Numerical control slurry spraying yarn repair lubricator and method thereof

A technology of lubricator and yarn, which is applied in the field of textile sizing, which can solve the problems of balanced lubrication, repair film formation of yarn that cannot be sizing, and synchronous smoothing of hairiness, so as to reduce friction, improve clarity, and reduce broken ends Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

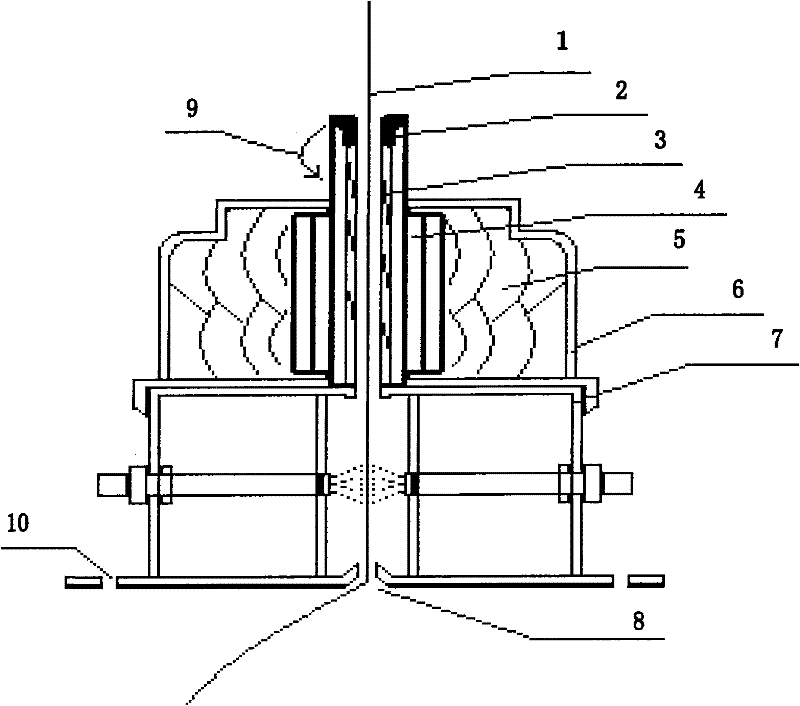

[0022] exist figure 1 As shown in the sectional view of the embodiment, the housing of the miniature speed-regulating hollow shaft motor (6) is connected to the coil (5), and the coil (5) is connected to the rotor hollow shaft (4). There is a spiral rifling (3) inside the hollow shaft (4), and the upper end of the central hole of the hollow shaft (4) is connected with an induction stop alarm (2) and the yarn (1) will automatically stop when the yarn (1) passes through. The hollow shaft (4) rotates in the opposite direction of the (9) arrow. The hollow-shaft motor housing (6) is connected to the upper and lower sides of the atomization spray chamber housing (7) and corresponds to the center hole.

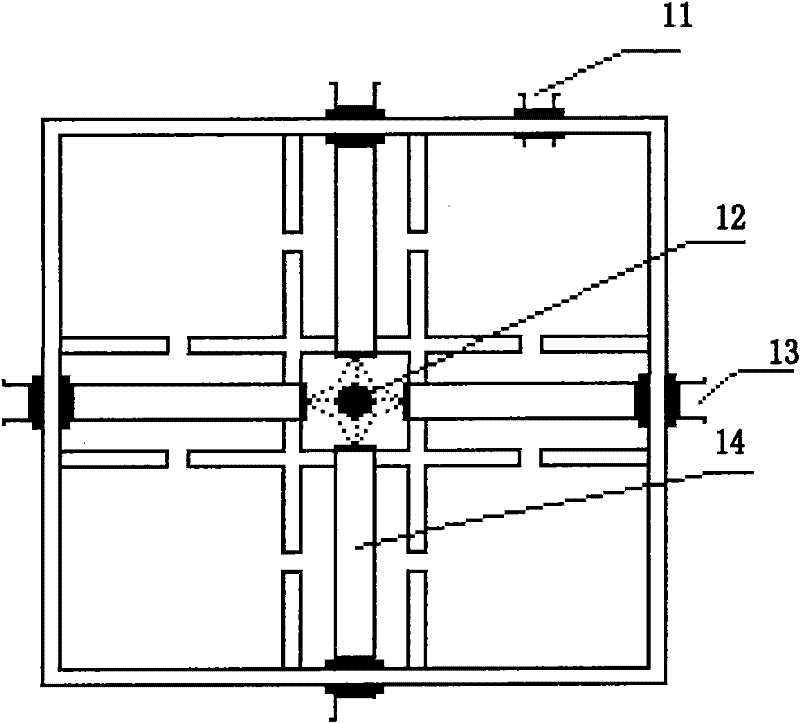

[0023] exist figure 2 As shown in the top view of the embodiment, the housing (7) is connected to the atomizing nozzle (13), and the mist (12) is evenly sprayed on the yarn (1), and the inside of the air inlet (11) of the heating chamber is connected and circulated as a nozzle (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com