Patents

Literature

187results about How to "Cleanliness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanometer photocatalyst material supported embedded composite film and preparation method and application thereof

ActiveCN104084053AImprove hydrophilicityImprove throughputSemi-permeable membranesWater/sewage treatment by irradiationNano catalystComposite film

The invention discloses a method for preparing a nanometer photocatalyst material supported embedded composite film. The method comprises the following steps: dissolving an organic polymer base film material, a pore-forming agent and a nanometer catalyst in a solvent, stirring and standing to prepare a casting film solution; dispersing the nanometer photocatalyst in the solvent to obtain dispersion liquid, spreading the dispersion liquid on a plate to prepare a spreading solution, and drying the spreading solution to obtain a spreading film; and covering the spreading film with the casting film solution, scraping a liquid film by utilizing a film scraper, immersing the scraped liquid film in a constant temperature gel bath, and curing the liquid film to prepare the nanometer photocatalyst material supported embedded composite film. The invention also provides the nanometer photocatalyst material supported embedded composite film and application thereof. According to the method, a nanometer photocatalyst coating is uniformly, effectively, stably and firmly supported on the surface of the embedded composite film. Moreover, according to the composite film, the removal rate of pollutants is effectively improved, and film pollution is reduced.

Owner:SHANGHAI JIAO TONG UNIV

Superhydrophobic inorganic organic nano composite polymeric coating material and preparation method thereof

InactiveCN101824278AWide range of usesReduce resistancePretreated surfacesSpecial surfacesChemical reactionFunctionalized nanoparticles

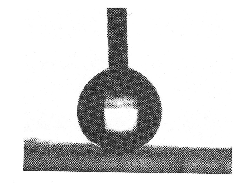

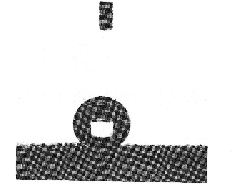

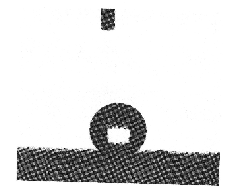

The invention discloses a superhydrophobic inorganic organic nano composite polymeric coating material and a preparation method thereof. The coating material is prepared from 30 to 98 mass percent of thermosetting polymeric precursor and 10 to 70 mass percent of surface functionalized nanoparticle under the action of 0 to 5 mass percent curing agent, wherein the obtained surface water contact angle and rolling angle of the material are 120 to 180 DEG and 1 to 20 DEG respectively; and a falling water drop which is spherical can bounce up and can freely roll on the surface. The method has the characteristic of simple preparation process by using the chemical reaction between organic groups on the surfaces of the polymeric precursor and the modified nanoparticle in the solution. The coating material has the functions of stain resistance, dust prevention and self cleaning.

Owner:NANJING UNIV OF TECH

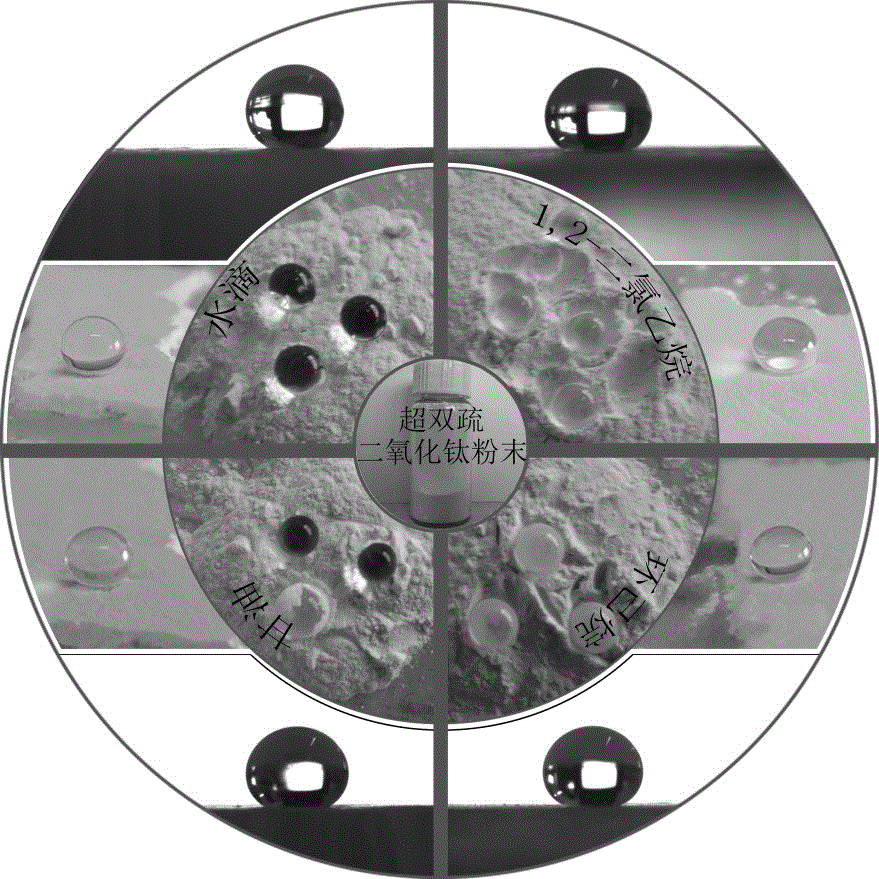

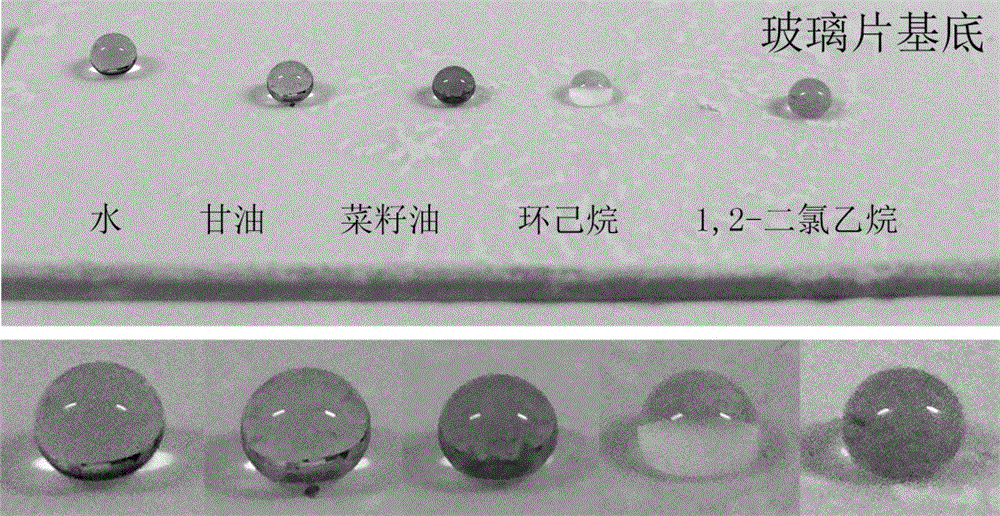

Preparation method of universal super-amphiphobic nano coating based on flower shape titanium dioxide nano particles

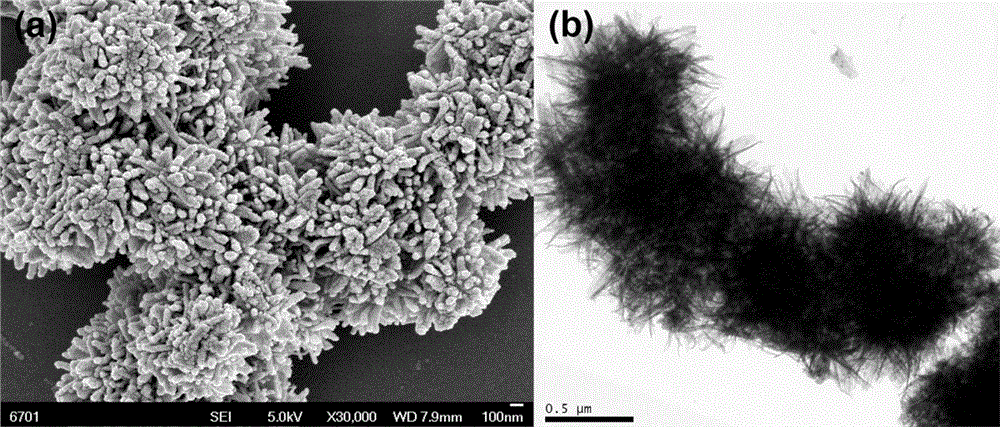

ActiveCN105820605AStabilized superamphiphobiaUniversalMaterial nanotechnologyAntifouling/underwater paintsOil waterChemical stability

The invention belongs to the technical field of super-amphiphobic nano coating preparation, and especially relates to a preparation method of a universal super-amphiphobic nano coating based on flower shape titanium dioxide nano particles. The preparation method comprises steps of flower shape titanium dioxide nano particle preparation, low surface energy modification, and combination between super-amphiphobic powder and a substrate. The contact angles between various substrates coated by super-amphiphobic powder and water / oil are all larger than 150 degrees and the roll angles are all smaller than 10 degrees. Moreover, after combination, the super-amphiphobic substrate has a strong performance on resisting wear, extrusion, and stretching and high chemical stability. The preparation technology is simple, the raw materials are easily available, not toxic, and environment-friendly; the cost is low, the stability is high, and the preparation method is suitable for large scale preparation and application. The coating is suitable for being used in an extreme work environment, can be applied to oil stain resistant equipment or waterproof equipment, and at the same time, can also be used in the fields such as industrial pipeline transportation, oil-water separation metal network, and the like.

Owner:HUBEI UNIV

Glass detergent

InactiveCN103952123AEasy to makeLong anti-fog timeNon-ionic surface-active compoundsOther chemical processesAlcoholSodium silicate

The invention discloses a glass detergent. The glass detergent is prepared from the following raw materials in parts by mass: 1-1.3 parts of absolute ethyl alcohol, 0.2-0.3 part of sodium lauryl sulfate, 0.1-0.3 part of ethanol, 0.2-0.3 part of saponin, 0.8-1 part of sodium silicate, 1.5-2 parts of saponin, 2-6 parts of alkanolamide and 90-95 parts of deionized water. The antifogging agent disclosed by the invention is simple in preparation, has two functions of cleaning and fog prevention, and is long in antifogging time, wide in usable range, free of explosion risk and convenient to carry.

Owner:江苏紫石化工科技有限公司

bathroom cleaning deodorant

The invention relates to a bathroom cleaning deodorant, which comprises 50-65% of potassium hydrogen persulfate complex, 2-8% of sulfamic acid, 0-25% of sodium citrate and 0-25% of sodium tartrate in terms of mass percentage. %, sodium hexametaphosphate 0-10% and sodium dodecylbenzenesulfonate 0-1%. The bathroom cleaning and deodorizing agent of the present invention is suitable for cleaning and disinfecting bath products such as bathtubs and bath towels in households, hotels / guesthouses, beauty and bathing places, has dual functions of cleaning and disinfection, and has good deodorizing effect, without specific temperature requirements. Good security.

Owner:宋海鹏 +1

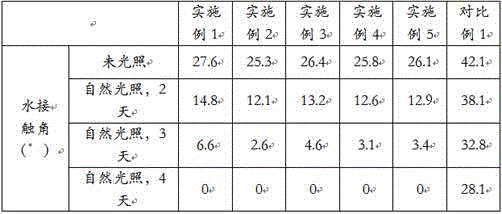

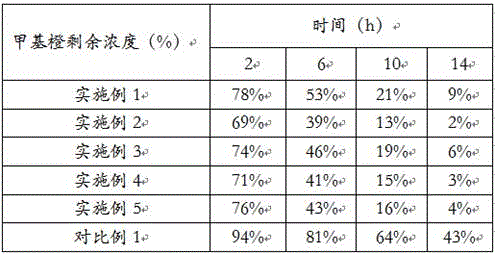

Modified nano titanium dioxide self-cleaning coating and preparation method thereof

ActiveCN106380981AHigh purityUniform particle sizeAntifouling/underwater paintsPaints with biocidesFiltrationUltrasonic dispersion

The invention belongs to the technical field of chemical coatings, and in particular, relates to a modified nano titanium dioxide self-cleaning coating and a preparation method thereof. The preparation method comprises the following steps: adding 1.5-3 parts of boron and nitrogen doped and coated nano titanium dioxide into an ethanol aqueous solution, stirring and dispersing, adding 0.5-2.5 parts of an organic silane coupling agent, carrying out stirring and heat preservation reaction, then carrying out suction filtration, drying and grinding to obtain silanized boron and nitrogen doped and coated nano titanium dioxide; dispersing 1.5-3 parts of the silanized boron and nitrogen doped and coated nano titanium dioxide into a mixed solution of 15-25 parts of an acrylate monomer and 0.5-2 parts of a co-emulsifier, stirring, carrying out ultrasonic dispersion, then adding 2-6 parts of an emulsifier and 50-90 parts of deionized water, stirring, carrying out ultrasonic dispersion, adding 0.3-0.6 part of an initiator, and carrying out heat preservation for 3-5 h, to obtain the modified nano titanium dioxide self-cleaning coating. The self-cleaning coating has the advantages of good dispersion of titanium dioxide and strong self-cleaning ability.

Owner:ZHEJIANG RUNYANG NEW MATERIAL TECH

Method for processing surface of multi-scale bionic structure

InactiveCN102094222ASimple processing technologyRaw materials are easy to getVacuum evaporation coatingSputtering coatingNano structuringEngineering

The invention discloses a method for processing the surface of a multi-scale bionic structure. The method combines a surface replica method and an electro-deposition method and sequentially comprises the following steps of: (1) replicating a biological prototype surface structure by using active carbon (AC) paper by using a soft sealing technique, and then evaporating a gold film on the AC paper to increase the electric conductivity; and (2) depositing a metal coating on the conductive treated AC paper by adopting the electro-deposition method in metal electrolyte, and finally, micro-processing the bionic structure with biological surface and high precision on the metal surface, wherein the shape and the size of the bionic structure are consistent with those of a micro / nano structure on the biological prototype surface.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

