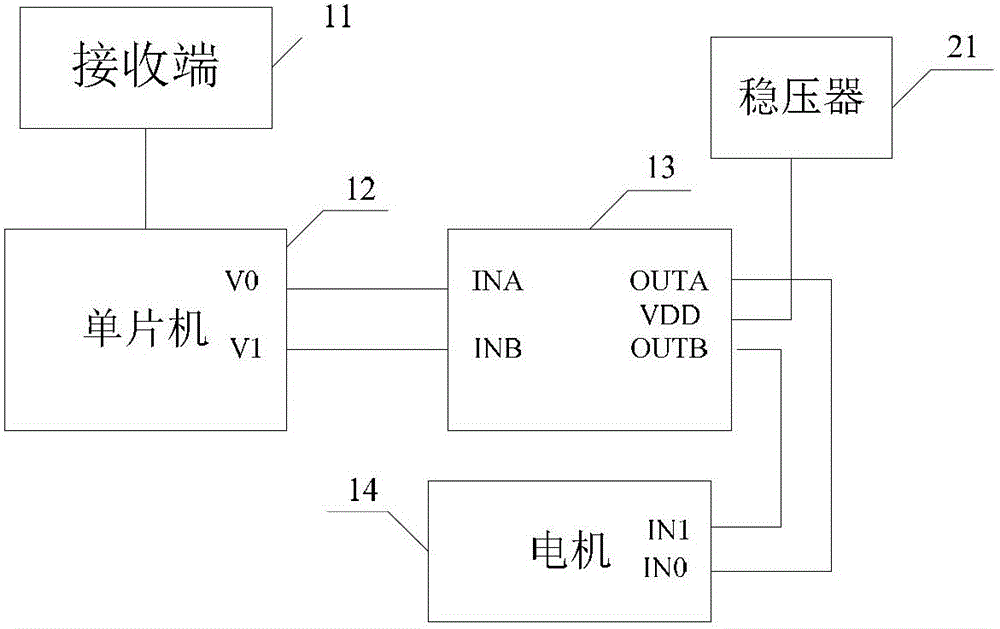

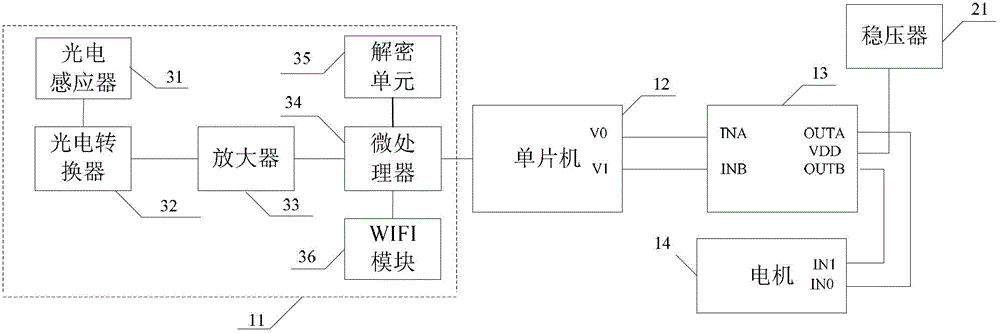

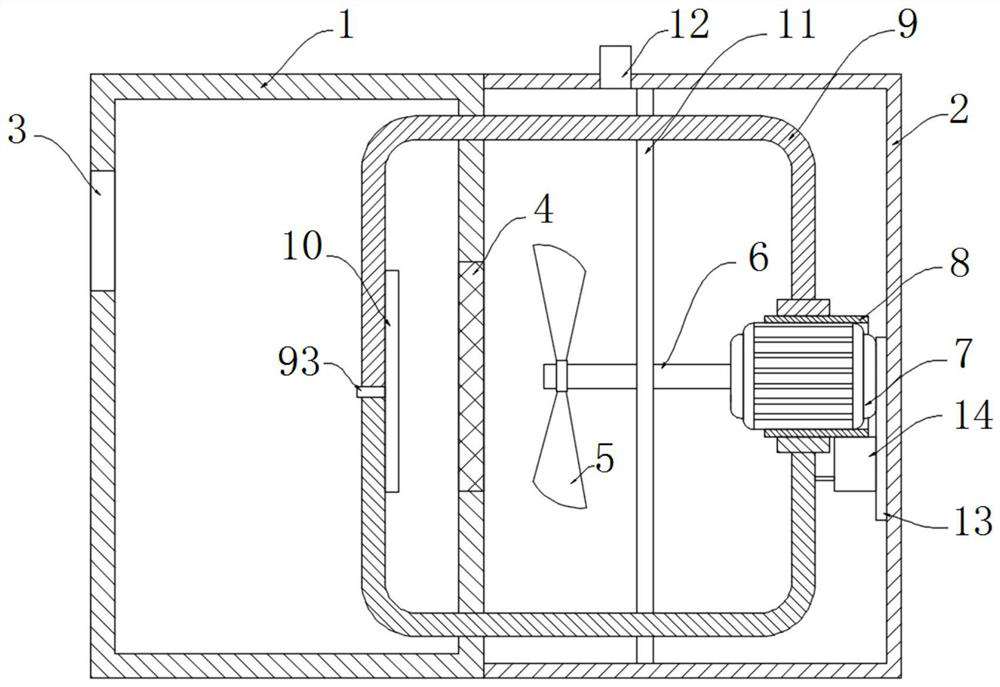

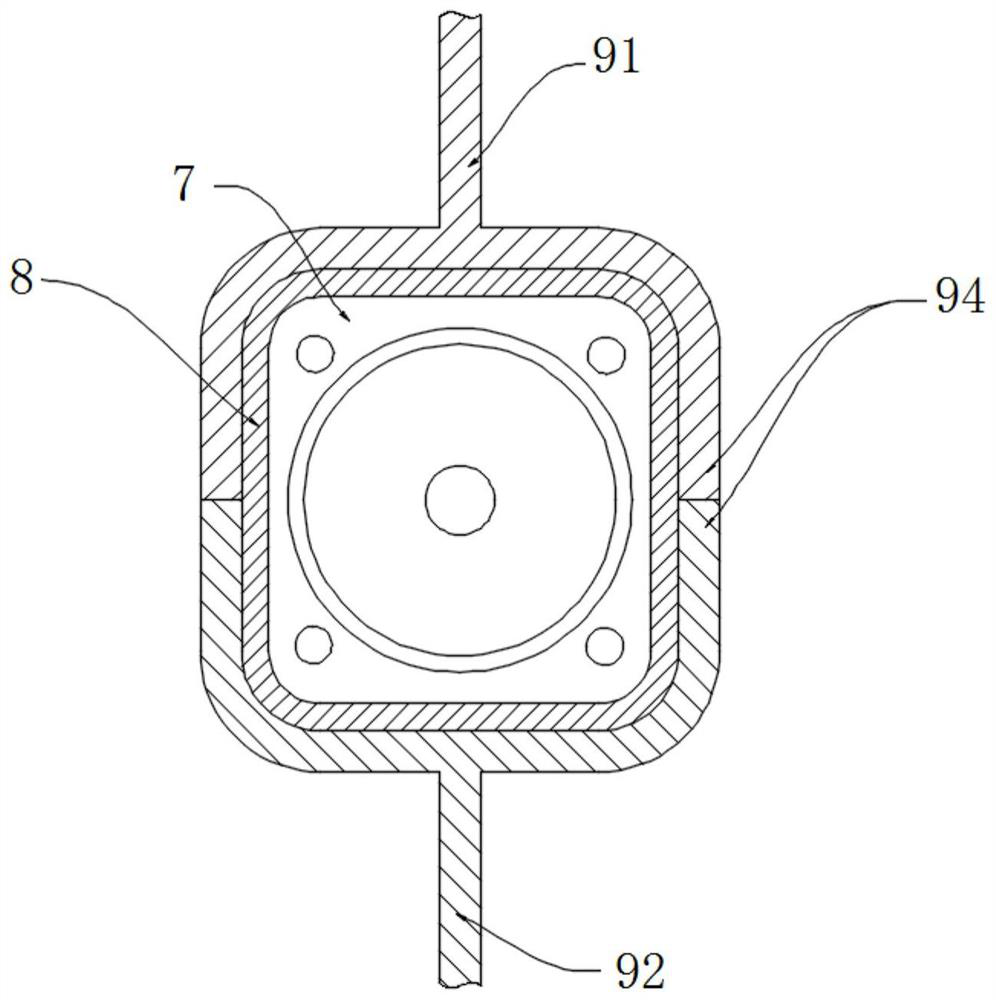

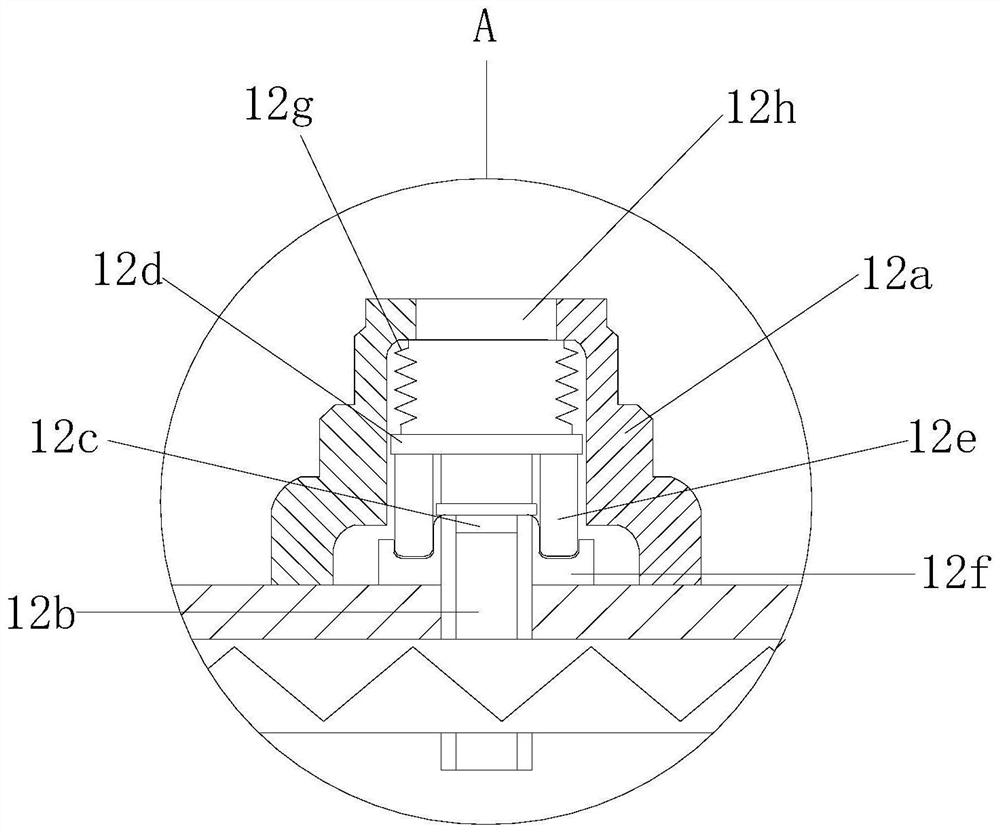

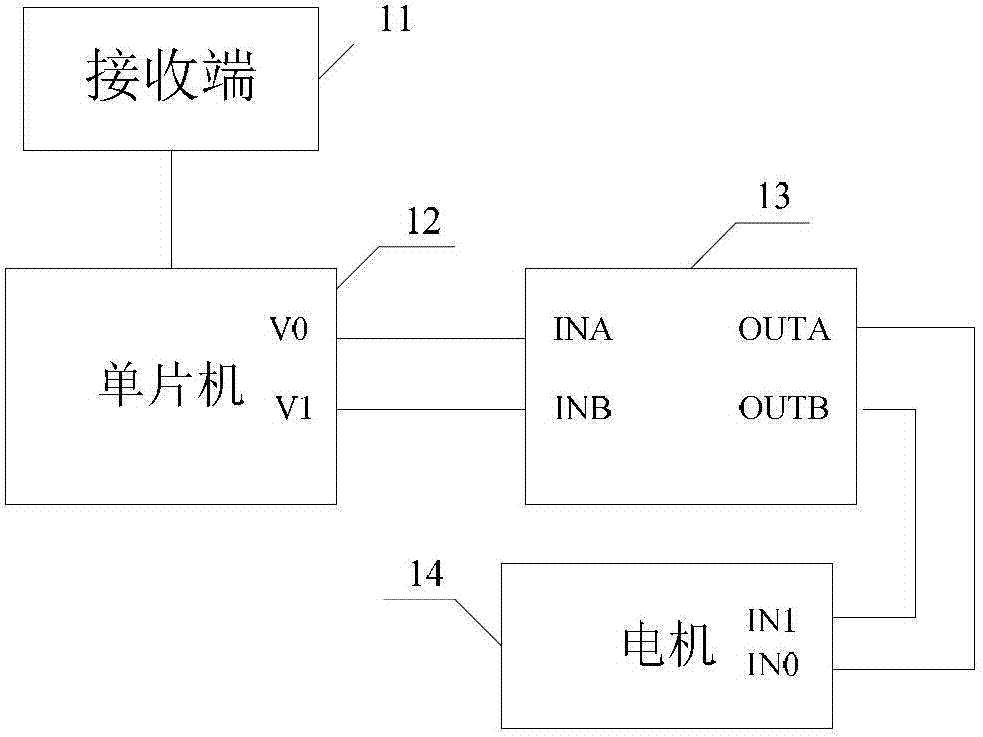

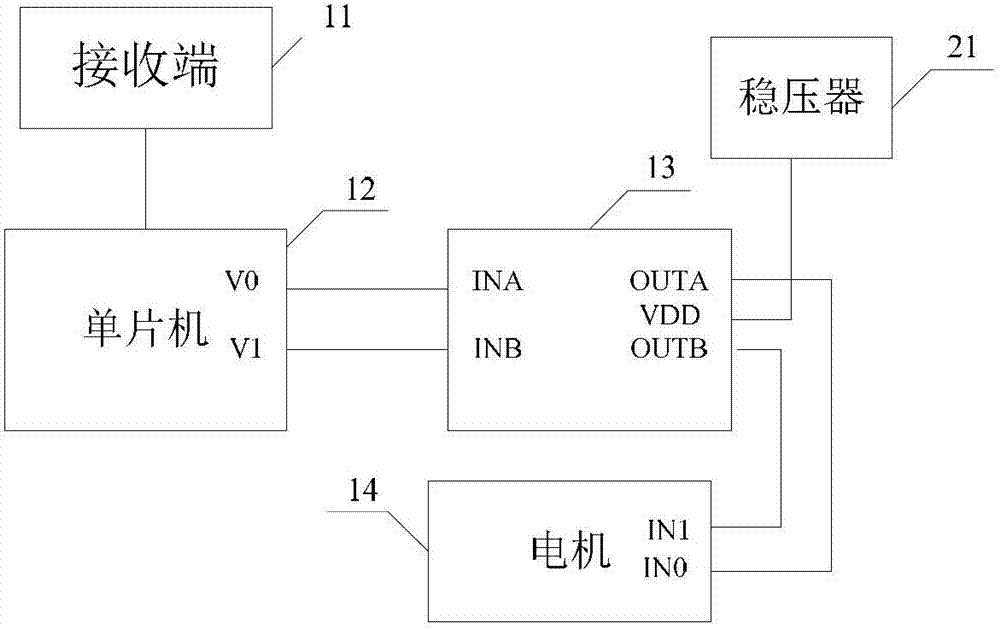

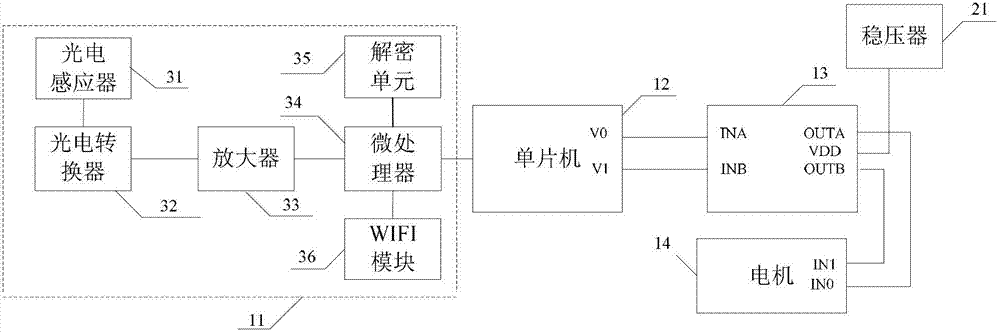

A light-controlled smart lock

ActiveCN102768776BBurn out preventionNormal loadIndividual entry/exit registersMicrocontrollerEngineering

The invention discloses a light control smart lock, which comprises a visible light signal receiving terminal and a singlechip connected with the receiving terminal, wherein a high level output end and a low level output end of the singlechip are respectively connected with a high level input end and a low level input end of a drive circuit, and a high level output end and a low level output end of the drive circuit are respectively connected with a high level input end and a low level input end of a motor. As a result, the utilization efficiency of the battery at the controlled end of the access control system can be improved, and the normal operation of the motor for the gate lock can be ensured.

Owner:KUANG CHI INTELLIGENT PHOTONIC TECH

Anti-clogging device for filter screen of textile vacuum equipment

ActiveCN110947256BNormal loadNormal dust filtering operationDispersed particle filtrationTransportation and packagingElectrical conductorElectric machine

The invention discloses an anti-blocking device for a filter screen of a dust collection device for textiles, which comprises an ash collection box, a feed opening is opened on one side of the ash collection box, and a filter screen is provided on the other side of the ash collection box. An air chamber is fixedly connected to the side of the ash collecting box close to the filter screen, a baffle is sealed in the air chamber, an impeller is arranged in the air chamber, and a rotating shaft is fixedly connected to the center of rotation of the impeller. The rotating shaft runs through the baffle and the rotating shaft is fixedly connected with a motor, which is connected with a conductive structure. In the present invention, when the filter screen is clogged, the temperature difference generated by the residual heat of the motor is used to form a thermoelectricity, so that the electric plate near the filter screen is electrified. Under the action of electrostatic adsorption, the dust in the filter is sucked off. On the other hand, when the internal energy of the motor is large, the voltage at both ends of the motor is reduced through the thermistor and the current is applied to the conductor ring, so that the principle of temperature difference refrigeration is used. The temperature of the motor drops to avoid burning out the motor.

