Filtering equipment of self-cleaning dust collector for spinning

A filter equipment and self-cleaning technology, applied in the textile field, can solve problems such as impeller blade idling, filter mesh clogging, suction drop, etc., and achieve the effect of reducing loss along the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

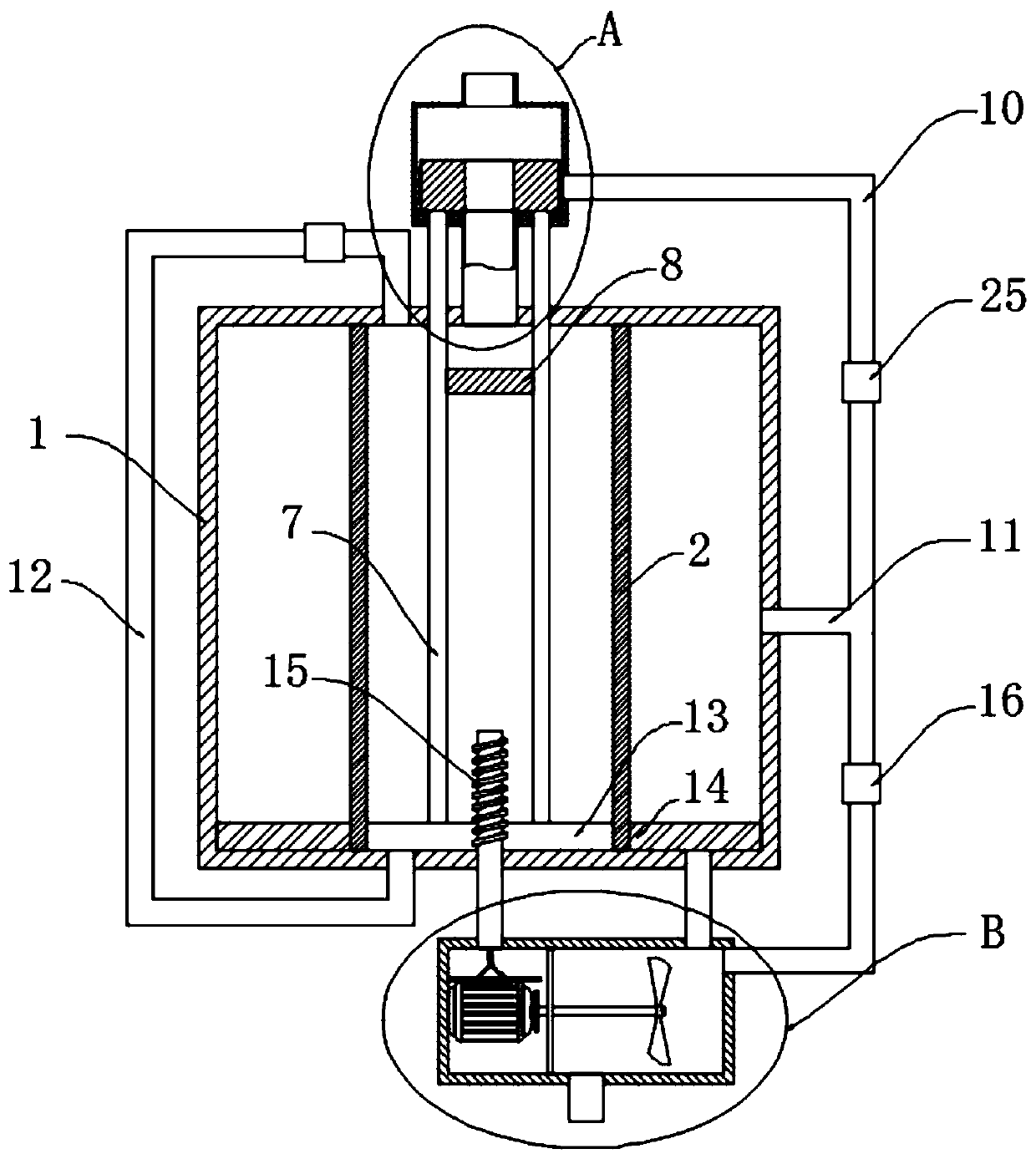

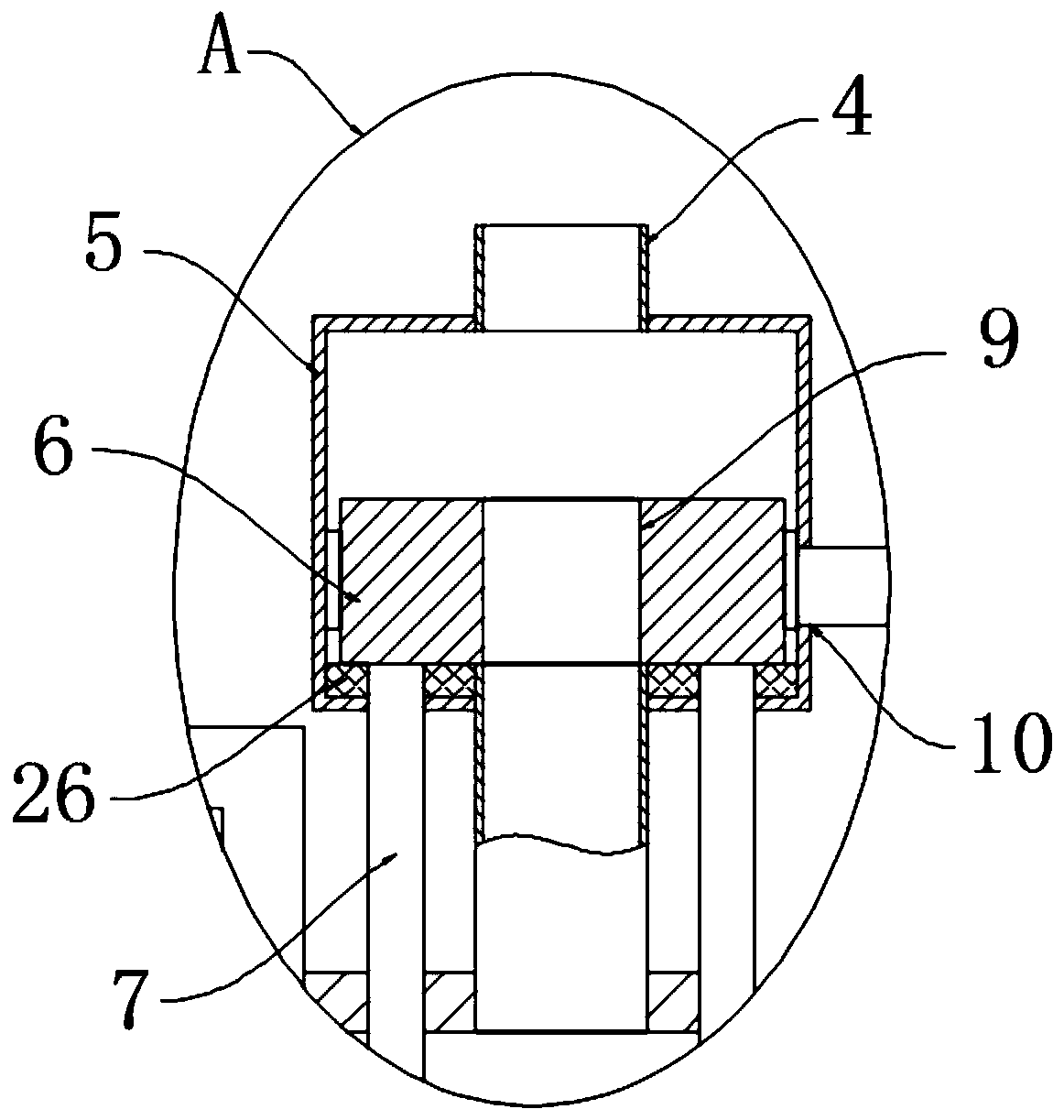

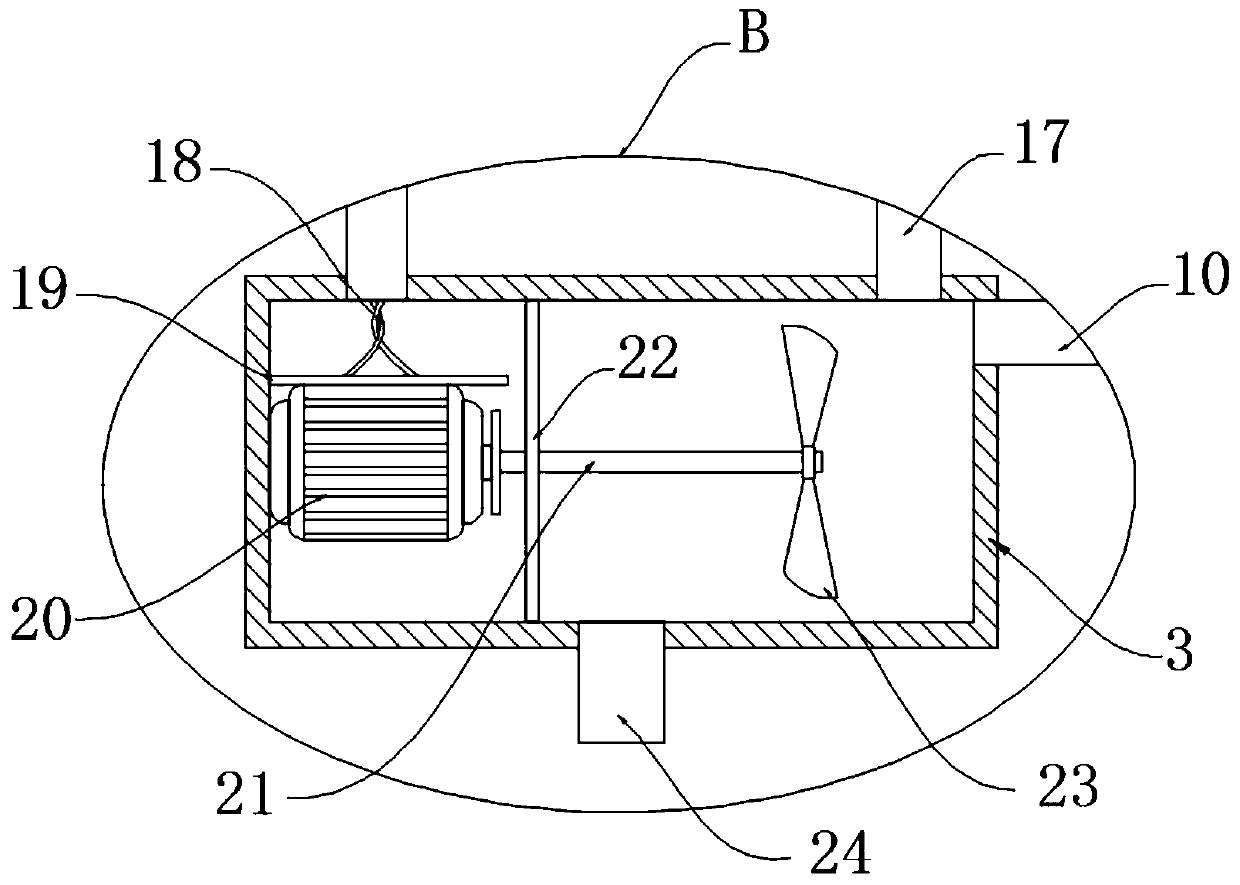

[0021] refer to Figure 1-3 , a self-cleaning vacuum cleaner filter device for textiles, comprising an ash-collecting bottle 1, an annular filter screen 2 is fixedly connected to the ash-collecting bottle 1, the geometric centerline of the filter screen 2 is aligned with the centerline of the ash-collecting bottle 1, There is an air chamber 3 under the ash collection bottle 1, and the top of the ash collection bottle 1 is sealed with a feed pipe 4, and a section of the feed pipe 4 is provided with a sliding chamber 5 that is sealed with the feed pipe 4, and the sliding chamber 5 is sealed to slide A slide block 6 is connected, and the center of the slide block 6 is provided with a through hole 9 having the same diameter as the feed pipe 4. The side wall of the slide chamber 5 is sealed and slidably connected with a first connecting pipe 10, and the end of the first connecting pipe 10 communicated with the air chamber 3;

[0022] The bottom of the slider 6 is welded with two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com