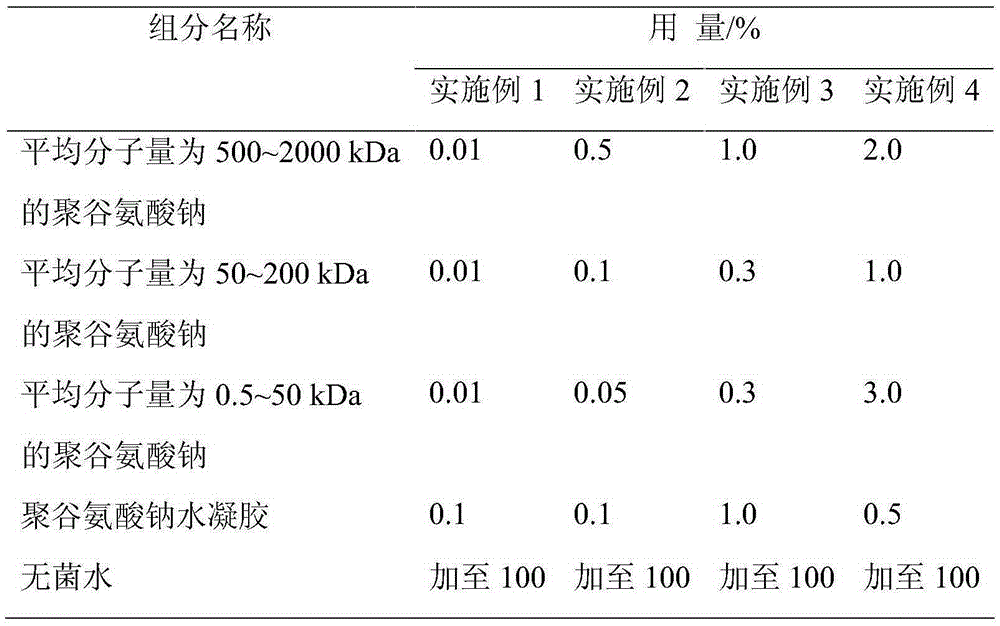

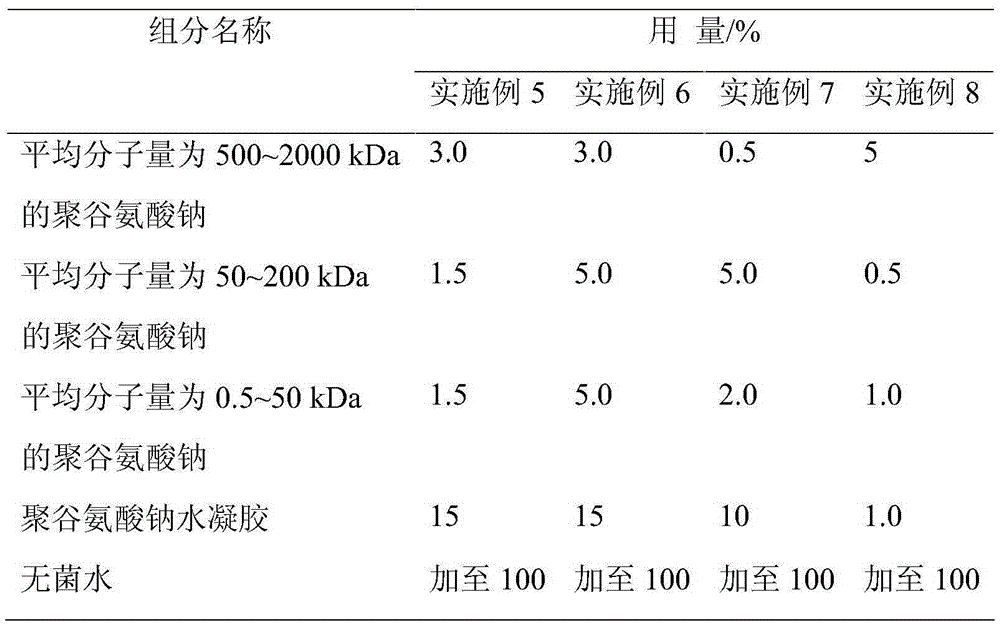

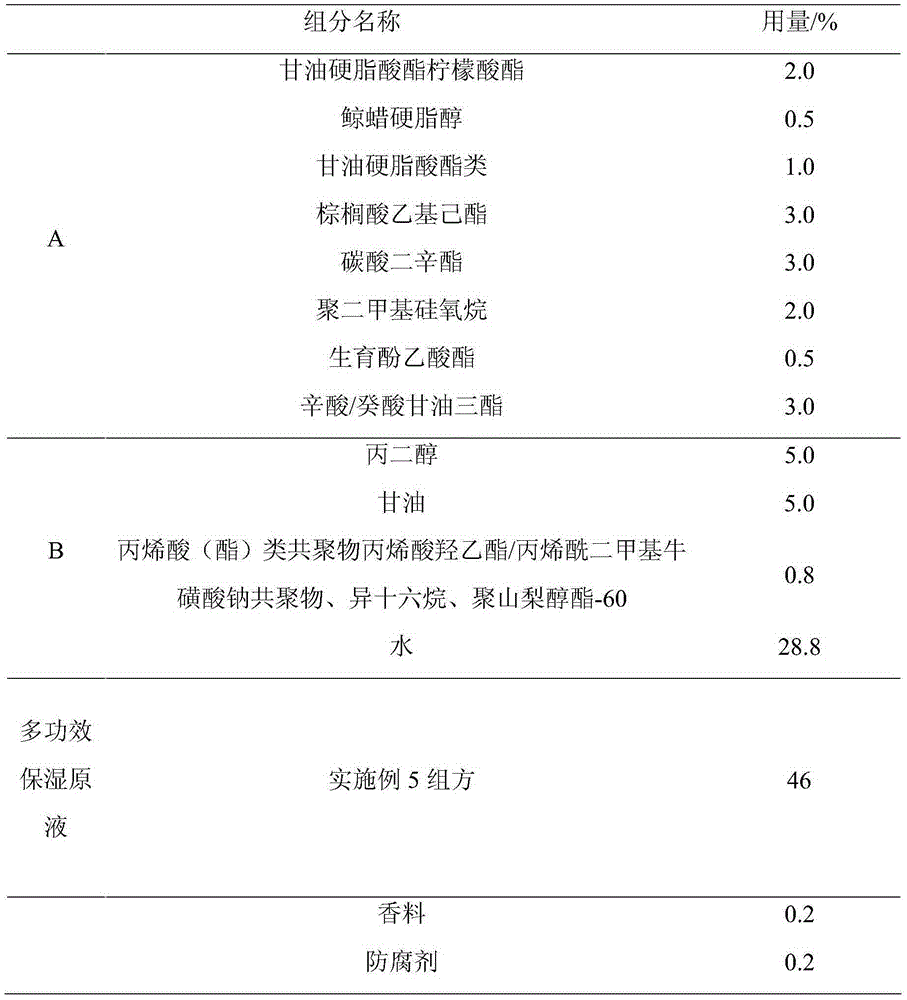

Multi-efficiency compound moisturizing essence and application method thereof

ActiveCN105342882AGive full play to the whitening effectGood biocompatibilityCosmetic preparationsHair cosmeticsEmulsionIrritation

The invention provides multi-efficiency compound moisturizing essence and application thereof. The compound moisturizing essence consists of polyglutamic acid or salt thereof within three molecular weight ranges, and further consists of a polyglutamic acid hydrogel or a polyglutamate hydrogel which is quite strong in water-absorbing capacity and is good in film-forming property. The compound moisturizing essence, in vitro and for human skin, has an excellent moisturizing effect, and the compound moisturizing essence is high in safety of ingredients thereof and free from toxicity and irritation to cells, animals and human bodies. The compound moisturizing essence can be also applied to various cosmetics; and the compound moisturizing essence can be prepared into emulsions, creams, facial masks and the like.

Owner:SHANDONG ACADEMY OF PHARMACEUTICAL SCIENCES

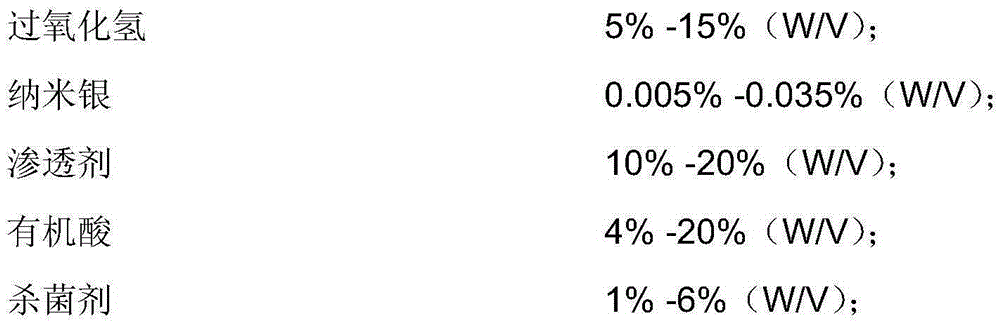

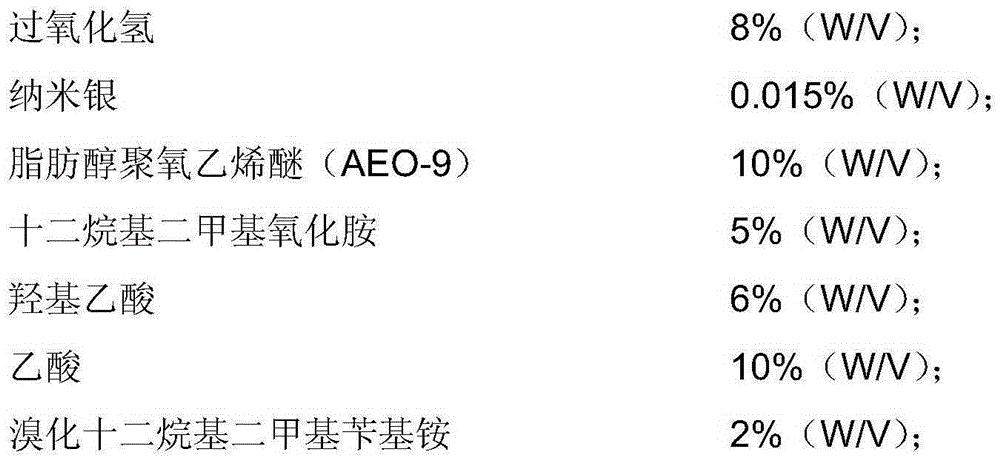

An acidic pipeline cleaning agent and a preparing method thereof

InactiveCN106800984AReduce the attachment areaEfficient removalOrganic detergent compounding agentsOrganic/inorganic per-compounds compounding agentsWater qualityBiological membrane

An acidic pipeline cleaning agent and a preparing method thereof are disclosed. The pH value range of the cleaning agent is 2.0-7.0. The cleaning agent is suitable for removing organic and inorganic composite dirt. A penetrant can penetrate into waterline biomembranes to dissolve fat, proteins, and the like. A sterilizing agent can kill bacteria hidden in the biomembranes, thus weakening adhesive force between the biomembranes and objects, and rapidly peeling off and cleaning clay dirt adhered to pipe walls. Hydrogen peroxide and nanometer silver play a role of purifying water. Pigment facilitates intuitive judgment of residues. The cleaning agent is used for cleaning and sterilizing a livestock drinking water system. For cleaning with existence of chickens, the cleaning agent is diluted according to a ratio of 1:500-1:1000 and then used.

Owner:RINGPU TIANJIN BIOLOGICAL PHARMA

Acne removing cream and method for preparing same

InactiveCN105342889AEasy to usePrevent acneCosmetic preparationsToilet preparationsIsomerizationButanediol

The invention relates to acne removing cream and a method for preparing the same. The acne removing cream comprises, by weight, steareth-2, lauroyl glutamate, steareth-21, cetyl alcohol, glyceryl stearate, dimethicone, isomerization cetane, capric triglyceride, isopalmitic acid ethylhexyl acrylate, vitamin E, bisabolol, propylene glycol, dipotassium glycyrrhizinate, butanediol, hexamidine (hydroxyethanesulphonic acid) dibasic, EDTA (ethylene diamine tetraacetic acid)-disodium, water, matrine, preservatives, asiaticoside, pH (potential of hydrogen) regulators and thickeners. The acne removing cream and the method have the advantages that various raw materials are mixed with one another, and accordingly facial skin cleaning and care effects can be realized; pimple, acne, papule, pustule and the like on the faces of users can be effectively removed.

Owner:ZHUHAI LEITEEN INT TRADE CO LTD

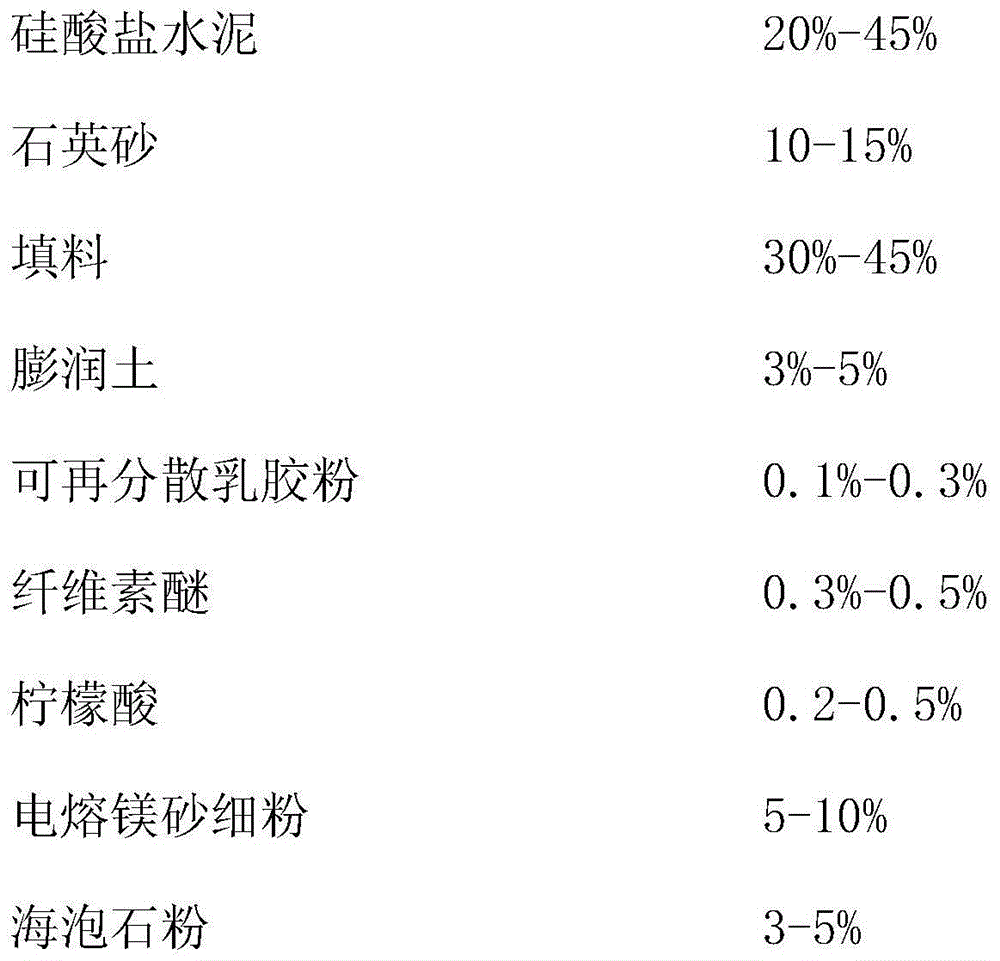

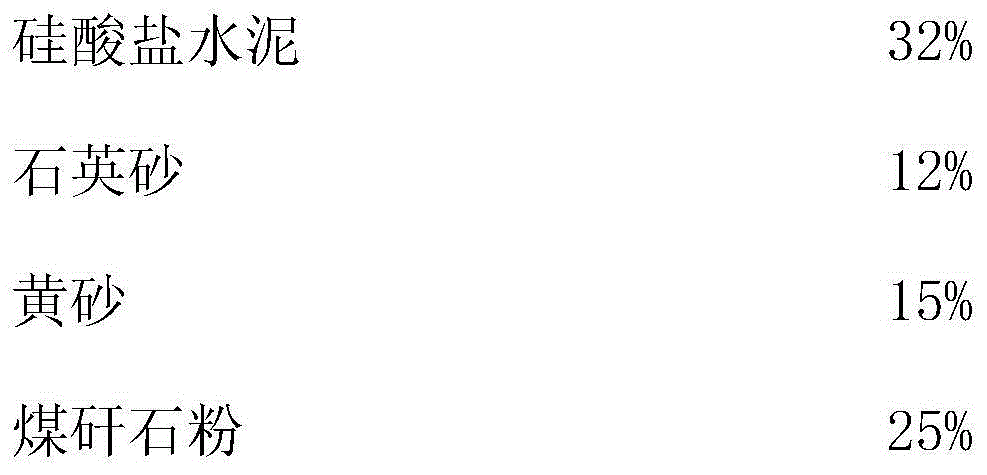

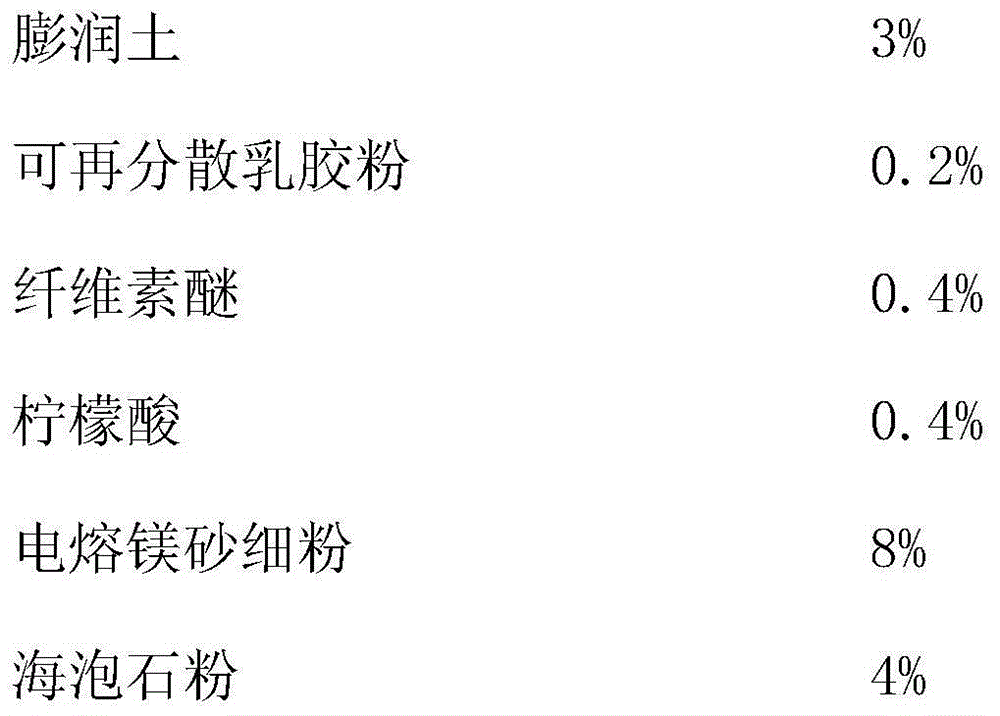

Fireproof dry-mixed mortar for exterior wall

The invention discloses fireproof dry-mixed mortar for an exterior wall. The fireproof dry-mixed mortar is composed of the following components in percentage by weight: portland cement, quartz sand, filler, bentonite, redispersible latex powder, cellulose ether, citric acid, fine fused magnesite powder and sepiolite powder. The fireproof dry-mixed mortar has a favorable adhesive force with a fundamental plane, and materials are economic and practical, so that the cost can be reduced; meanwhile, a base layer treated by using the material cannot bulge and flake, so that a construction site can be kept clean, and the requirement for environment friendliness can be better met; and part of yellow sand is replaced with gangue, so that the pollution can be relieved, the cost can be reduced, and the fireproof effect can also be achieved.