Owner:夏邑恒天永安新织造有限公司

Document restoration method, system, readable storage medium and computer device

ActiveCN107479910BNormal loadImplement modificationSemi-structured data indexingProgram loading/initiatingRestoration methodEngineering

The invention provides a document restoration method and system, a readable storage medium and computer equipment. The method comprises the steps that whether all the XSD documents in a current selected file directory contain wrong reference information or not is judged; if yes, the corresponding imported XSD documents are searched for according to the associated reference information related to the wring reference information; the wrong reference information is modified to be consistent with the corresponding information in the imported XSD documents. According to the document restoration method, the wrong imported information in XSD files can be repaired.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD +1

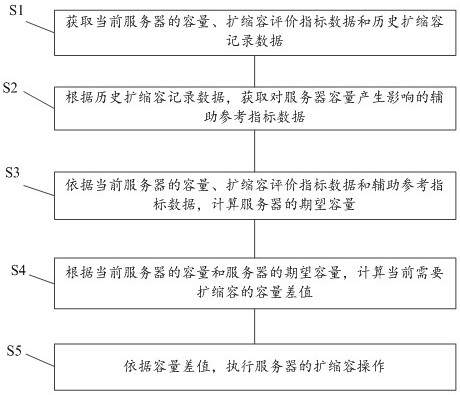

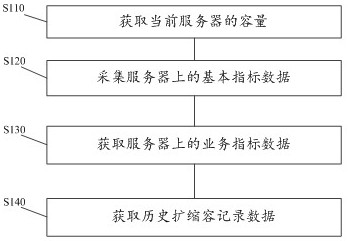

A kind of server automatic intelligent expansion and contraction method and system

ActiveCN113032157BSafe and stable continuous operationNo waste of resourcesResource allocationHardware monitoringData packEngineering

Owner:睿至科技集团有限公司

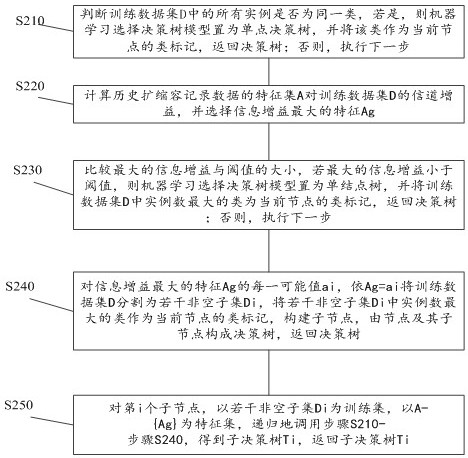

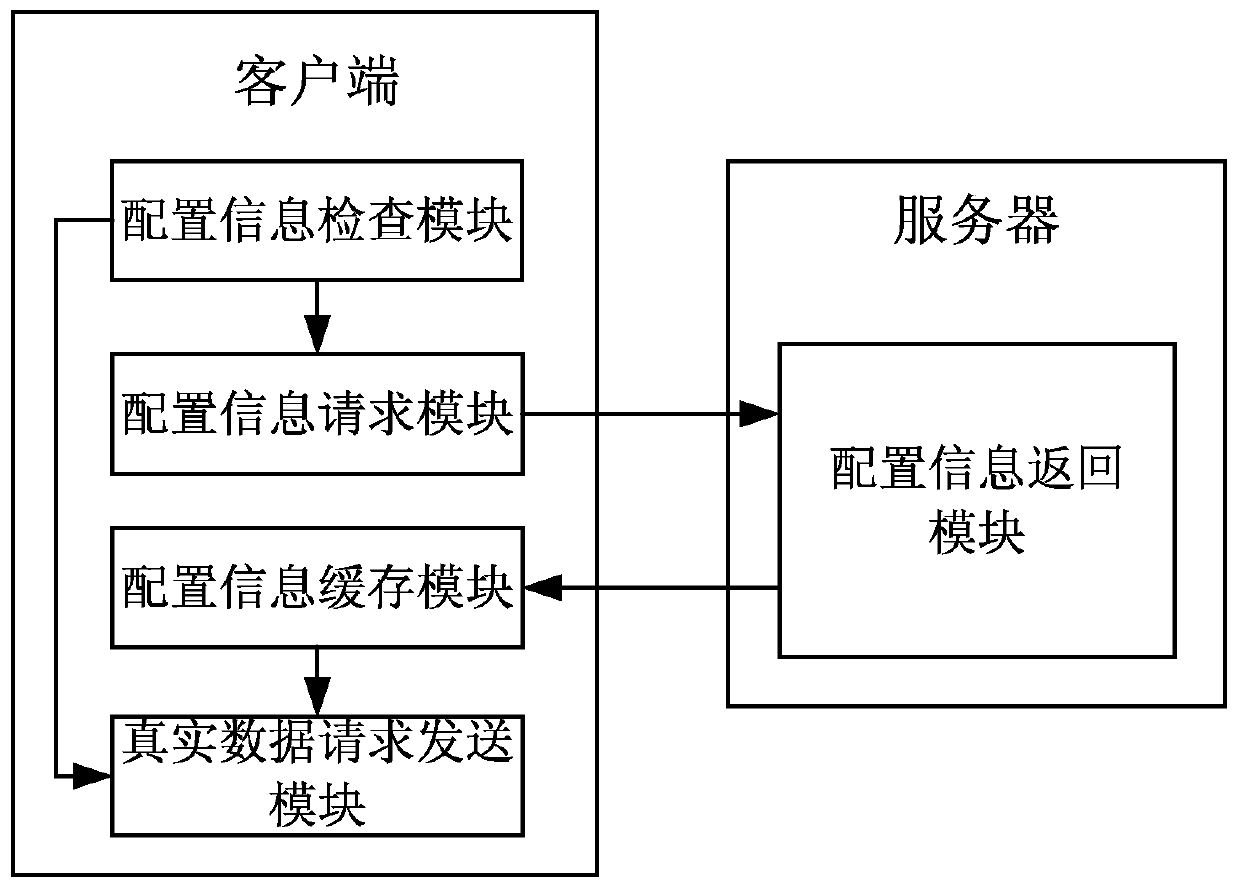

A method, storage medium, device and system for reducing the number of function page requests

ActiveCN107612982BSolve the problem of returning empty dataRelieve pressureProgram loading/initiatingExecution for user interfacesClient-sideData interface

The invention discloses a method, a storage medium, a device and a system for reducing the number of function page requests, and relates to the technical field of application program development. The method includes: the client checks whether there is data request configuration information in the local configuration file, and if so, directly sends a data request for a corresponding type of functional partition to a corresponding data interface of the server according to the data request configuration information in the current local configuration file; If not, send a configuration request to the server to request configuration information. When the client successfully receives the data request configuration information returned by the server, write the data request configuration information into the local configuration file, and then request the configuration information according to the data A data request for a corresponding type of functional partition is sent to a corresponding data interface of the server. The invention can reduce the number of function page requests, avoid sending useless requests, reduce server pressure, and save client traffic overhead.

