Modified nano titanium dioxide self-cleaning coating and preparation method thereof

A nano-titanium dioxide, self-cleaning technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problem of reducing the photocatalytic activity of titanium dioxide films, dispersing nano-titanium dioxide is not uniform enough, and affecting the self-cleaning effect of products and other problems, to achieve the effect of enhancing the visible light response, broadening the light response range, and improving the photocatalytic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

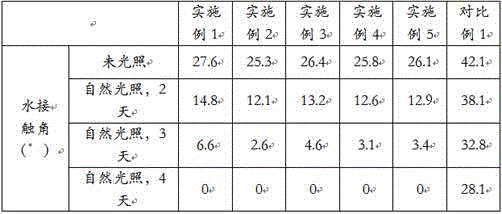

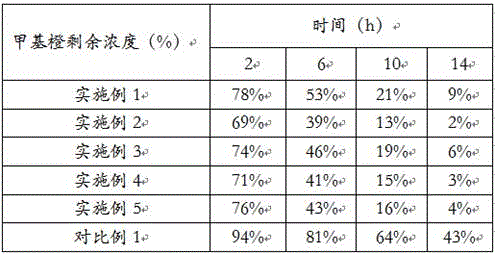

Examples

Embodiment 1

[0038] A modified nano-titanium dioxide self-cleaning coating, in parts by mass, whose raw materials include the following components:

[0039] Boron nitrogen doped coated nano-titanium dioxide 1.5

[0040] tert-butyl methacrylate 15

[0041] Sodium Lauryl Sulfate 2

[0042] Cetyl alcohol 0.5

[0043] Potassium persulfate 0.3

[0044] Deionized water 50

[0045] Vinyltrimethoxysilane coupling agent 0.5

[0046]The preparation method of the above-mentioned self-cleaning coating is as follows: in parts by mass, 1.5 parts of the prepared boron-nitrogen-doped and coated nano-titanium dioxide are added to an aqueous ethanol solution, and fully dispersed under strong stirring; 0.5 parts of vinyltrimethoxysilane coupling agent, magnetic stirring and heat preservation reaction for 1 hour, cooled to normal temperature, suction filtration, drying, and grinding to obtain silanized boron-nitrogen-doped nano-titanium dioxide; 1.5 parts of silylated boron-nitrogen Dope and coat nano-t...

Embodiment 2

[0050] A modified nano-titanium dioxide self-cleaning coating, in parts by mass, whose raw materials include the following components:

[0051] Boron and nitrogen doped coated nano-titanium dioxide 3

[0052] Hydroxyethyl Acrylate 25

[0053] Tween 80 6

[0054] n-Pentanol 2

[0056] Deionized water 90

[0057] Vinyltriethoxysilane coupling agent 2.5

[0058] The preparation method of the above-mentioned nano-titanium dioxide self-cleaning coating is as follows: in parts by mass, 3 parts of the prepared boron-nitrogen-doped coated nano-titanium dioxide are added to an aqueous ethanol solution, and fully dispersed under strong stirring; Add 2.5 parts of vinyltriethoxysilane coupling agent to the mixture, and after magnetic stirring and heat preservation for 3 hours, cool to normal temperature and suction filter, dry and grind to obtain silanized boron-nitrogen-doped nano-titanium dioxide; 3 parts of silane Boron nitrogen doped coated nano-ti...

Embodiment 3

[0062] A modified nano-titanium dioxide self-cleaning coating, in parts by mass, whose raw materials include the following components:

[0063] Boron and nitrogen doped coated nano-titanium dioxide 2

[0064] 2-ethyl acrylate 20

[0065] Polyoxyethylene sorbitan trioleate 4

[0066] Hexadecane 1.5

[0067] Ammonium persulfate 0.5

[0068] Deionized water 70

[0069] Vinyl tris(2-methoxyethoxy)silane coupling agent 1.5

[0070] The preparation method of the above-mentioned modified nano-titanium dioxide self-cleaning coating is as follows: in parts by mass, 2 parts of the prepared boron-nitrogen-doped coated nano-titanium dioxide are added to an aqueous ethanol solution, and fully dispersed under strong stirring; Add 1.5 parts of vinyl tris (2-methoxyethoxy) silane coupling agent to the dispersion liquid, after 2 hours of magnetic stirring and heat preservation reaction, cool to normal temperature and suction filter, dry and grind to obtain silanized boron nitrogen doped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com