Owner:DEQING YANGTAI BUILDING MATERIAL

Self-cleaning and environmental-friendly interior and exterior wall coating of buildings and preparation method thereof

InactiveCN104710919AHas a decomposition effectEfficient removalAntifouling/underwater paintsPaints with biocidesWeather resistanceEthylic acid

The invention relates to self-cleaning and environmental-friendly interior and exterior wall coating of buildings and a preparation method thereof. Raw materials comprise SiO2 sol, anatase TiO2 nanometer powder, glacial acetic acid, a film forming agent and water. The preparation process is as follows: hydrolyzing with an alcohol salt solution of silicon to obtain the SiO2 sol, mixing the anatase TiO2 nanometer powder, the glacial acetic acid, the film forming agent and the water, grinding to obtain a uniform and semitransparent solution, and thus the self-cleaning coating is prepared. The self-cleaning coating is uniformly spray coated on clean and incompletely dry surfaces of interior walls or exterior walls of buildings, to obtain self-cleaning coating after natural drying, the self-cleaning coating has excellent weather fastness and super-hydrophilicity and can be used for effectively removing surface contaminants and decomposing a variety of pollutants through the sunlight to purify the air and reduce environmental pollution, so that the self-cleaning and environmental-friendly interior and exterior wall coating of buildings has a very good application prospect and important social significance.

Owner:UNIV OF JINAN

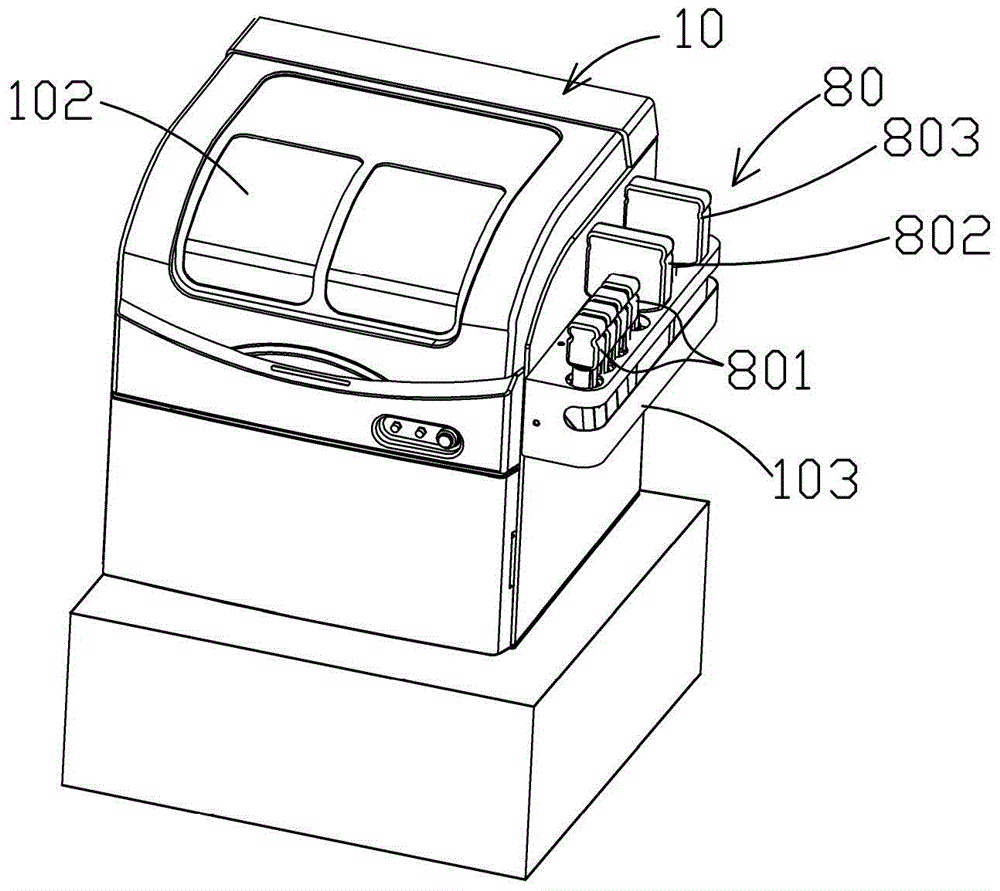

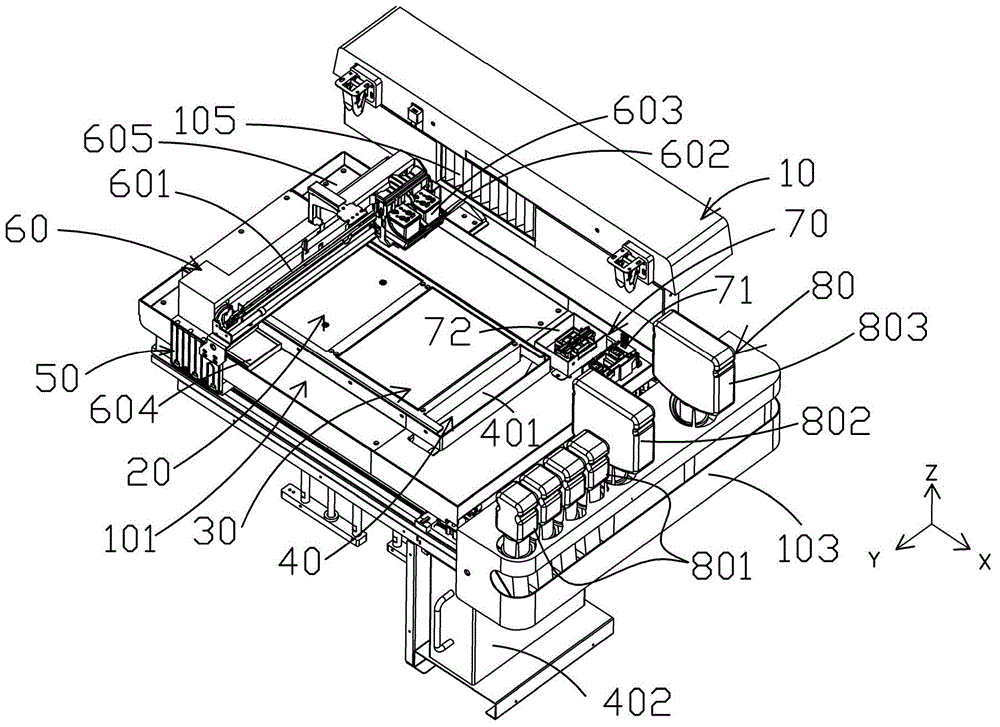

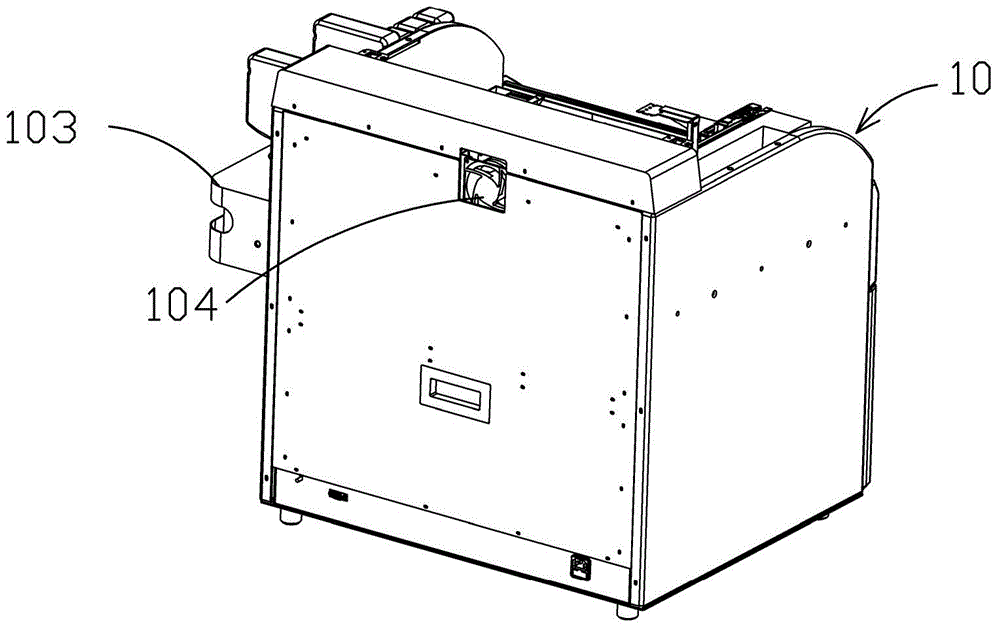

Three-dimension printer

The invention relates to a three-dimension printer. The three-dimension printer comprises a host body, wherein a construct platform is arranged on the host body, exhausting equipment and a filter are arranged in the host body, and an ink feeding unit frame is erected outside the host body; a feeding chamber erected on the construct platform for temporary storage of a powder construct material; a construct chamber erected on the construct platform for stacking the powder construct material for moulding; a construct displacement mechanism erected on the construct platform for performing relative displacement; and a jet printing module arranged on the construct displacement mechanism for performing link displacement, wherein a jet printing displacement mechanism drives a supporting seat used for bearing a built-in cartridge to perform reciprocating displacement, a waste print cartridge is fixed by one end of the jet printing displacement mechanism, a pushing stopping roller is arranged at the bottom of the jet printing module, so that the powder construct material is pushed into the construct chamber. Thereby, three dimensional object moulding work through laminated jet printing is completed.

Owner:MICROJET TECH

Lace printing sheet and double-fitting process thereof

The invention relates to the technical field of sheets, in particular to a lace printing sheet and a double-fitting process thereof. The lace printing sheet is prepared from, by weight, 45-55 parts of PVC resin, 55-65 parts of filler, 23-35 parts of plasticizer, 2-4 parts of heat stabilizer, 1-3 parts of foaming agent, 0.4-1.0 part of lubricant, 0.01-0.15 part of titanium dioxide, 0.01-0.16 part of pigment powder and 0.15-0.70 part of other additives. The lace printing sheet is good in abrasion resistance, good in anti-slipping effect, delicate in texture, exquisite in pattern, gorgeous in color, smooth in surface and comfortable in hand feeling, also has the advantages of being environmentally friendly, non-toxic, waterproof, oilproof, high in cold resistance, antistatic, flame-retardant, easy to clean and the like and has excellent comprehensive performance.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

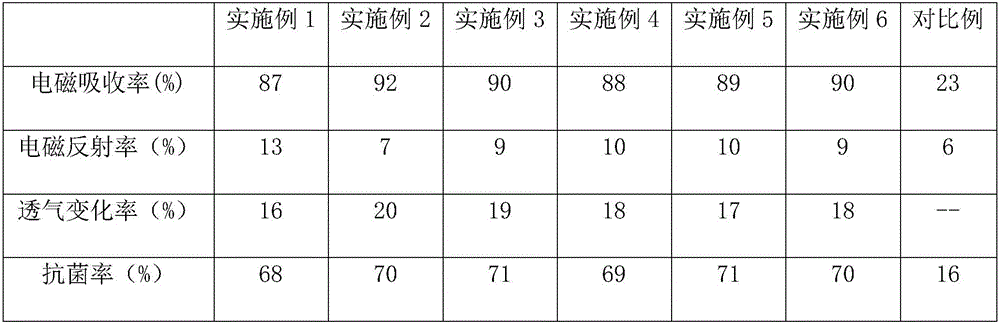

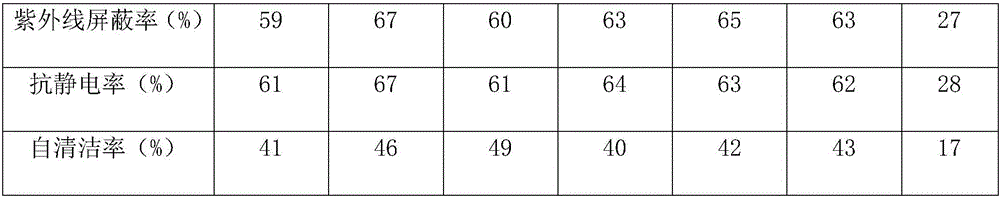

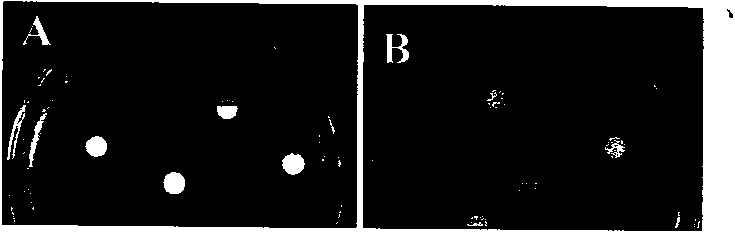

Radiation resistant fabric based on ferrite coating finishing and preparation method of fabric

ActiveCN106436347AGood adhesionGood film formingUltrasonic/sonic fibre treatmentCoatingsRadiation resistantCarbon nanotube

The invention provides a preparation method of a radiation resistant fabric based on ferrite coating finishing. The preparation method includes the steps: treating a fabric by low temperature plasma, dipping the fabric in a bottom finishing agent containing nano-ferrite and chitosan, dipping and rolling the fabric once, taking out the fabric and drying the fabric to obtain a primary finished fabric; finishing the primary finished fabric by the low temperature plasma, coating the surface of the primary finished fabric with carbon nano-tube / polyaniline composite finishing agents, standing, airing the fabric, coating the fabric with nano-titania gel, and drying and baking the fabric to form the radiation resistant fabric based on ferrite coating finishing. By comprehensive application of microencapsulation, polymerization reaction, low temperature plasma treatment and coating technology, the preparation method is simple, and the prepared fabric has radiation resistant, antibacterial, ultraviolet resistant, antistatic and self-cleaning functions.

Owner:深圳东方逸尚服饰有限公司

Novel artemisia annua health care toilet soap

The invention relates to a novel artemisia annua health care toilet soap, which is characterized by mainly comprising, by weight: 28-34 parts of a composite soap base, 40-45 parts of water, 1-2 parts of volatile oil, 1-2 parts of rose essential oil, 1-3 parts of sodium dodecyl sulfate and 22 parts of an auxiliary agent, wherein the composite soap base comprises a soap base and an artemisia annua fatty acid soap base according to a mass ratio of 7-8:3-2, and the auxiliary agent comprises glycerol, white sugar, propolis, EDTA-2Na, betaine, titanium dioxide powder and dehydrated alcohol according to a mass ratio of 6:2:5:1:1:1:6. According to the present invention, the product is added with the artemisia annua fatty acid and the volatile oil, such that the toilet soap has health care effects of stain removal, bacterial inhibition, sterilization, skin odor removal, and the like.