Owner:WUHAN DOUYU NETWORK TECH CO LTD

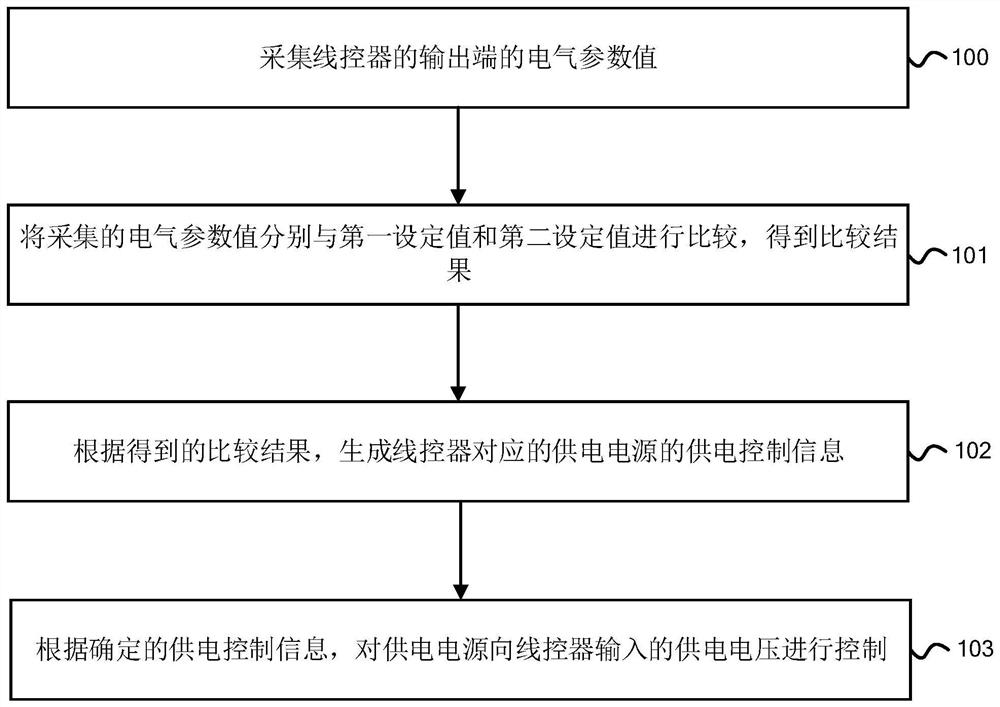

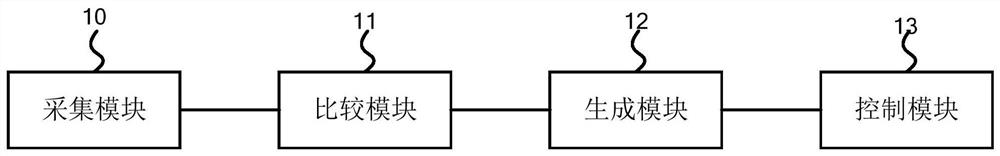

Power management method, device and multi-connection system

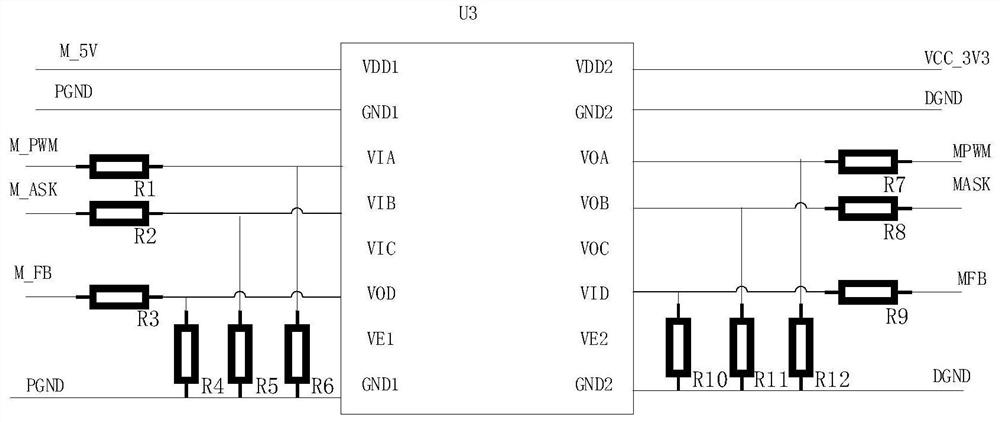

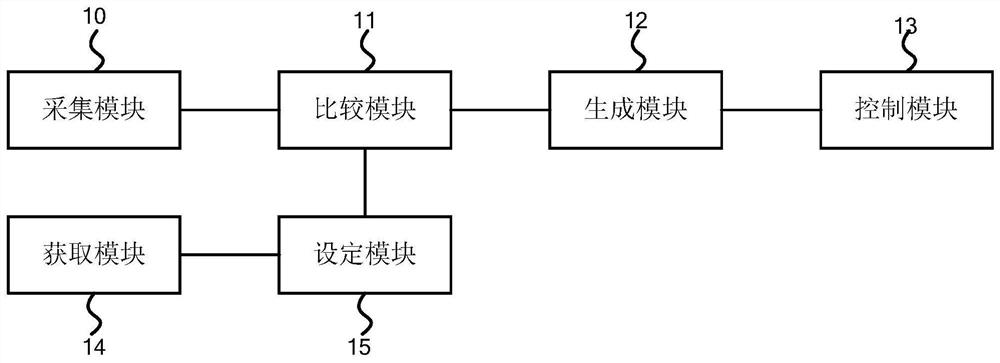

ActiveCN111089413BNormal loadMechanical apparatusSpace heating and ventilation safety systemsControl engineeringCarrier signal

The present invention relates to a power management method, device and multi-connection system. The method includes: collecting the electrical parameter value of the output terminal of the wire controller; and comparing the electrical parameter value with the first set value and the second set value respectively , to obtain a comparison result; wherein, the first set value is smaller than the second set value; according to the comparison result, generate power supply control information of the power supply corresponding to the wire controller; according to the power supply control information Controlling the power supply voltage input from the power supply to the wire controller, so that the wire controller outputs electrical parameters that match the load corresponding to the wire controller, realizing dynamic adjustment of the power supply to the wire controller The power supply voltage input by the wire controller. By adopting the technical solution of the present invention, under the condition of long-distance power carrier communication, the load corresponding to the wire controller can be normally supplied with power.

Owner:GREE ELECTRIC APPLIANCES INC

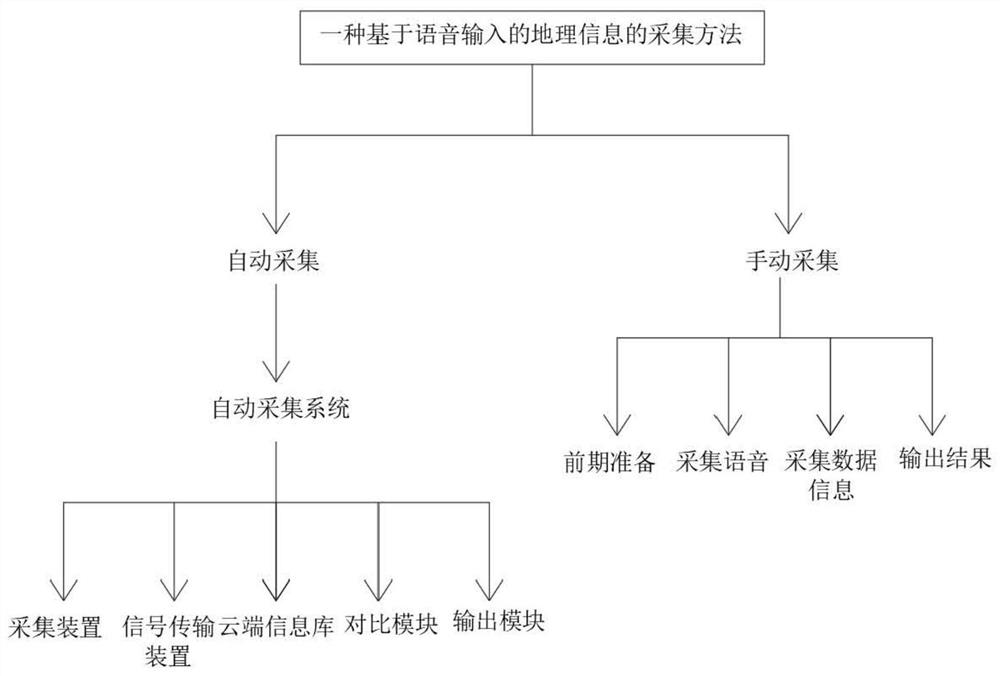

Geographic information acquisition method based on voice input

PendingCN111611272AScientific and reasonable structureEasy to useSpeech analysisGeographical information databasesInformation repositoryTelecommunications

The invention discloses a geographic information acquisition method based on voice input. The acquisition method comprises automatic acquisition and manual acquisition. The automatic acquisition is directly carried out through an acquisition device, data conversion is carried out on the automatic acquisition, and then external transmission and storage are carried out; the manual acquisition needspersonnel to arrive at the scene to input related technical data and obtain geographic information, the automatic acquisition comprises an automatic acquisition system, and the automatic acquisition system comprises an acquisition device, a signal transmission device, a cloud information base, a comparison module and an output module; the system is scientific and reasonable in structure and safe and convenient to use, collection in different environments and different fields is facilitated through automatic collection and manual collection, convenience of geographic information collection is achieved, proper operation according to places is achieved, and great convenience is brought to operators and collectors.

