Extrusion device with gear pump

A technology of extrusion device and gear pump, which is applied in the field of steel wire manufacturing equipment, can solve the problems of normal extruder power, influence on gluing effect, high output power, etc., achieve low heat generation, ensure gluing effect, and reduce load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to specific embodiments.

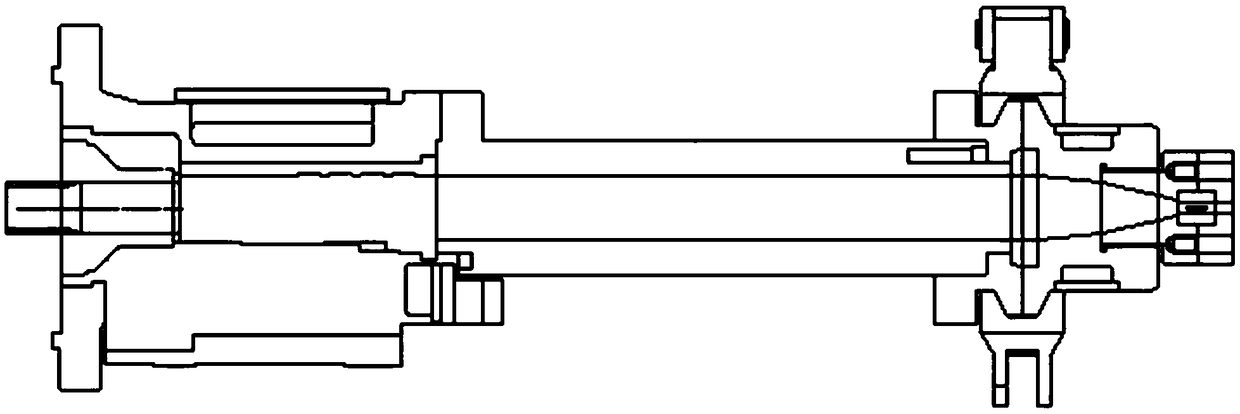

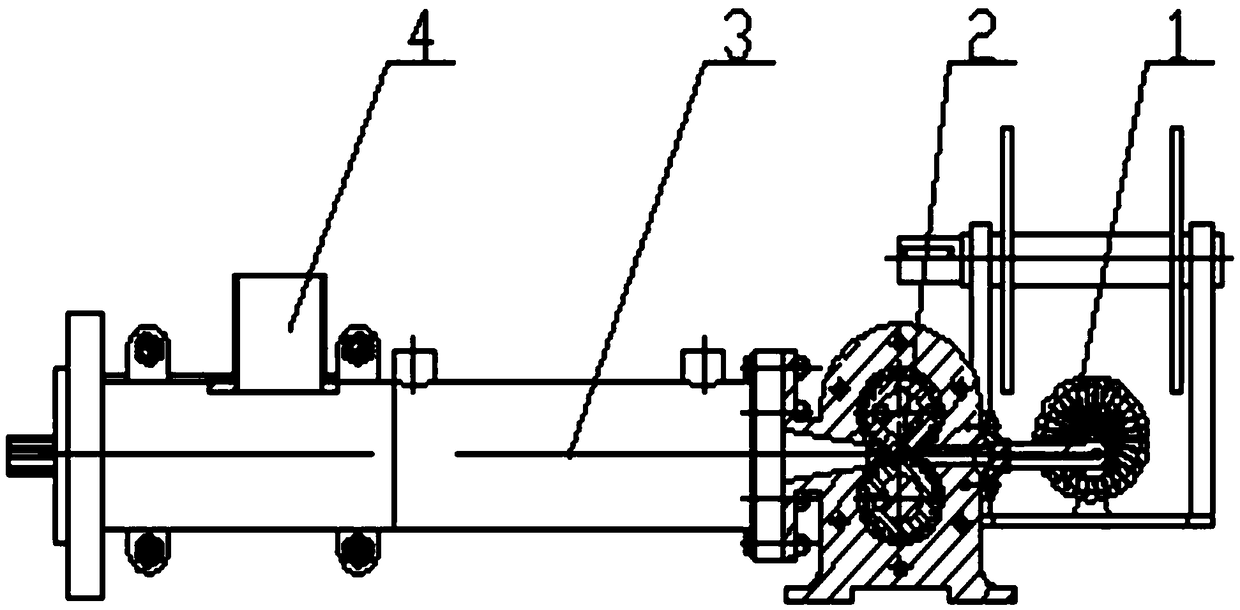

[0018] Embodiments of the present invention provide an extrusion device with a gear pump, such as figure 1 As shown, it includes: machine head 1, gear pump 2, extruder 3, and feeding port 4.

[0019] The feeding port 4 is connected to the extruder 3, the output end of the extruder 3 is connected to the gear pump 2, and the output end of the gear pump 2 is connected to the machine head 1. When working, fill the material from the feeding port 4, and then pass it into the extruder 3, and then pass it into the gear pump 2 after the processing of the extruder 3, and the gear pump 2 pressurizes the rubber material, and the pressurized rubber material enters the extruder Head 1, and then glue the steel wire through the head 1, and the head 1 adopts a side-type hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com