Owner:JISHOU UNIVERSITY

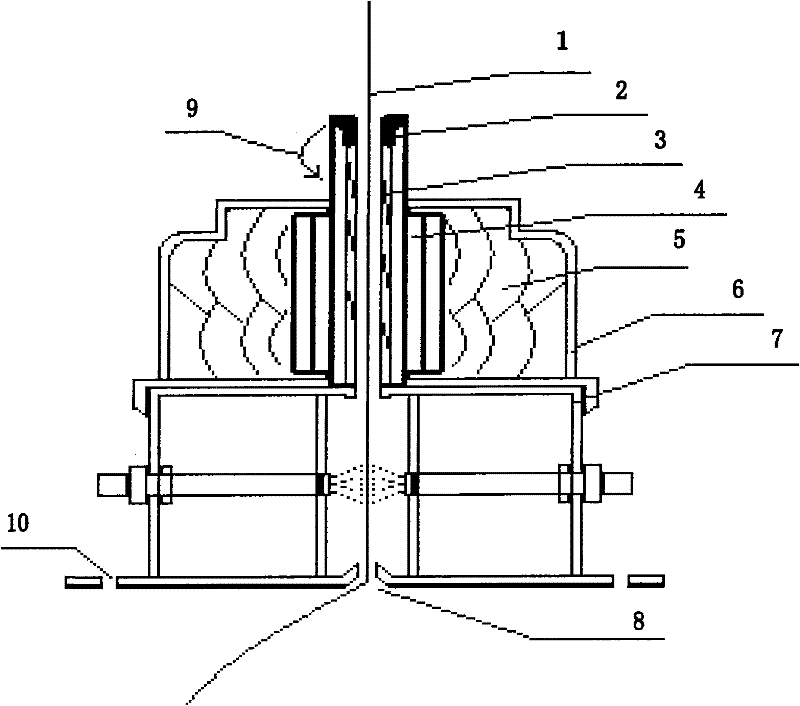

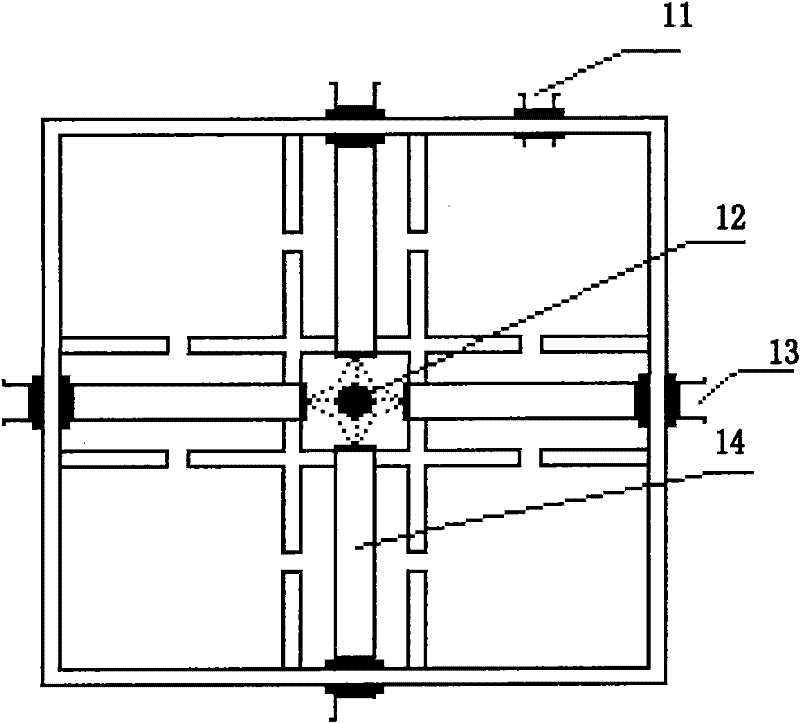

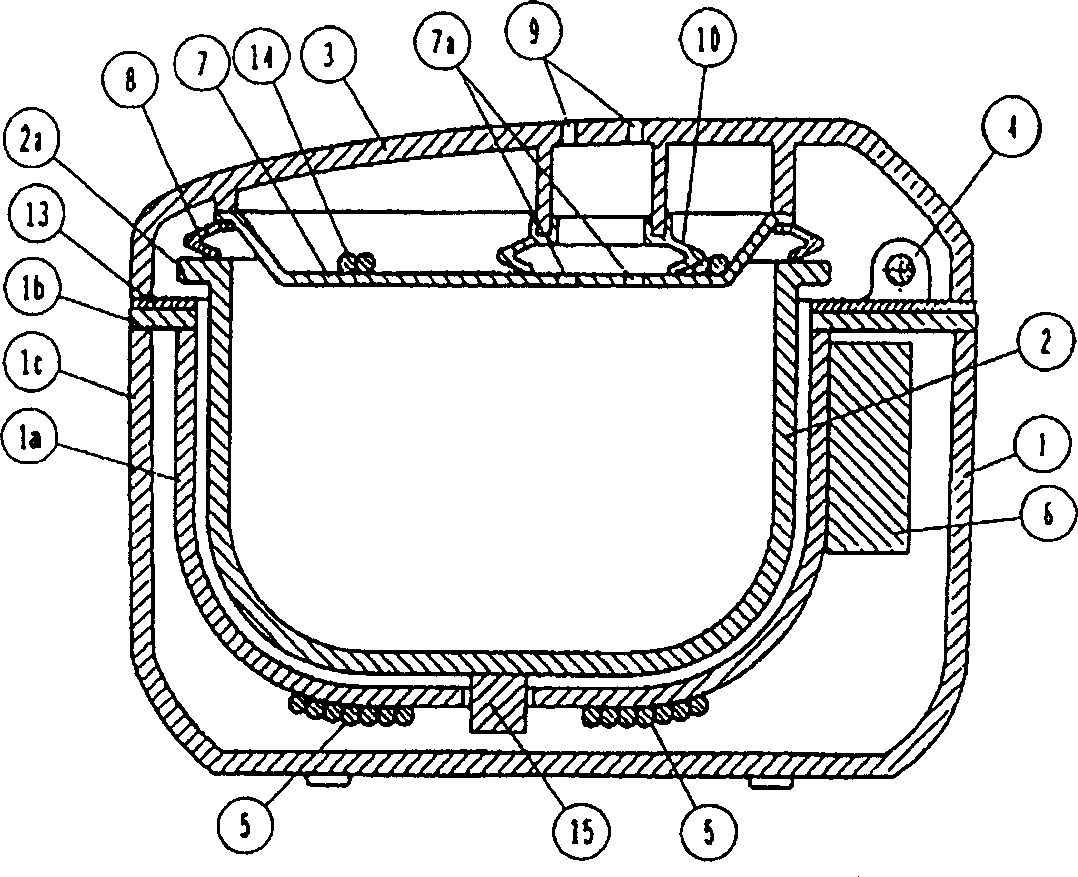

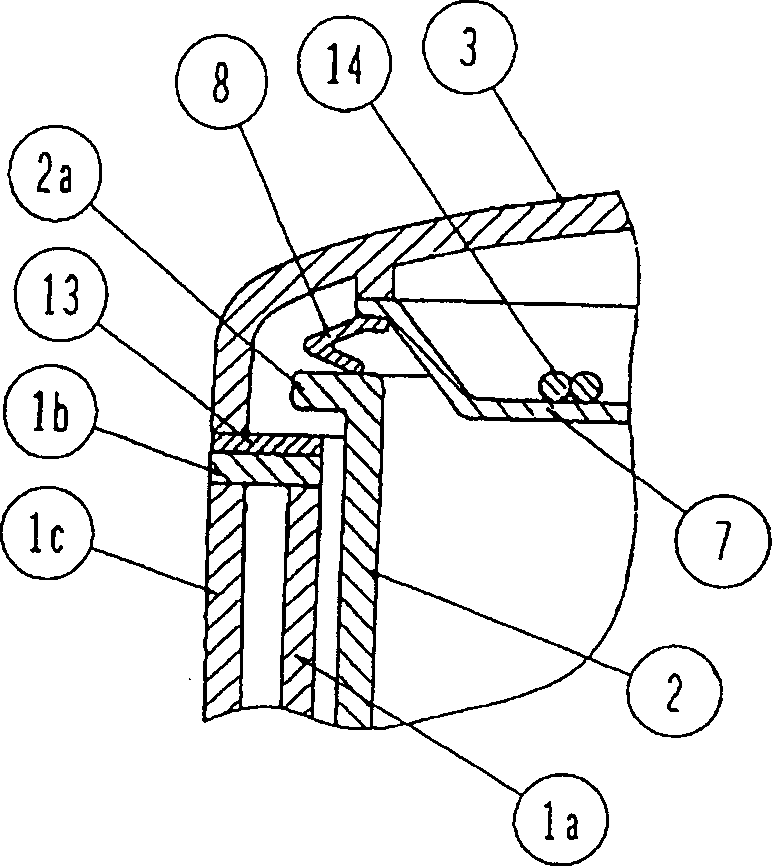

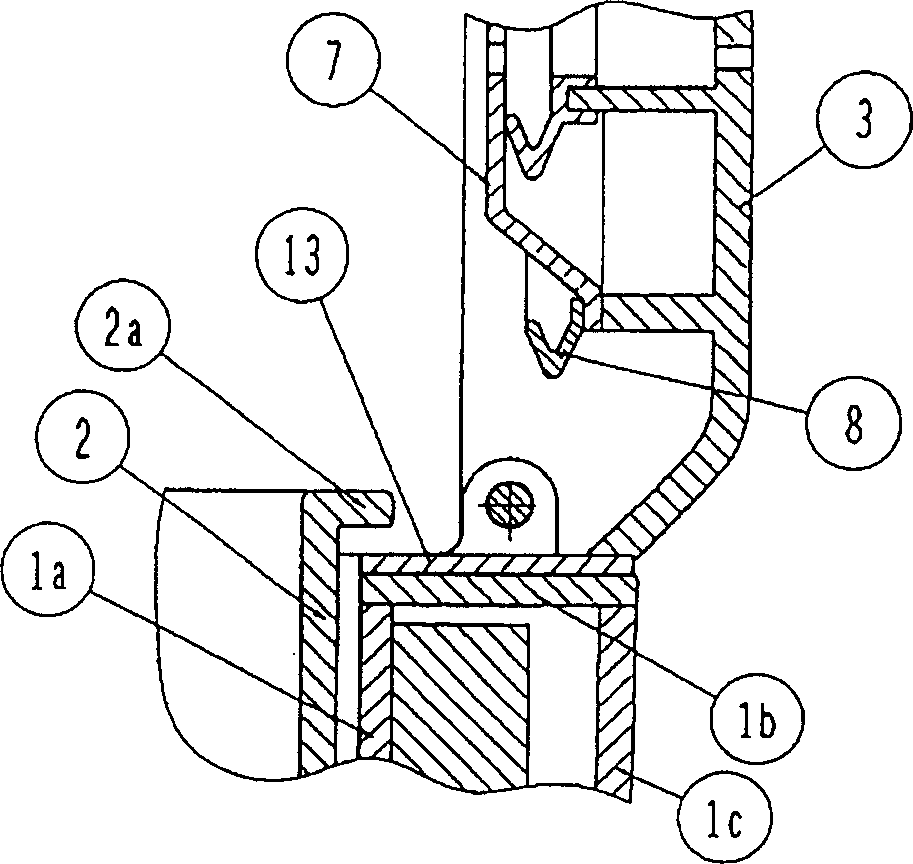

Numerical control slurry spraying yarn repair lubricator and method thereof

InactiveCN102220666ACleanlinessReduce occupational diseasesTextile treatment by spraying/projectingLubricationPositive direction

The invention relates to a numerical control slurry spraying yarn repair lubricator and a method thereof. The numerical control slurry spraying yarn repair lubricator mainly comprises a micro speed-regulating hollow shaft motor, an atomization slurry spraying chamber, a yarn clew dust cover and a numerical control metering pump which are connected in sequence. The lubricator is characterized in that the micro speed-regulating hollow shaft motor is connected with the atomization slurry spraying chamber, and the lower end of the atomization slurry spraying chamber is connected with yarn clew dust cover which is provided with a dust exhaust port and is internally embedded with a gravity pressure spring; and nozzles on two sides of the atomization slurry spraying chamber are formed by connecting a slurry supply pipeline and a high-pressure metering pump. When yarns are reeled off from cheese, a rotary balloon naturally spirally lifted in positive direction is produced, the yarns pass through the high-pressure atomization slurry spraying chamber in time, and input slurry is automatically and preciously controlled by the high-pressure metering pump according to a computer instruction; the high-pressure slurry spraying chamber is provided with two or a plurality of nozzles for balanced multidimensional stereoscopic slurry spraying with multiple surfaces, multiple points and multiple angles; the yarn sprout ratio reaches a critical point of saturation and unsaturation; after being repaired and film-formed, the yarns are flexible internally and smooth externally and are rich in elasticity; and the method is an unsaturated slashing method. The working procedures of slashing and lubrication are merged and finished in one time, and a wrapped lubricant slurry film (30) is arranged outside the yarns. The method is grain-saving, water-saving, electricity-saving, time-saving, waste water zero-discharged, energy-saving and environmentally-friendly.

Owner:崔建明

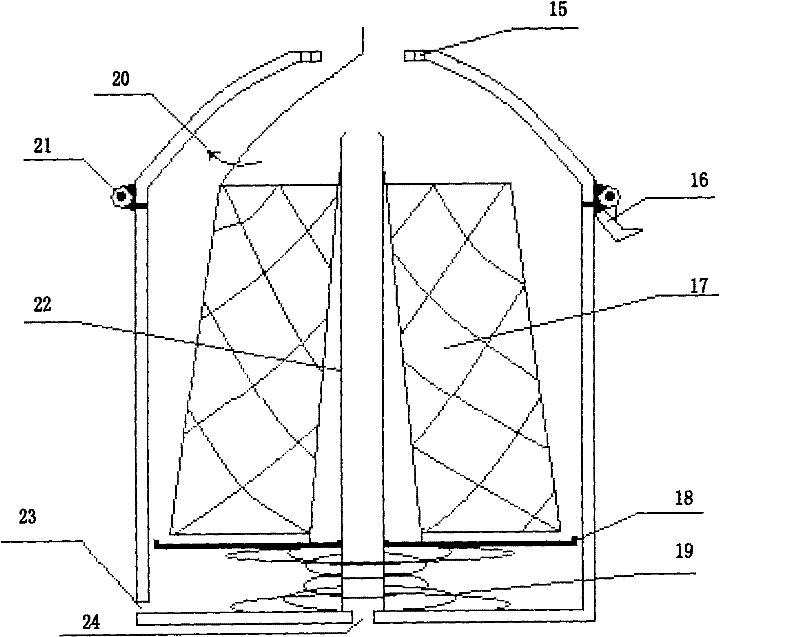

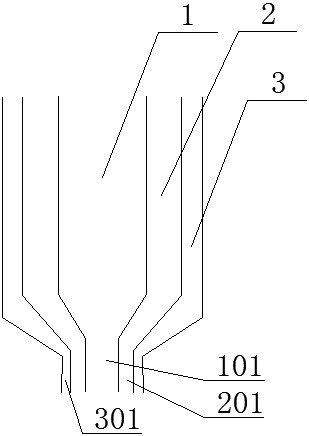

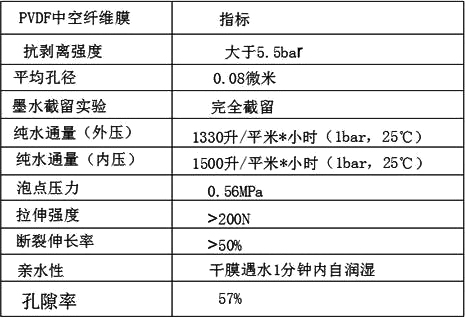

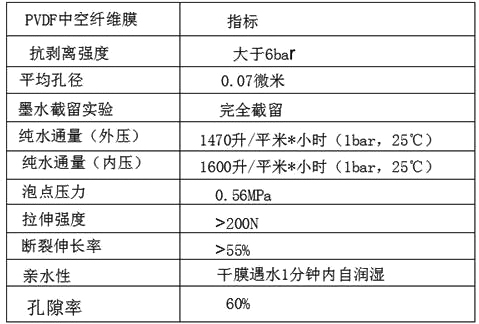

Method for preparing nano-composite polyvinylidene fluoride hollow fiber membrane by three-layer co-extrusion and co-extrusion equipment

InactiveCN112588131ASuperhydrophilicPollutedMembranesSemi-permeable membranesPolymer scienceSpinning

The invention discloses a method for preparing a nano composite polyvinylidene fluoride hollow fiber membrane through three-layer co-extrusion and co-extrusion equipment, and belongs to the technicalfield of membranes. The preparation method comprises the steps of 1) putting polyvinylidene fluoride resin and an additive into a solvent or a diluent, uniformly dissolving, and defoaming to obtain apolyvinylidene fluoride membrane casting solution; 2) uniformly dispersing a nano functional material into the polyvinylidene fluoride solution to prepare a nano functional material solution; 3) performing double-layer co-extrusion on the polyvinylidene fluoride membrane casting solution and the nano functional material solution by using a three-layer channel spinning nozzle; and 4) finally, immersing a polyvinylidene fluoride hollow fiber membrane blank into a coagulating bath tank for phase inversion, and curing to form the nano composite polyvinylidene fluoride hollow fiber membrane. According to the method for preparing the nano composite polyvinylidene fluoride hollow fiber membrane through three-layer co-extrusion and the co-extrusion equipment, the modification process does not influence the flux, solute interception and other properties of the membrane, the nano-functional layer compounded on the surface is not prone to falling off, and better stability and better modificationeffect are shown.