Owner:陕西天泽中孚实业有限公司

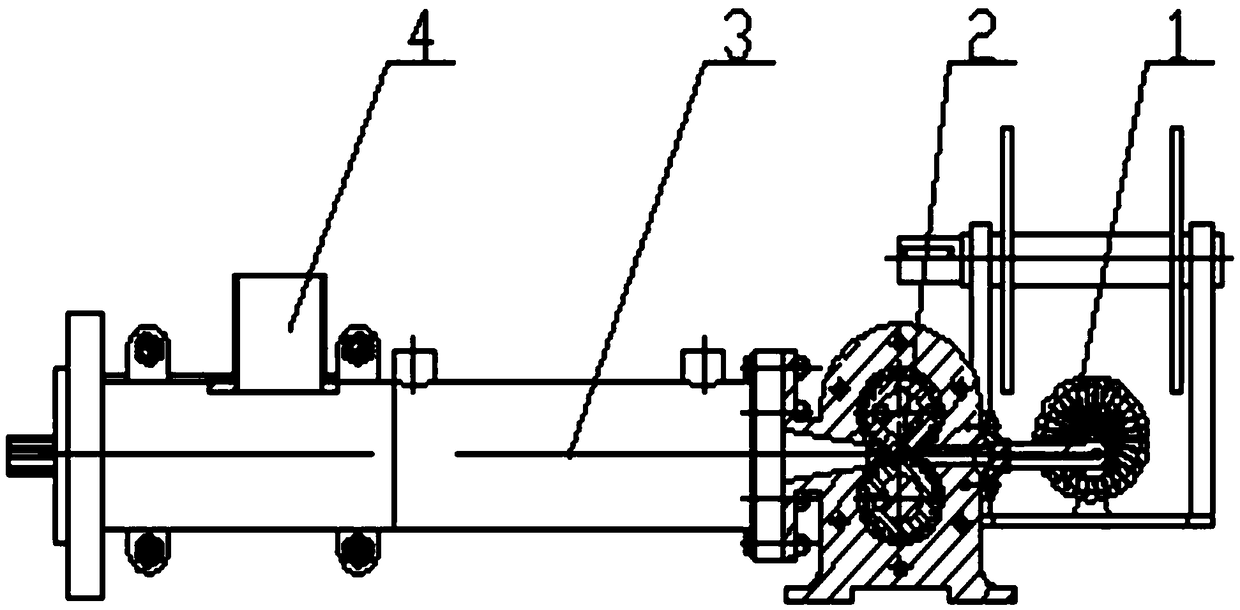

Extrusion device with gear pump

The invention discloses an extrusion device with a gear pump, and relates to the field of steel wire manufacturing equipment. Outlet glue flow is sufficient, extruder load is normal, and the temperature of a machine body is normal. The extrusion device comprises a machine head, the gear pump, an extruder and a feeding hole, wherein the feeding hole is connected with the extruder; the output end ofthe extruder is accessed into the gear pump; and the output end of the gear pump is connected with the machine head. During work, materials are filled from the feeding hole, are led into the extruder, and are led into the gear pump after being processed by the extruder, so that the gear pump pressurizes glue stock, the pressurized glue stock enters the machine head, and the machine head is used to perform steel wire gluing. The extruded glue stock is pressurized by the gear pump, so that the flow size is increased, and therefore, load of the extruder is reduced, the machine body temperature of the extruder is relatively low, and the problems that the glue stock temperature is too high, and the gluing effect is not good are avoided.

Owner:无锡市江南橡塑机械有限公司

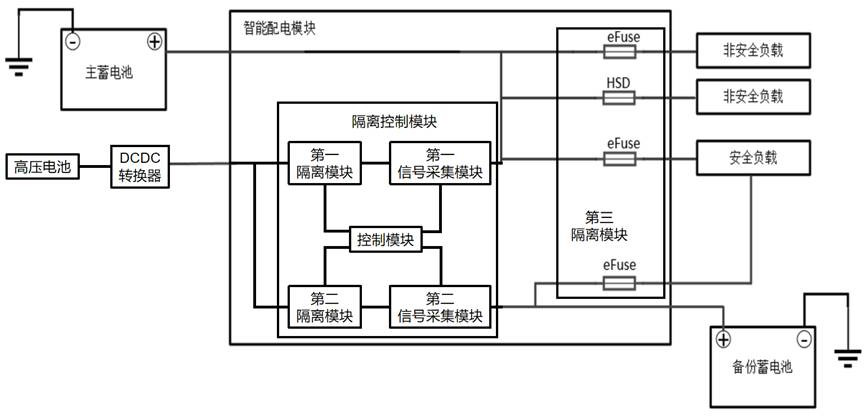

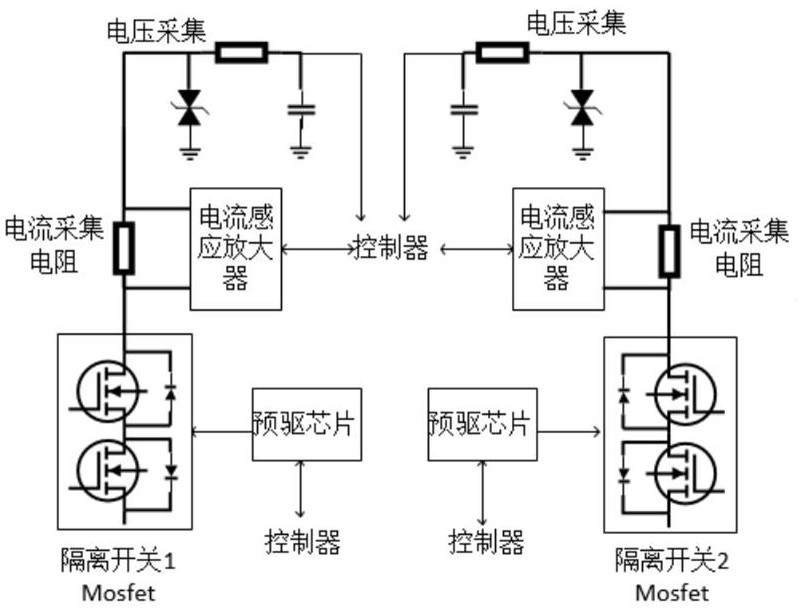

Intelligent power distribution module and power supply system

PendingCN114614542AAvoid load abnormal workAvoid abnormal work of safety loadCircuit monitoring/indicationElectric devicesControl engineeringComputer science

The invention discloses an intelligent power distribution module and a power supply system. The intelligent power distribution module comprises an isolation control module. The isolation control module comprises a first isolation module and a first signal acquisition module which are connected, a second isolation module and a second signal acquisition module which are connected, and a control module; the control module is respectively connected with the first isolation module, the first signal acquisition module, the second isolation module and the second signal acquisition module; and the control module is used for controlling the first isolation module to execute corresponding operation according to the current and / or voltage signal of the first loop acquired by the first signal acquisition module, and controlling the second isolation module to execute corresponding operation according to the current and / or voltage signal of the second loop acquired by the second signal acquisition module. According to the invention, the cost and weight can be greatly reduced, the system design difficulty is reduced, the isolation range is improved, and the maintenance difficulty is reduced.

