A kind of energy consumption AC electronic load and its working method

An electronic load and energy consumption technology, applied in the field of power electronic equipment, can solve the problems of complex system, high cost, only adjustment, and no energy feedback, etc., to overcome complex circuit, high cost, accurate simulation and control, and simple circuit structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

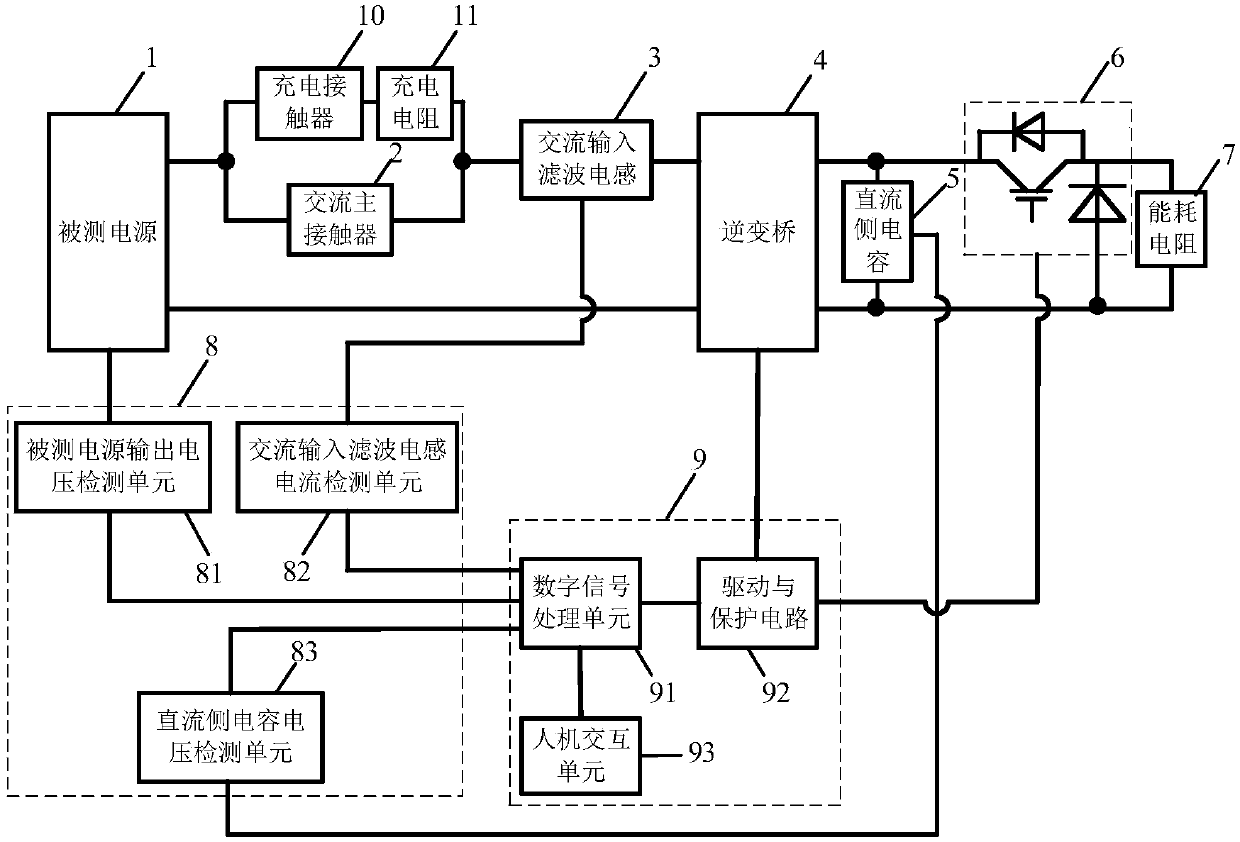

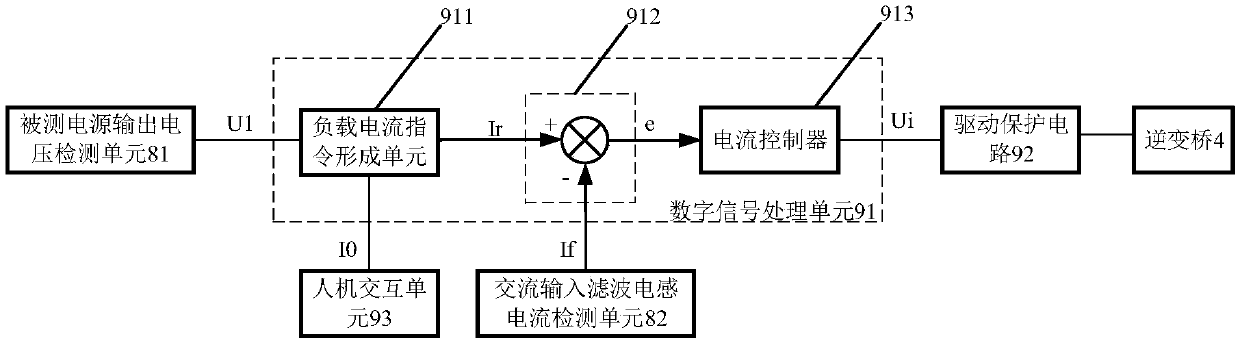

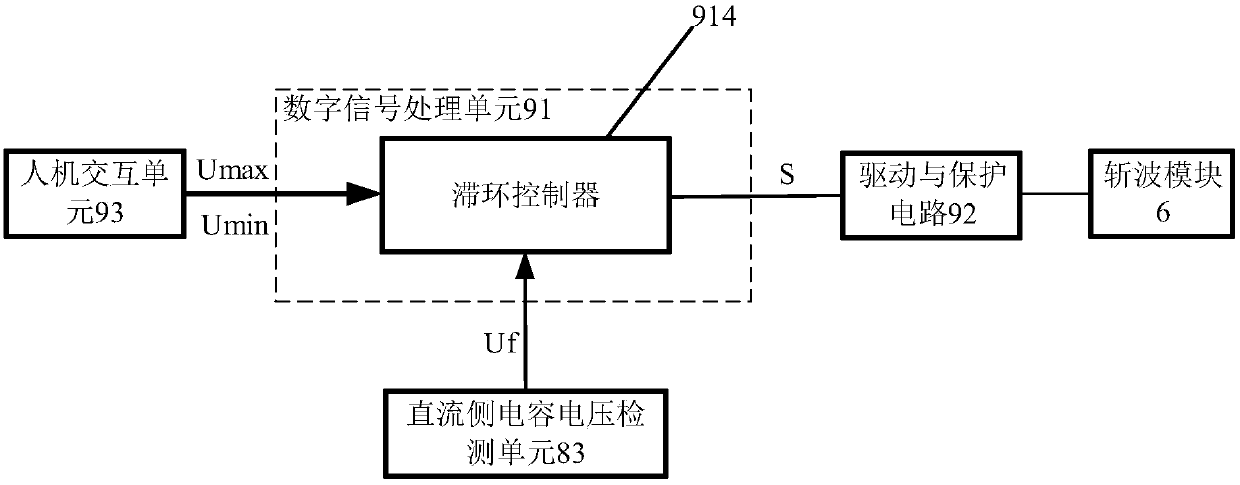

[0046] Such as figure 1 As shown, an energy-consuming AC electronic load includes an AC contactor 2, an AC input filter inductor 3, an inverter bridge 4, a DC side capacitor 5, a chopper module 6, an energy consumption resistor 7, a detection module 8 and a control module 9. ; The first end of the AC contactor 2 is used as a one-pole connection interface with the tested power supply 1, the second end of the AC contactor 2 is connected to the first end of the AC input filter inductor 3, and the second end of the AC input filter inductor 3 Terminal is connected to the first terminal of the inverter bridge 4, and the second terminal of the inverter bridge 4 is used as an interface for connecting the other pole of the power source 1 under test; the inverter bridge 4 passes through the third terminal and the fourth terminal of the inverter bridge 4 The terminal is connected in parallel with the DC side capacitor 5, and the chopper module 6 and the energy consumption resistor 7 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com