Owner:杭州高通膜技术有限公司

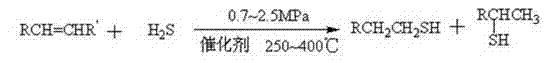

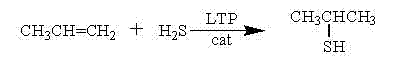

Method for synchronizing low-level mercaptan

ActiveCN102766078AHigh selectivityExtended service lifeThiol preparationChemical recyclingPetrochemicalDirect production

The invention discloses a method for directly producing low-level mercaptan by byproducts of the petrochemical industry, including gaseous olefin and hydrothion gas. The method includes the following steps of sufficiently mixing gaseous olefin and hydrothion gas in a static pipeline mixer, subjecting the mixed gas to react in a plasma reaction bin at normal temperature and normal pressure, separating and purifying to obtain target products. Conditions of reaction at the normal temperature and normal pressure are mild, and the method is high in safety, low in cost and high in yield.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

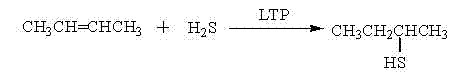

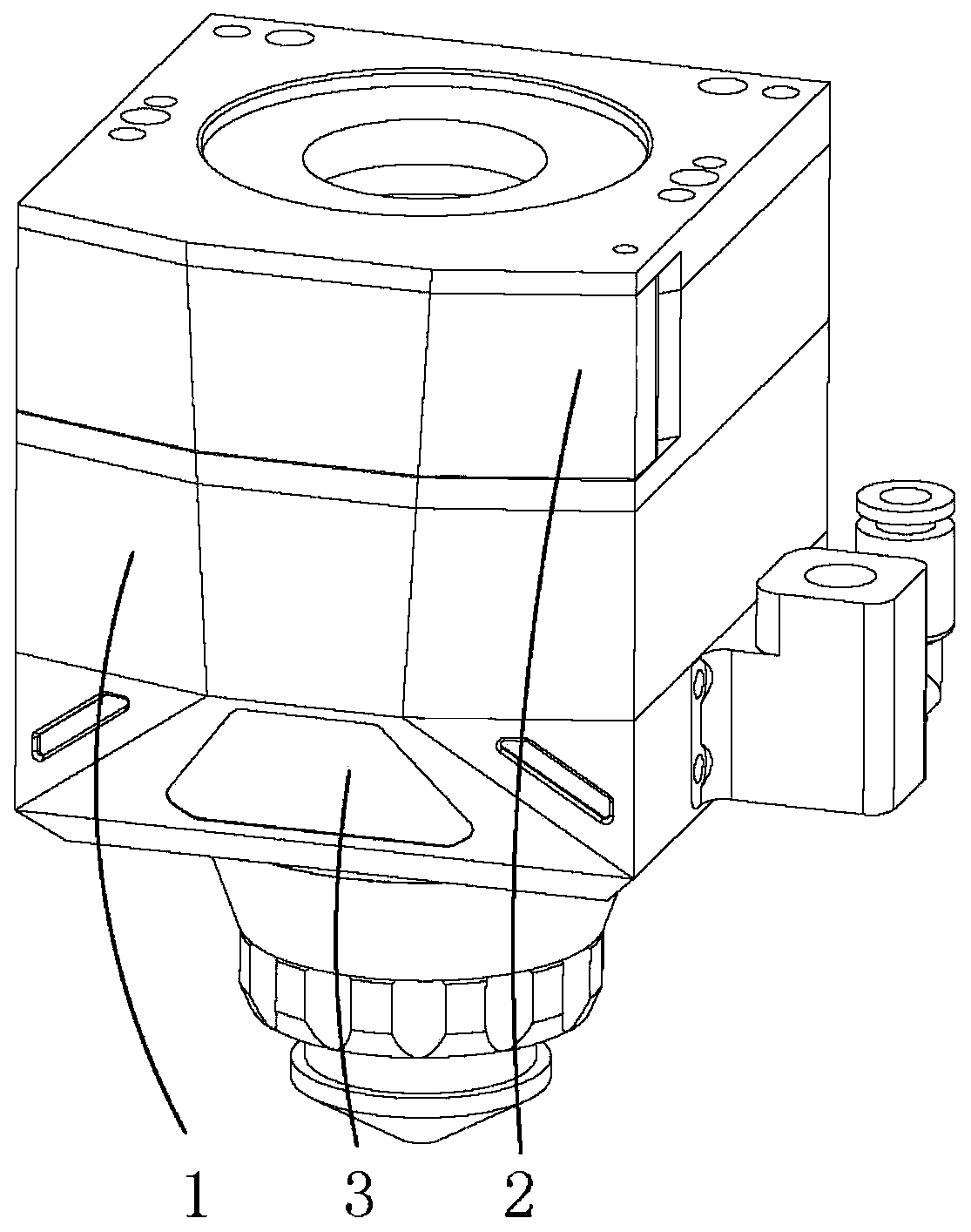

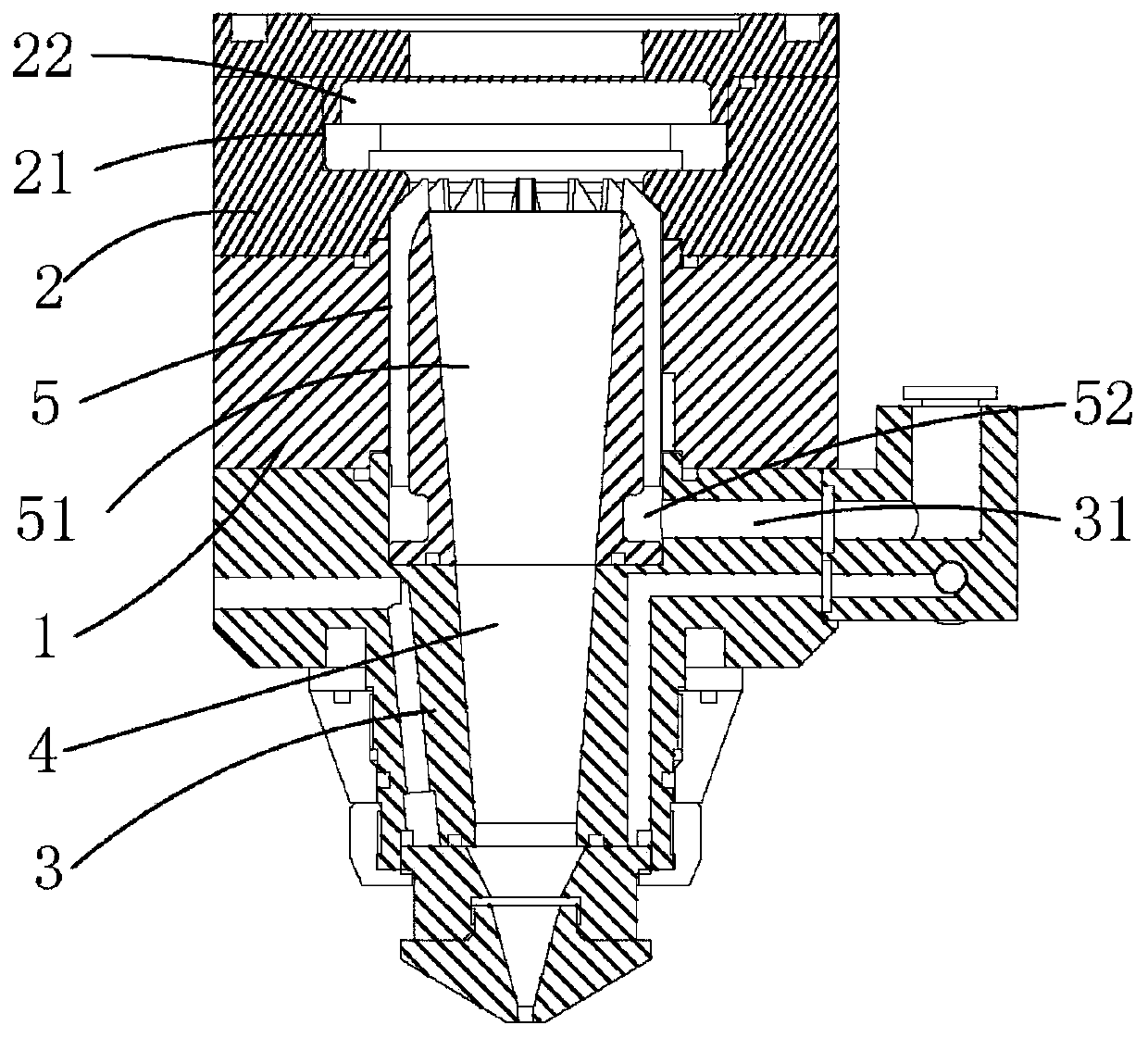

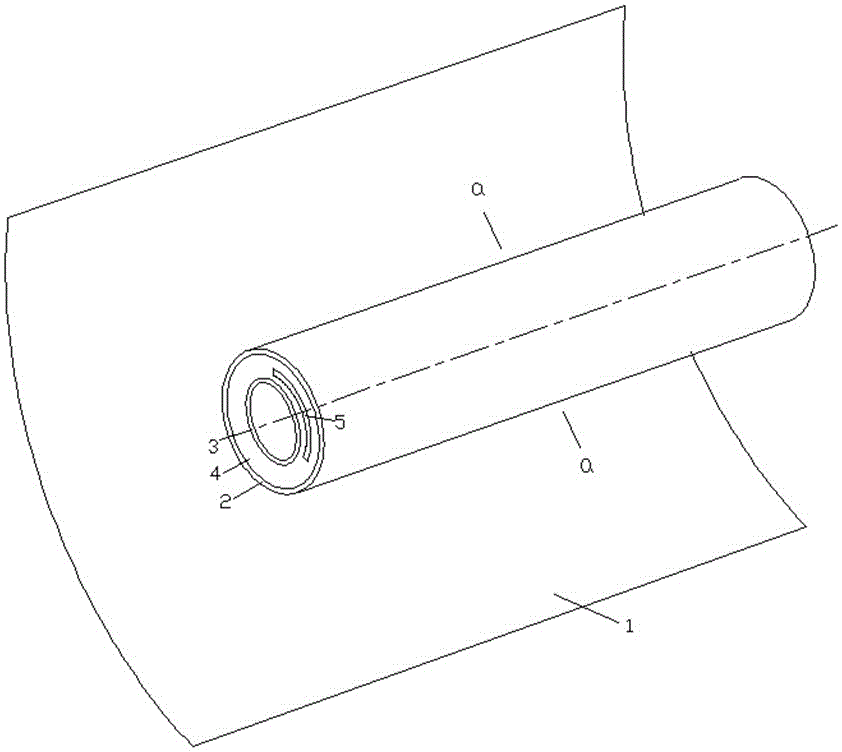

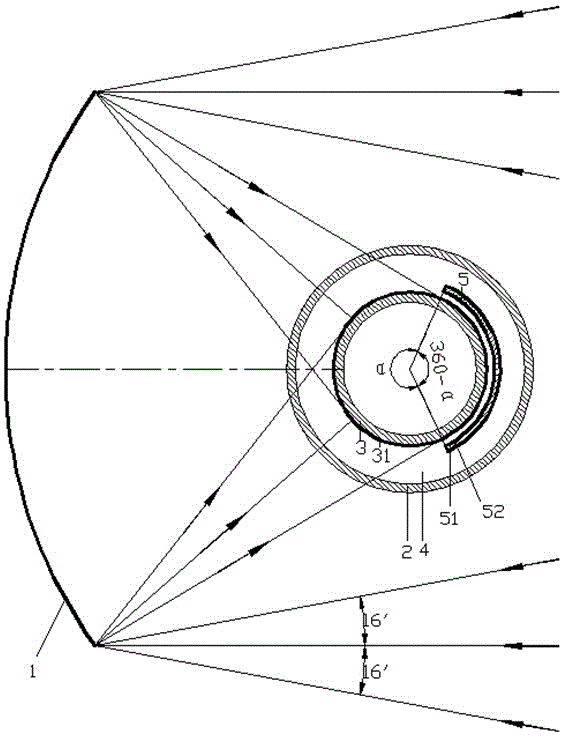

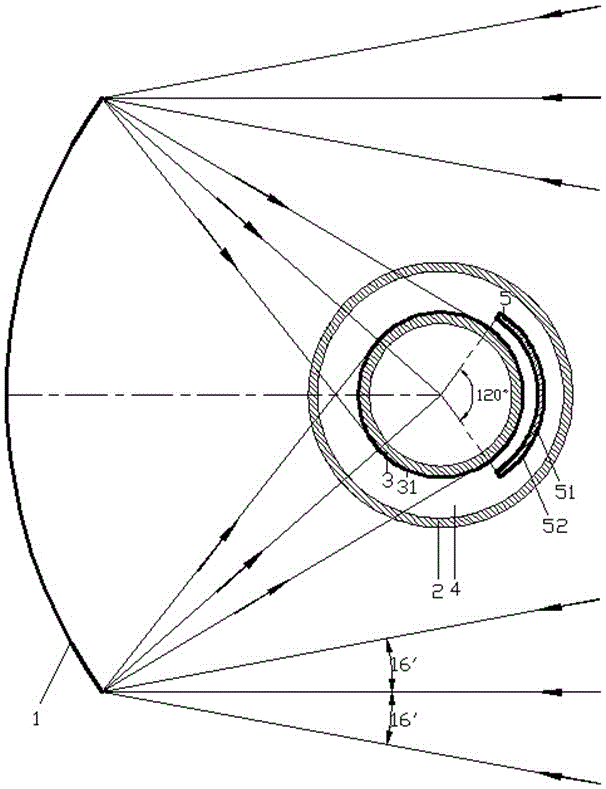

Nozzle air guide device for laser cutting head

The invention provides a nozzle air guide device for a laser cutting head. The nozzle air guide device comprises a hollow shell, a lower protective glass seat, a nozzle and a hollow guide cylinder, wherein the lower protective glass seat is arranged at the end, close to optical fiber, of the shell, and the nozzle is arranged at the end, far away from the optical fiber, of the shell; the shell is fixedly connected with the lower protective glass seat and the nozzle respectively, and the inner parts of the shell, the lower protective glass seat and the nozzle successively communicates to form athrough-going laser passage; a through-going air inlet pipe is arranged on the nozzle, an air source communicates with the laser passage through the air inlet pipe, and the air inlet pipe is used forconveying cutting gas; the guide cylinder is arranged in the laser passage and is fixedly connected with the inner surfaces of the shell, the lower protective glass seat and the nozzle respectively; and the guide cylinder communicates with the air inlet pipe and the laser passage respectively. The nozzle air guide device uses the guide cylinder to adjust the direction and the flow speed of airflow, so that the airflow is more stable. An air storage tank is combined with a flow guide tank, so that an effect of redistributing the airflow can be achieved.