Owner:ZHIJI AUTOMOTIVE TECH CO LTD

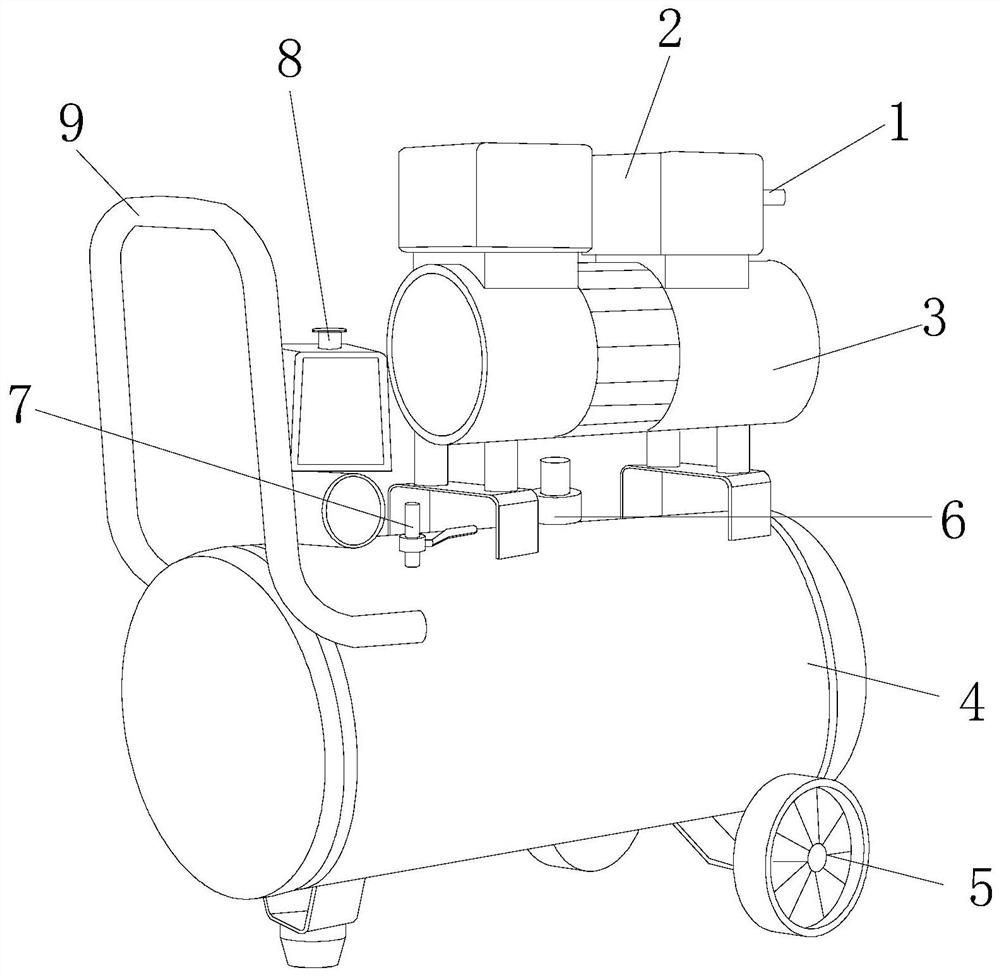

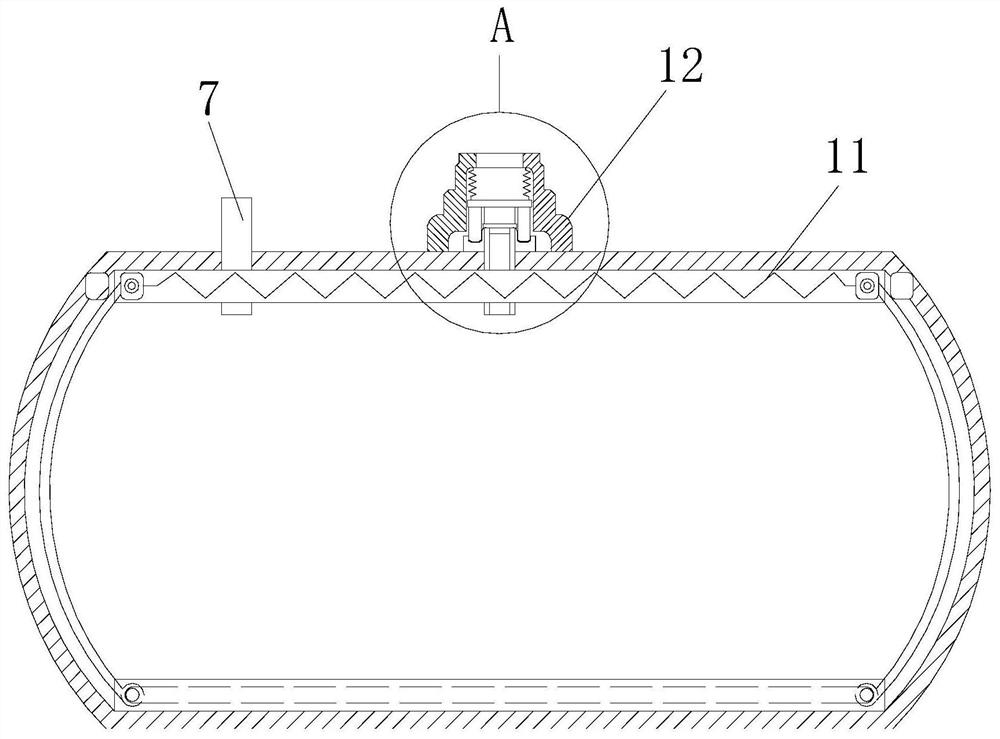

An easy-to-move oil-free air compressor

ActiveCN110454358BNormal loadPrevent hot startPositive displacement pump componentsPiston pumpsElectric machineryAir cleaning

The invention discloses an oil-free air compressor capable of being easy to move, and the oil-free air compressor structurally comprises a suction nozzle, a machine head, a driving machine, a compression air cylinder, a movable roller, an air purge and pressure relief device, a gas outlet valve, a switch and a push-pull handle. The suction nozzle is arranged on the side of the machine head and iscommunicated with the machine head, the driving machine is arranged on the top of the compression air cylinder and is connected with the machine head, and the moving roller is arranged on the bottom four ends of the compression air cylinder. According to an opposite air purge mechanism which is arranged on the compression air cylinder, two purge push plates are used to slide from both sides of thecompression air cylinder to the middle of the compression air cylinder oppositely and the remaining air is concentrated in the middle position of the compression air cylinder when the compressor is powered off; and meanwhile, according to an electromagnetic pressure release mechanism which is arranged in the middle of the compression air cylinder, the electromagnetic magnetic loss can open the pressure relief valve, and the electromagnetic pressure relief mechanism and the opposite air cleaning mechanism can cooperate to clear all the air, prevent the equipment from starting with pressure, ensure the motor load is normal, protect the motor and mechanical parts, and prolongs the service life.

Owner:佛山市威盈加科技有限公司

Light control smart lock

ActiveCN102768776ABurn out preventionNormal loadIndividual entry/exit registersMicrocontrollerElectric machinery

The invention discloses a light control smart lock, which comprises a visible light signal receiving terminal and a singlechip connected with the receiving terminal, wherein a high level output end and a low level output end of the singlechip are respectively connected with a high level input end and a low level input end of a drive circuit, and a high level output end and a low level output end of the drive circuit are respectively connected with a high level input end and a low level input end of a motor. As a result, the utilization efficiency of the battery at the controlled end of the access control system can be improved, and the normal operation of the motor for the gate lock can be ensured.

Owner:KUANG CHI INTELLIGENT PHOTONIC TECH

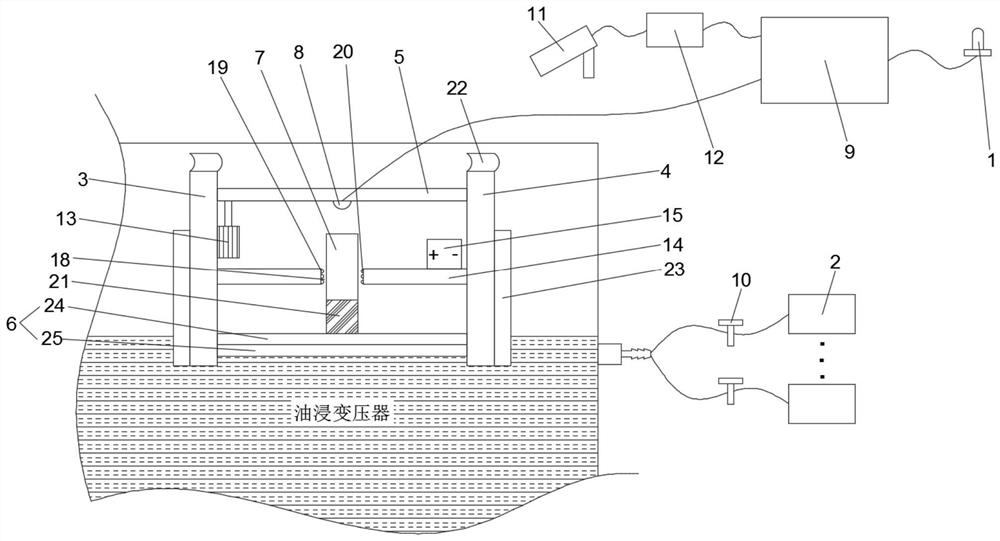

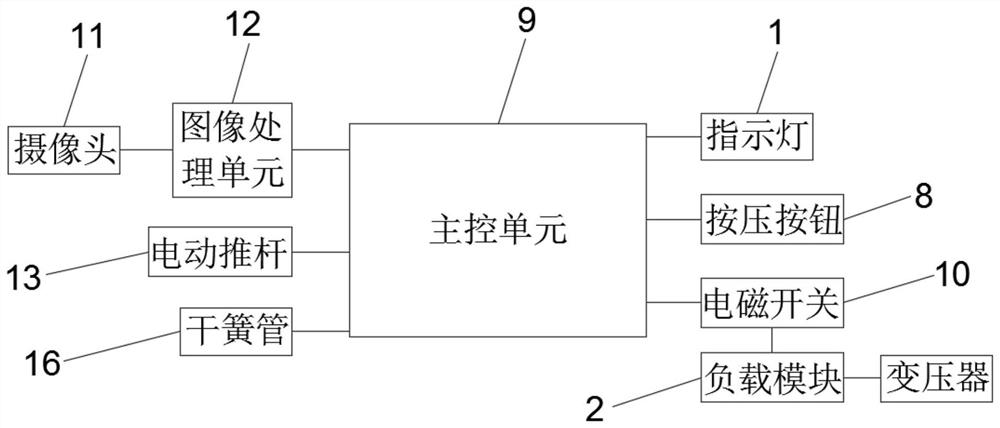

A Transformer Comprehensive Load Capacity Evaluation System

ActiveCN112577765BEasy loadingPrevent affecting power consumptionThermometers using material expansion/contactionStructural/machines measurementTransformerControl engineering

The invention provides a transformer comprehensive load capacity evaluation system, an oil temperature detection mechanism, an evaluation module, an indicator light and several load modules. The oil temperature detection mechanism includes a first straight rod, a second straight rod, an adjustment rod, and a thermal bimetallic sheet And the push rod, after obtaining the rated load on the transformer nameplate and the upper limit of the insulating oil temperature, move the adjustment lever, and select the corresponding load module at the same time, the main control unit controls the load modules to connect to the transformer in turn, and after the transformer is running with load, The temperature of the internal insulating oil will rise, causing the heated bimetal to bend upwards, thereby driving the push rod to move upward. If all the load modules are connected to the transformer, the push rod can just move to the bottom of the adjustment rod and press the button Contact, the main control unit judges that the load status of the transformer is normal. If the button is triggered when the load modules are not fully connected, it means that the load status of the transformer does not match the calibration, and maintenance is required to prevent accidents.