Owner:武汉奥森迪科智能科技股份有限公司

Slot type light gathering type solar vacuum heat collecting pipe

InactiveCN105157257AReduce lossReduce external heat lossSolar heat devicesSolar thermal energy generationGlass coverLow emissivity

The invention relates to a slot type light gathering type solar vacuum heat collecting pipe. The slot type light gathering type solar vacuum heat collecting pipe comprises an outer glass cover pipe and an inner heat absorbing pipe. An inner pipe coating is arranged on the outer cylindrical face of the inner heat absorbing pipe. A cavity between the outer glass cover pipe and the inner heat absorbing pipe is vacuum annular space. A heat shielding plate is arranged in the vacuum annular space. The side face, corresponding to the inner heat absorbing pipe, of the heat shielding plate is a reflection face, and the side face, corresponding to the outer glass cover plate, of the heat shielding plate is an absorption face. The inner surface of the heat shielding plate has the properties of high reflectivity and low emissivity in an infrared band, the outer surface of the heat shielding plate is coated with a selective absorption coating and has the properties of high absorptivity in the solar radiation wave band of 0.2-3 microns and low emissivity in the infrared wave band larger than 3 microns. The external radiation heat loss of the inner pipe of the vacuum heat collecting pipe under the medium-high temperature heat collecting situation can be greatly reduced, and the heat collecting efficiency is improved.

Owner:UNIV OF SCI & TECH OF CHINA

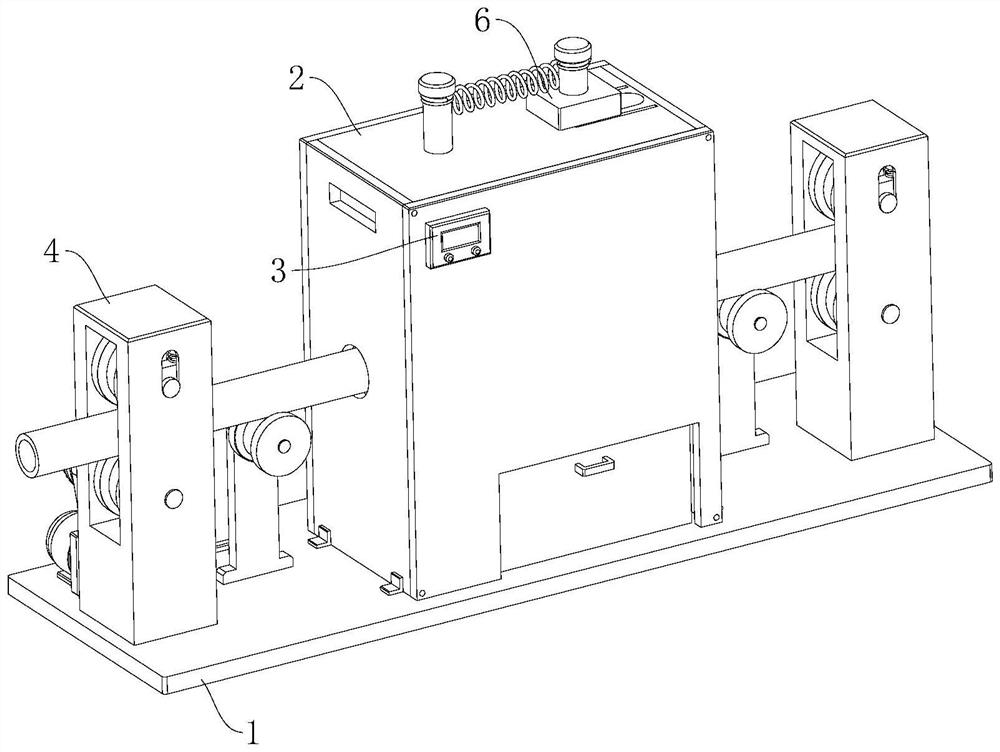

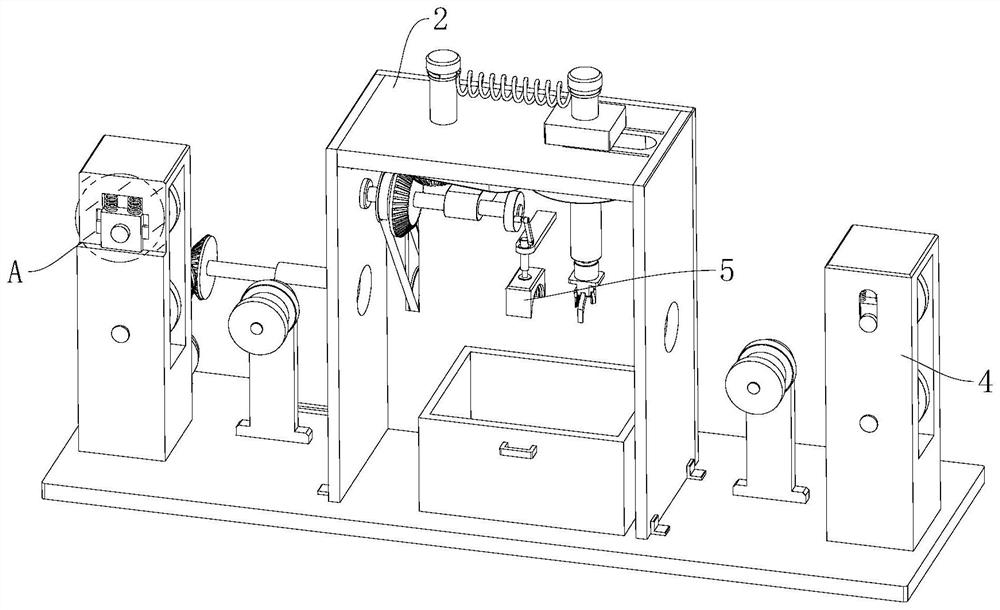

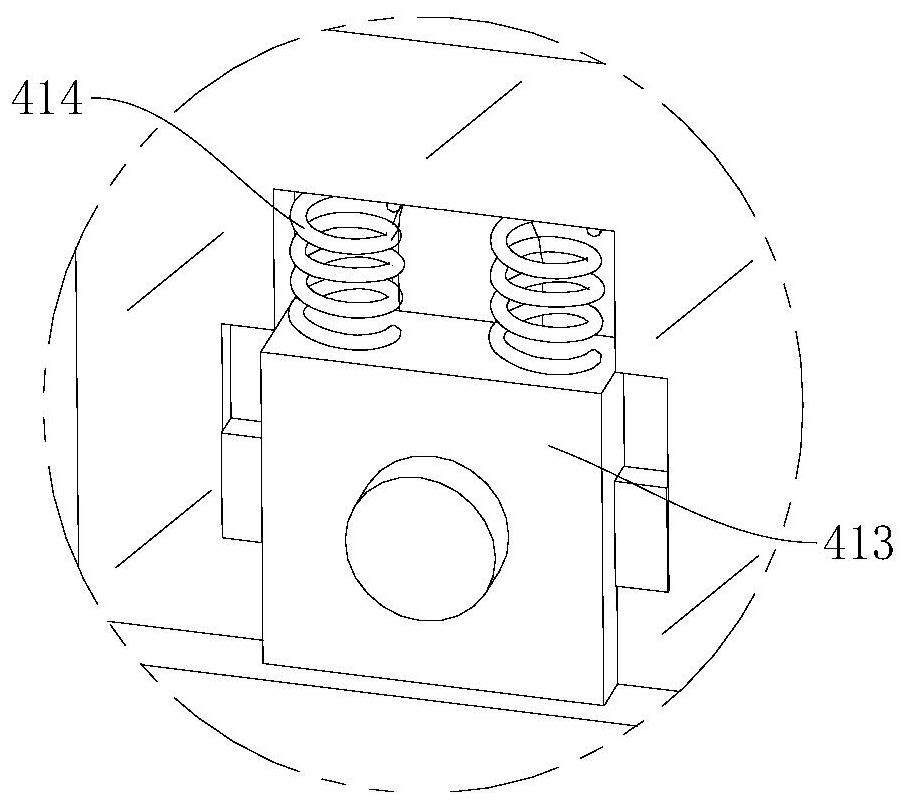

Construction site steel pipe surface cleaning equipment

ActiveCN112354979AReduce labor intensityReduce cleanup stepsHollow article cleaningDirt cleaningSurface cleaningPipe

The invention relates to the field of cleaning devices, in particular to construction site steel pipe surface cleaning equipment. The equipment comprises a base and a cleaning box and further comprises a controller, a conveying mechanism, a beating mechanism and a scraping mechanism. The conveying mechanism is arranged at the top of the base to be used for conveying steel pipes and comprises a transmission assembly and two conveying tables. The beating mechanism is arranged at the top of the inner side of the cleaning box and used for beating the steel pipes, the beating mechanism comprises ahammer head and a rotating assembly, the scraping mechanism is arranged at the top of the inner side of the cleaning box and used for scraping impurities such as concrete on the surfaces of the steelpipes, the scraping mechanism comprises a scraping head, a pushing assembly and a limiting assembly, and the transmission assembly is electrically connected with the controller. According to the construction site steel pipe surface cleaning equipment, manpower is automatically replaced, the cleaning efficiency is high, the labor intensity is low, the noise is low, meanwhile, the power consumptionis low, the cleaning cost can be reduced, the cleaned impurities can be effectively collected, and pollution is avoided.

Owner:巢湖市鼎力铁塔有限公司

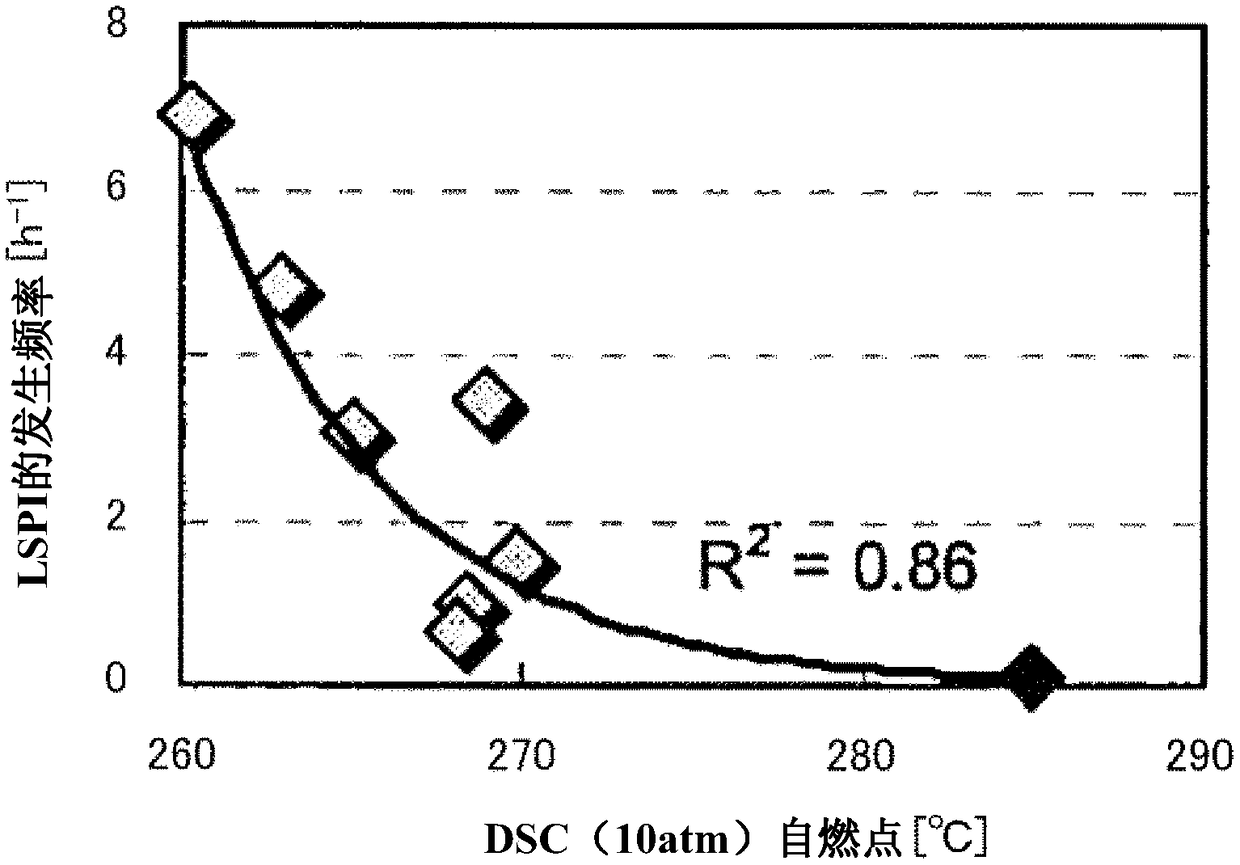

Lubricant oil composition for internal combustion engine

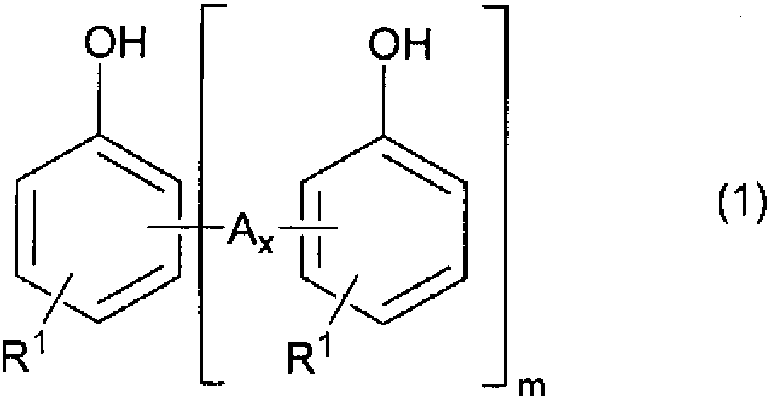

ActiveCN108473905AImprove LSPI suppression performanceCleaning savingsAdditivesBase-materialsCalcium carbonateSulfide

According to the present invention, a lubricant oil composition for an internal combustion engine contains (A) a base oil having a kinematic viscosity of 2-8 mm2 / s at 100 DEG C and 10 mass% or less aromatic content, (B) a metal-based detergent including (B1) a metal-based detergent overbased by calcium carbonate and (B2) a metal-based detergent over-based by magnesium carbonate, and (C) molybdenumdithiocarbamate sulfide or oxymolybdenum dithiocarbamate sulfide; wherein, based on the total amount of the lubricant oil composition, the calcium content is 1500 or less ppm by mass, the magnesium content is 300 or more ppm by mass and the molybdenum content is 600 or more ppm by mass; and wherein the HTHS viscosity at 150 DEG C is 2.7 or less mPa.s.