Owner:HAINAN POWER GRID CO LTD ELECTRIC POWER RES INST

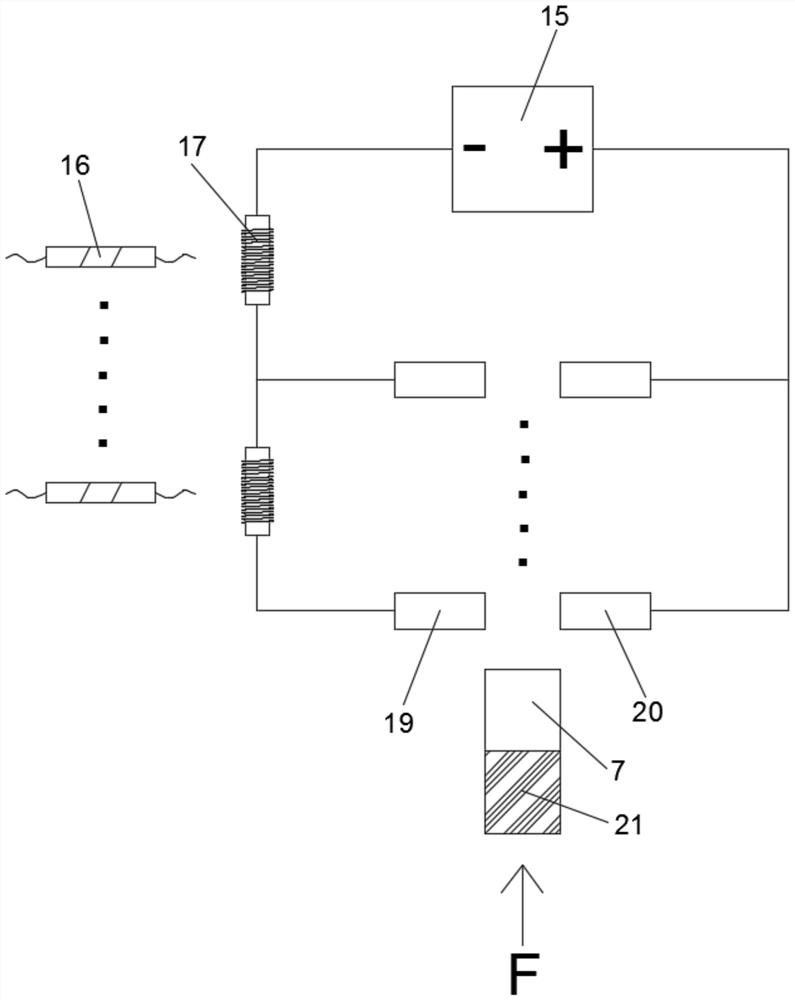

A kind of energy consumption AC electronic load and its working method

ActiveCN106772128BNormal loadOvercome the disadvantages of high complexity and high costPower supply testingCapacitanceElectronic load