Owner:JXTJ NIPPON OIL & ENERGY CORP +1

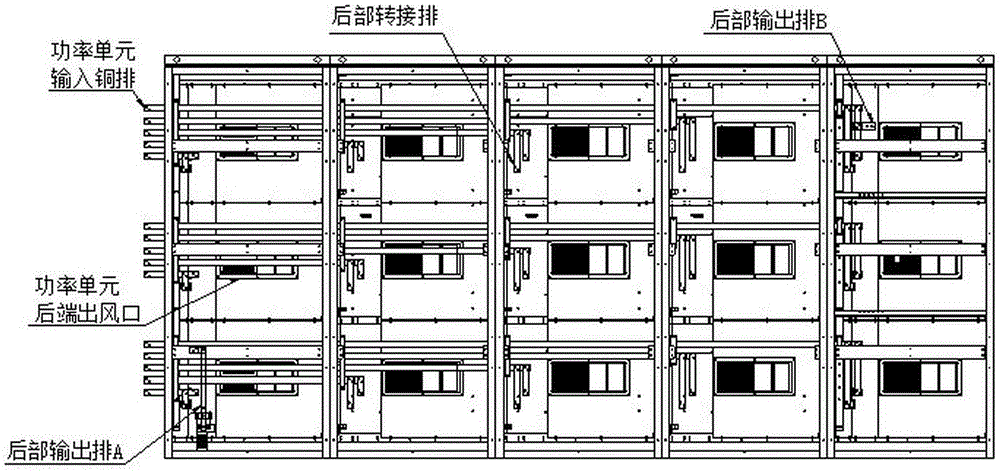

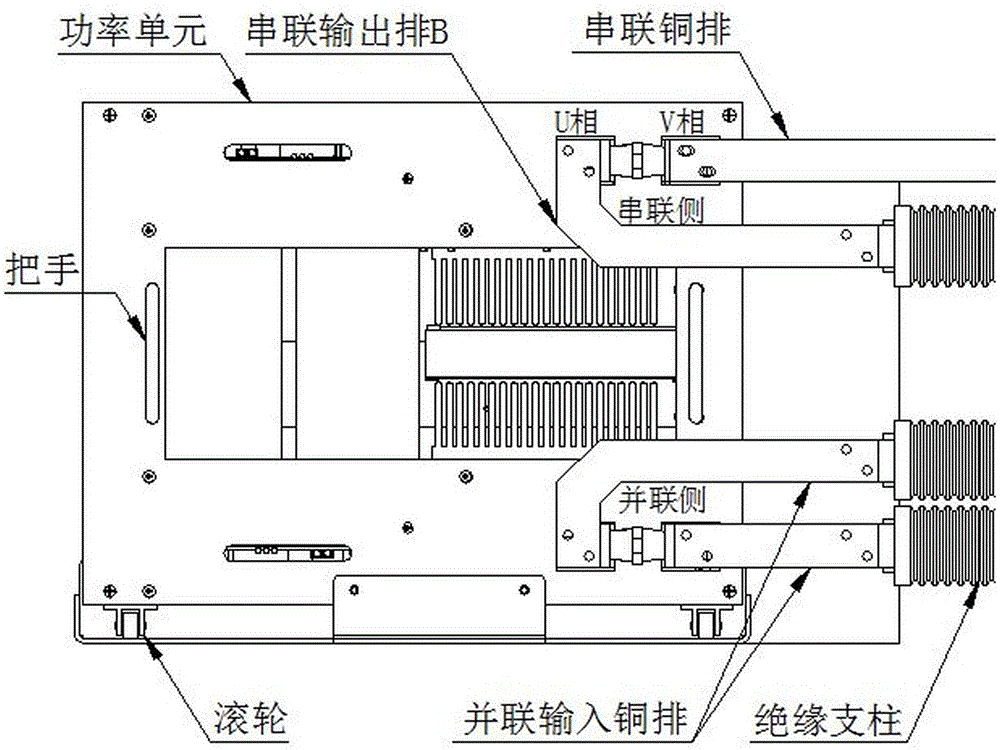

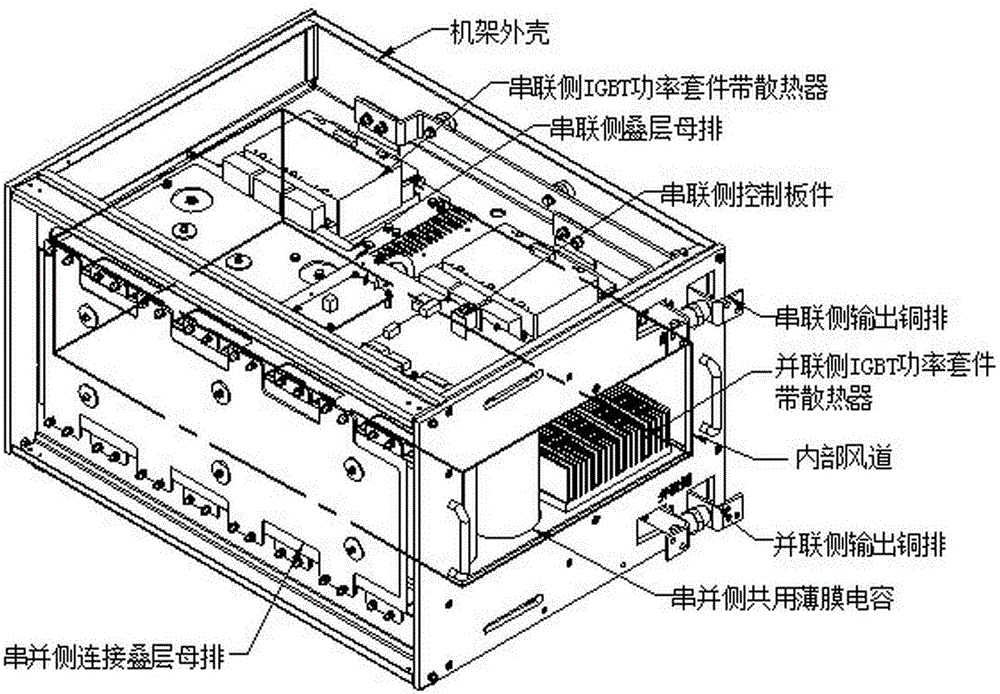

Structural device for cascaded type cophase power supply converter

ActiveCN105162310AImprove securityImprove comfortCooling/ventilation/heating modificationsPower conversion systemsSymmetric designHarmonic

The invention relates to a structural device for a cascaded type cophase power supply converter. The device comprises power units which can be connected in series and in parallel, multiple columns of cabinet bodies which are formed by connecting power unit single cabinets and a container for containing the cabinet bodies. According to the structural device for the cascaded type cophase power supply converter, the whole structural design and connections aiming at the power units are optimized in the structural device, and by means of the efficient series-wound and shunt-wound design and the symmetric design of the electrical structure, back-to-back power units are formed, so that the functions of a high-voltage cophase power supply system are achieved in structure, and the technical effects that electrical sectioning is canceled, the safety and the comfort of a train are improved, and damage of an idle current and a harmonic current to the system is reduced are achieved.

Owner:DONGFANG HITACHI CHENGDU ELECTRICAL CONTROL EQUIP CO LTD

Room-temperature cured nanometer self-cleaning antireflection coating solution and preparation method thereof

The invention discloses a room-temperature cured nanometer self-cleaning antireflection coating solution and a preparation method of the room-temperature cured nanometer self-cleaning antireflection coating solution. The room-temperature cured nanometer self-cleaning antireflection coating solution comprises anatase titanium dioxide, silicon dioxide, tin antimony oxide, a silane coupling agent, asurfactant and a solvent; the preparation method of the room-temperature cured nanometer self-cleaning antireflection coating solution comprises the following steps: fully mixing an anatase titanium dioxide aqueous dispersion liquid with silica ethanol dispersion liquid according to the ratio, adding the surfactant and the silane coupling agent and stirring for 1h; then adding a tin antimony oxidedispersion liquid, and fully stirring to obtain transparent and stable room-temperature cured nanometer self-cleaning antireflection coating solution. The room-temperature cured nanometer self-cleaning antireflection coating solution provided by the invention is low in cost of raw materials, low in operating temperature, simple in equipment, pollution-free and easy in industrial production, and cured at a room temperature and does not need to be sintered at high temperature, thereby being extremely convenient by being taken as a room temperature self-cleaning product, and further has the characteristics of good stability and transparency, and a thin film obtained by pulling has self-cleaning and anti-fogging properties.

Owner:NANCHANG UNIV

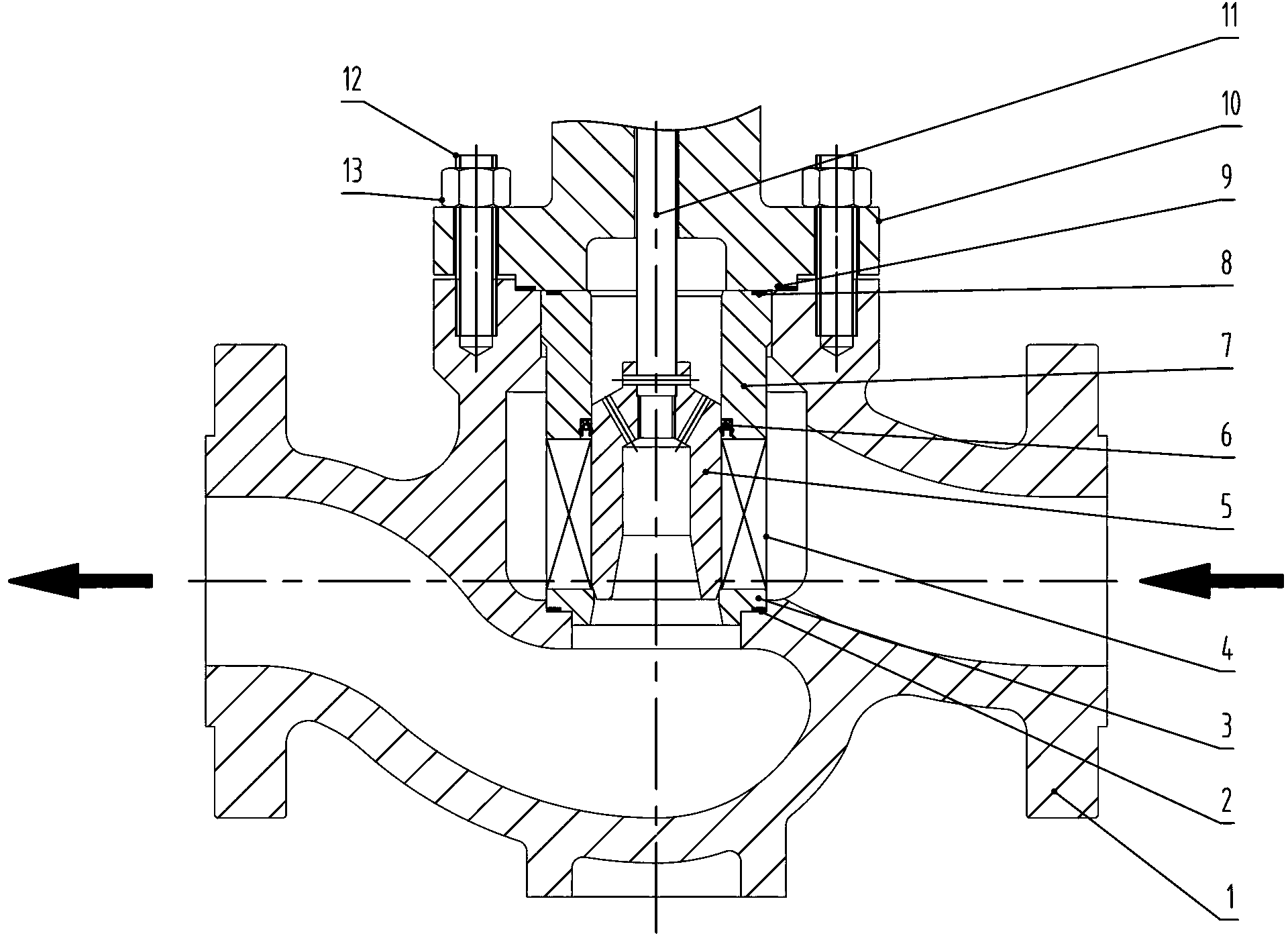

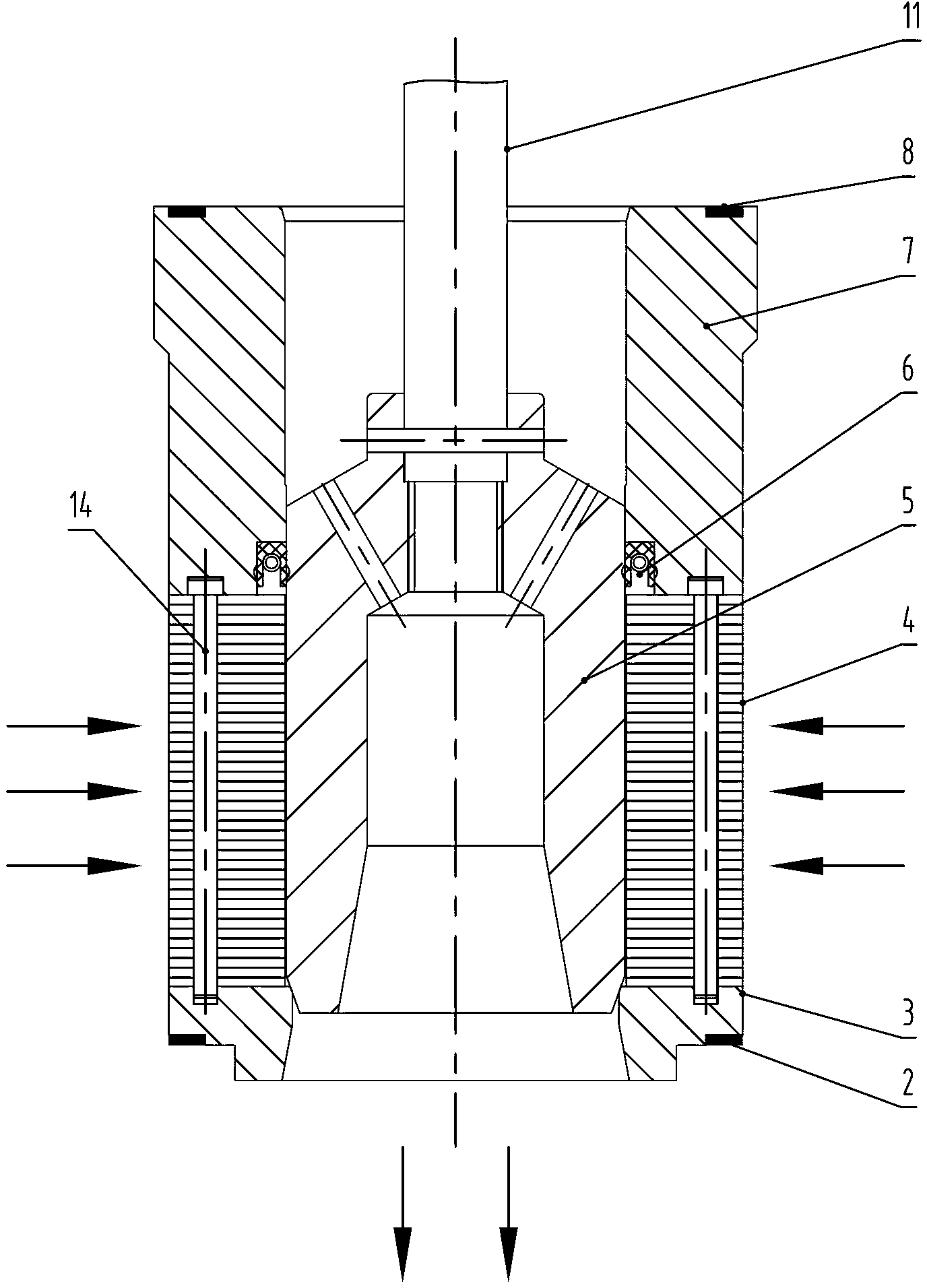

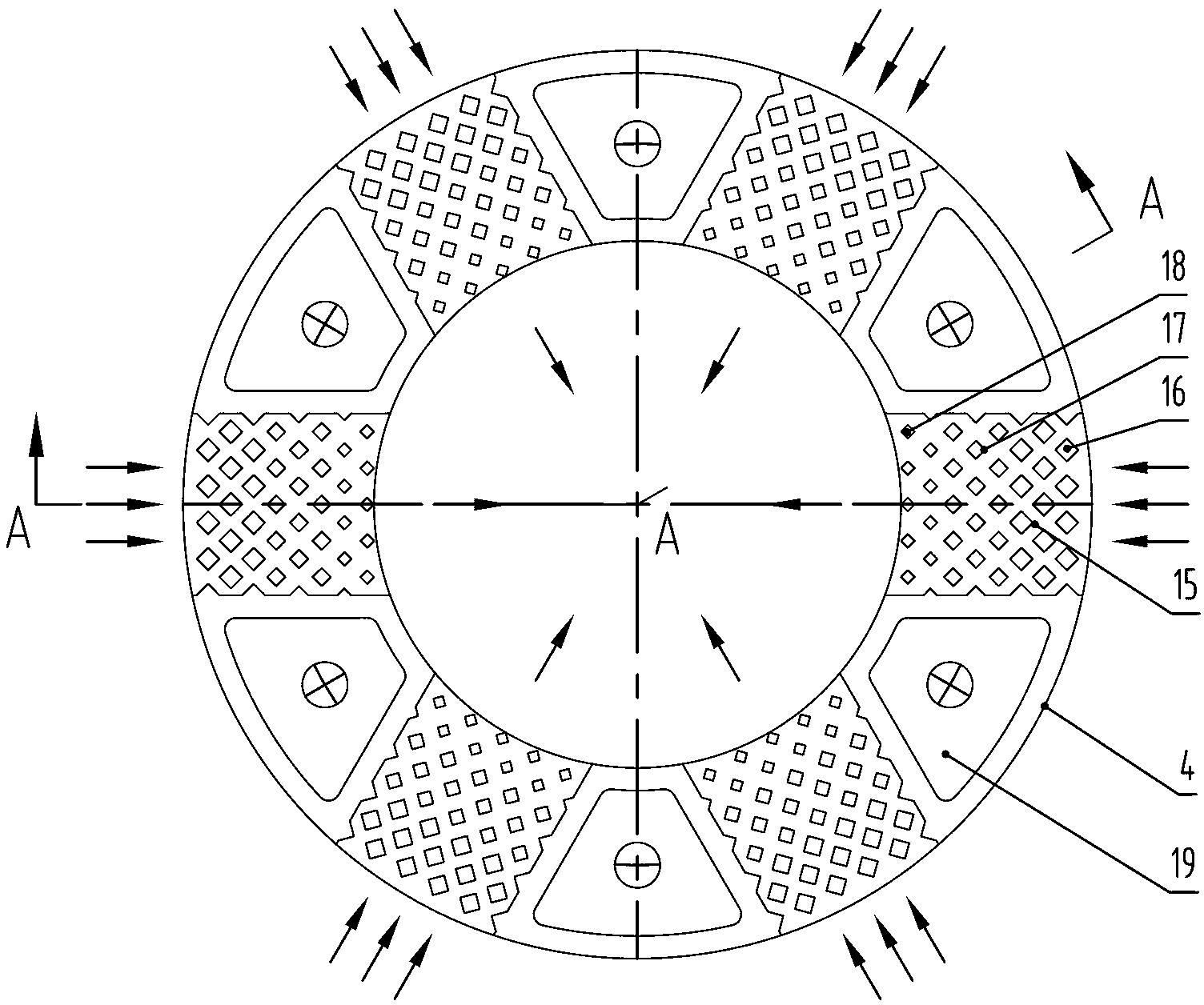

Array flow velocity control valve structure suitable for incompressible fluid

InactiveCN102937188AReduce kinetic energyImprove efficiencyValve members for absorbing fluid energyLift valveCavitationEngineering

The invention relates to an array flow velocity control valve structure suitable for incompressible fluid. The structure comprises a valve body, a valve base, valve cores, an upper cover and valve rods, wherein the base valve is arranged in the valve body, a plurality of throttle slices are arranged installed on the valve base, the throttle slices are positioned through positioning pins, each of the throttle slices comprises a parallel thin plate body and a rhombic pillar-shaped array structure, a guide base is installed on the throttle slices, balancing sealing rings are installed in the guide base, valve cores are installed in the throttle slices, the valve cores are connected with the valve rods, and the upper cover is installed on the valve body; and the upper cover is fixed on the valve body through a screw bolt and a nut. According to the structure, the fluid pressure is kept to be above the saturated vapor pressure, bubbles are avoided, and a cavitation phenomenon is eliminated; damages of inner parts of a valve, which are caused by energy blasting energy, are reduced; the valve is convenient to disassemble and clean, and on-line maintenance is facilitated; and the pressure is reduced step by step through flow rate control of high-speed incompressible fluid, the cavitation phenomenon is avoided, and the normal operation of the valve is guaranteed.

Owner:WUXI SMART AUTO CONTROL ENG CO LTD

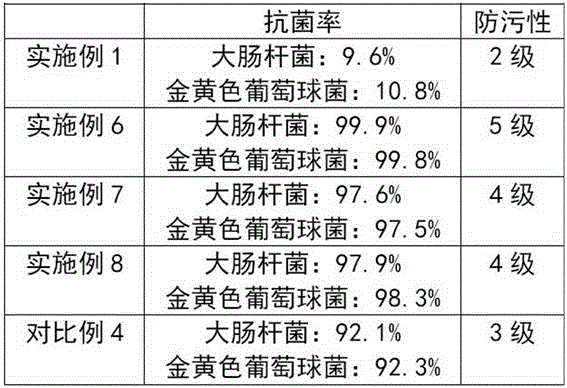

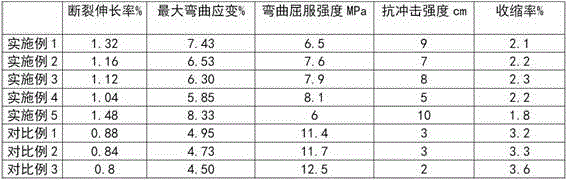

Self-cleaning antibacterial light-cured resin material used for 3D printing

InactiveCN106167537ACleanlinessFunctionalAdditive manufacturing apparatusMechanical propertyLight cure

The invention discloses a self-cleaning antibacterial light-cured resin material used for 3D printing. The self-cleaning antibacterial light-cured resin material is prepared from, by weight, 75 to 85 parts of epoxy acrylate, 1 to 5 parts of a reactive diluents, 1 to 5 parts of a photoinitiator, 1 to 3 parts of other accessory ingredients, 1 to 10 parts of a graphene / TiO2 cleaning material, and 1 to 10 parts of a multiwalled carbon nanotube / nano-silver antibacterial material; wherein the weight ratio of epoxy acrylate: the graphene / TiO2 cleaning material: the multiwalled carbon nanotube / nano-silver antibacterial material is 80:(2-5):(2-8). According to the self-cleaning antibacterial light-cured resin material, a composite material is formed via absorption of nano silver particles and nano TiO2 powder onto multiwalled carbon nanotube and graphene, a scientific ratio is obtained via a plurality of experiments, and the composite material is distributed in a light-cured resin, so that the self-cleaning antibacterial light-cured resin material is capable of achieving preferably 3D printing product mechanical properties, and providing the 3D printing products with self-cleaning functions and antibacterial functions.

Owner:佛山市高明区诚睿基科技有限公司

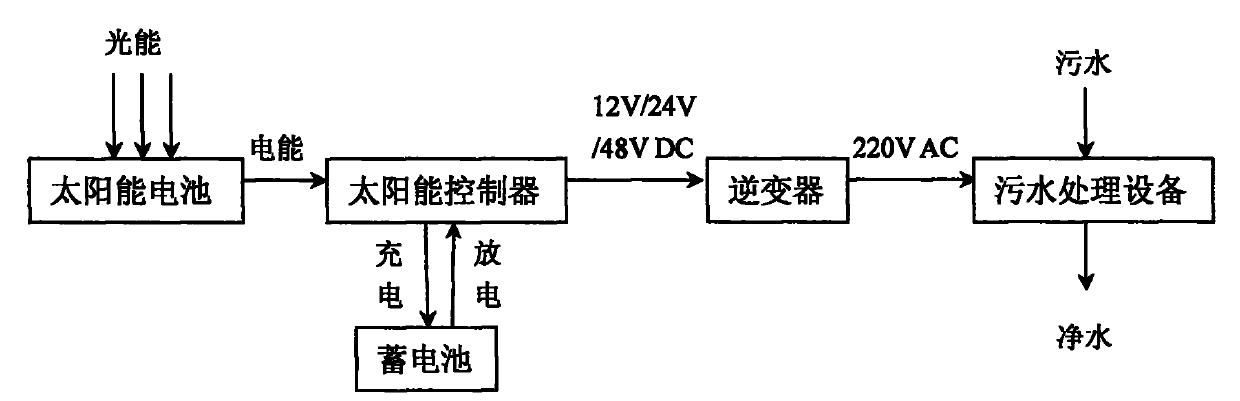

Dispersed sewage treatment system with solar power generation

InactiveCN102020323APermanentSolution to short lifeBatteries circuit arrangementsGeneral water supply conservationLight energyElectrical battery

The present invention discloses a dispersed sewage treatment system with solar power generation, which comprises a solar cell, a storage battery, a solar energy controller, an inverter, and a sewage treatment device. The solar cell transforms light energy into electric energy by photoelectric effect and delivers the electric power to the storage battery for charging the storage battery; the solar energy controller is connected respectively with the solar cell and the storage battery, while the inverter is connected respectively with the solar energy controller and the sewage treatment device. Existing dispersed sewage treatment equipment and facilities that require commercial power supply have the defects of high running cost and are difficult to popularize and apply on large scale in economically undeveloped areas and places with power supply difficulties, while the present invention provides an energy-saving and economical dispersed sewage treatment system which provides the required electric power for the sewage treatment system by solar power generation; provides electric energy for the sewage treatment system by using the solar cell to transform light energy into electric energy; and achieves the advantages of permanence, cleanness, economy and universality.

Owner:JIANGXI JDL ENVIRONMENTAL PROTECTION CO LTD

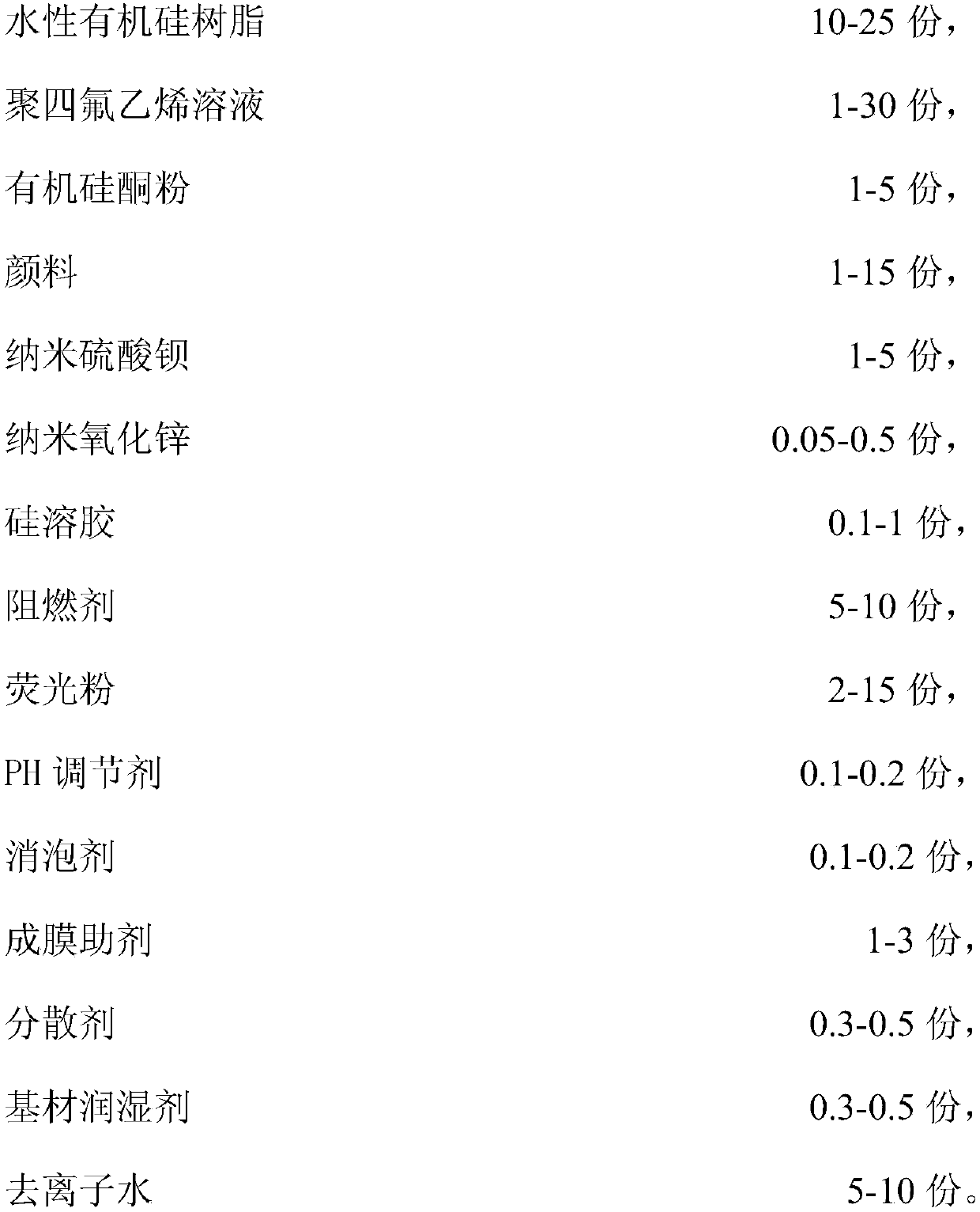

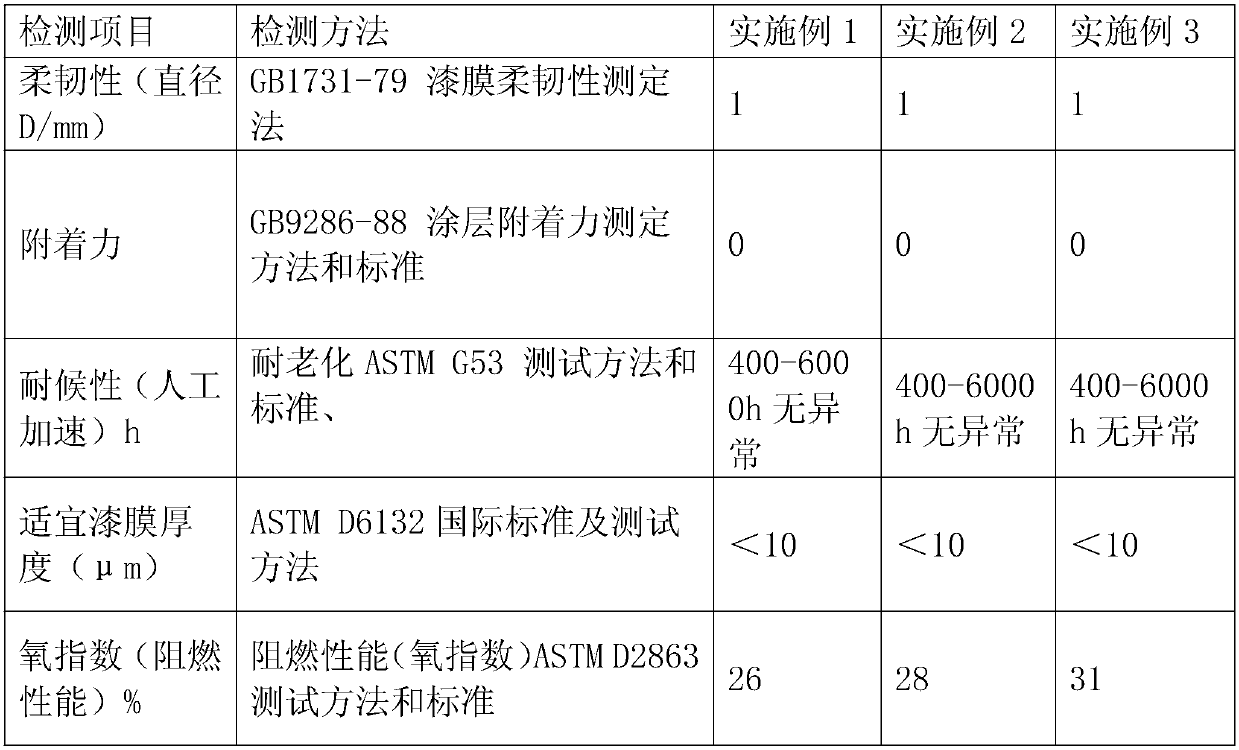

Water-based paint for multifunctional fiber textile and preparation method thereof

PendingCN107841241ALow refractive indexLarge specific surface areaFireproof paintsAntifouling/underwater paintsWater basedFiber

The invention discloses water-based paint for multifunctional fiber textile. The water-based paint is prepared from the following raw material components in parts by mass: 10 to 25 parts of water-based organic silicon resin, 1 to 30 parts of a polytetrafluoroethylene solution, 1 to 5 parts of organic silicone powder, 1 to 15 parts of a pigment, 1 to 5 parts of nano barium sulfate, 0.05 to 0.5 partof nano zinc oxide, 0.1 to 1 part of silica sol, 5 to 10 parts of a flame retardant, 2 to 15 parts of fluorescent powder and the like. Furthermore, the invention further provides a simple and feasible preparation method of the water-based paint for the multifunctional fiber textile. By adopting the formula and the method, disclosed by the invention, the prepared paint has adhesive force, flexibility, weather resistance and flame-retarding performance and has a suitable paint film thickness; meanwhile, the water-based paint also has the characteristics of no fluffiness, no fading and smooth hand feeling, and a plurality of effects of heat prevention, flame retarding, corrosion resistance, fluorescence warning, easiness for cleaning, bacterium inhibition and sterilization, environment protection and the like, so that the water-based paint has very strong market competitiveness.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com