Owner:HUAZHONG UNIV OF SCI & TECH

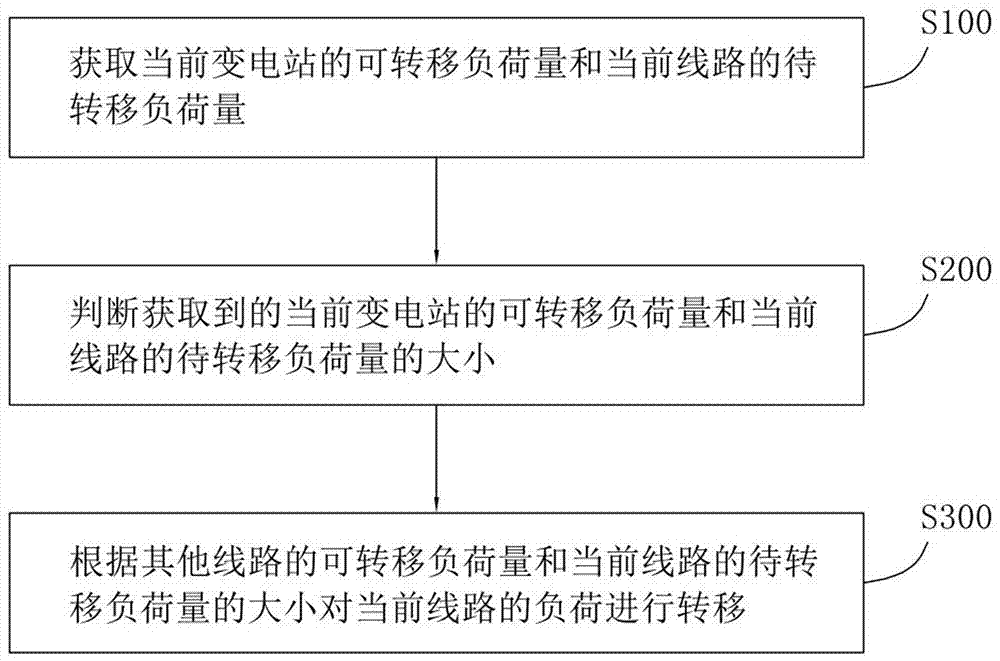

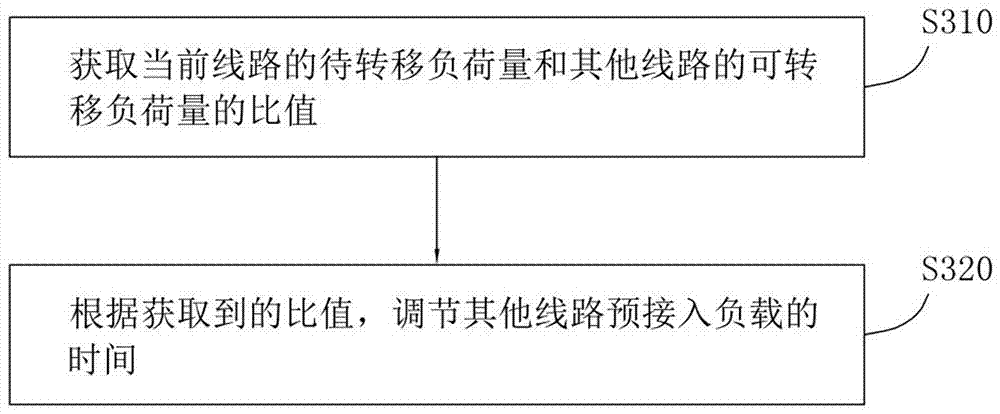

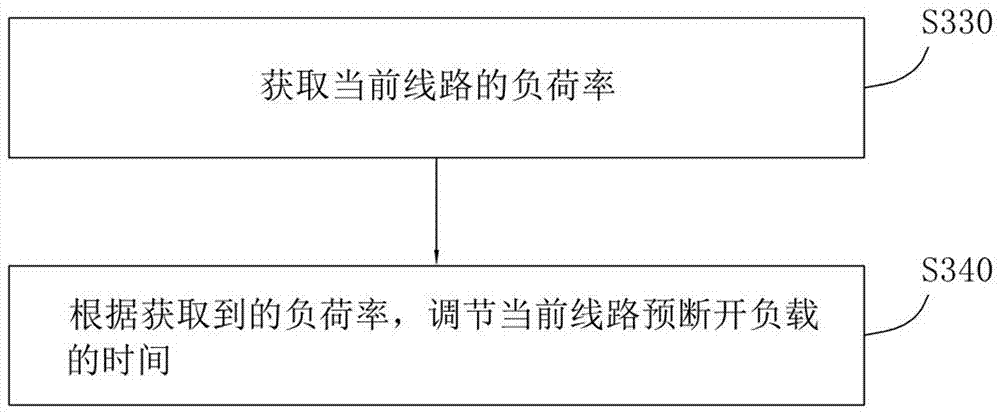

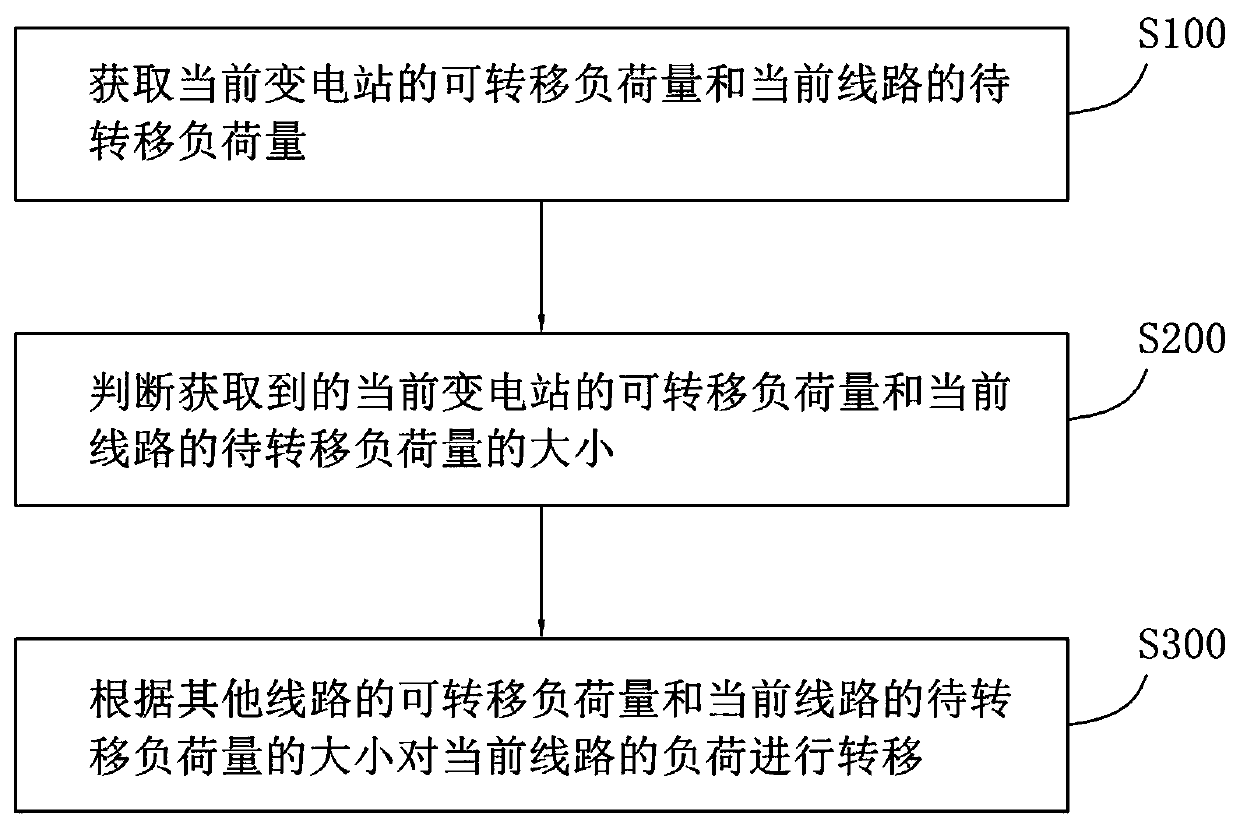

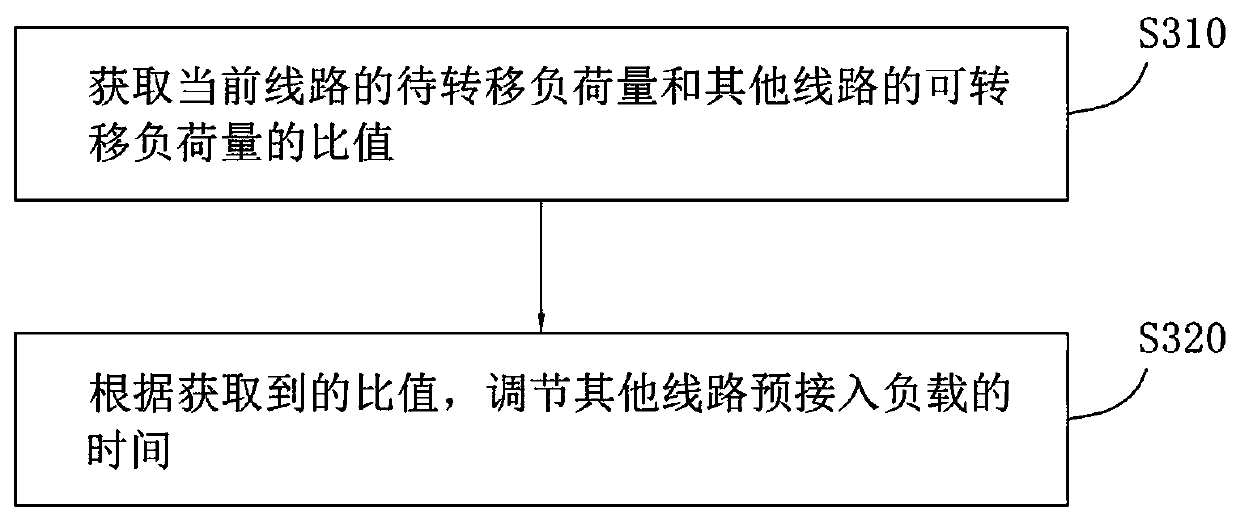

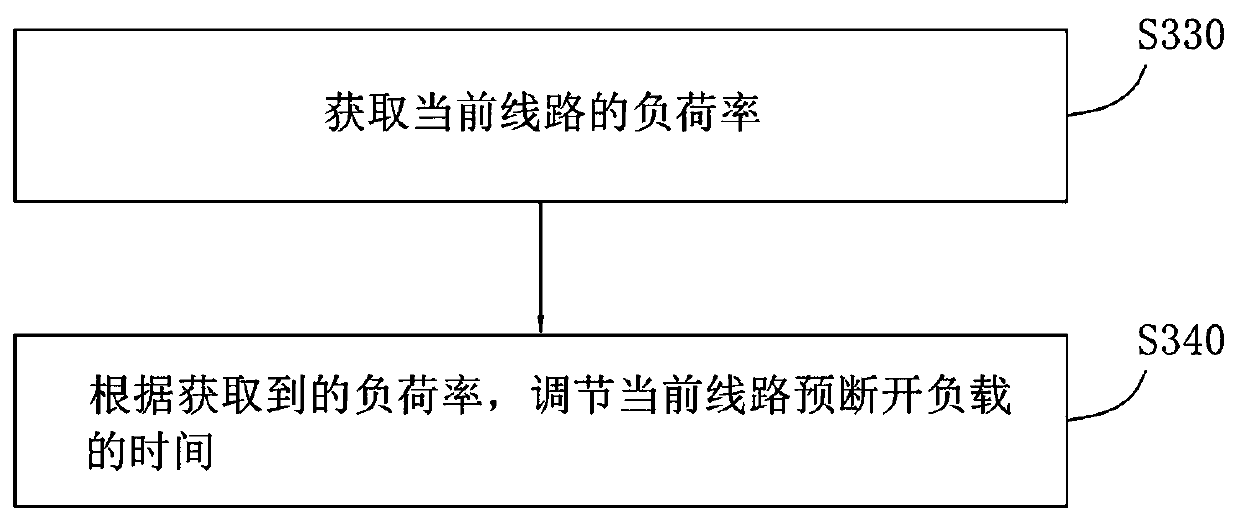

Substation complete-shutdown and complete-transfer method

The invention discloses a substation complete-shutdown and complete-transfer method. The substation complete-shutdown and complete-transfer method comprises the steps of: step 1, acquiring transferable load quantity of a current substation and load quantity to be transferred of a current line; step 2, judging magnitudes of the obtained transferable load quantity of the current substation and the obtained load quantity to be transferred of the current line, so as to transfer load of the current line; step 3, and transferring the load of the current line according to magnitudes of the transferable load quantity of other lines and the load quantity to be transferred of the current line, wherein a transfer equation is that x is equal to beta*Y / (1+alpha)<n>, x is the load quantity transferred to the other lines, Y is the transferable load quantity of the other lines, beta is an adjusting factor, alpha is a power supply margin of the other lines, and n is the year limit of a reserved margin of the other lines.

Owner:WENZHOU ELECTRIC POWER DESIGN

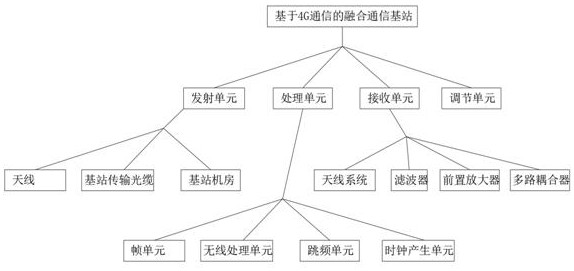

Converged communication base station based on 4G communication

InactiveCN111641886AEnsure safetyEnsure stabilityData switching networksWireless communicationProcessing elementReceiver front end

The invention discloses a converged communication base station based on 4G communication. The base station comprises a transmitting unit, a processing unit, a receiving unit and an adjusting unit, thetransmitting unit, the processing unit, the receiving unit and the adjusting unit are in signal connection with one another. The processing unit is used for processing analog quantity signals from the transmitting unit, the receiving unit and the adjusting unit; the transmitting unit comprises an antenna, a base station transmission optical cable and a base station machine room. The installationstandard is limited; the safety and the stability of the base station are ensured; then, the wireless processing is performed for further improvement; therefore, normal transmission and signal loadingof the antenna are realized, the stability in transmission is improved through a transmitter, the transmitter sharing device, the receiver front end and the receiver, the receiving unit realizes filtering and normal transmission of unnecessary signals of external signals, and the distribution effect is improved.

Owner:徐州瑞控机电科技有限公司

A method for full stop and full rotation of a substation

Owner:WENZHOU ELECTRIC POWER DESIGN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com